Method for predicting edge forming limit of high-strength steel plate stamping part

A technology for stamping parts and high-strength steel plates, which is applied in the directions of measuring devices, strength characteristics, and testing material strength by applying a stable bending force. edge cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The embodiment of the present application solves the technical problem that the high-strength steel stamping part is prone to edge cracking in the prior art by providing a method for predicting the forming limit of the edge part of the high-strength steel stamping part.

[0037] The technical solution in the embodiment of the present application is to solve the above-mentioned technical problems, and the general idea is as follows:

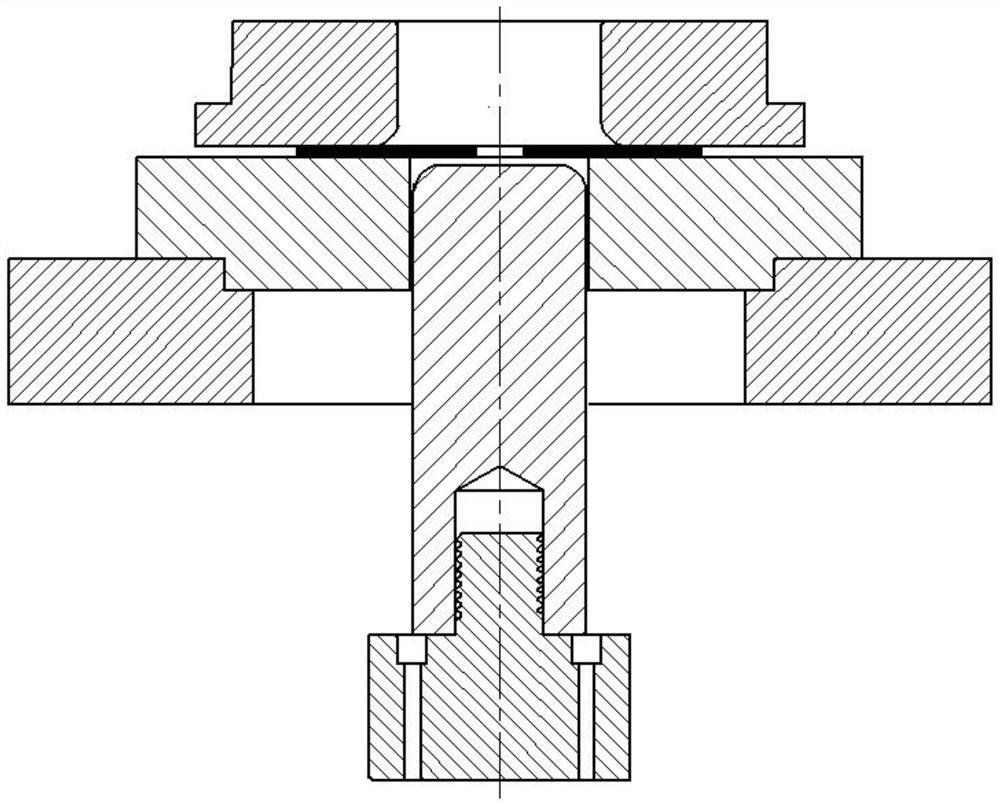

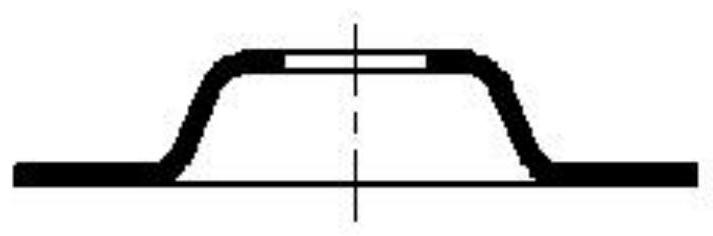

[0038] Such as figure 1 As shown in -8, the present application provides a method for predicting the edge forming limit of a high-strength steel stamping part, the method comprising the following steps:

[0039] Step 1. The deformation process of the part edge is divided into three deformation primitives: tensile deformation, bending deformation and stretch-bending compound deformation. Combined with the part forming process, the deformation primitives of the part are judged;

[0040] Step 2, the ultimate strain test of the deformation ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com