A kind of press-molding method and equipment for refractory box and refractory box

A technology of pressing and forming boxes, which is applied in the field of pressing and forming fire-resistant boxes, which can solve the problems of high-temperature structural strength reduction of fire-resistant boxes, difficulty in ensuring uniformity, and crack formation, so as to reduce equipment requirements and control accuracy requirements, reduce Defects such as molding cracks and the effect of preventing molding fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention is further described in detail below.

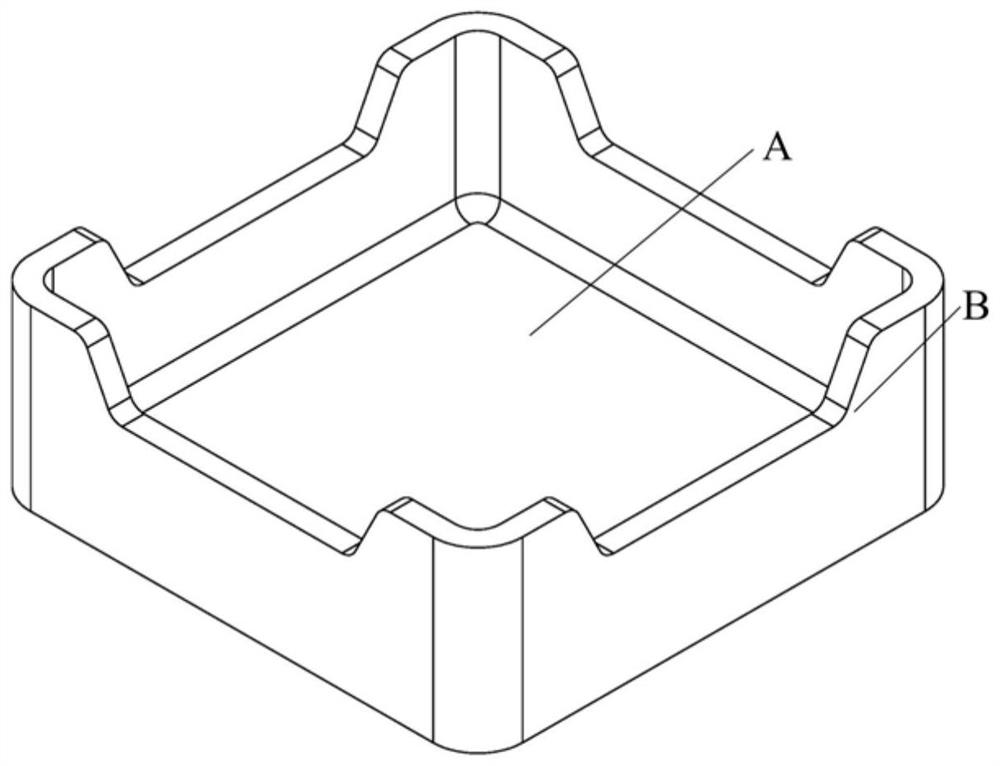

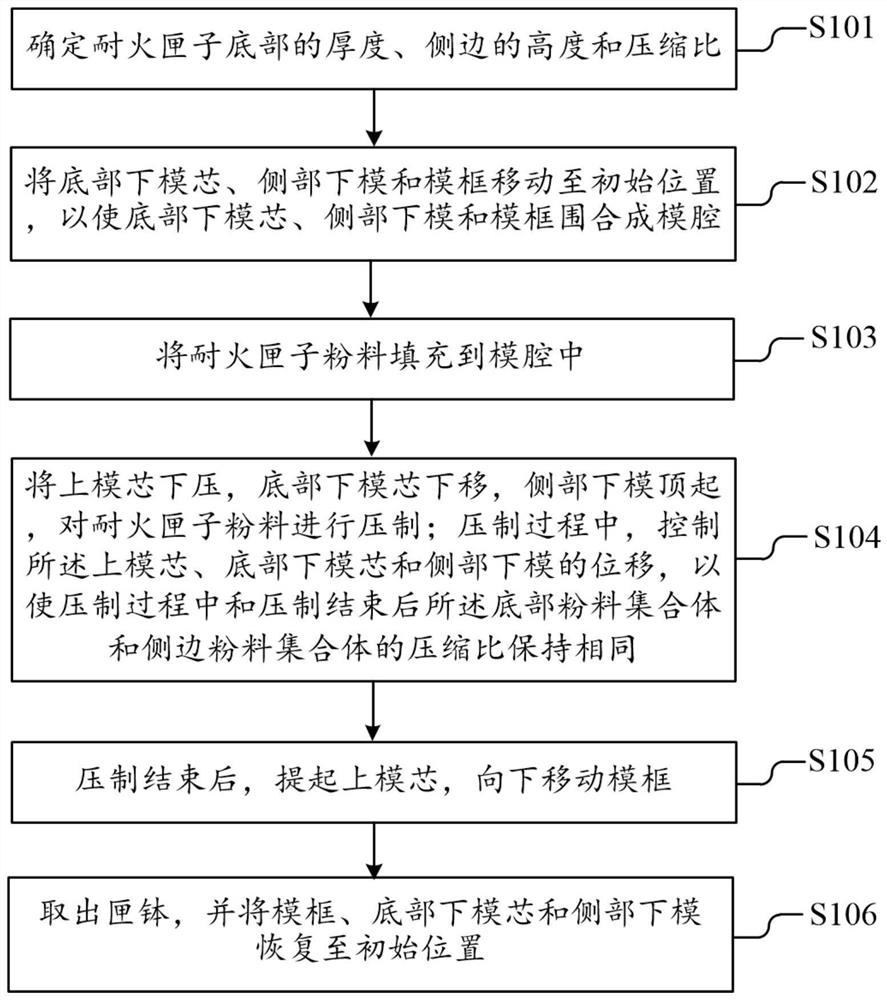

[0072] As a first aspect of the present invention, the present invention discloses a press-molding method for a refractory box, comprising:

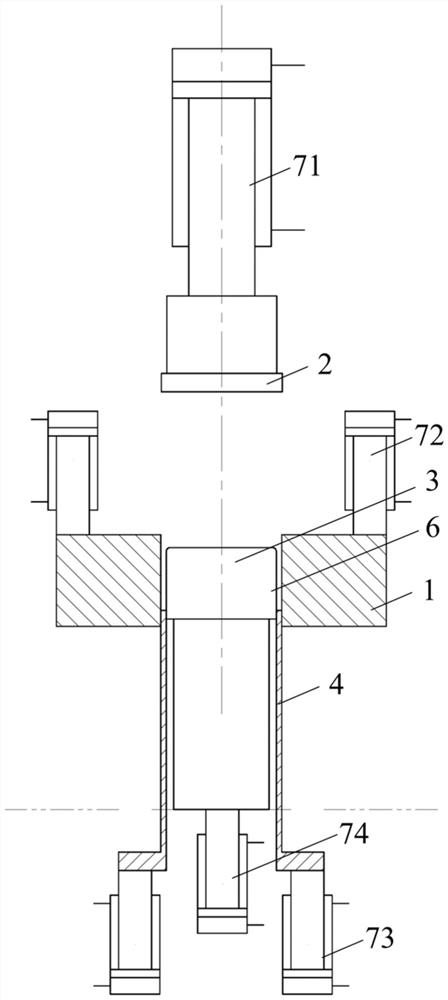

[0073] (1) Distribute the refractory box powder according to the preset height in the mold cavity formed by the mold frame, the bottom lower mold core and the side lower mold; the bottom lower mold core and the side lower mold divide the refractory box powder above it into two parts Bottom powder aggregate and side powder aggregate;

[0074] (2) Press the upper mold core to the mold cavity, the bottom lower mold core moves downward, and the side lower mold lifts upward, and passes through the upper mold core, the bottom lower mold core and the side lower mold. The relative motion is pressed to form a refractory box;

[0075] During and after pressing, the compression ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com