Semi-continuous casting process of large-diameter medium-strength heat-resistant magnesium alloy ingot

A casting process and large-diameter technology, which is applied in the field of magnesium alloy casting and semi-continuous casting of g-Al-Ag magnesium alloy ingots, can solve the problems of increasing edge cracking tendency, increasing casting difficulty, inclusions, etc., to avoid The effect of edge cracking and reducing slag inclusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

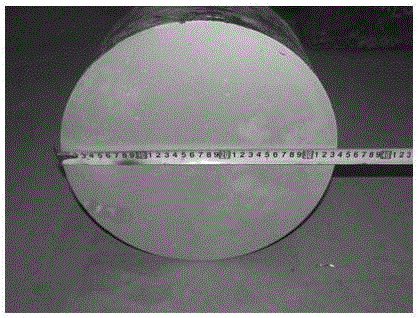

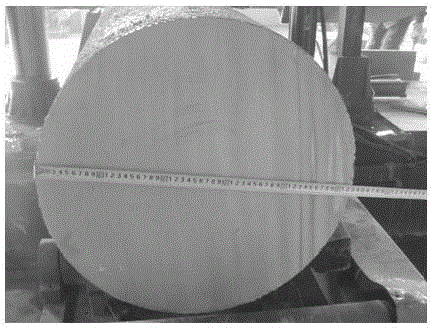

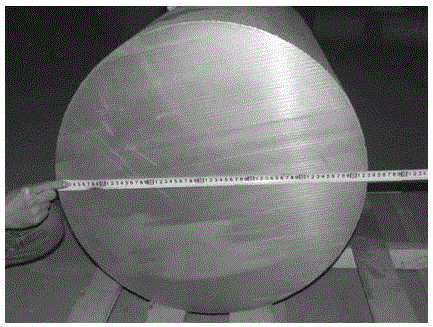

Image

Examples

Embodiment 1

[0016] Example 1 : In a smelting furnace with a capacity of 1 ton, high-purity magnesium, high-purity aluminum, high-purity zinc, Mg-Mn master alloy, high-purity silver, Mg-RE master alloy, and Mg-Ca master alloy are melted in sequence, and the melting temperature is controlled at 650- 680°C. After all the raw materials are melted, the surface slag is removed, and then argon gas is introduced to stir for 20 minutes. After stirring, close the furnace cover and pass SF to the surface of the melt 6 with CO 2 The mixed gas is used for protection, and at the same time, the temperature of the melt is raised to 730-740°C for 15 minutes. After the high-temperature heat preservation, cut off the power of the heating furnace, control the temperature of the melt at 690-700°C, and let it stand for 2 hours. Then cast the ingot. During the casting process, the melt temperature in the furnace is controlled at 670-680° C., the melt temperature in the crystallizer is 650-660° C., and the ...

Embodiment 2

[0017] Example 2 : In a smelting furnace with a capacity of 1 ton, high-purity magnesium, high-purity aluminum, high-purity zinc, Mg-Mn master alloy, high-purity silver, Mg-RE master alloy, and Mg-Ca master alloy are melted in sequence, and the temperature of the melt is controlled at 630 during the melting process -640°C. After all the raw materials are melted, the surface slag is removed, and then argon gas is introduced to stir for 25 minutes. After stirring, close the furnace cover and pass SF to the surface of the melt 6 with CO 2 The mixed gas is used for protection, and at the same time, the temperature of the melt is raised to 730-740°C for 20 minutes. After the high-temperature heat preservation, cut off the power of the heating furnace, control the temperature of the melt at 680-690°C, and let it stand for 3 hours. Then cast the ingot, and control the temperature of the melt in the furnace to 660-670°C, the temperature of the melt in the crystallizer to 640-650°...

Embodiment 3

[0018] Example 3 : In a smelting furnace with a capacity of 1 ton, high-purity magnesium, high-purity aluminum, high-purity zinc, Mg-Mn master alloy, high-purity silver, Mg-RE master alloy, and Mg-Ca master alloy are melted in sequence, and the melt temperature is controlled at 640 during the melting process -650°C. After all the raw materials are melted, remove the slag on the surface, and then introduce argon gas to stir for 30 minutes. After stirring, close the furnace cover and pass SF to the surface of the melt 6 with CO 2 The mixed gas is used for protection, and at the same time, the temperature of the melt is raised to 730-740°C for 20 minutes. After the high-temperature heat preservation, cut off the power of the heating furnace, and control the temperature of the melt at 690-700°C for 3 hours. Then cast the ingot. During the casting process, the temperature of the melt in the furnace is controlled at 670-680° C., the temperature of the melt in the crystallizer i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com