A kind of carbon foam and preparation method thereof

A foamed carbon and constant temperature technology, which is applied in the preparation/purification of carbon, can solve the problems of poor thermal insulation effect and micro-cracks in carbon foam, and achieve the effects of good thermal insulation, uniform cell size and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

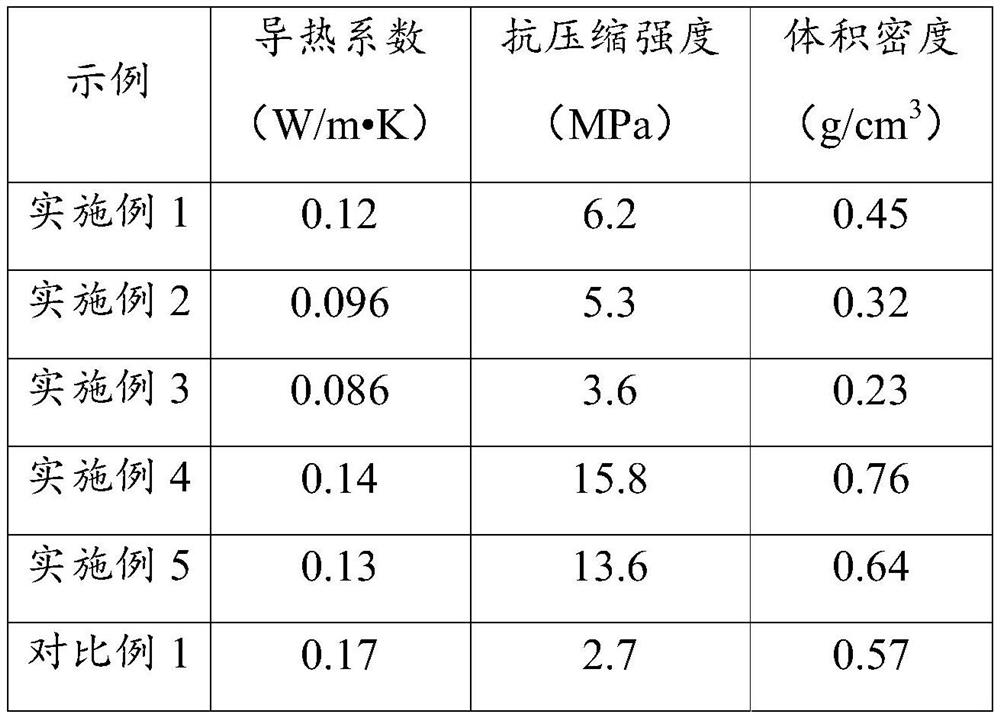

Examples

Embodiment 1

[0029] This embodiment provides a method for preparing foamed carbon, specifically comprising:

[0030] 35wt% lignite powder, 64.95wt% 1-methylnaphthalene and 0.05wt% zinc iodide catalyst were fully stirred and mixed to form a coal slurry, and the coal slurry was thermally dissolved and catalyzed to generate a thermally soluble product. The hydrogenation temperature was 420°C and the pressure was 6MPa, hydrogen oil volume ratio is 500, space velocity 1h -1 , separating the obtained thermally liquefied product into light thermally soluble and heavy components of lignite thermally soluble and catalyzed with a boiling point of 500°C;

[0031] Grind the heavy components of the lignite hot-melt catalyst through a 200-mesh sieve, and set aside; weigh 110kg of the crushed heavy components, place them in a nitrogen-enclosed environment of 1MPa, and then raise the temperature at a heating rate of 6°C / min to 320°C, keep the temperature constant for 2 hours, then raise the temperature t...

Embodiment 2

[0033] This embodiment provides a method for preparing foamed carbon, specifically comprising:

[0034] 42wt% lignite powder, 56.9wt% 1-methylnaphthalene and 1.1wt% zinc iodide catalyst were fully stirred and mixed to form a coal slurry, and the coal slurry was thermally dissolved and catalyzed to generate a thermally soluble product. The hydrogenation temperature was 445°C and the pressure was 10MPa, hydrogen-to-oil volume ratio 520, space velocity 0.8h -1 , separating the obtained thermally liquefied products into light thermally soluble substances and lignite thermally soluble catalytic heavy components with a boiling point >500°C;

[0035]The heavy component of the lignite hot-melt catalyst is crushed through a 200-mesh sieve, and set aside; weigh 110kg of the crushed heavy component, place it in a nitrogen-enclosed environment of 2MPa, and then raise the temperature at a heating rate of 5°C / min to 280°C, keep the temperature constant for 2 hours, then raise the temperatu...

Embodiment 3

[0037] This embodiment provides a method for preparing foamed carbon, specifically comprising:

[0038] 42wt% lignite powder, 56.9wt% 1-methylnaphthalene and 1.1wt% zinc iodide catalyst were fully stirred and mixed to form a coal slurry, and the coal slurry was hot-melted and catalyzed to generate a hot solution product. The hydrogenation temperature was 445 °C and the pressure was 10MPa, hydrogen-to-oil volume ratio 520, space velocity 0.8h -1 , separating the obtained thermally liquefied products into light thermally soluble substances and lignite thermally soluble catalytic heavy components with a boiling point >500°C;

[0039] The heavy component of the lignite hot-melt catalyst is crushed through a 200-mesh sieve and set aside; weigh 110kg of the crushed heavy component, place it in a nitrogen-enclosed environment of 1.5MPa, and then, at a heating rate of 6°C / min Raise the temperature to 410°C, hold the temperature for 3 hours, then raise the temperature to 510°C at a he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com