Patents

Literature

45results about How to "Few defects such as cracks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sol-gel method for preparing micro/nano titanium dioxide and lyophobic film thereof on metal surfaces

InactiveCN102553813AImprove corrosion resistanceLower surface free energySpecial surfacesCoatingsFree energiesSilanes

The invention discloses a sol-gel method for preparing micro / nano titanium dioxide and lyophobic film thereof on metal surfaces, which includes the following steps of (a) pretreating metal substrates; (b) preparing micro / nano TiO2 films on surfaces of the metal substrates which are pretreated; and (c) preparing (heptadecafluoro-1,1,2,2-tetradecyl) triisopropoxysilane-silicon dioxide lyophobic films on the micro / nano TiO2 films on the surfaces of the metal substrates. The sol-gel method has the advantages of high operability, simplicity in processing and equipment and easiness in industrialization. Besides, the titanium dioxide films are used as transitional layers so that corrosion of acid sol to the metal substrates during the process of directly coating the silane lyophobic films is avoided, wettability to silane sol is enhanced, and uniform and compact lyophobic films are prepared finally. Meanwhile, defects such as cracking and the like can be reduced by means of multiple coating processes, corrosion resistance performance of the films is improved, surface free energy of the films is decreased by lyophobic treatment, and dirt settled on the films is reduced.

Owner:TIANJIN UNIV

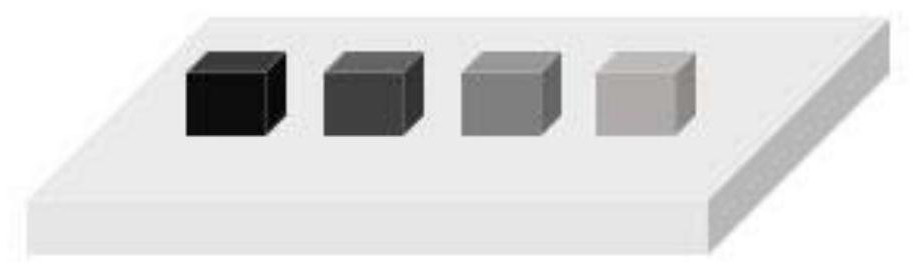

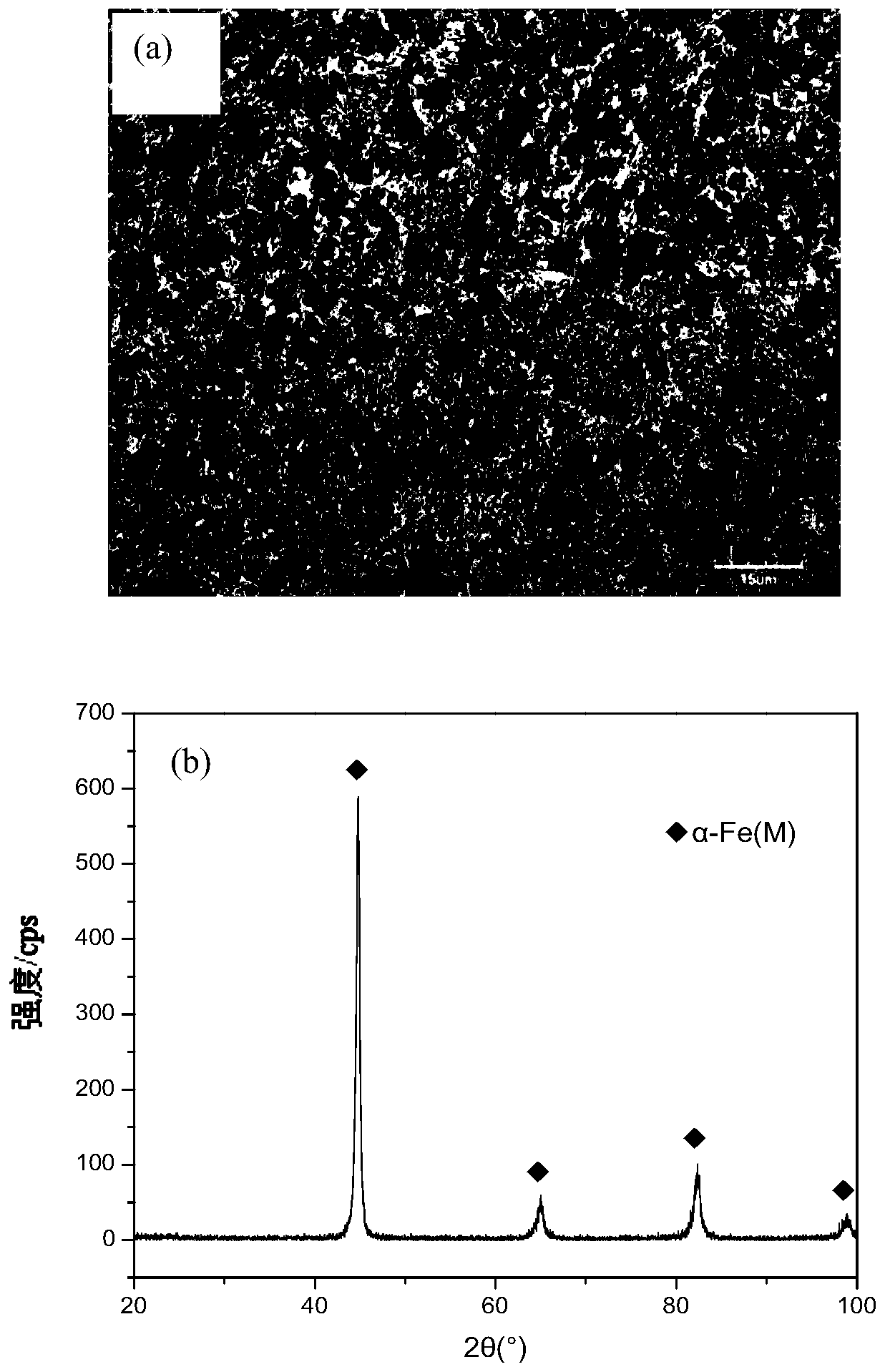

Method for preparing 24CrNiMo bainite alloy steel by using selective laser melting technology

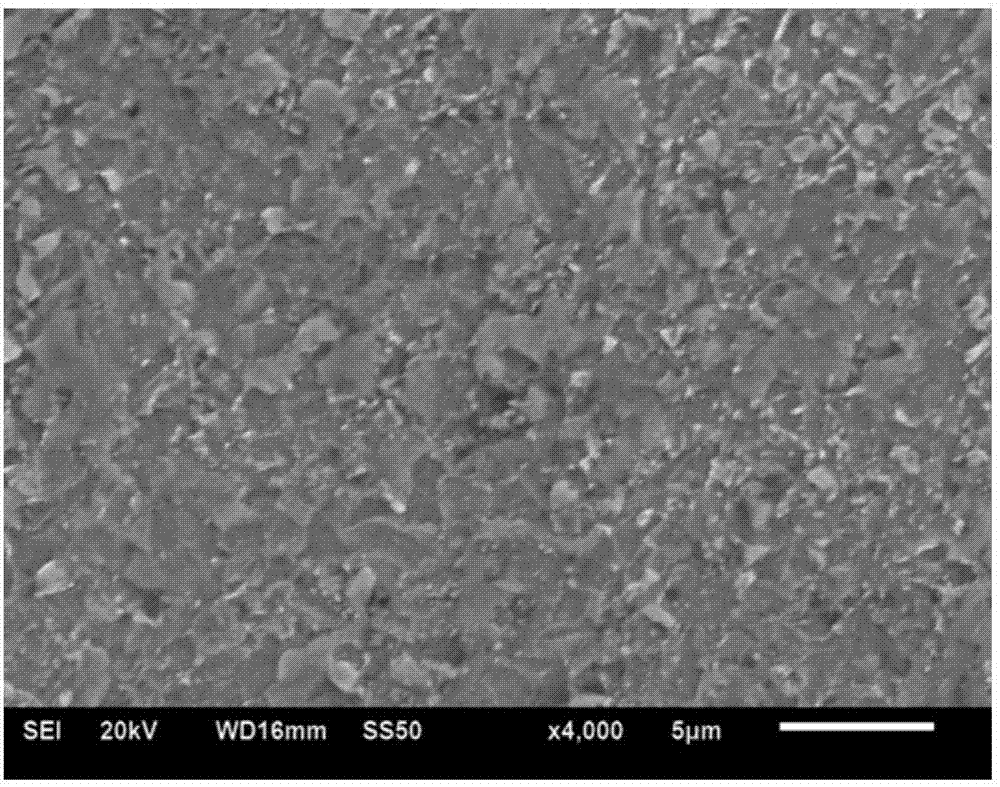

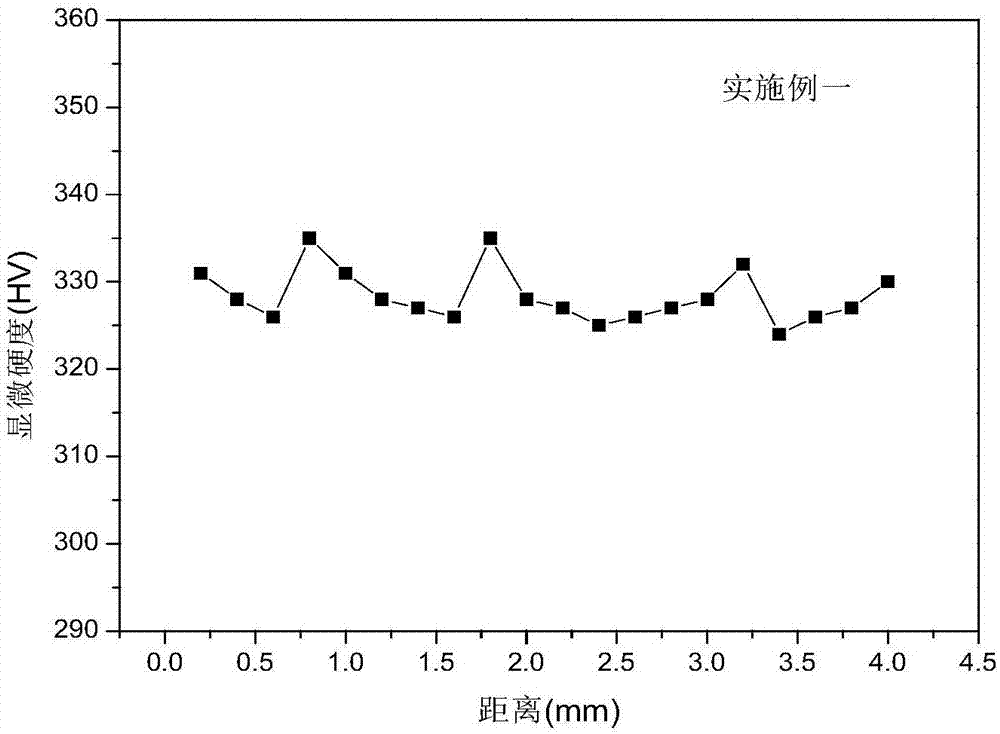

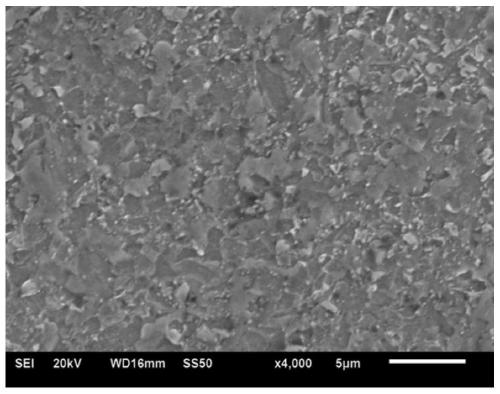

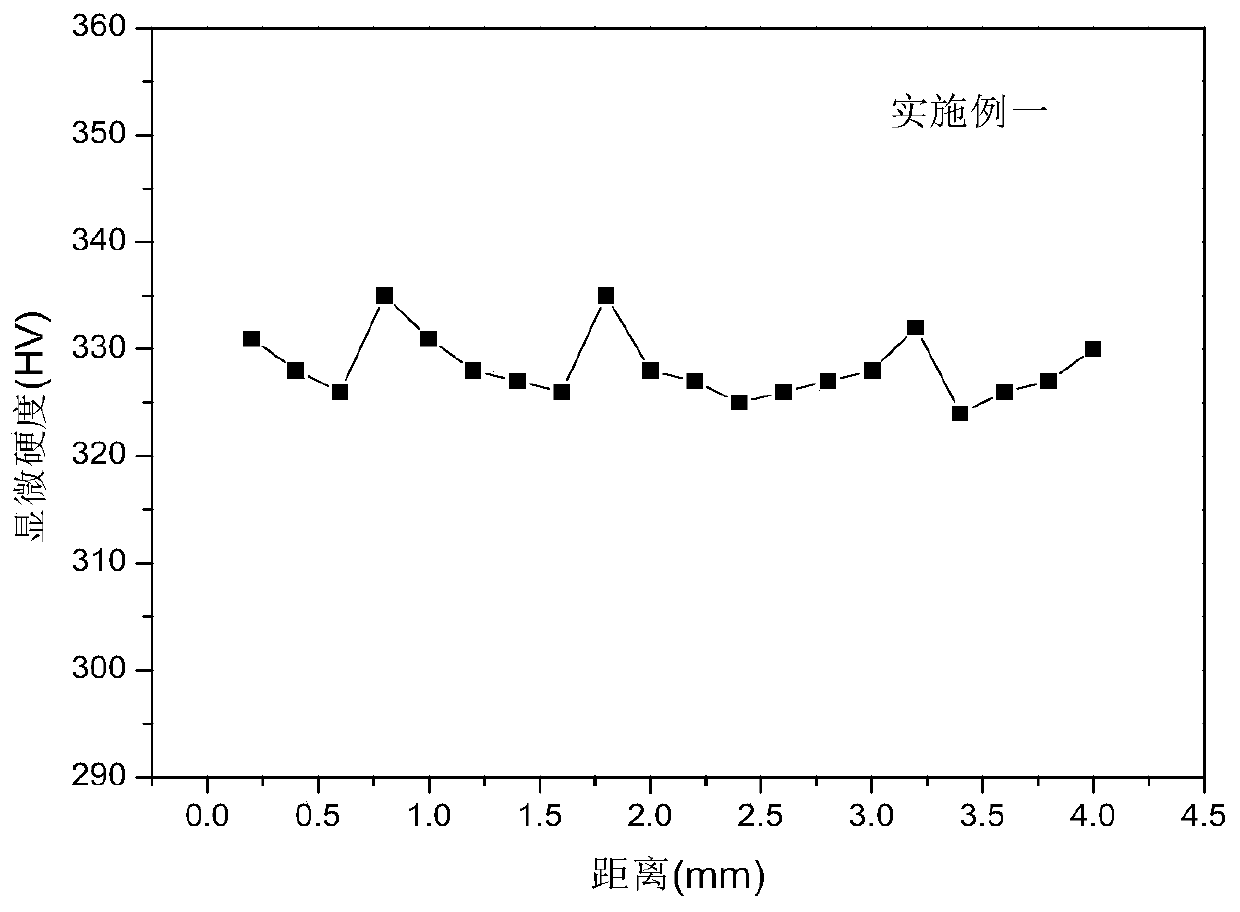

ActiveCN107214336ARemarkable effect of fine grain strengtheningImprove mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingHardness

The invention provides a method for preparing 24CrNiMo bainite alloy steel by using a selective laser melting technology. The method includes the steps that a laser device is used for conducting scanning on 24CrNiMo alloy steel power which is spread out on a base plate according to a preset selective laser melt scanning route till the power melts. According to the method, by optimizing technology parameters, taking use of the effects of alloy elements such as C, Cr, Ni, Mo, the bainite alloy steel which is uniform in microstructure is obtained at a high selective laser melting cooling speed, the average micro-hardness of the obtained bainite microstructure reaches 330-346 HV, the tensile strength is 962-978 Mpa, the elongation ratio is 16.4-17.6%, the product of tensile strength and elongation reaches 16.1-16.9 Gpa%, and the microstructure has excellent matched strength and toughness. The method and the technology are mainly applied to selective laser melting manufacture of 24CrNiMo alloy steel high speed rail brake discs.

Owner:NORTHEASTERN UNIV

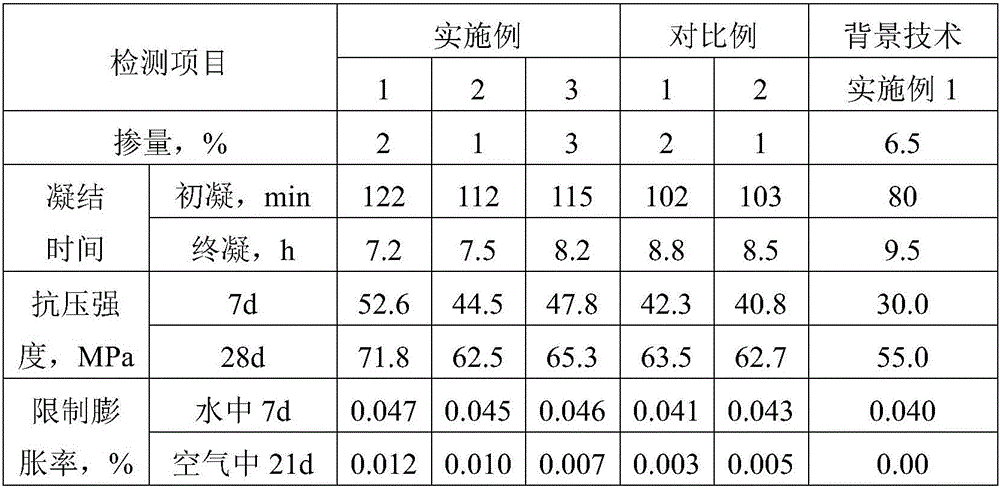

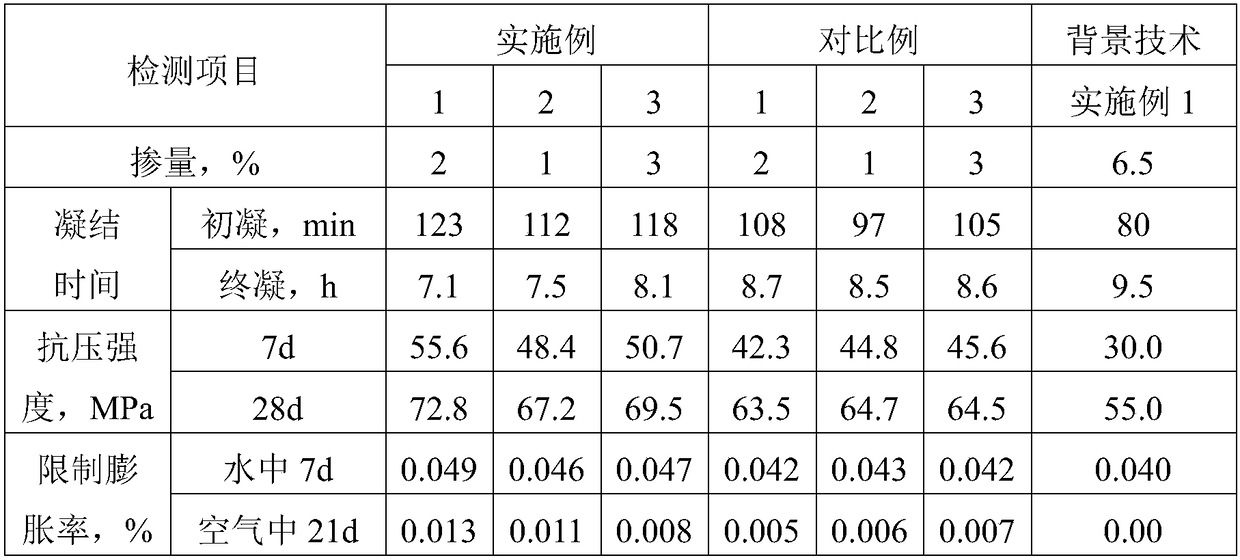

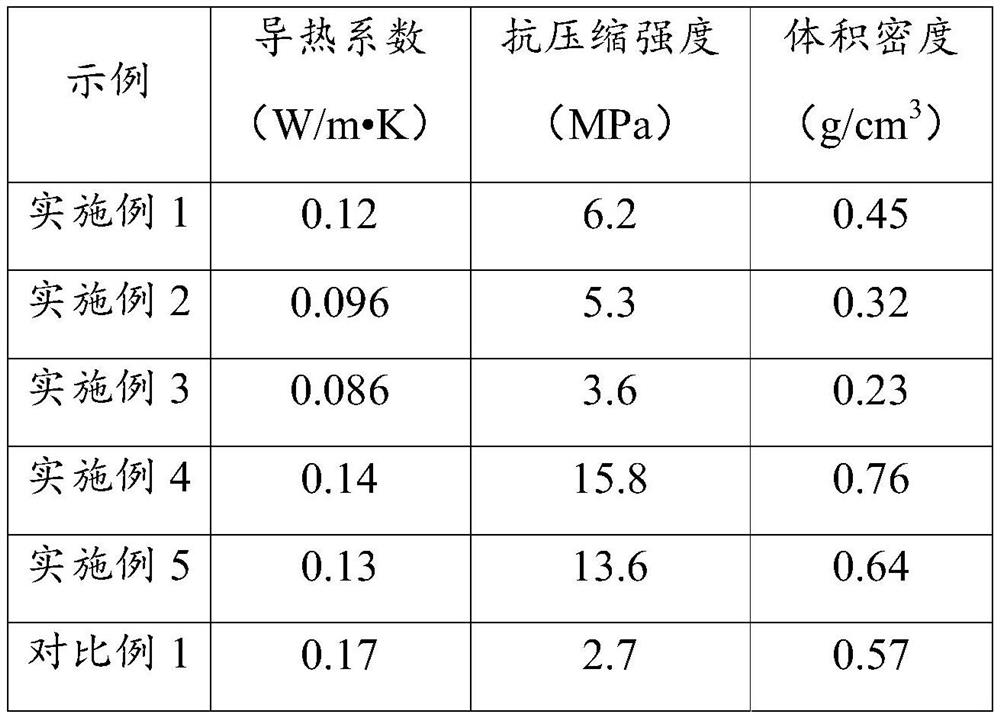

Compound concrete expanding agent

The invention discloses a compound concrete expanding agent. The compound concrete expanding agent is prepared by using the following components in parts by weight: 15 to 20 parts of calcium aluminosilicate, 25 to 30 parts of calcium sulphoaluminate, 20 to 30 parts of sulfur fixation waste residue, 10 to 20 parts of red mud, 10 to 15 parts of lithium slag, 4 to 8 parts of modified calcium oxide, 3 to 6 parts of magnesium oxide, 5 to 8 parts of methyl sodium silicate, 0.1 to 0.3 part of azodicarbonamide, 0.4 to 0.7 part of sodium tripolyphosphate, 2 to 4 parts of lauryl sodium sulfate, 0.3 to 0.6 part of ethylene-acrylic acid copolymer, 0.7 to 0.9 part of polycarboxylate superplasticizer and 0.5 to 0.7 part of nano calcium carbonate. The compound concrete expanding agent has the advantages of high strength, good compensation capability, calcium oxide reaction regulation and the like, and is a concrete additive which has a great development prospect.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

Light-weight porous floor tile and manufacturing method thereof

InactiveCN106630939AHigh strengthIntensity does not affectSingle unit pavingsCeramic materials productionSlagSlurry

The invention relates to a light-weight porous floor tile and a manufacturing method thereof. The light-weight porous floor tile is formed by mixing base materials, additives, filling agents and water, making the materials into slurry, and then performing forming and firing. Aluminum ash, iron ore waste slag and river sand are added into clay for firing the floor tile, so that the reutilization of wastes such as aluminum ash, iron ore waste slag and the like can be realized; in addition, the intensity of the fired floor tile is improved; (aluminum oxide, aluminum and the like contained in aluminum ash and ferric oxide in iron ore waste slag form enhanced body structures similar to hercynite in high-temperature environment during the floor tile firing); the silicon carbide, carbon powder and calcium carbonate powder are added to be used as additives, so that the fired floor tile has some open air pores (or being called as opening air pores) on the surface; the air pores can absorb certain noise; in addition, the surface water downward seepage is also facilitated; meanwhile, the intensity of the floor tile cannot be influenced.

Owner:河南同伟建材有限公司

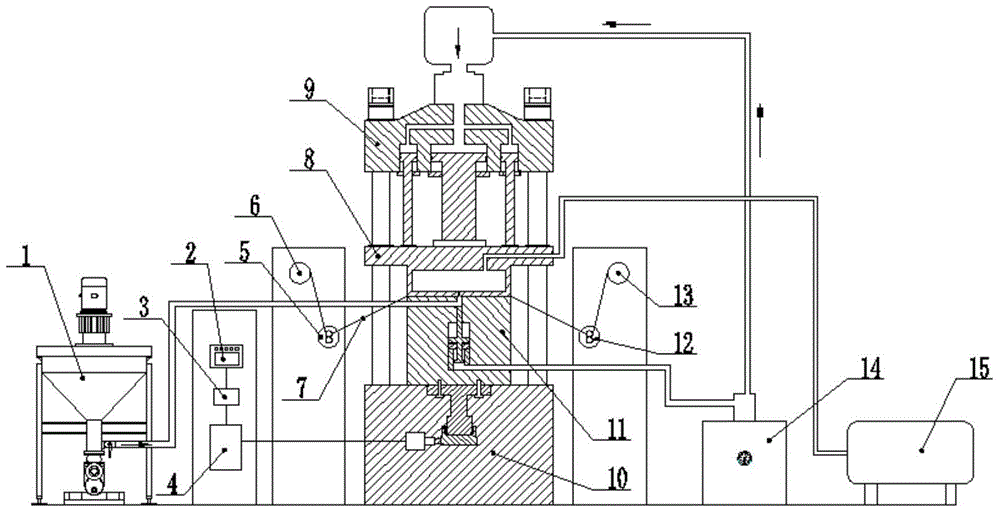

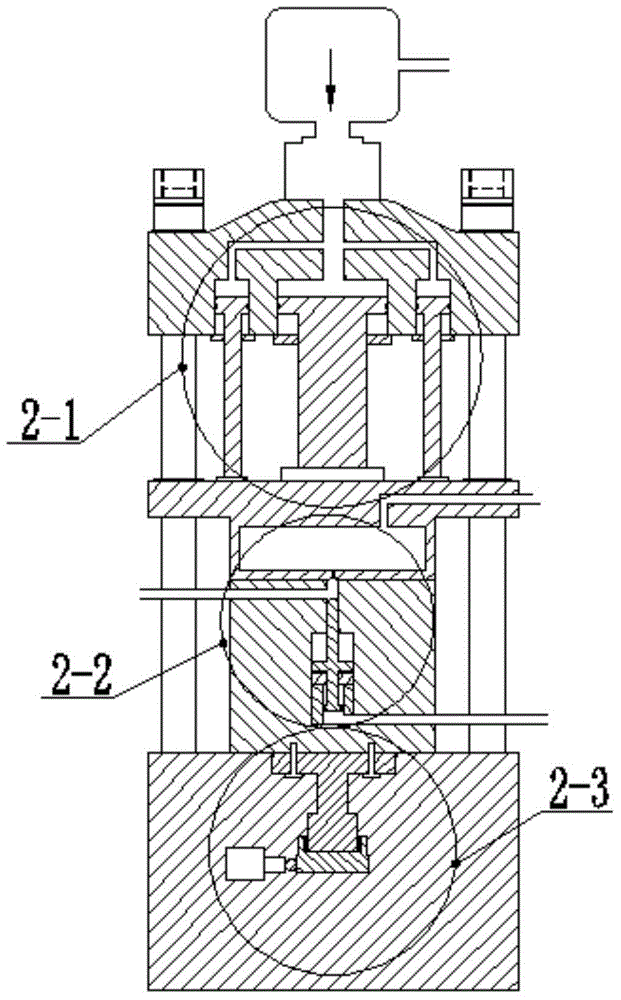

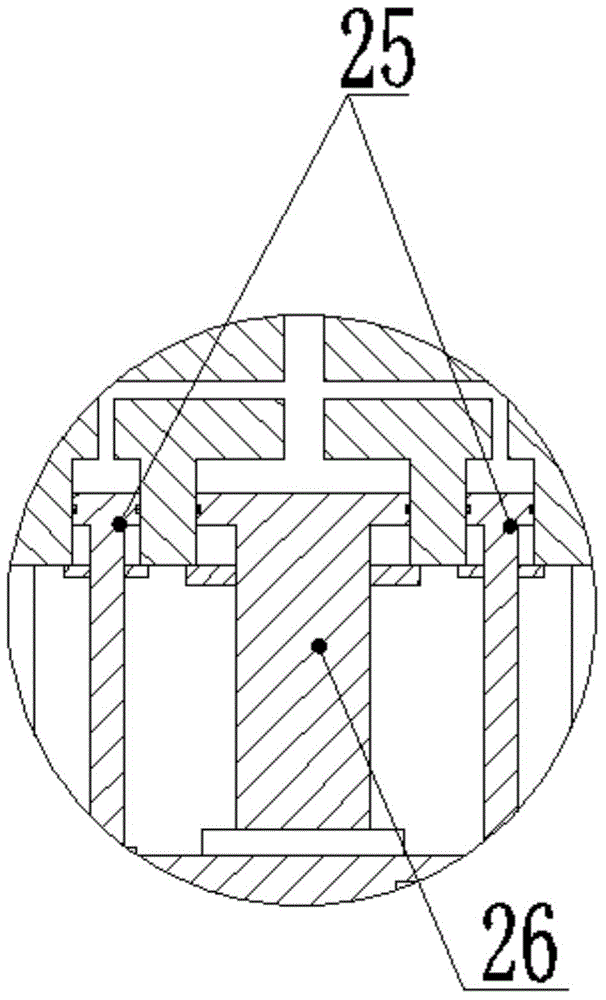

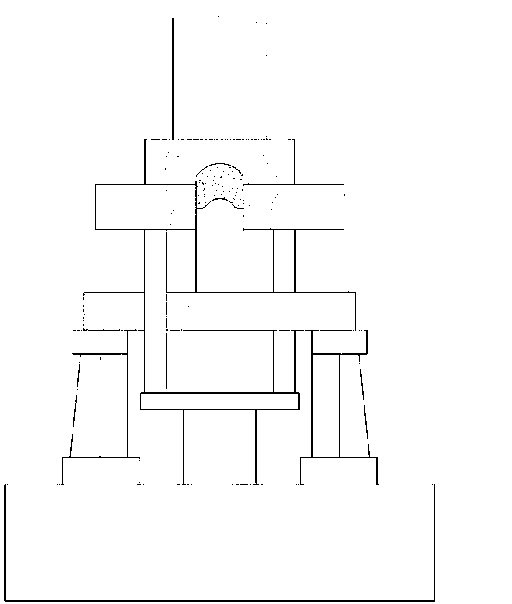

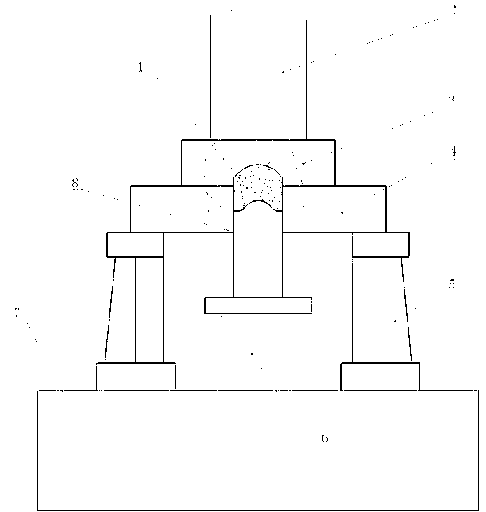

Downward-pushing magnetic material wet forming hydraulic machine and use method thereof

The invention discloses a downward-pushing magnetic material wet molding hydraulic machine and a use method thereof and belongs to the magnetic material wet forming field. The downward-pushing magnetic material wet molding hydraulic machine comprises a downward-pushing pressing structure. The downward-pushing magnetic material wet molding hydraulic machine further comprises a mechanical limiting structure, a packing structure, a blank fetching system, a double-oil cylinder balance system and a mould surface cleaning system; the downward-pushing pressing structure comprises an upper mould seat, a pushing rod, a large-bore oil cylinder, a fixing mould frame and a lower mould hydraulic cylinder, wherein the upper mould seat is driven by the large-bore oil cylinder, the pushing rod is located in the fixing mould frame, and the fixing mould frame is connected with the lower mould hydraulic cylinder, the large-bore oil cylinder and the lower mould hydraulic cylinder are both communicated with a hydraulic station; the mechanical limiting structure includes a horizontal mechanical limiting structure and a longitudinal mechanical limiting structure; the horizontal mechanical limiting structure comprises the pushing rod and the fixing mould frame; a fixing mould cavity is arranged in the fixing mould frame; the pushing rod is located in the fixing mould cavity in the fixing mould frame; and the longitudinal mechanical limiting structure includes a servo motor A and a transmission mechanism. With the downward-pushing magnetic material wet molding hydraulic machine and the use method thereof adopted, product formation error is small, and the pollution source of slurry to hydraulic oil can be eliminated.

Owner:MAANSHAN QILI ELECTRICAL & MECHANICAL EQUIP CO LTD

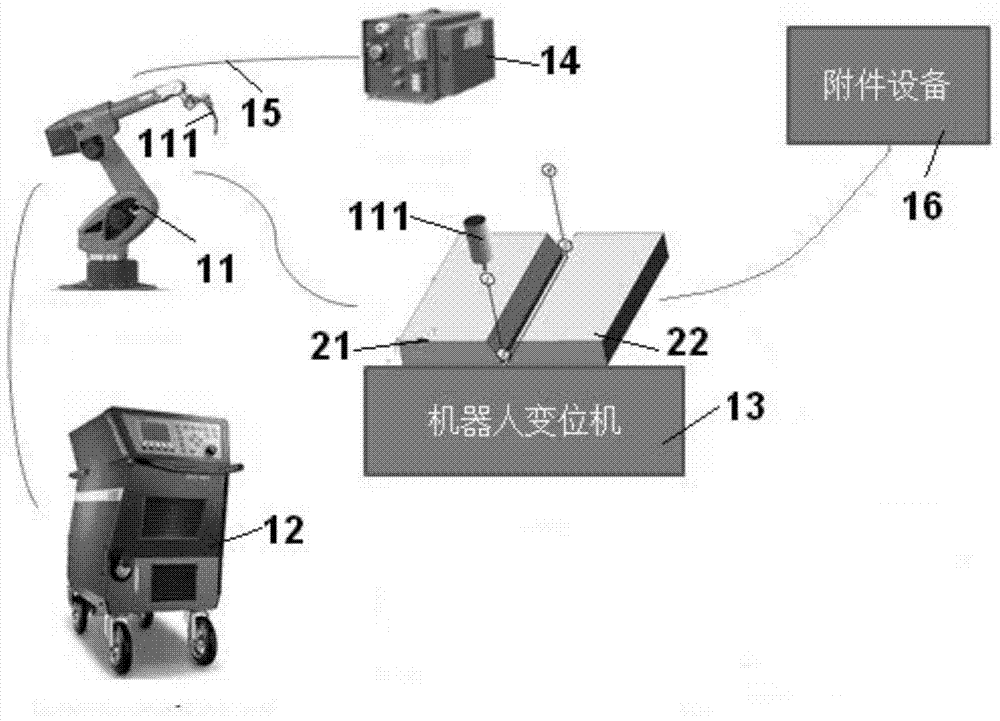

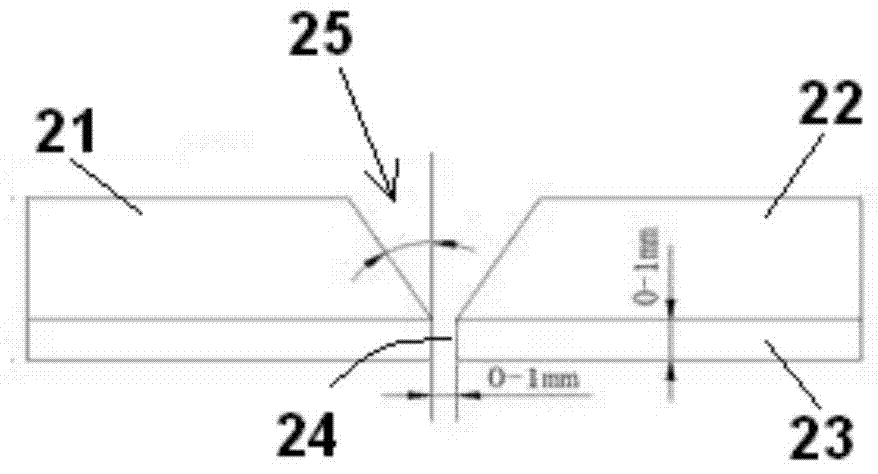

Automatic MIG (metal-inert gas) welding method for hard alloy and steel

ActiveCN103537783AIncrease the level of automationImprove bindingArc welding apparatusWelding/soldering/cutting articlesShielding gasRobot position

The invention discloses an automatic MIG (metal-inert gas) welding method for hard alloy and steel. The automatic MIG welding method includes steps of firstly, removing surface oil stain and an oxidation film layer on welded surfaces of welded materials which are hard alloy and steel in thickness ranging from 2mm to 6mm and are uniform in thickness; respectively fixing the hard alloy and the steel on a worktable of a robot position changing machine, keeping a gap between the welded surface of the hard alloy and the welded surface of the steel within 1mm; delivering protective gas which is argon gas or helium gas, adjusting protective gas flow within 15-25L / min; moving a welding gun over the welding surfaces of the welded materials, starting automatic welding and finally performing post-welding inspection. Accordingly, the problems of low productivity, proneness to generating cracks at welding joints and the like in the prior art can be effectively solved, binding force between the hard alloy and the steel is improved, automation level of welding of the hard alloy is improved, durability of the welding joints of the hard alloy is improved, and strength and durability are integrated.

Owner:SHANGHAI UNIV OF ENG SCI

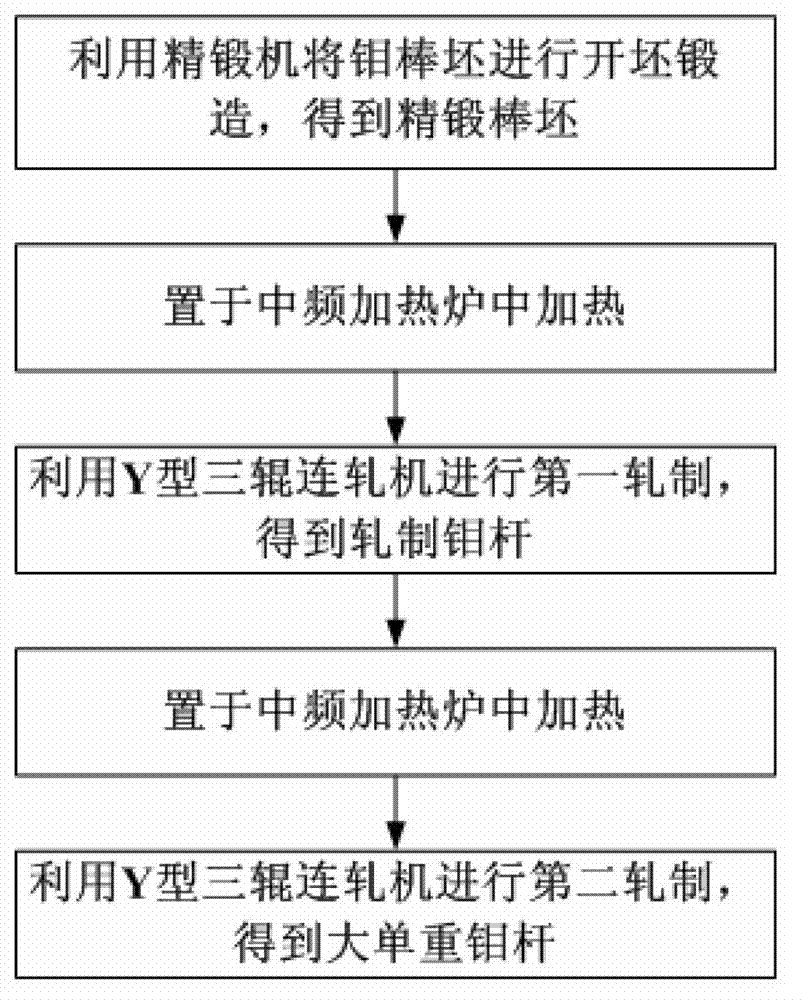

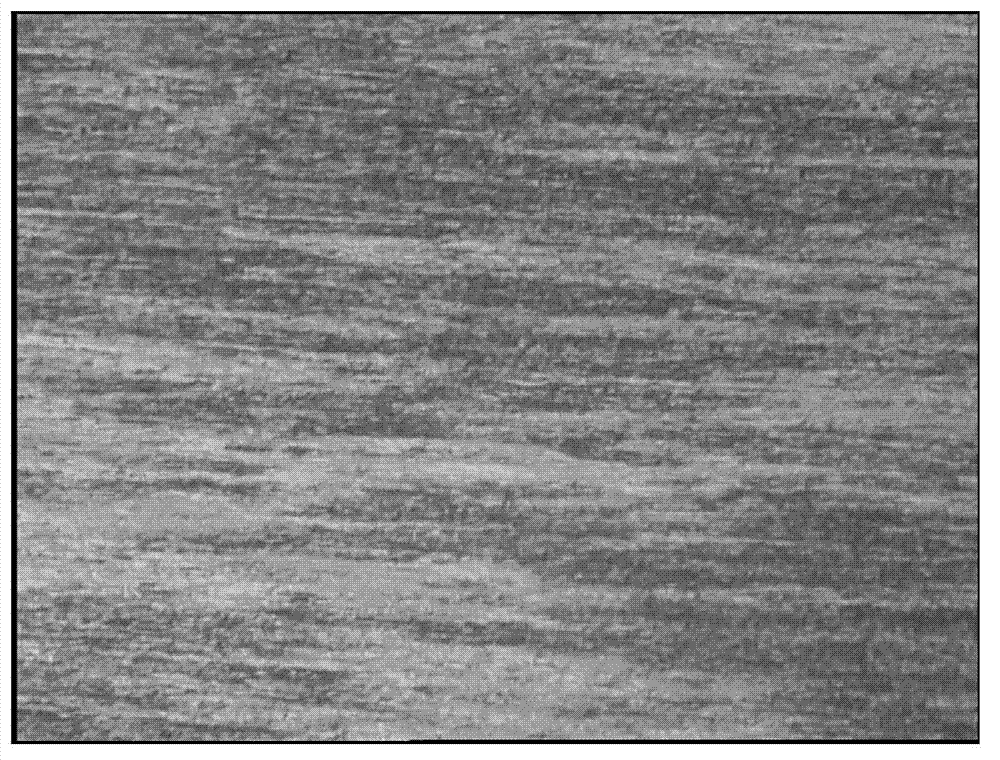

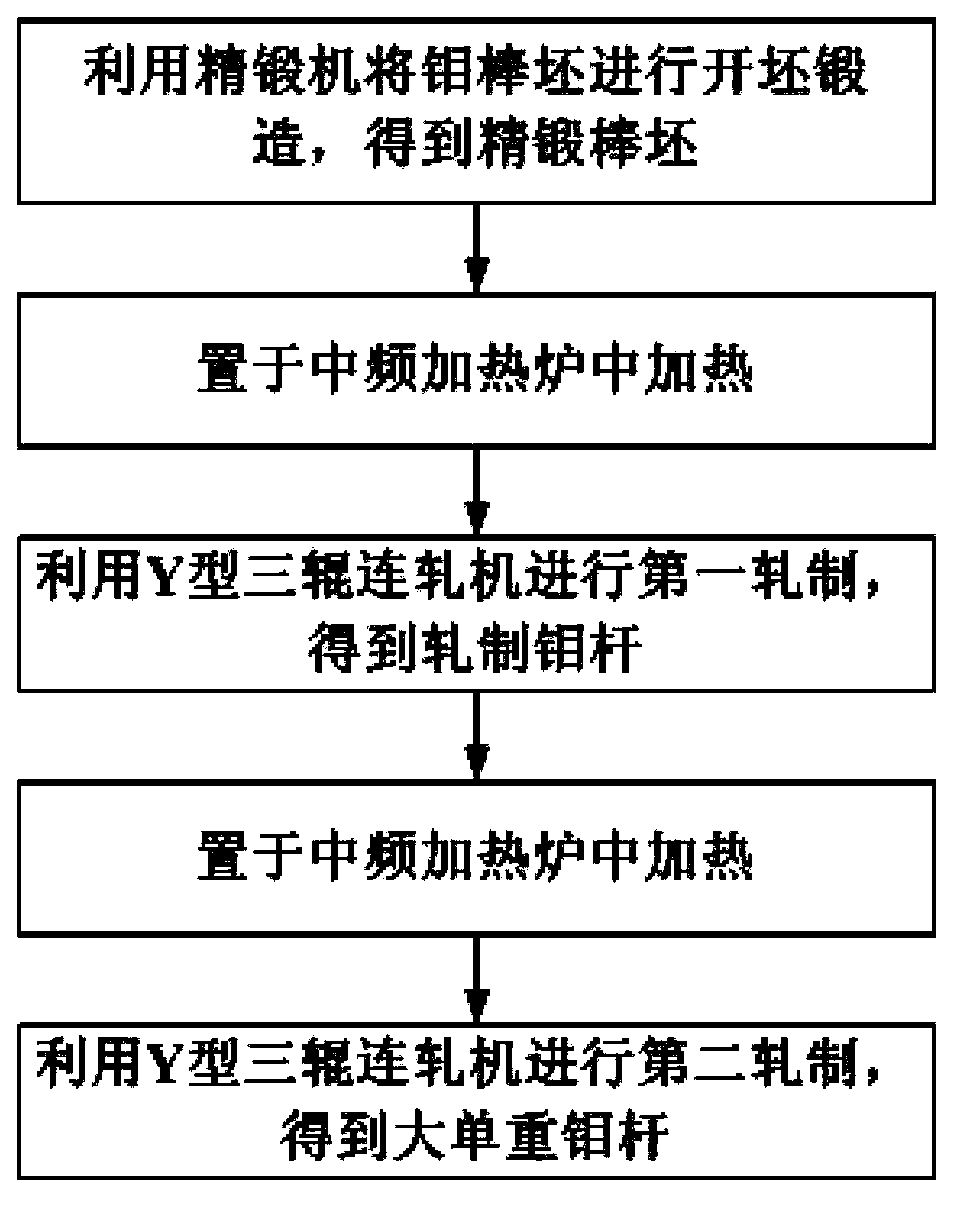

Precise forging-continuous rolling production technology of large and heavy single molybdenum rod

ActiveCN103042389ARealize deep processingIncrease productivityTemperature control deviceOther manufacturing equipments/toolsThermal treatmentContinuous rolling

The invention provides a precise forging-continuous rolling production technology of a large and heavy single molybdenum rod. The production technology comprises the following steps of: 1, carrying out billet forging on the molybdenum rod by a precision forging machine to obtain a precision forging bar; 2, heating the precision forging bar; 3, rolling for the first time by a Y-shaped three-roller continuous mill to obtain a rolled molybdenum rod; 4, heating the rolled molybdenum rod; and 5, rolling for the second time by the Y-shaped three-roller continuous mill and obtaining the large and heavy single molybdenum rod of which the piece weight is 45-50kg. Deep processing of a molybdenum bar is successfully achieved by setting and optimizing each parameter in precision forging, thermal treatment and continuous rolling processes; the large and heavy single molybdenum rod, which is suitable for subsequent wire drawing, and of which the piece weight is 45-50kg, is finally produced; and the production efficiency is obviously improved. The piece weight of the molybdenum rod produced by the production technology is much greater than that of the molybdenum rod produced by a traditional technology; and the precise forging-continuous rolling production technology has no welding spot on the whole, and is even in internal organization, high in product quality and suitable for large-scale industrial production.

Owner:JINDUICHENG MOLYBDENUM CO LTD

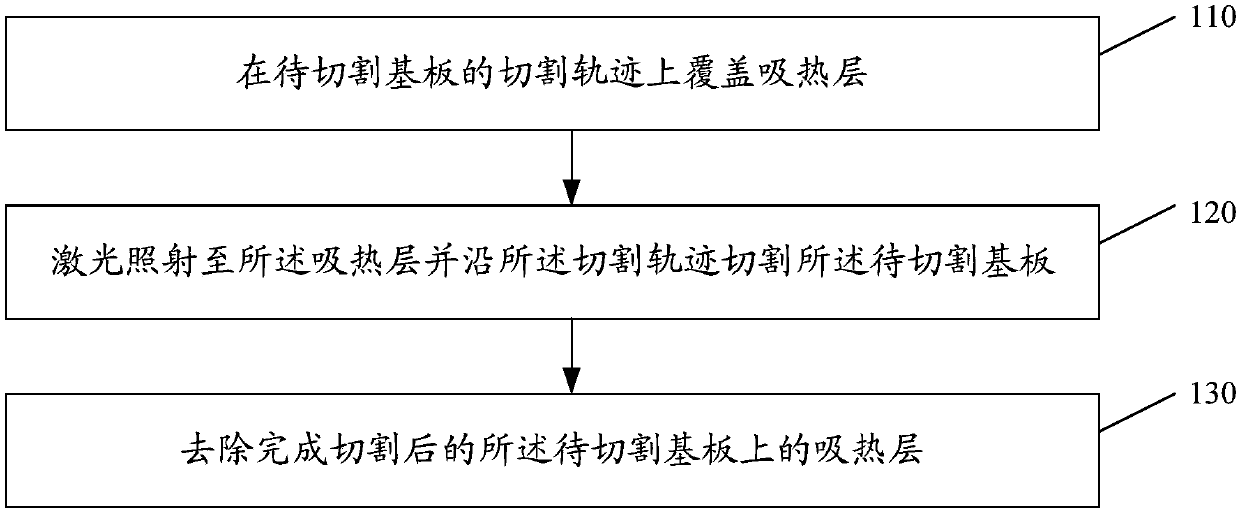

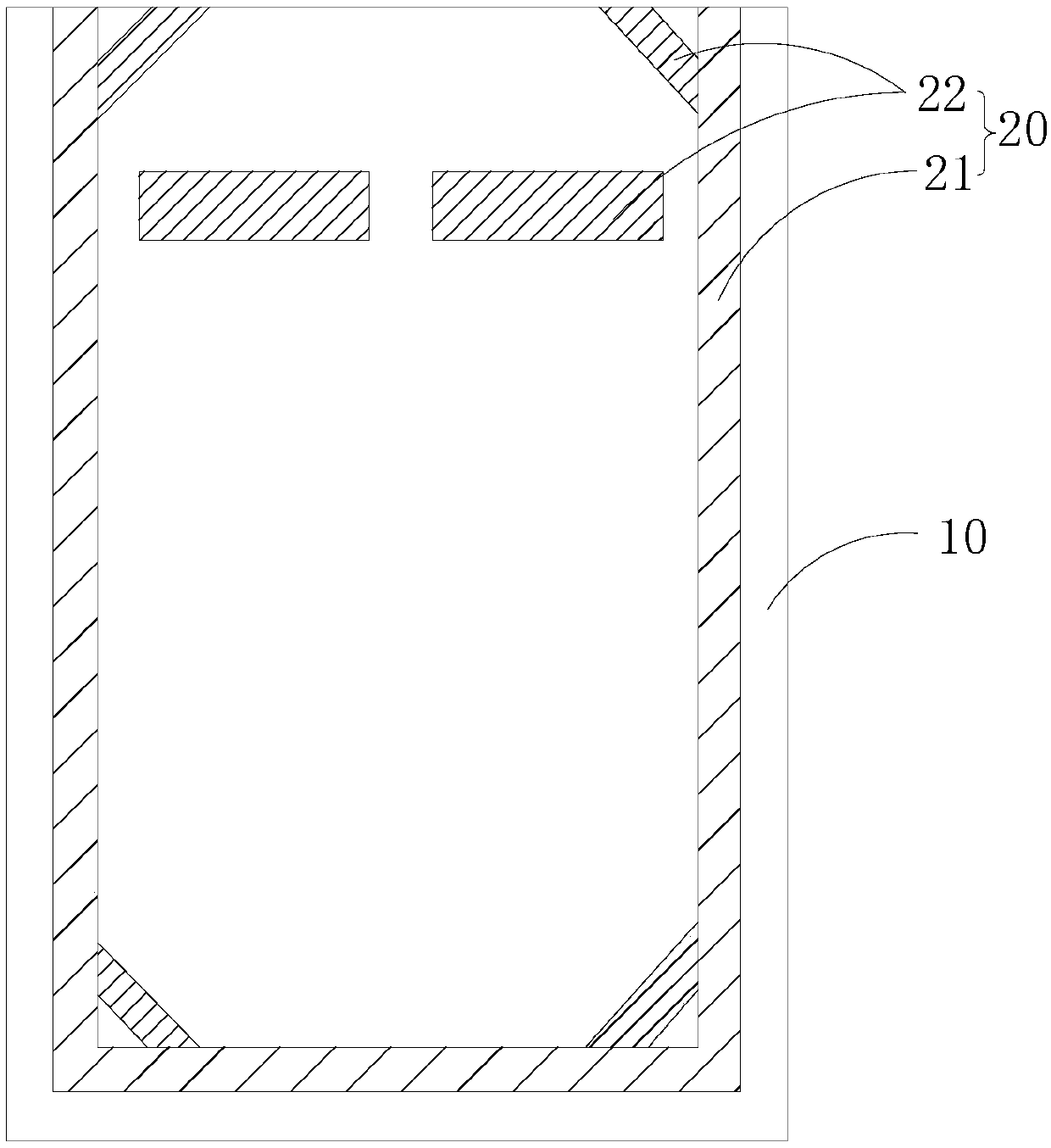

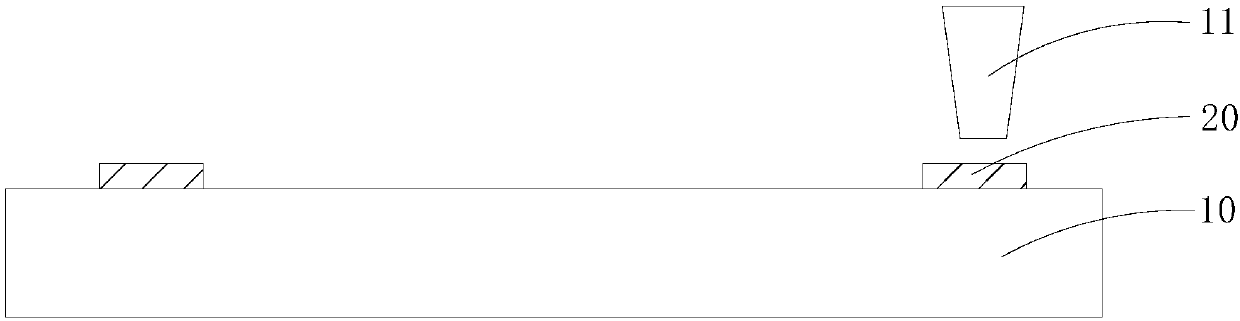

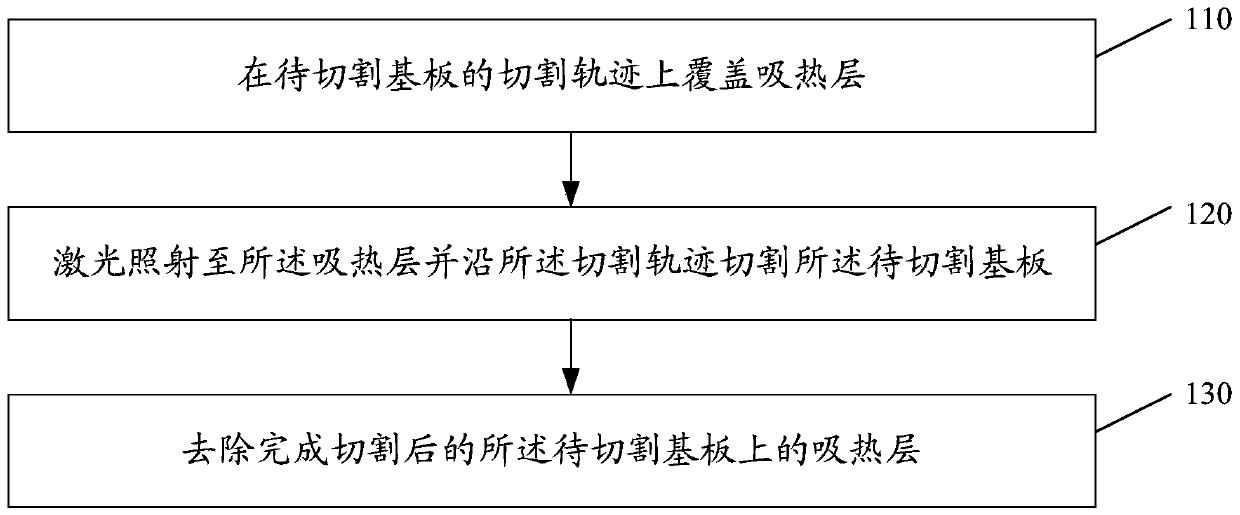

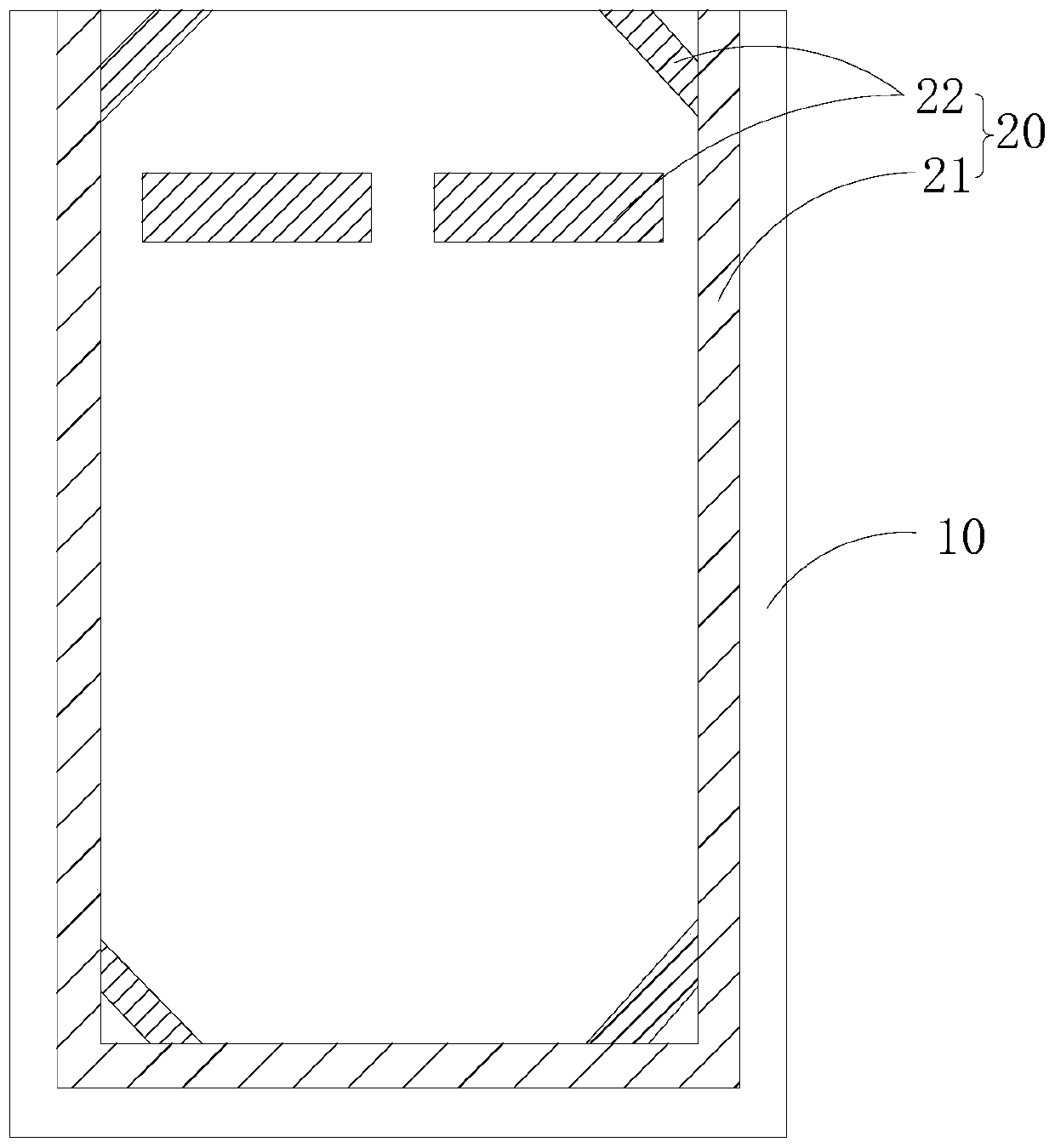

Laser cutting method

ActiveCN107695533AReduce the size of the temperature gradientReduce thermal stressLaser beam welding apparatusEngineeringLaser cutting

The invention provides a laser cutting method. According to the laser cutting method, the cutting track of a to-be-cut substrate is covered with a heat absorbing layer before the laser cutting operation is performed, so that the heat energy of a laser can be partially absorbed by the heat absorbing layer when the to-be-cut substrate is cut by the laser along the cutting track of the to-be-cut substrate; accordingly, the temperature gradient between the cutting position on the to-be-cut substrate and non-cutting positions around the cutting position during the cutting process can be reduced, the heat stress can be reduced, and then cracks and other defects can be reduced; and a relatively-high-quality product can be obtained.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

High-performance yttrium zirconium ceramic bearing ball and preparation method thereof

InactiveCN102942362AIncrease starting densityReduce sintering temperature and sintering shrinkageYttriumAdhesive

The invention relates to a high-performance yttrium zirconium ceramic bearing ball and a preparation method thereof, and belongs to the field of structural ceramics. The invention adopts yttrium oxide powder and zirconium oxide powder in submicron order, which are added with a variety of polymers as dispersant agent, adhesive, lubricant and moisturizing agent; a solid spherical granulation material with good particle size distribution and good fluidity are obtained through high-speed stirring distribution and spray granulation process. Granulation material ball billet subjected to two-way pressing needs to be subjected to cold isostatic pressing treatment to obtain a ceramic ball blank. Ceramic ball blank is dried and sintered; and a cooling speed is controlled in a cooling process to obtain the high-performance yttrium zirconium ceramic ball. The invention has advantages of simple process and high process reliability, and can realize low-cost mass production.

Owner:JIANGXI JLMAG RARE EARTH

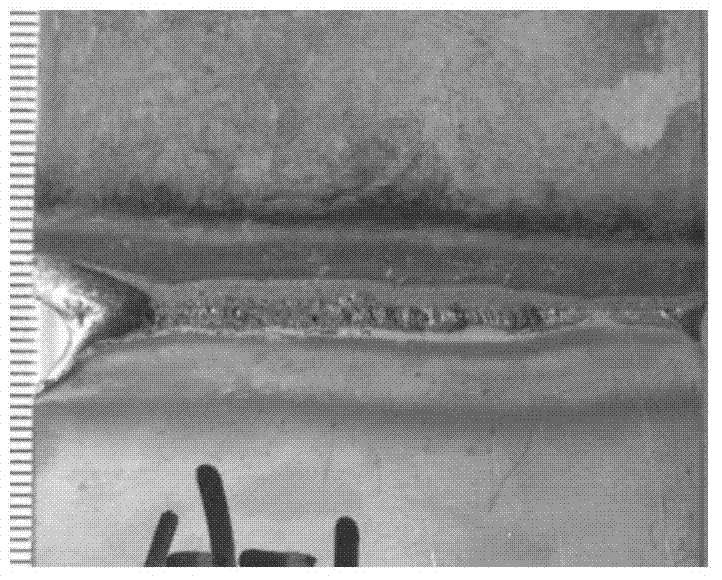

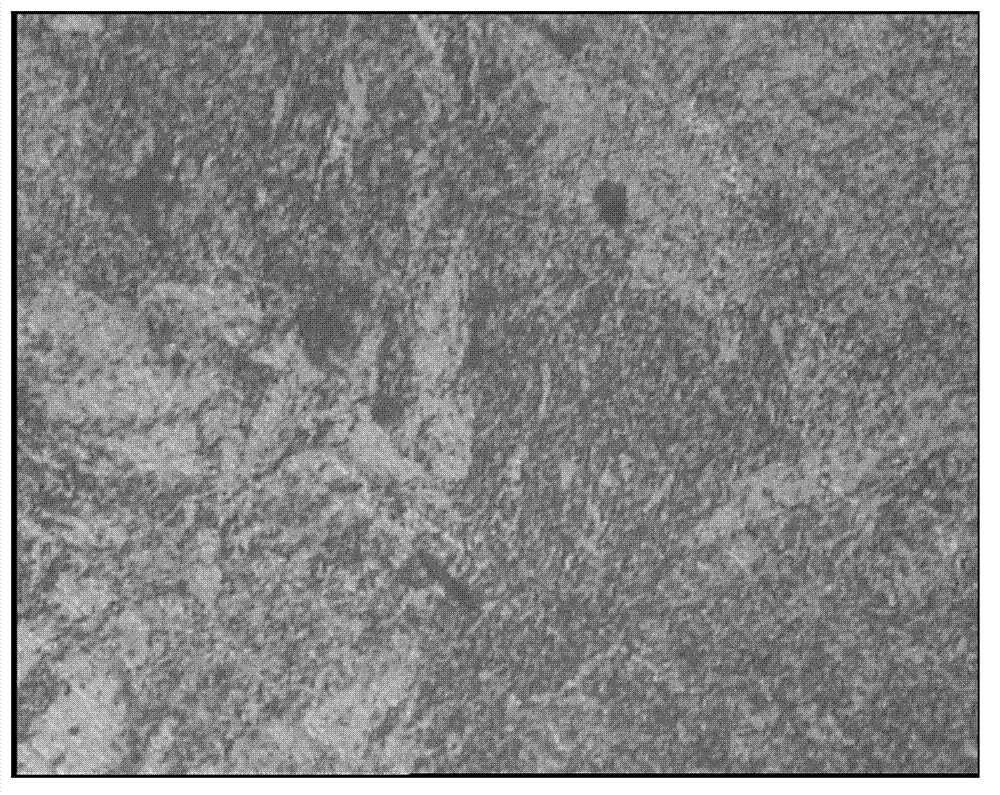

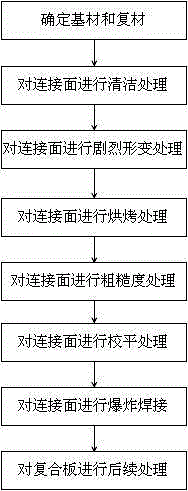

Explosive welding method for pre-processing rare and precious metal composite plate through severe surface deformation

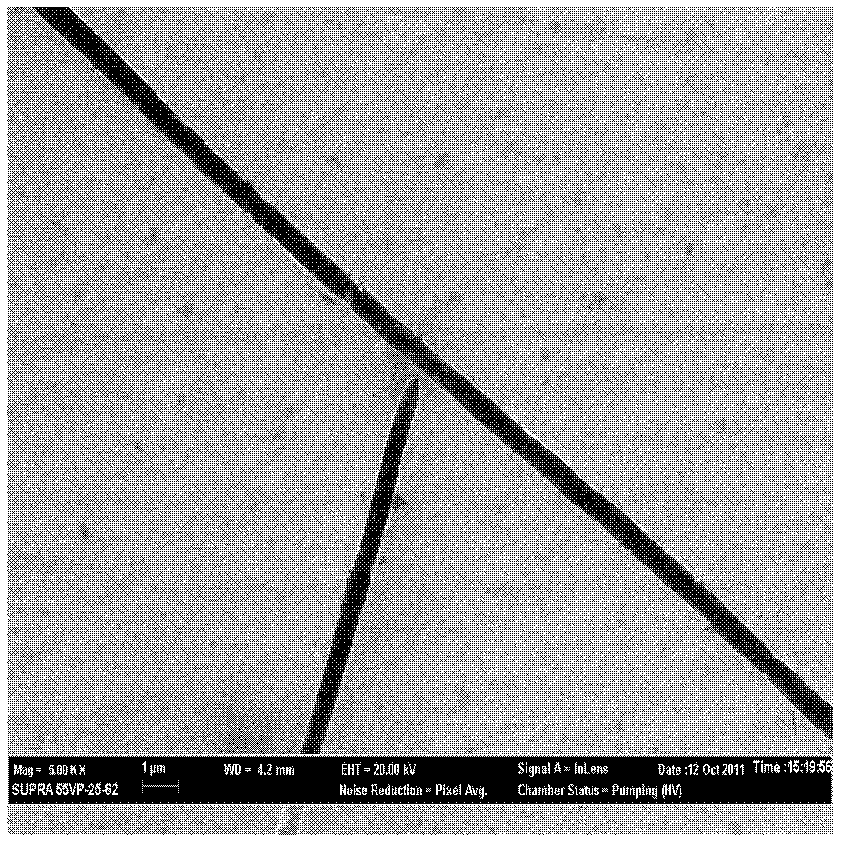

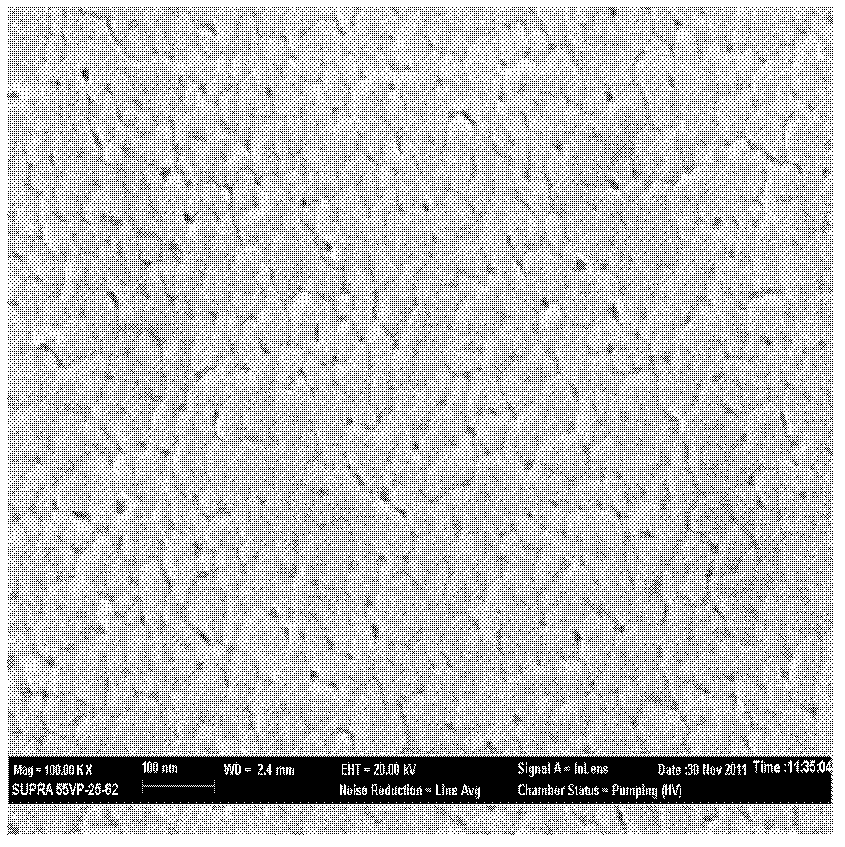

ActiveCN105397266AReduce defects such as cracksFew defects such as cracksWelding/soldering/cutting articlesNon-electric welding apparatusComposite plateMicrostructure

The invention provides an explosive welding method for pre-processing a rare and precious metal composite plate through severe surface deformation. The method includes the following steps that a base material and a composite material are determined, a connecting face of the base material and the composite material is cleaned and processed, severe deformation processing is performed on the connecting face, the connecting face is baked, roughness processing is performed on the connecting face, leveling processing of the connecting face is performed, and explosion welding and cladding and follow-up repair welding, leveling, edge cutting and mechanical polishing are performed, wherein a severe deformation processing method includes rolling, mechanical grinding, mechanical impacting, shot blasting or sand blasting. Before explosive cladding, the severe surface deformation processing is performed on the base material and the composite material, the connecting face can be of a multi-stage micro structure in different sizes, and the defect that cracks and the like happen easily in the explosive cladding process of rare and precious metal can be reduced; and besides, the severe surface deformation induces a large number of crystal structure defects, intermetallic compounds can be reduced, and the interface binding strength is remarkably improved.

Owner:NANJING INST OF TECH +2

Refractory castable for lining of thermal equipment and using method of refractory castable

The invention relates to a refractory castable for a lining of thermal equipment and a using method of the refractory castable for the lining of the thermal equipment. The invention adopts the technical scheme as follows: the refractory castable consists of an aggregate I, an aggregate II and a matrix, wherein the aggregate I comprises corundum particles, high bauxite particles, corundum-alloy composite particles and high bauxite-alloy composite particles, and has the particle size of 8-15mm; the aggregate II comprises three grades of corundum particles and high bauxite particles with the particle size range being greater than or equal to 1mm and less than 8mm; the matrix comprises corundum fine powder, high bauxite fine powder, rho-Al2O3 micropowder, silicon micropowder and calcium aluminate cement. The using method of the refractory castable for the lining of the thermal equipment comprises the following steps: uniformly mixing polycarboxylic acid and the matrix to obtain premixed matrix; uniformly stirring the aggregate II and the premixed matrix, adding water, and stirring to obtain a slurry; putting the aggregate I into a mould, adding the slurry, performing vibration moulding, and curing. The refractory castable can automatically adjust the temperature, so that the problems of high overtemperature energy consumption of a casing and casing corrosion caused by low-temperature medium enrichment on the casing are solved.

Owner:WUHAN UNIV OF SCI & TECH

Fire resistant brick used for lining of thermal equipment and preparation method thereof

ActiveCN106045485AImprove thermal shock resistanceStable temperatureHeat-exchange elementsBrickHigh energy

The invention relates to a fire resistant brick used for a lining of thermal equipment and a preparation method thereof. The preparation method includes the steps of: 1) employing 5-25 wt% of corundum granules, 5-25 wt% of high bauxite granules, 10-30 wt% of corundum-alloy composite granules and 10-30 wt% of high bauxite-alloy composite granules as aggregates and 10-20 wt% of corundum fine powder and 10-20 wt% of high bauxite fine powder as base materials; 2) mixing the base materials uniformly to prepare a pre-mixed base material; 3) mix-grinding the aggregates with resin to prepare a mix-ground aggregate, and adding the mix-ground aggregate to the pre-mixed base material, grinding the mixture, press-moulding a brick, and performing thermal-treatment at 150-300 DEG C for 12-48 h to prepare the fire resistant brick used for the lining of thermal equipment. The brick can regulate temperature automatically and can stabilize the temperature of a shell of the equipment when environment temperature or medium temperature in the thermal equipment is changed, so that problems of high energy consumption due to overheat of the shell and corrosion on the shell material due to enrichment of low-temperature medium in the shell.

Owner:WUHAN UNIV OF SCI & TECH

Ground tile specially used for square and manufacturing method of same

InactiveCN106592367AHigh strengthGuaranteed mechanical strengthSingle unit pavingsSidewalk pavingsButadiene-styrene rubberPlastic materials

A ground tile specially used for square and a manufacturing method of same. A rubber elastomer layer is arranged on the surface of the ground tile. The ground tile is prepared by mixing a basic material, an additive agent, a filler and water to prepare slurry, and shaping the slurry and sintering the ground tile; the rubber elastomer layer is prepared by mixing styrene butadiene rubber, polyacrylonitrile fibers, a vulcanizing agent, carbon black, modified hollow glass micro-bead, silicon dioxide micro-powder, modified potassium tetratitanate whiskers and a reinforcing agent. In the invention, the rubber elastomer layer is pre-formed on the surface of the ground tile, so that the ground tile can prevent bruise when people fall down; by means of the rubber elastomer layer, the comfort degree of the ground tile when people walk thereon is improved. Meanwhile, by means of the pre-formed rubber elastomer layer, a layer of rubber elastomer layer is formed on the ground of a square when the ground tiles are paved. The method, compared with a method of firstly tidying the ground and paving a plastic material or a rubber material on the ground, is greatly improved in pavement efficiency and also reduces construction period.

Owner:河南同伟建材有限公司

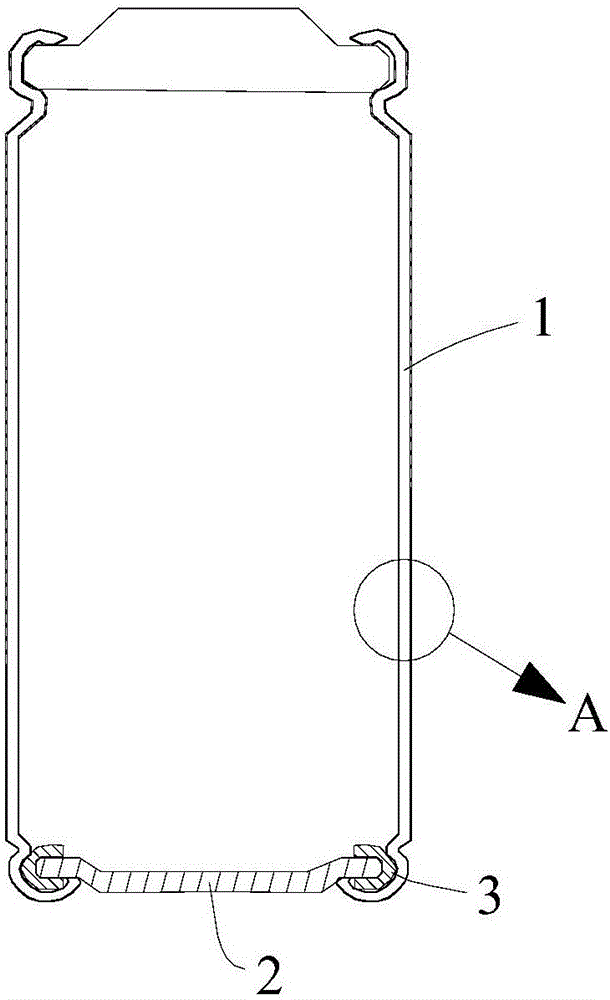

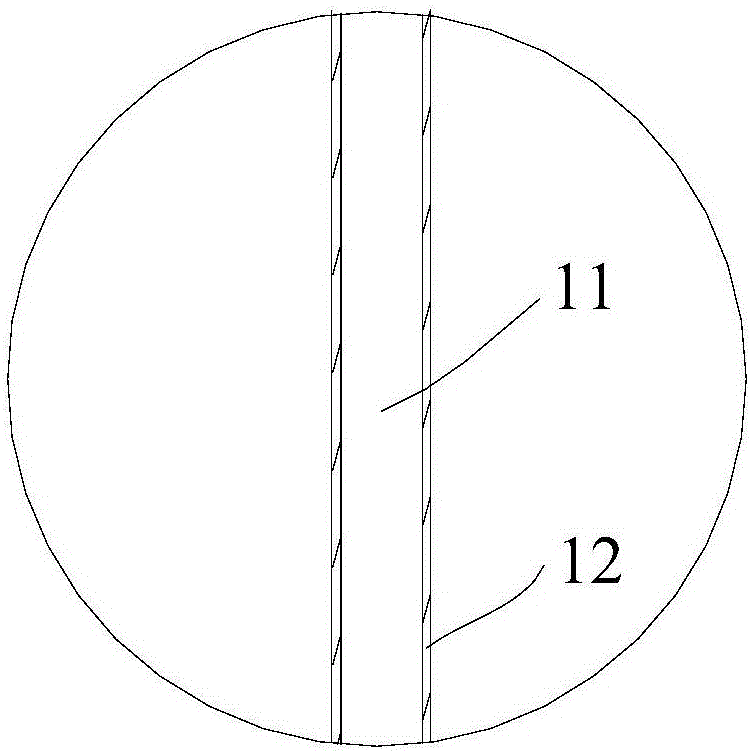

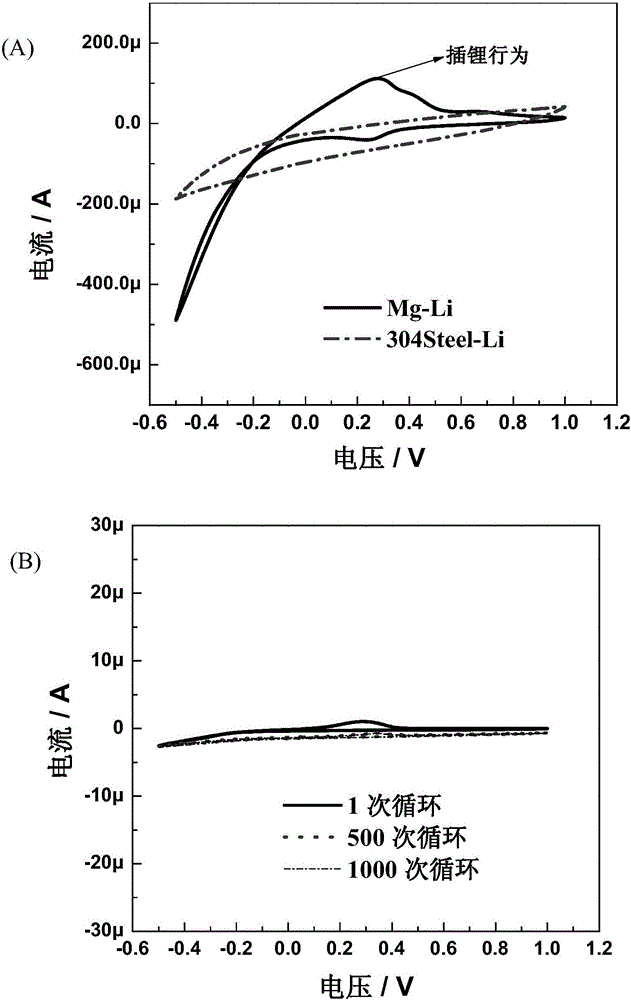

Lithium ion battery

ActiveCN106025345AImprove compactnessLess holesAnodisationSecondary cellsMicro arc oxidationPlasma electrolytic oxidation

The invention discloses a lithium ion battery, and belongs to the field of material preparation. The lithium ion battery comprises a shell, a base material of the shell is magnesium alloy, and the surface of the shell is provided with a micro-arc oxidized ceramic layer; the thickness of the micro-arc oxidized ceramic layer is 5 micrometers to 40 micrometers, and the phase composition mainly comprises magnesium fluoride, trifluoro-magnesium potassium and a small amount of magnesium oxide, wherein the PBR of magnesium fluoride is larger than 1. The invention further discloses a preparation method of the battery shell. According to the lithium ion battery, magnesium alloy of which the surface is provided with the micro-arc oxidized ceramic layer is applied to the lithium-ion power battery shell, and therefore the mass of the prepared battery shell is decreased by about 60% relative to a stainless steel shell; the battery shell does not spontaneously burn if the battery shell burns within 5 minutes at 1,000 DEG C; through 1,000 times of circulating charge and discharge testing, no obvious lithium inserting phenomenon is generated in a Mg-Li electric pair.

Owner:TIANNENG SAFT ENERGY JOINT CO

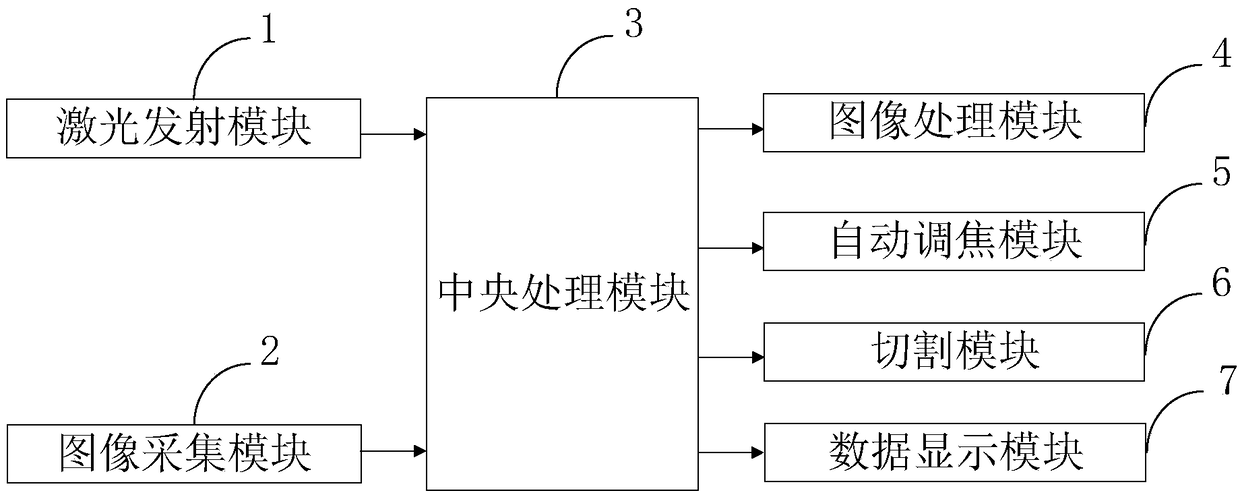

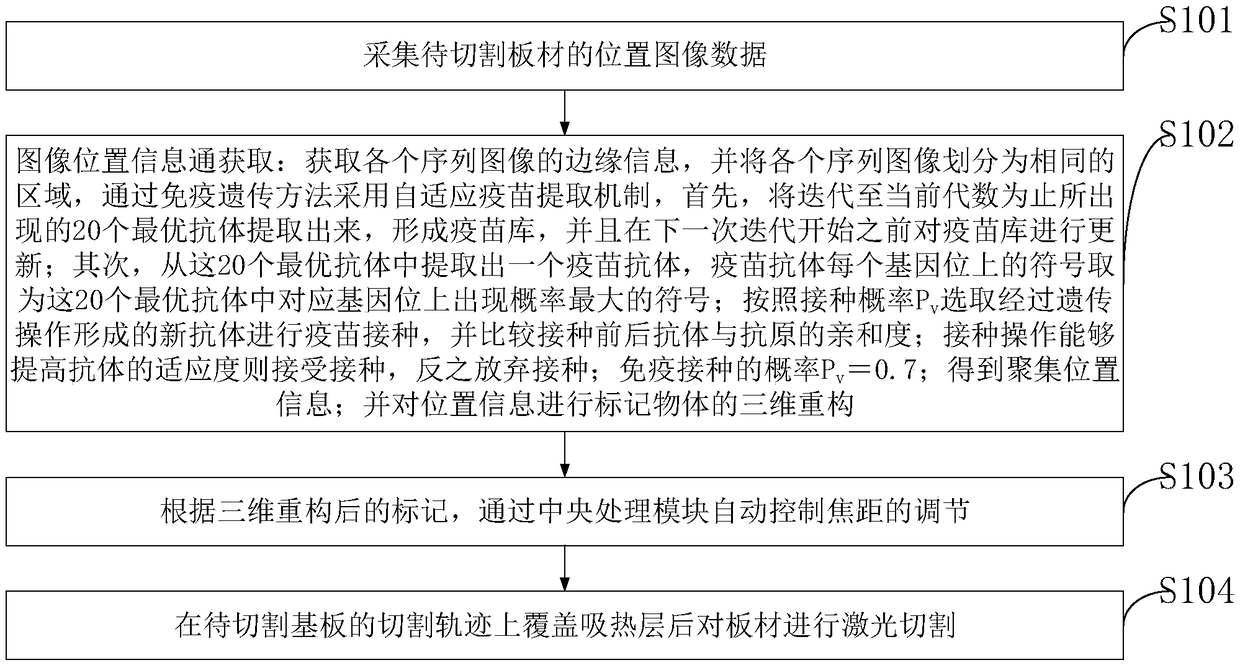

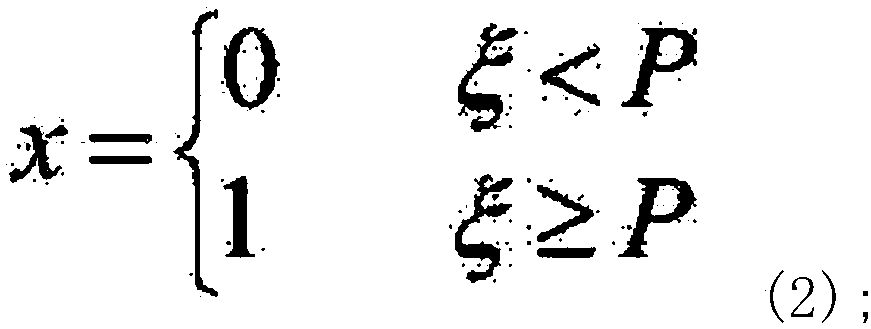

Plate laser cutting machine, control method thereof, and computer

InactiveCN108747043AThe location information is accurateImprove defectsLaser beam welding apparatusComputer modulePass rate

The invention belongs to the technical field of laser cutting, and discloses a plate laser cutting machine, a control method thereof, and a computer. Position image data of a to-be-cut plate are collected; image position infotom obtaining is conducted, specifically, edge information of each sequence image is obtained, all the sequence images are divided into identical areas, and aggregation position information is obtained through an immune genetic method by adopting an adaptive vaccine extraction mechanism; the position information is subjected to three-dimensional reconstruction of a markedobject; focal length adjusting is automatically controlled through a central processing module according to the three-dimensional reconstructed mark; and the cutting track of the to-be-cut plate is covered with a heat absorbing layer, and then the plate is subjected to laser cutting. According to the plate laser cutting machine, the control method thereof, and the computer, through the immune genetic method, the accuracy rate is increased by nearly 10% compared with that of the prior art, the product pass rate is increased by nearly 15%, and the guarantee is provided for enterprise benefits; and meanwhile, the control method can be popularized to other fine chemical industry or other precision control production fields.

Owner:GUANGDONG TECHN COLLEGE OF WATER RESOURCES & ELECTRIC ENG

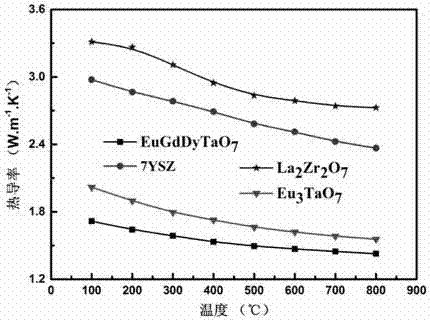

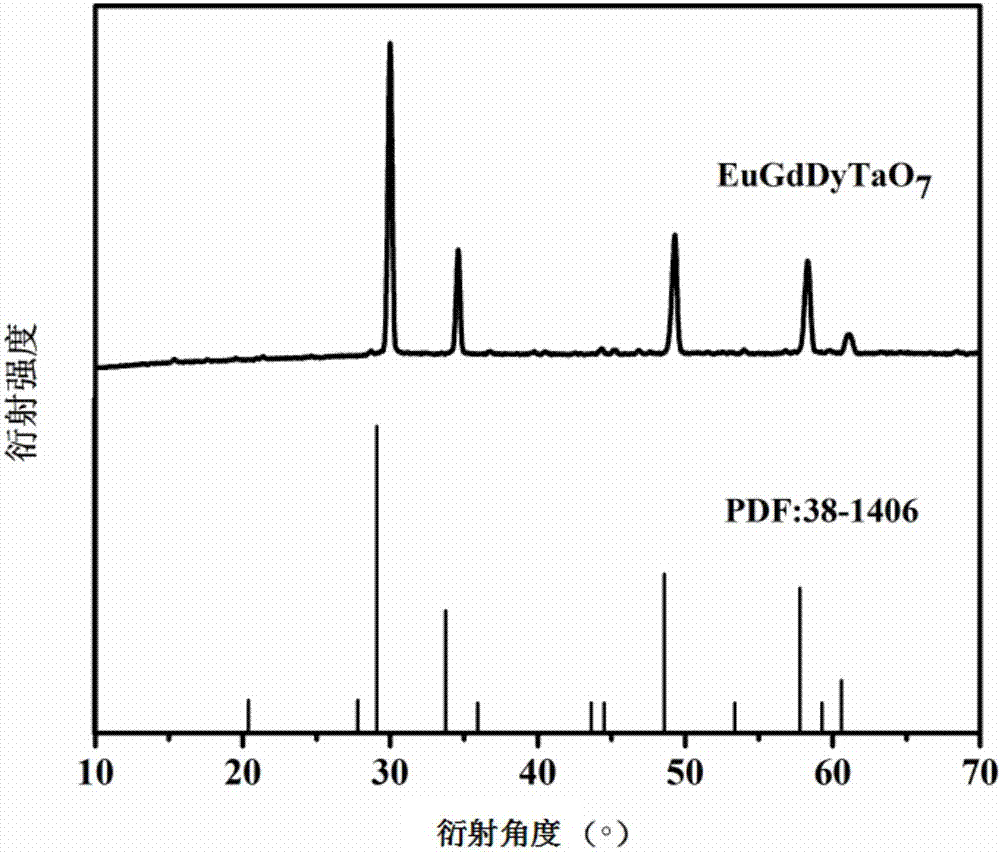

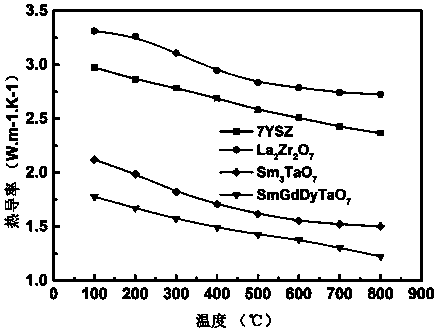

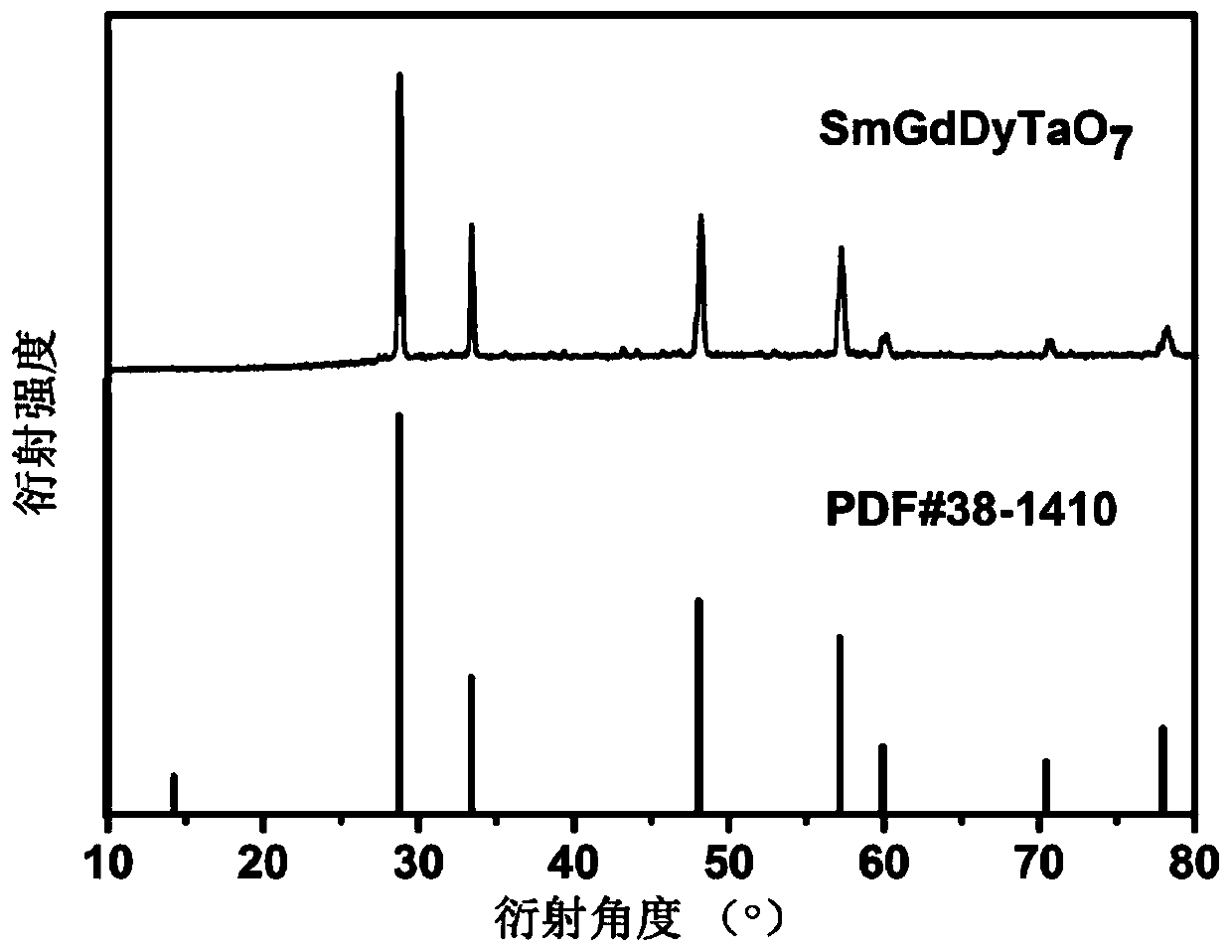

Eu-Gd-Dy trirare earth ion tantalate and preparation method and application thereof

The invention discloses Eu-Gd-Dy trirare earth ion tantalate and a preparation method and an application thereof, the Eu-Gd-Dy trirare earth ion tantalate has the chemical general formula of EuaGdbDycTaO7, wherein a+b+c=3, and a, b and c is 0.8-1.2. The preparation method comprises the following steps: 1) according to the stoichiometric ratio, weighing europium chloride, gadolinium nitrate, dysprosium nitrate and tantalum oxalate, mechanically mixing with citric acid with a set amount under a heat-retaining condition, adding strong aqua ammonia in the mixing process to neutralize the solution,and then mechanically mixing to promote the process of the reaction under a heat-retaining condition; and 2) drying the obtained solution, then calcining at high temperature to remove carbon impurities, and thus obtaining an Eu-Gd-Dy trirare earth ion tantalate powder. The Eu-Gd-Dy trirare earth ion tantalate has the advantages of good high temperature thermal stability and low thermal conductivity coefficient, and can be used as a thermal barrier coating material.

Owner:陕西天璇涂层科技有限公司

Forming method of high-thermal-conductivity silicon nitride substrate

InactiveCN114538935AIncrease the proportionEvenly distributedChemical industryCeramic shaping apparatusPlasticizerCross linker

The invention discloses a forming method of a high-thermal-conductivity silicon nitride substrate, and the forming process comprises the following steps: S1, burdening and ball milling: adding an organic monomer and a cross-linking agent into a solvent to prepare a premixed solution, and then mixing the premixed solution, a dispersing agent, silicon nitride and auxiliary ceramic powder for ball milling; and S2, adding a plasticizer to increase the flexibility of the silicon nitride sheet after tape casting. Then carrying out secondary ball milling, wherein the ball milling time is 4-30 hours; s3, vacuum defoaming: performing vacuum defoaming on the slurry obtained by secondary ball milling, and meanwhile, adding an initiator and stirring; s4, gel tape casting: carrying out tape casting operation on the slurry obtained by vacuum defoaming; and S5, drying the thin sheets, namely drying the thin sheets with certain strength and toughness after being cured for a certain time. According to the preparation method, a gel and tape casting combined technology is adopted, the advantages of two types of forming are integrated, the production cost is reduced, the environmental pollution is reduced, and the preparation of the high-performance silicon nitride ceramic substrate is realized.

Owner:天津硕科科技有限公司

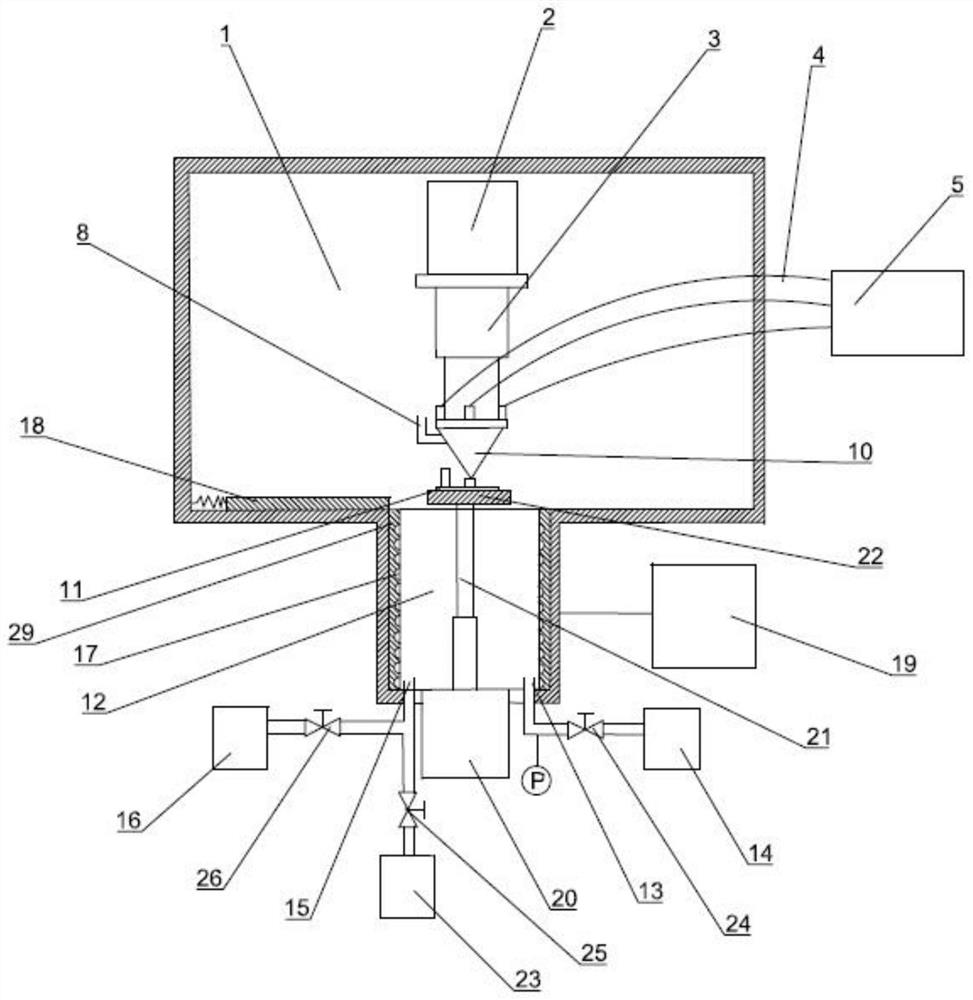

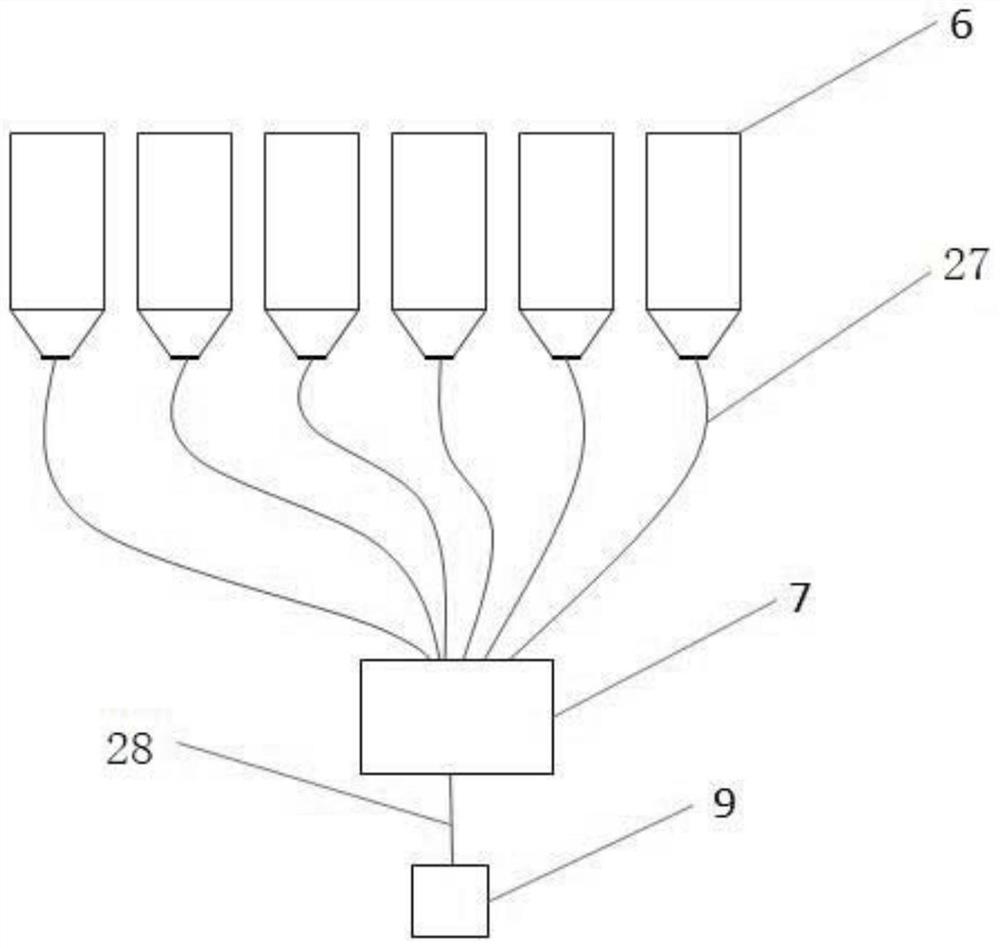

High-throughput preparation device and method for bulk alloy

PendingCN114309660AImprove production efficiencyEasy to operateAdditive manufacturing apparatusQuenching devicesTemperature controlMaterials preparation

The invention provides a block alloy high-flux preparation device and method.The block alloy high-flux preparation device is provided with a laser cladding vacuum glove box, a gas quenching furnace, a hydraulic elevator, a powder feeding system and a temperature control system, and the laser cladding vacuum glove box is provided with a laser cladding system and the powder feeding system connected with the laser cladding system; alloy powder is fed into the laser cladding system through the powder feeding system to be subjected to laser cladding treatment, the gas quenching furnace is arranged at the lower end of the laser cladding vacuum glove box and used for base plate preheating and alloy heat treatment, and one side of the gas quenching furnace is connected with the temperature control system and used for controlling the base plate preheating temperature and the alloy heat treatment temperature. And a hydraulic elevator is arranged at the lower end of the gas quenching furnace, and a substrate is fed into the gas quenching furnace and the laser cladding vacuum glove box through the hydraulic elevator. The invention also provides a preparation method thereof. The method can be widely applied to the technical field of alloy material preparation.

Owner:YANTAI UNIV

Permanent-magnetism wet pressure bottom-jacking type forming hydraulic press

ActiveCN103009464AFew defects such as cracksQuality improvementShaping press ramEngineeringSmall deviations

The invention discloses a permanent-magnetism wet pressure bottom-jacking type forming hydraulic press, which is used for solving the problems of long forming time, low efficiency, poor consistency of green bodies, large deviation and poor quality in the conventional permanent-magnetism wet pressure forming hydraulic press. The permanent-magnetism wet pressure bottom-jacking type forming hydraulic press comprises a pressure-bearing oil cylinder, a top-entering oil cylinder and a mold, wherein the mold is arranged between the pressure-bearing oil cylinder and the top-entering oil cylinder, the pressure-bearing oil cylinder is positioned above the mold, and the top-entering oil cylinder is positioned below the mold. During the wet pressure forming process, the pressure-bearing oil cylinder does not move, the top-entering oil cylinder moves upwards, so that the wet pressure forming process is finished, and the permanent-magnetism wet pressure bottom-jacking type forming hydraulic press has the characteristics of short forming time, high efficiency, good consistency of green bodies, small deviation and high quality.

Owner:YIBIN DAZHENG ELECTRONICS EQUIP

Long-storage-period low-temperature-curing epoxy resin-based prepreg and preparation method thereof

ActiveCN113045859AReduce consumptionReduced temperature resistance requirementsGlass fiberCarbon fibers

The invention belongs to the technical field of composite materials, and particularly provides a low-temperature-curing epoxy resin-based prepreg with a relatively long room-temperature storage period and a preparation method thereof. A resin system of the prepreg is formed by mixing a Lycure M-10 latent low-temperature curing agent, solid epoxy resin and liquid epoxy resin; reinforced fibers in the prepreg can be carbon fibers, glass fibers, aramid fibers and the like and fabric forms thereof; and the prepreg is prepared by adopting a hot melting process. The preparation method comprises the following steps: firstly, preparing a resin adhesive film at 40 DEG C by adopting a film coating machine, then compounding the resin adhesive film and the reinforced fibers on a prepreg at 40-45 DEG C, and then conducting cooling, trimming, laminating and rolling to obtain the low-temperature-curing prepreg. The prepreg has the advantages that a preparation temperature is low, a curing temperature is low, curing time is short, room-temperature working life is long, batch preparation can be realized, the performance is not greatly different from the performance of a high-temperature cured prepreg, the internal stress in the curing process of the composite material and the manufacturing energy consumption of the composite material can be reduced, and the preparation efficiency of the composite material is improved.

Owner:SHANDONG NON METALLIC MATERIAL RES INST

sm-gd-dy triple rare earth ion tantalate and its preparation method and application

ActiveCN107585786BExtended service lifeGood thermal propertiesTantalum compoundsDysprosium nitrateCalcination

Owner:陕西天璇涂层科技有限公司

Modified Concrete Expansive Agent

The invention discloses a modified concrete expansive agent, made from, by weight, 10-20 parts of calcium silicoaluminate, 25-30 parts of calcium sulfoaluminate, 20-25 parts of sulfur fixing waste residue, 10-20 parts of modified red clay, 1-5 parts of tourmaline powder, 6-8 parts of iron slag, 4-6 parts of modified calcium oxide, 4-6 parts of magnesium oxide, 3-5 parts of sodium methyl silicate, 2-4 parts of calcium formate, 0.1-0.3 part of azodicarbonamide, 0.4-0.7 part of maltodextrin, 1-4 parts of sodium lignin sulfonate, 0.3-0.6 part of polyglycol ether, 1-3 parts of a polycarboxylate superplasticizer, 2-5 parts of modified diatomite powder, and 0.5-0.8 part of nano calcium carbonate. The modified concrete expansive agent has the advantages of high strength, good compensating capacity and the ability to control calcium oxide reaction and is a promising concrete admixture.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

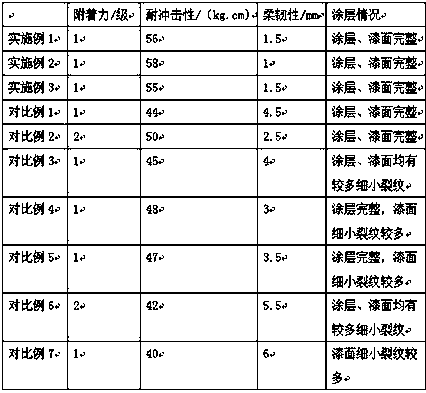

Coating liquid for preventing defects on paint surface after paint spraying

The invention discloses a coating liquid for preventing paint surface defects after paint spraying, which is prepared by the following steps: adding sodium borohydride and sodium hydrogen sulfite intoa graphene oxide dispersion liquid, and carrying out a reaction to obtain graphene aerogel; 2) adding the graphene aerogel into a tetrahydrofuran solution, adding triethylamine, transferring the mixture into an ice-water bath, and adding the mixed solution for reaction to obtain brominated graphene aerogel; 3) adding anhydrous citric acid and tetramethyl propane diamine into methanol, stirring the mixture for carrying out a reaction, and adding the graphene aerogel methanol dispersion liquid to obtain modified graphene oxide; and 4) emulsifying epoxy resin, propylene glycol monomethyl ether and an emulsifier, and adding the remaining raw materials to obtain the coating liquid. The coating liquid has certain self-repairing performance and high curing temperature, cracks of the finish paintcan be reduced in the curing process, and the cracks can be filled and repaired, so that the quality of the finish paint can be improved, and the coating liquid has a wide application prospect.

Owner:界首市金龙机械设备有限公司

Precise forging-continuous rolling production technology of large and heavy single molybdenum rod

ActiveCN103042389BRealize deep processingIncrease productivityTemperature control deviceOther manufacturing equipments/toolsThermal treatmentContinuous rolling

The invention provides a precise forging-continuous rolling production technology of a large and heavy single molybdenum rod. The production technology comprises the following steps of: 1, carrying out billet forging on the molybdenum rod by a precision forging machine to obtain a precision forging bar; 2, heating the precision forging bar; 3, rolling for the first time by a Y-shaped three-roller continuous mill to obtain a rolled molybdenum rod; 4, heating the rolled molybdenum rod; and 5, rolling for the second time by the Y-shaped three-roller continuous mill and obtaining the large and heavy single molybdenum rod of which the piece weight is 45-50kg. Deep processing of a molybdenum bar is successfully achieved by setting and optimizing each parameter in precision forging, thermal treatment and continuous rolling processes; the large and heavy single molybdenum rod, which is suitable for subsequent wire drawing, and of which the piece weight is 45-50kg, is finally produced; and the production efficiency is obviously improved. The piece weight of the molybdenum rod produced by the production technology is much greater than that of the molybdenum rod produced by a traditional technology; and the precise forging-continuous rolling production technology has no welding spot on the whole, and is even in internal organization, high in product quality and suitable for large-scale industrial production.

Owner:JINDUICHENG MOLYBDENUM CO LTD

laser cutting method

ActiveCN107695533BReduce the size of the temperature gradientReduce thermal stressLaser beam welding apparatusLaser cuttingHeat stress

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

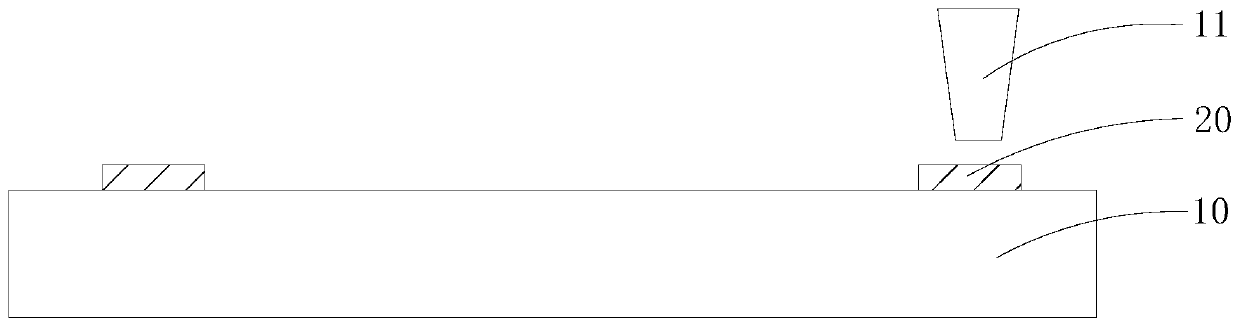

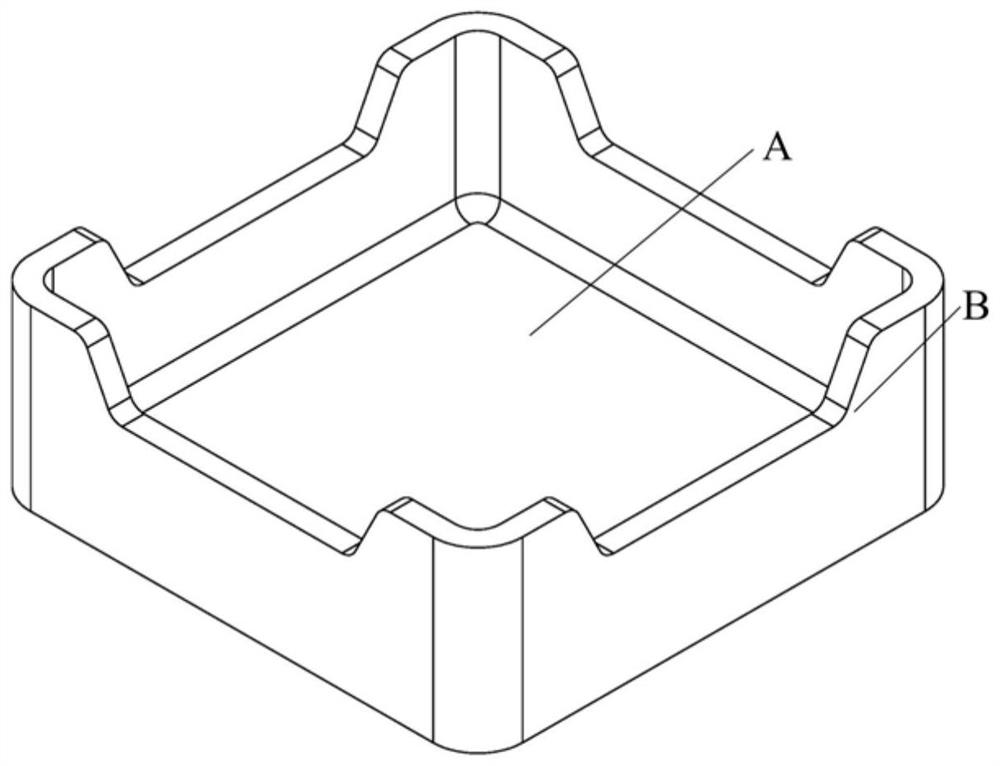

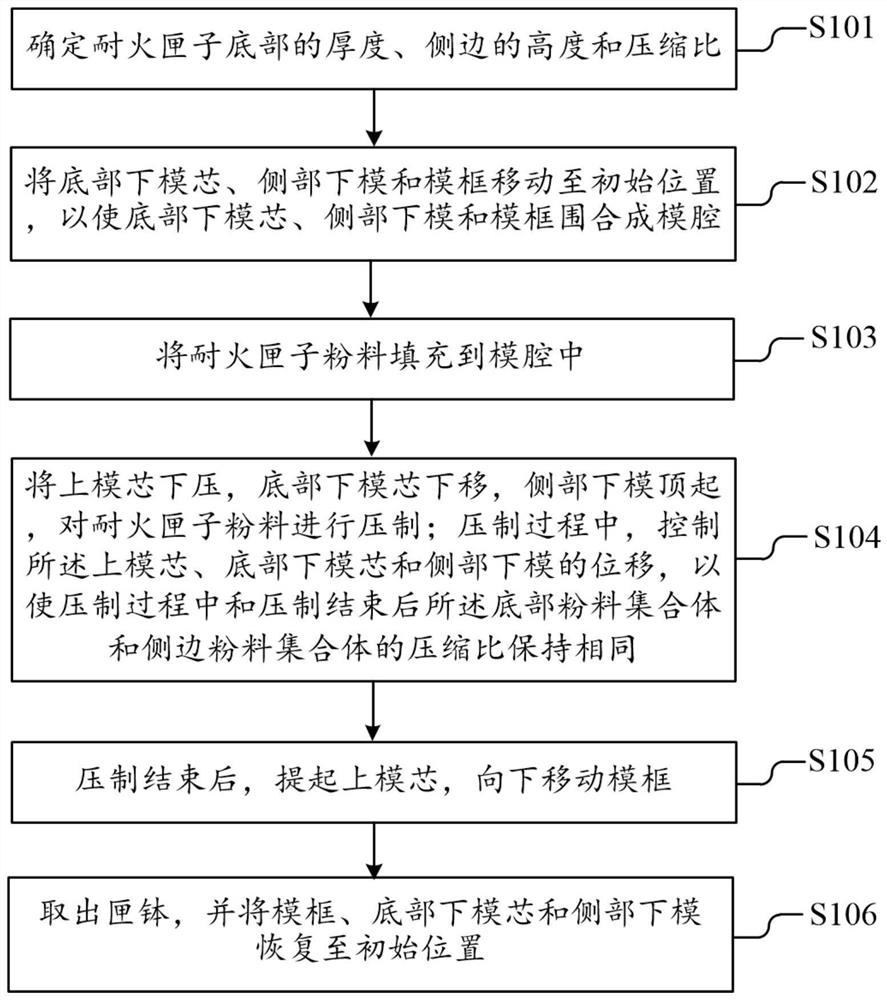

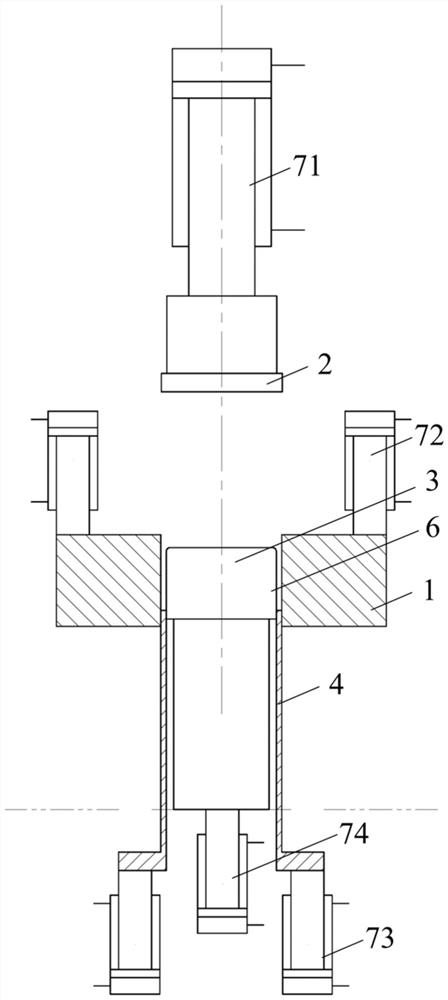

A kind of press-molding method and equipment for refractory box and refractory box

The invention discloses a method for pressing and forming a refractory box, which comprises the following steps: distributing refractory box powder according to a preset height into a mold cavity formed by a mold frame, a bottom lower mold core and a side lower mold; the bottom lower mold core and the side lower mold The mold divides the refractory box powder located above it into a bottom powder aggregate and a side powder aggregate; the upper mold core is pressed down to the mold cavity, and the bottom lower mold core moves downward, so The side lower mold is lifted upward, and the refractory box is formed by the relative movement of the upper mold core, the bottom lower mold core and the side lower mold; during and after the pressing process, the bottom powder aggregate and the side powder aggregate are aggregated. The compression ratio of the body remains the same. Correspondingly, the present invention also discloses a press-forming device for a refractory box and a refractory box. The implementation of the present invention can effectively improve the uniformity of different positions of the refractory box, prevent its forming and fracture, and reduce defects such as forming cracks.

Owner:FOSHAN HENGLITAI MACHINERY

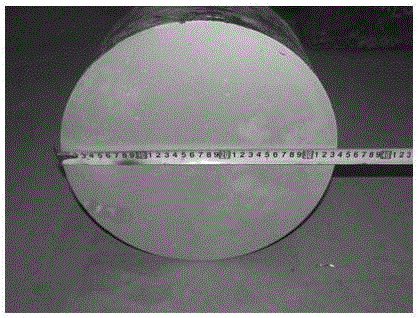

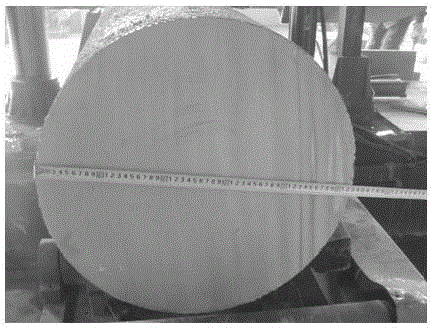

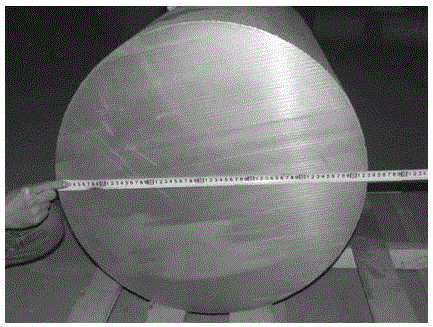

Semi-continuous casting process of large-diameter medium-strength heat-resistant magnesium alloy ingot

The invention discloses a semi-continuous casting process of a large-diameter medium-strength heat-resistant magnesium alloy, and the alloy composition (wt.%) aimed at is: Al? 7.5-9.0%, Ag? 0.02-0.80%, Zn? 0.35-0.55%, Mn? 0.05-0.20%, RE? 0.01-0.10%, Ca? 0.001-0.020%, the rest is Mg and non-removable impurity elements. The process includes the steps of melting raw materials at 620-680°C, ventilating and stirring, raising the temperature to 720-740°C for 10-20min, standing at 680-700°C for 1-3h, and casting at low temperature. By adjusting the process parameters of each step, a magnesium alloy ingot with a diameter of Ф330-630mm and a length of ≥1000mm was successfully cast. Large-diameter, high-quality ingots can provide high-quality blanks for the forming of large-scale structural parts, which is of great significance for promoting the wide application of magnesium alloys.

Owner:CENT SOUTH UNIV

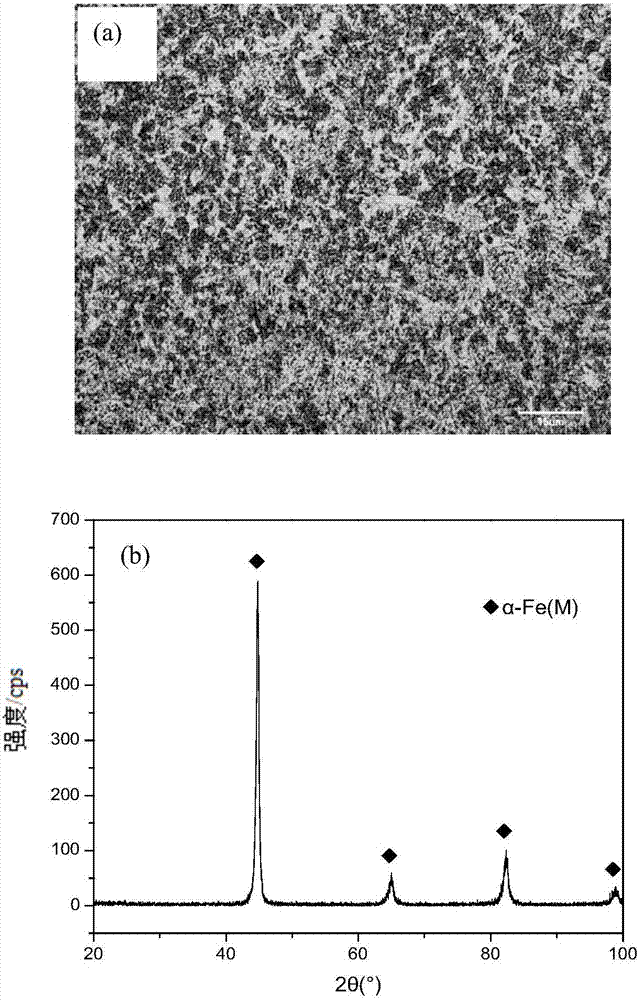

A method of preparing 24crnimo bainite alloy steel by laser selective melting technology

ActiveCN107214336BRemarkable effect of fine grain strengtheningImprove mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingHardness

The invention provides a method for preparing 24CrNiMo bainite alloy steel by laser selective melting technology. The method includes scanning the 24CrNiMo alloy steel powder spread on the substrate according to the preset laser selective melting scanning path until the powder is melted. A step of. In the present invention, by optimizing the process parameters and using the effects of alloy elements such as C, Cr, Ni, Mo, etc., the bainite alloy steel with uniform structure is obtained under the high cooling rate of laser selective melting, and the average microhardness of the obtained bainite structure is It reaches 330-346HV, the tensile strength is 962-978Mpa, the elongation is 16.4-17.6%, and the strong-plastic product reaches 16.1-16.9Gpa·%. The tissue has excellent strength and toughness matching. The method and process are mainly used for laser selective melting manufacturing of 24CrNiMo alloy steel high-speed rail brake discs.

Owner:NORTHEASTERN UNIV LIAONING

A kind of carbon foam and preparation method thereof

ActiveCN109867272BAvoid crackingUniform cell sizeCarbon preparation/purificationCrazingThermal insulation

Owner:广东煤基碳材料研究有限公司

A preparation method of low-cost high-strength and tough titanium alloy pipe for marine engineering

ActiveCN112605123BGuaranteed formabilityReduce multiple deformation processesFurnace typesWork cleaning devicesIngotTitanium alloy

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com