Patents

Literature

48results about How to "Uniform cell size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

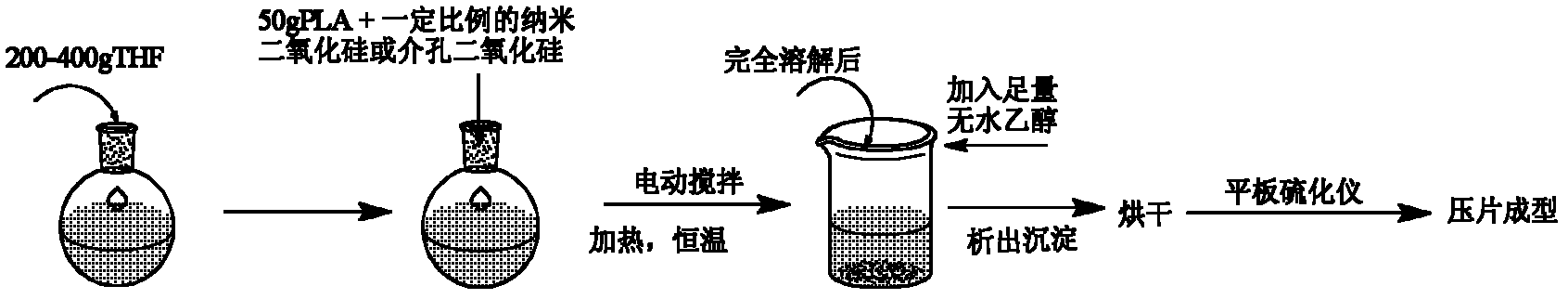

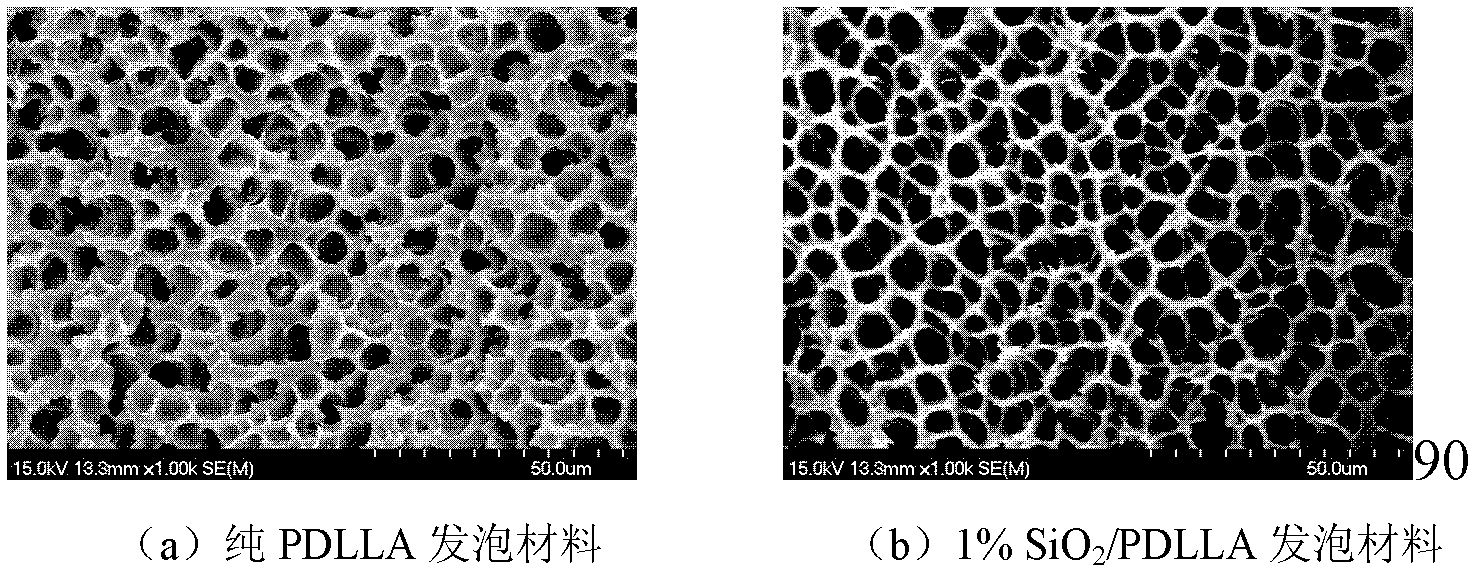

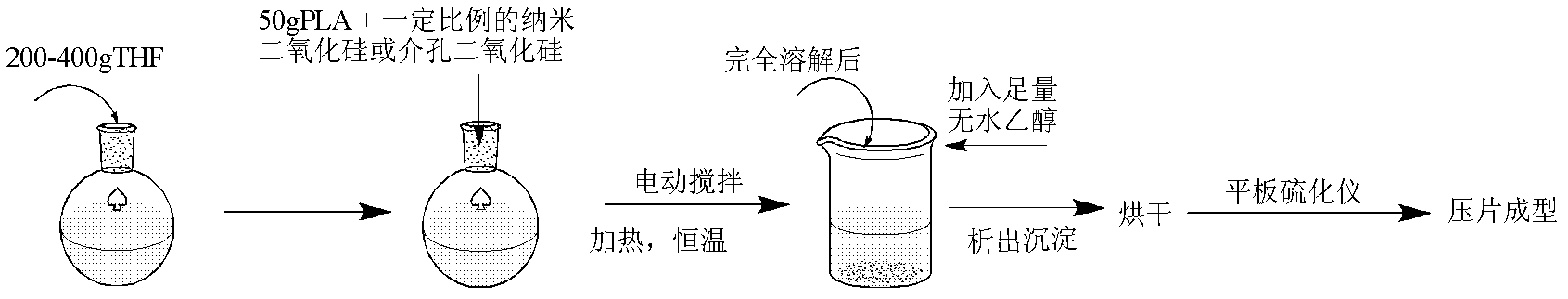

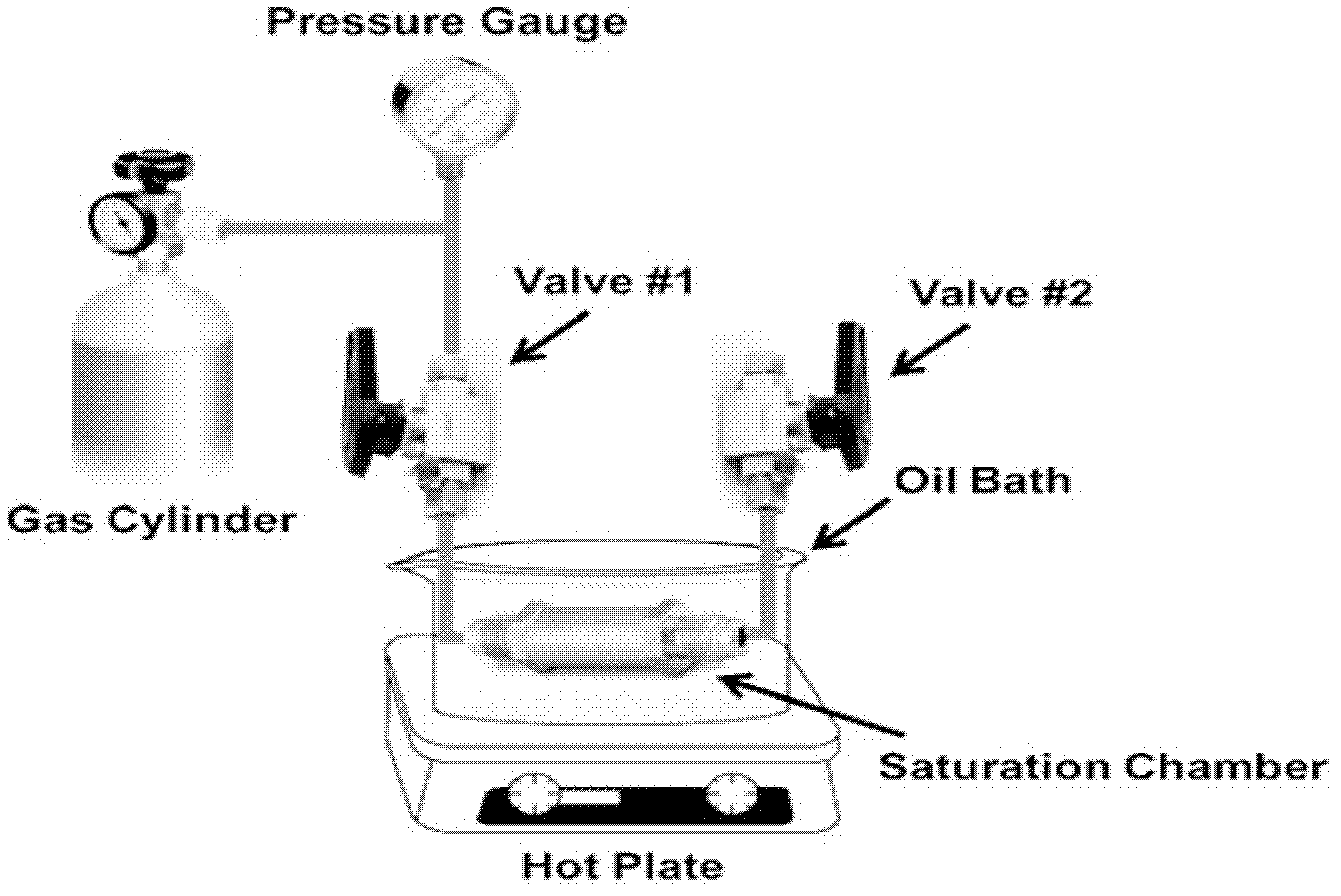

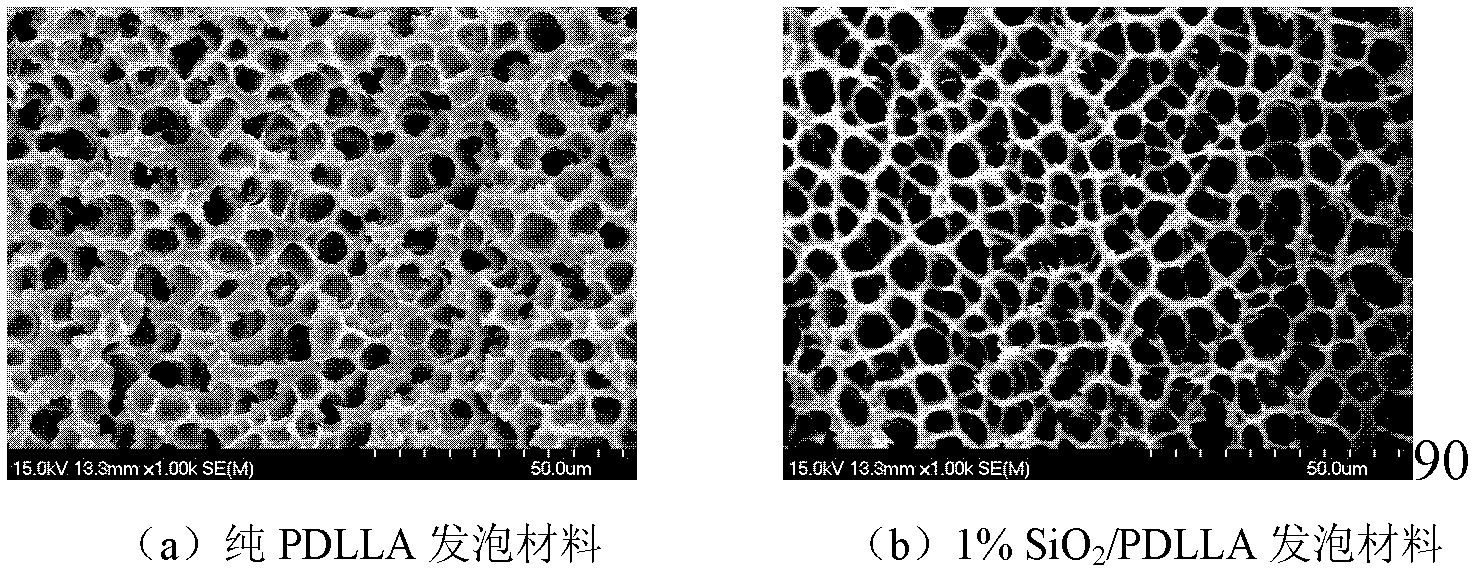

Method for preparing meso-porous silica/polylactic acid foamed material by supercritical CO2 foaming

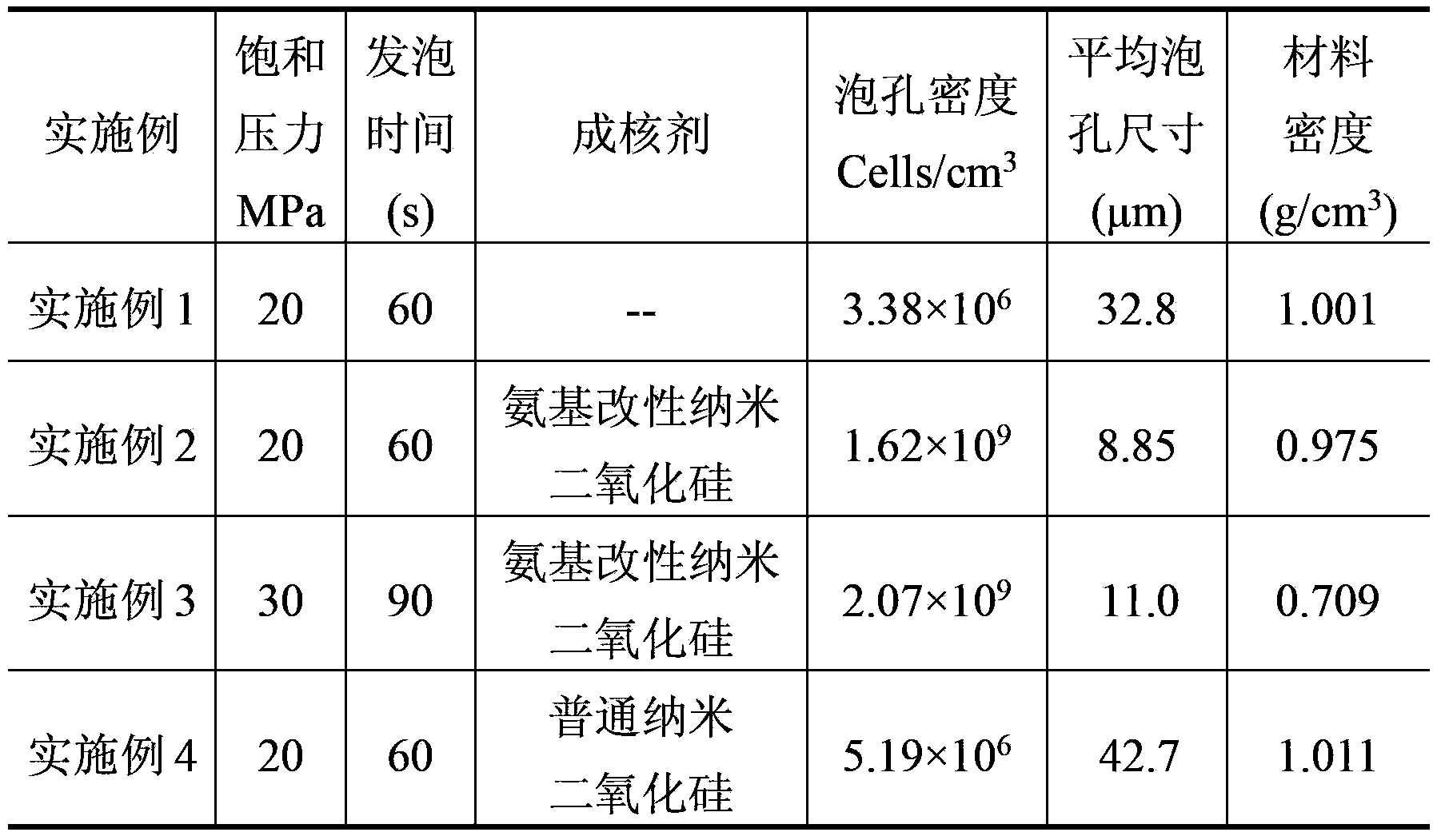

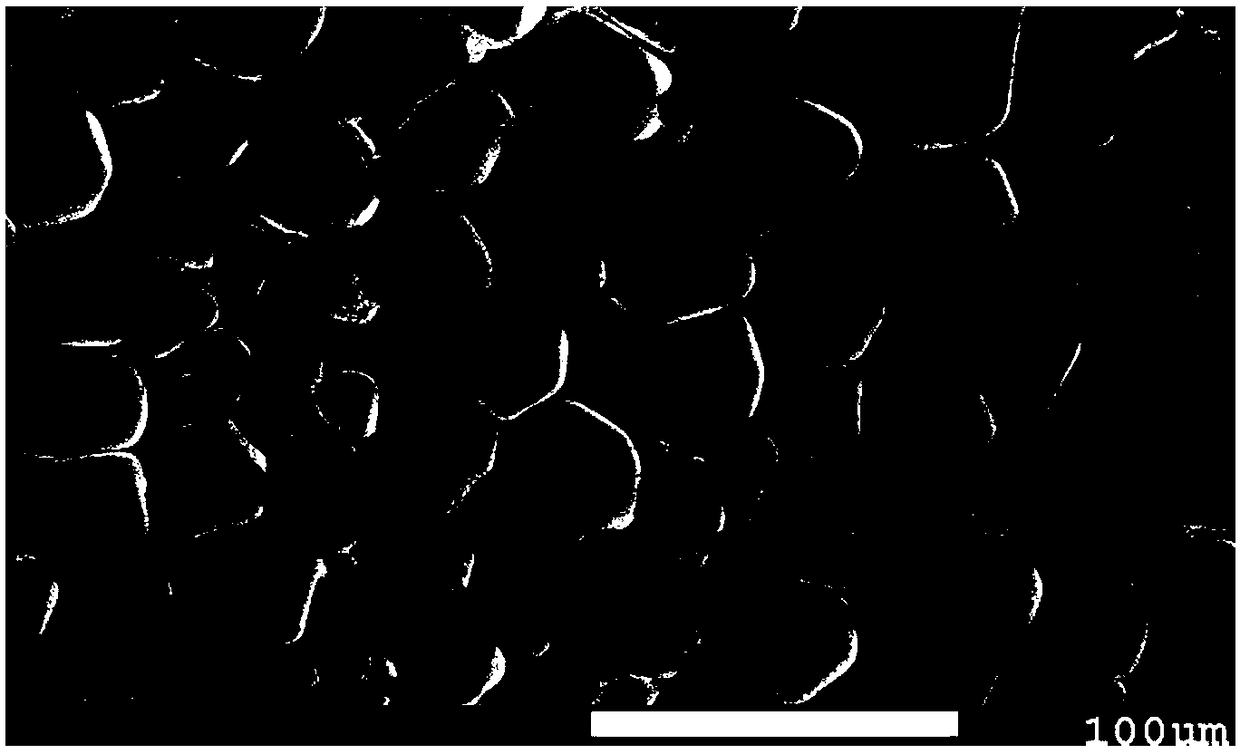

The invention discloses a method for preparing a meso-porous silica / polylactic acid foamed material by supercritical CO2 foaming, and the method prepares a polylactic acid foamed material by using meso-porous silica as a nucleating agent; the foaming process is simple; foams of the obtained foamed material have a uniform foam size and high density.

Owner:弗润德力新材料宁夏股份有限公司

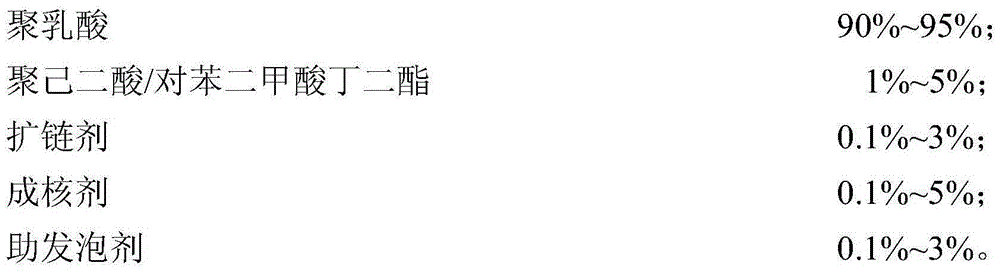

Full biodegradable heat-resistant polylactic acid foaming material and preparation method thereof

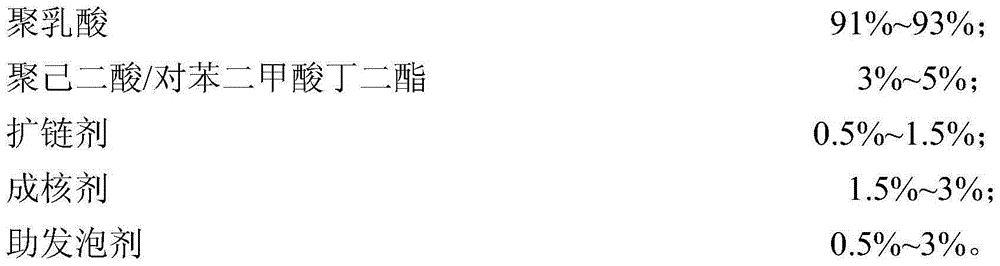

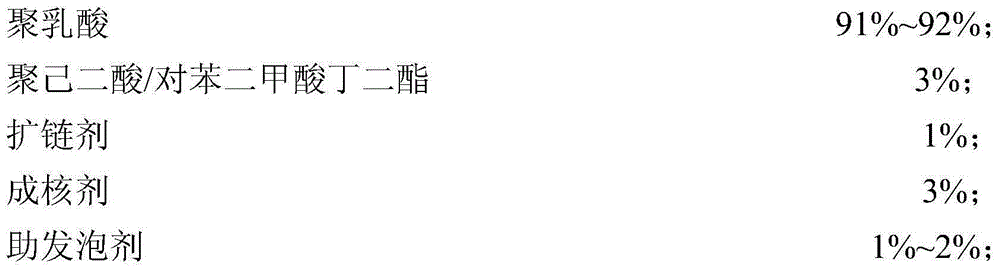

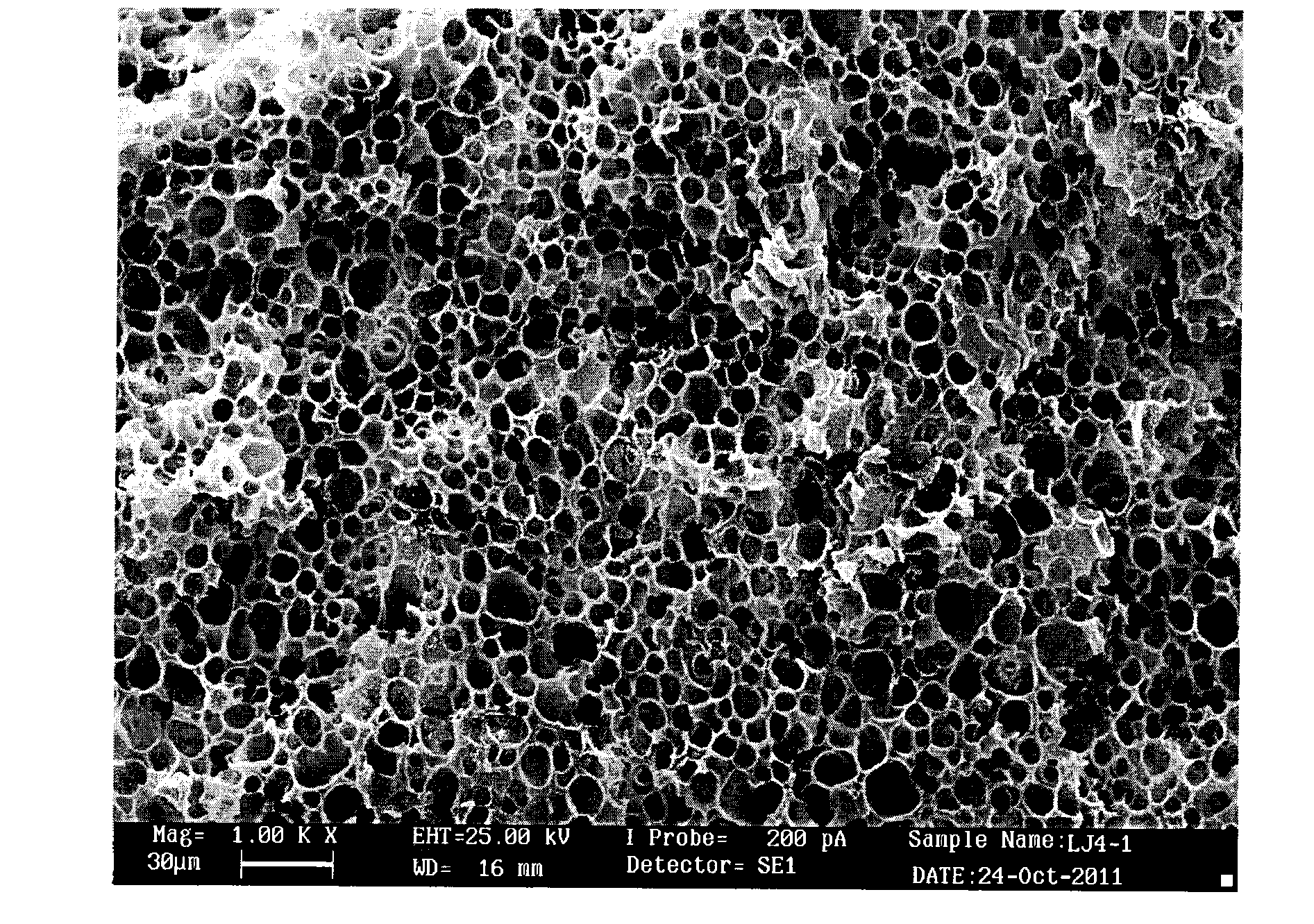

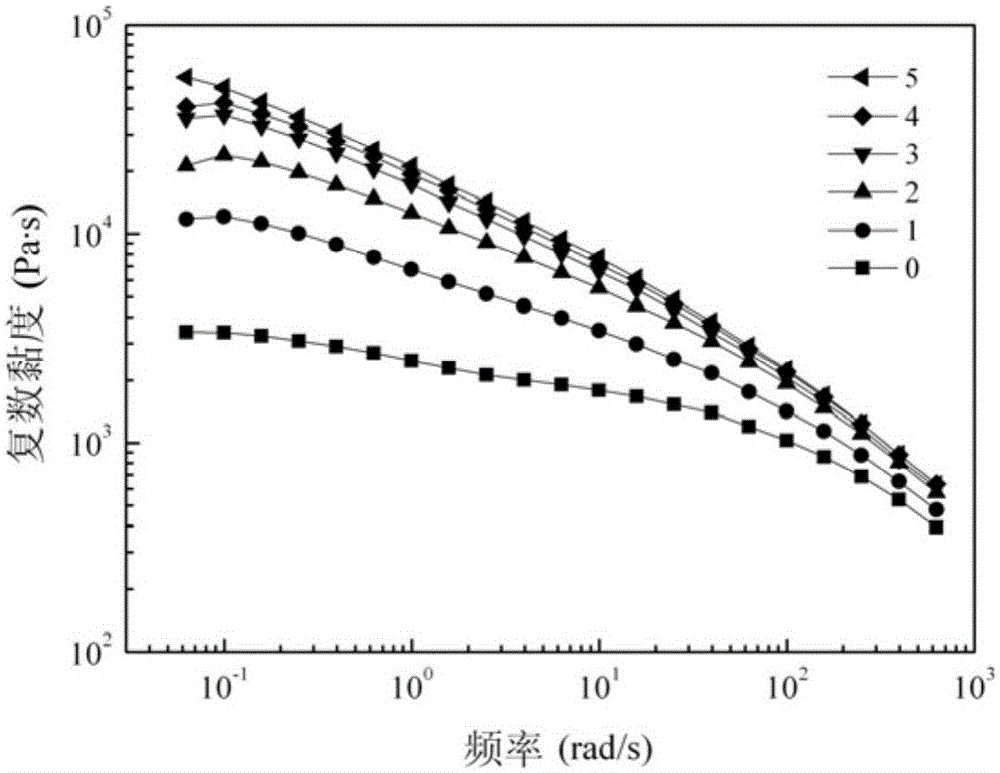

The invention discloses a full biodegradable heat-resistant polylactic acid foaming material and a preparation method thereof. The full biodegradable heat-resistant polylactic acid foaming material consists of the following ingredients by weight percent: 90 to 95 percent of polylactic acid, 1 to 5 percent of PBAT resin, 0.1 to 3 percent of chain expander, 0.1 to 5 percent of nucleating agent and 0.1 to 3 percent of foaming additive. By adopting the foaming material, a continuous foaming technology can be realized, and a prepared foamed product has advantages of uniform size of bubbles and high rate of closed holes; moreover, the advantage of the polylactic acid biodegradation is maintained, the development requirement of the environment-friendly low-carbon sustainable economy can be completely met, and the full biodegradable heat-resistant polylactic acid foaming material has wide application market in the fields such as disposable lunch boxes, snack boxes, hamburger boxes, instant noodles bowels and packaging. The preparation method comprises the following steps: first drying polylactic acid, cooling polylactic acid, then adding other components, and uniformly mixing; then melting and blending the mixture in a dual-screw extruder, drawing bars, cooling the bars by air and cutting the bars into particles. The preparation method is simple, easy to control and implement, high in operability and easy in industrialized production.

Owner:宁波家塑生物材料科技有限公司

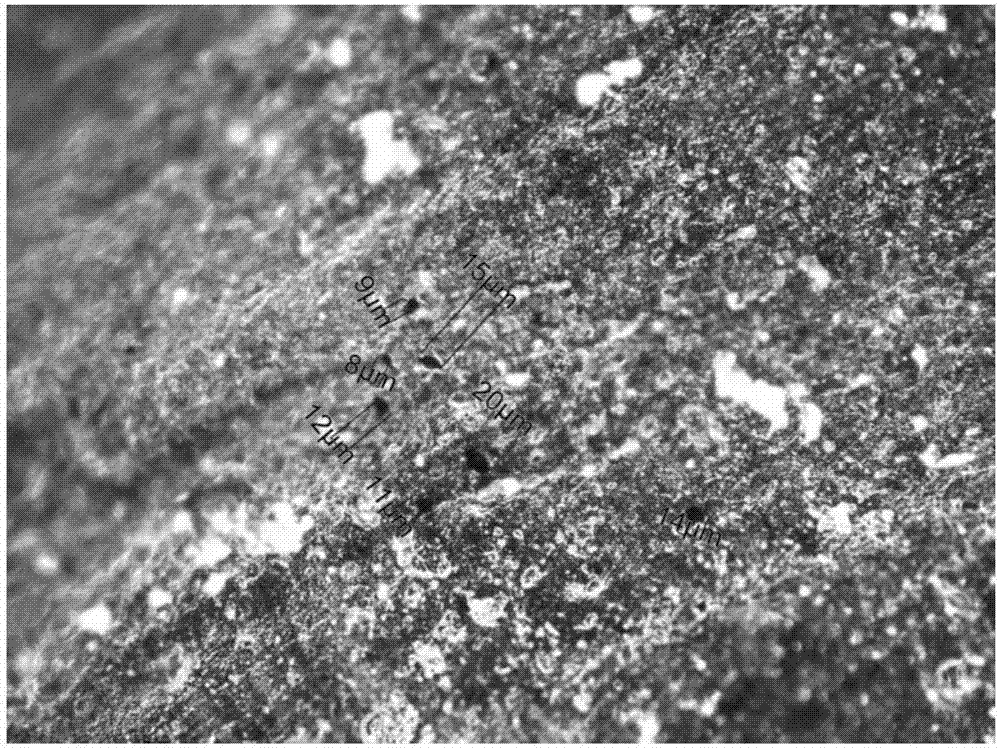

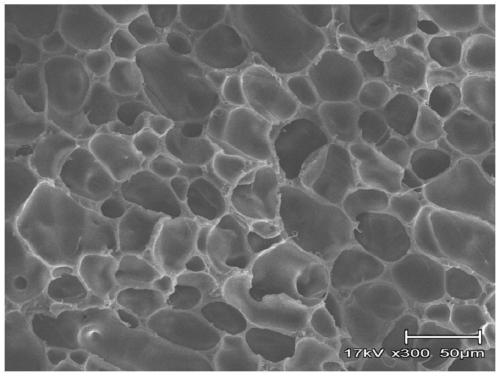

Supercritical CO2 micro-foaming polylactic acid/wood-flour composite material and preparation method thereof

The invention provides a supercritical CO2 micro-foaming polylactic acid / wood-flour composite material and a preparation method of the supercritical CO2 micro-foaming polylactic acid / wood-flour composite material, and relates to a micro-foaming composite material and a preparation method of the micro-foaming composite material, solving the problems of common wood-plastic composite material that the density is high, the impact strength is low, and the resulting waste is easy to pollute the environment. The preparation method comprises the following steps: getting raw materials such as polylactic acid, wood flour, a coupling agent, a toughening agent and a lubricant; mixing the raw materials in a high-speed mixer based on a certain ratio; melting and blending by a two-roll mill; preparing a sample by compression molding; then swelling the sample by adopting the supercritical carbon dioxide as the foaming agent; and finally quickly releasing the pressure, thus obtaining the micro-foaming polylactic acid / wood-flour composite material. The supercritical CO2 micro-foaming polylactic acid / wood-flour composite material has the advantages that the temperature for foaming is low, the pressure is held within a short time, a cellular structure is easy to control, and the prepared micropore composite material is small in aperture and high in cellular density; and the supercritical CO2 micro-foaming polylactic acid / wood-flour composite material is a green and environment-friendly foaming material with good performance.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Polylactide-based blended material, preparation method thereof and method for preparing foam material from polylactide-based blended material

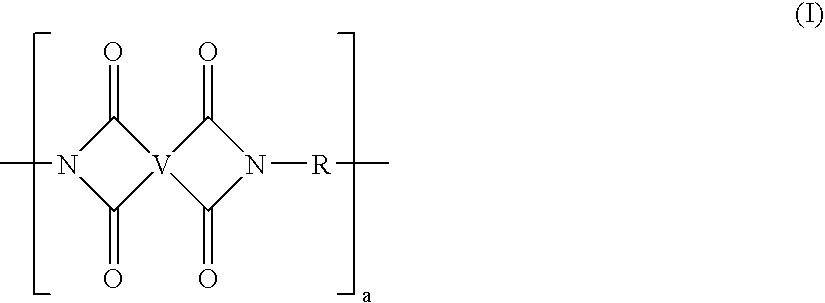

The invention discloses a polylactide-based blended material, a preparation method thereof and a method for preparing a foam material from the polylactide-based blended material. The mass ratio of PLA to an elastomer in main components of the blended material is (70-90):(30-10), and the mass percentage of a chain extender is 0.2-2.0% calculated according to the fact that the mass sum of PLA and the elastomer is 100%. The preparation method of the blended material comprises the following steps: mechanically mixing PLA, the elastomer and the chain extender according to the ratio to form a premix; then, placing the premix into an extruder; and reacting and carrying out melt blending to obtain the polylactide-based blended material. According to the preparation method of the foam material, the prepared polylactide-based blended material is placed in a high-pressure kettle cavity and is foamed through introducing a supercritical fluid, or the prepared polylactide-based blended material is added into an injection molding machine or extruder and is foamed through introducing the supercritical fluid. The blended material prepared by using the preparation method not only has very high toughness, but also remains the original strength of a polylactic acid material.

Owner:SOUTH CHINA UNIV OF TECH

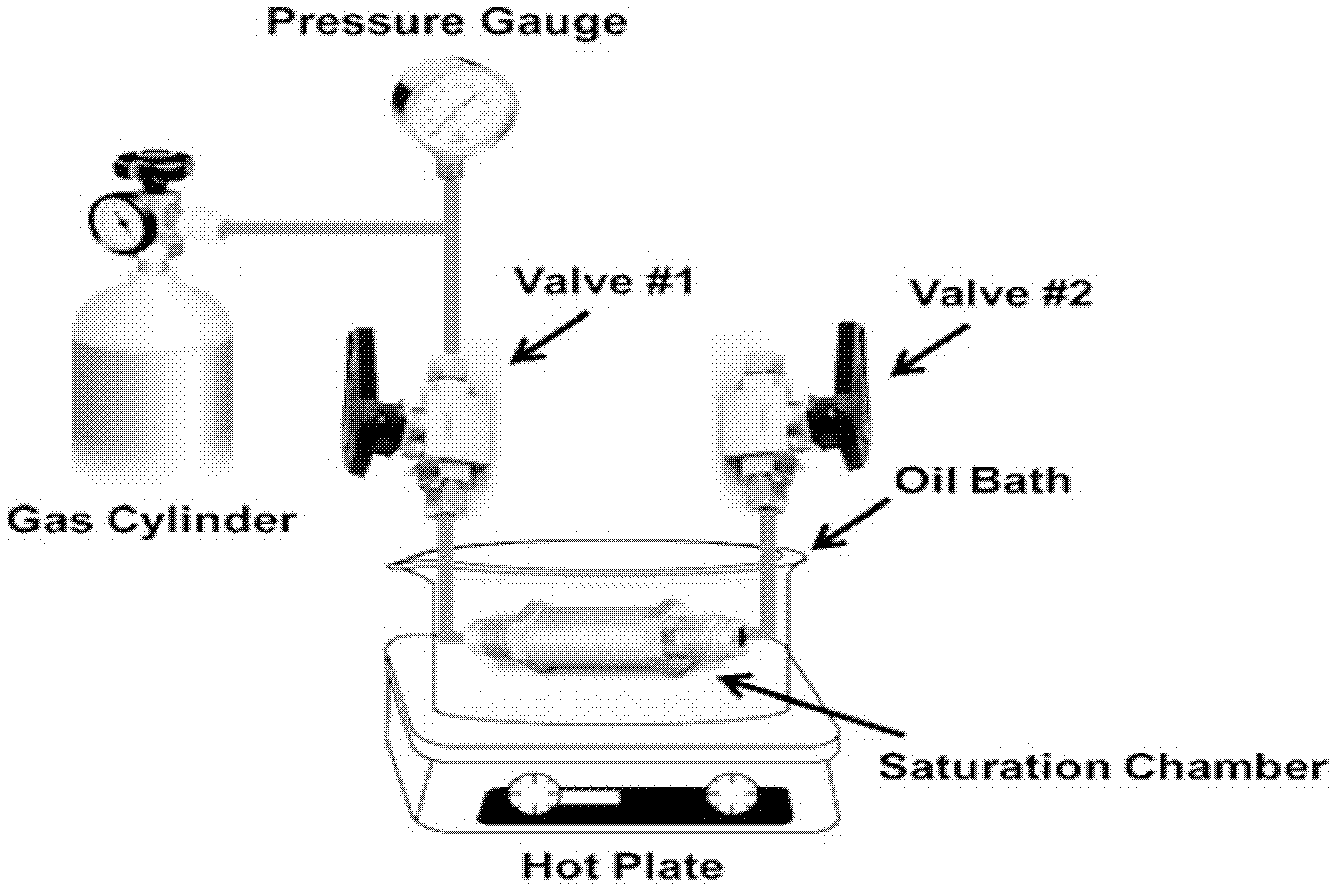

Method for preparing polyetherketone foaming material by using supercritical CO2

The invention discloses a method for preparing a polyetherketone foaming material by using supercritical CO2. The method specifically comprises: taking fluid CO2 in supercritical state as a physical foaming agent to perform physical foaming on polyetherketone, saturating a polyetherketone sheet material in an autoclave, and realizing foaming on the saturated polyetherketone sheet material in high-temperature oil bath to obtain a closed-cell foamed material with uniform cell distribution, wherein the cell size can be changed through the technological conditions. By taking polyetherketone as the raw material and using the green environment-friendly foaming method, the obtained high-temperature resistant polymer is not only guaranteed in the original excellent performances, but also substantially reduced in production cost, and is a foaming material with a wide application prospect.

Owner:大连疆宇新材料科技有限公司

Micro-foamed plylactic acid material and preparation method thereof

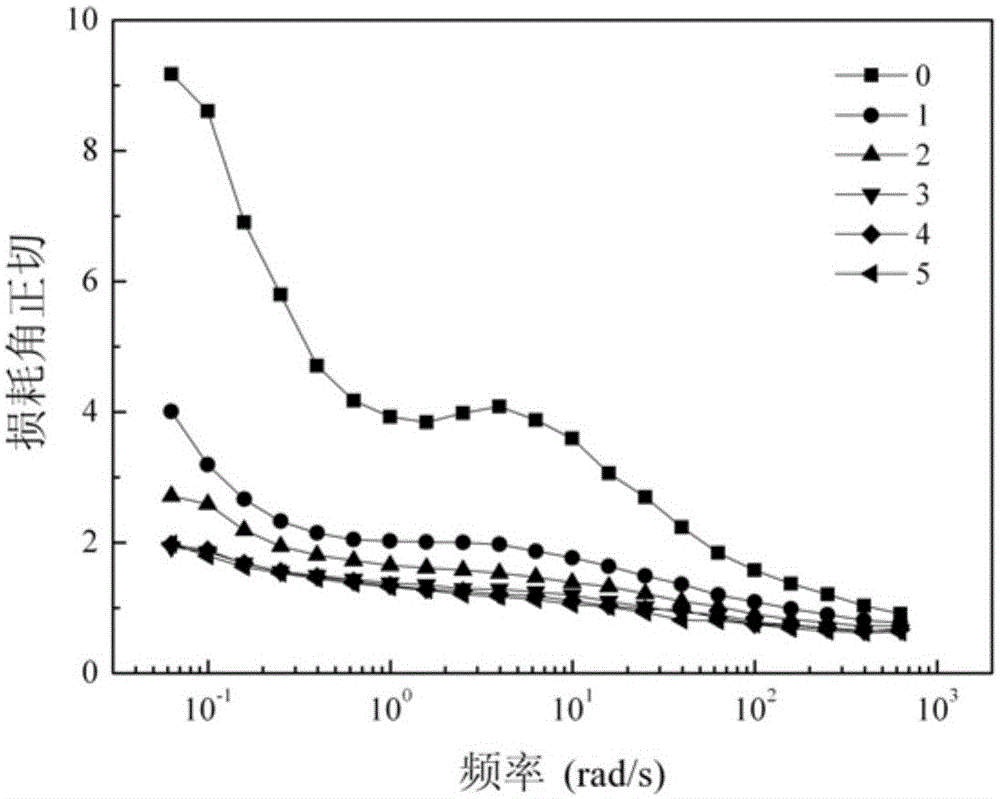

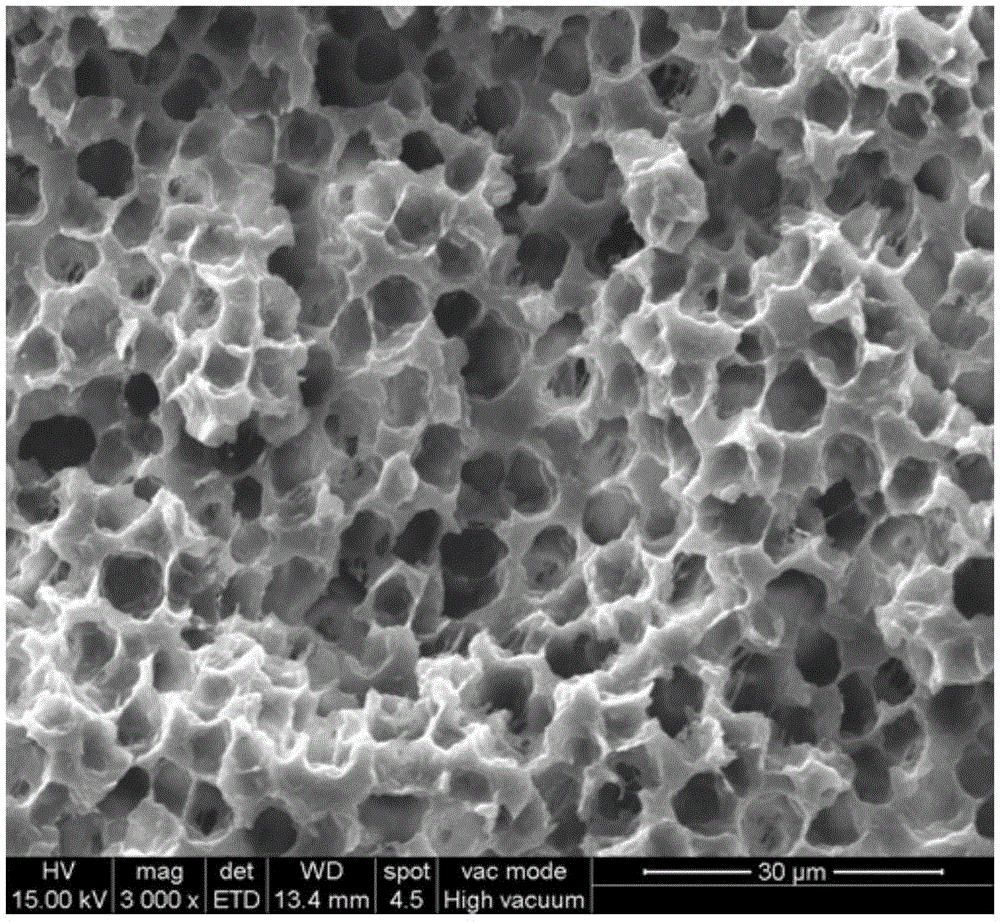

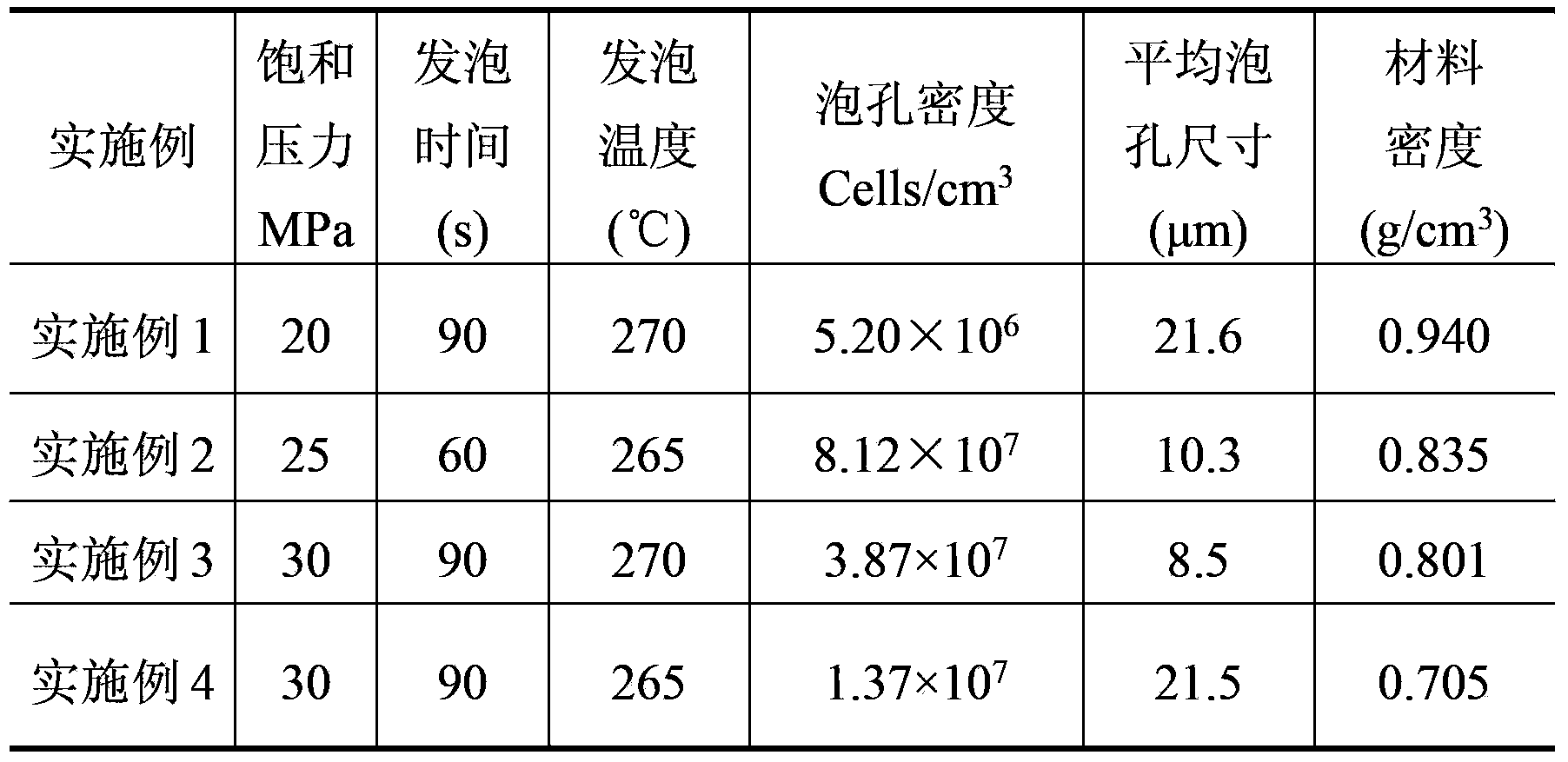

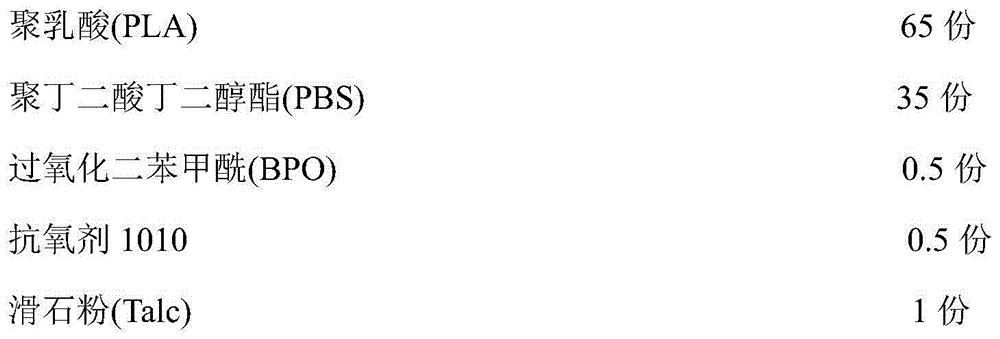

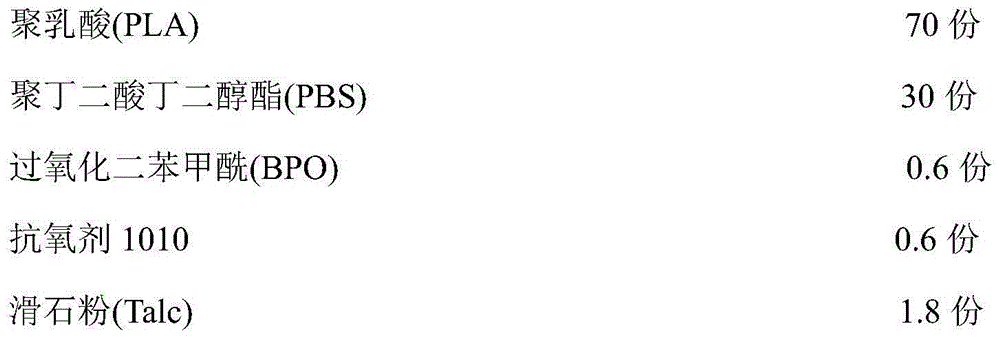

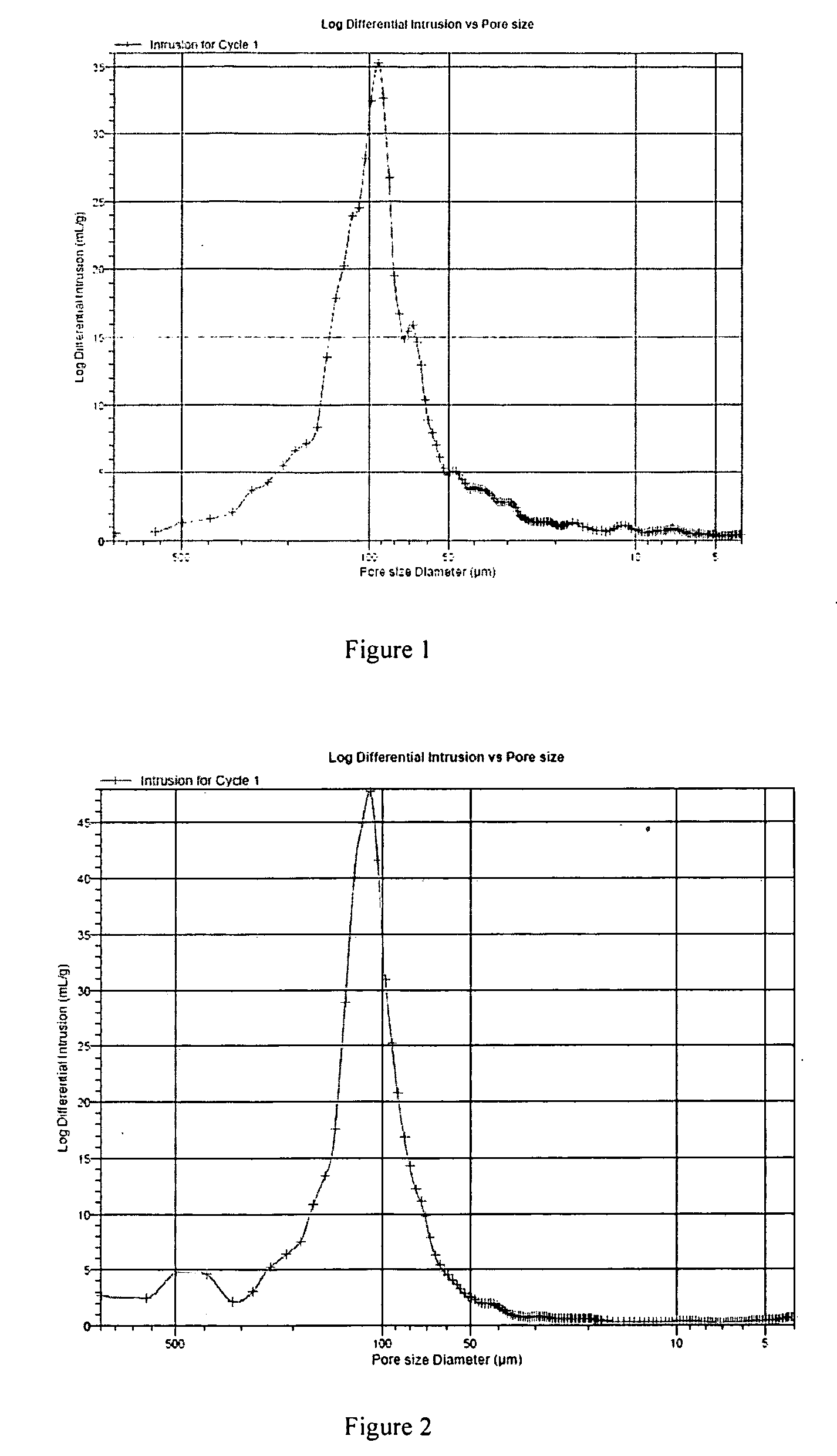

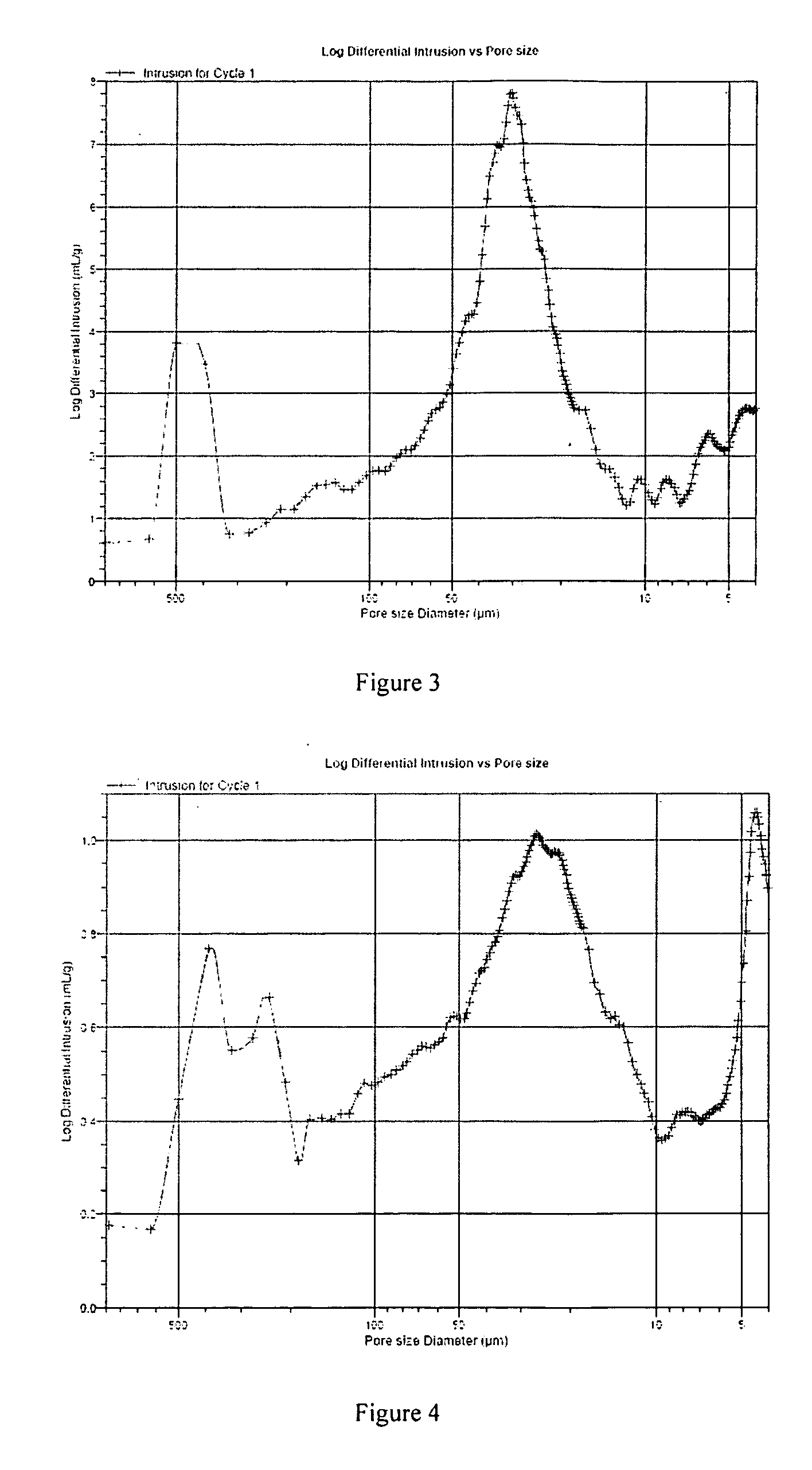

The invention discloses a micro-foamed plylactic acid material and a preparation method thereof. The disadvantages of high application cost, poor toughness, small quantity of molecular branched chains, unstable processing, easy molecular chain fracture, low melt viscosity and strength, and unfavourable foaming molding of polylactic acid are overcome in the invention. The method comprises the following steps: preparing a dibenzoyl peroxide tackified polydactyl acid / poly(butylene succinate) composite material through a melt blending technology, preparing a sample through compression molding, swelling the sample with supercritical carbon dioxide as a foaming agent, and rapidly releasing pressure to obtain the micro-foamed plylactic acid material. The preparation method has the advantages of low temperature foaming, high speed pressure relief, simple foaming process and short time, and the micro-foamed plylactic acid material prepared in the invention has the advantages of uniform cell dimension, large cell density and small material density.

Owner:常州龙骏天纯环保科技有限公司 +1

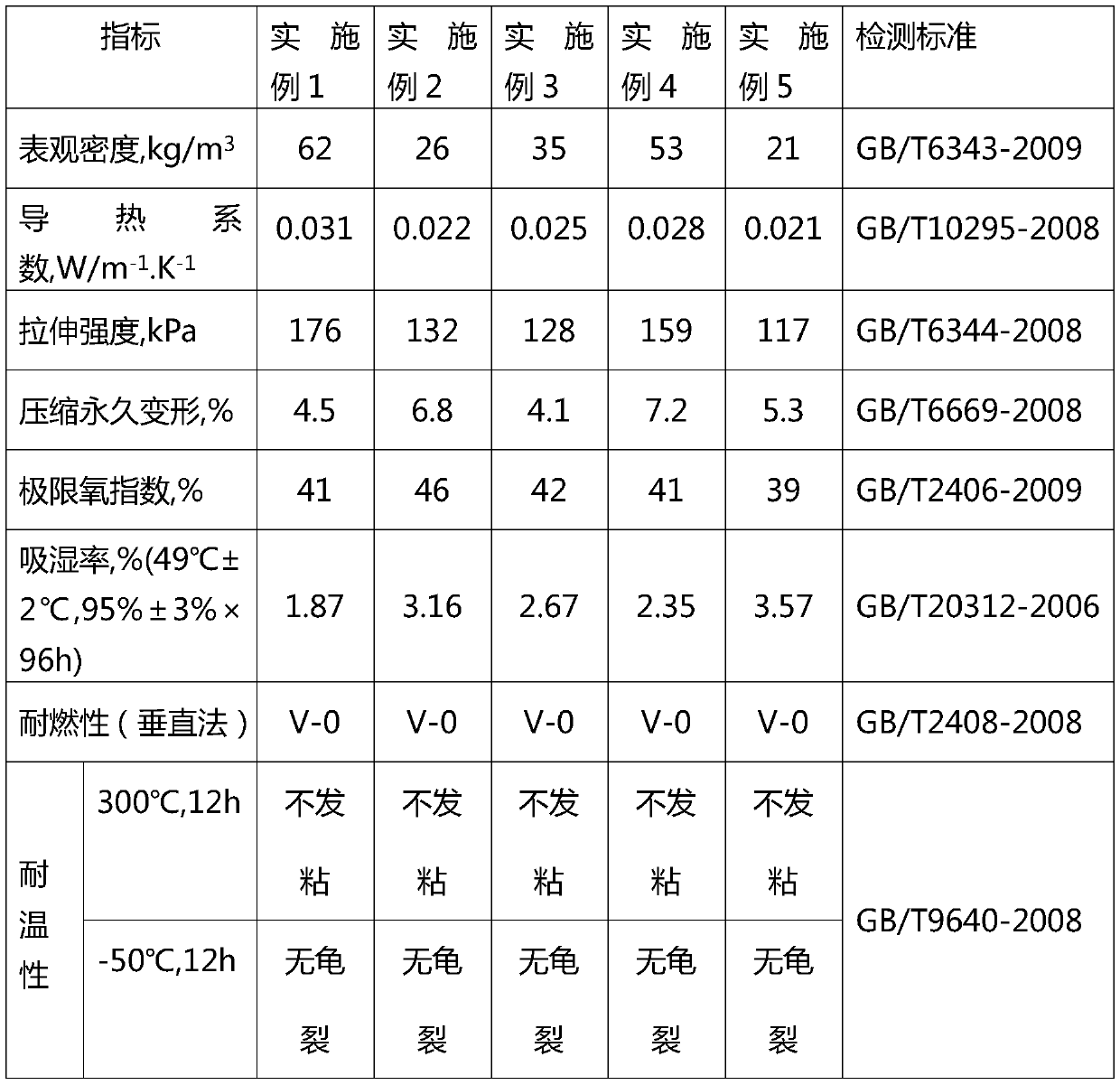

High-strength and high-flame retardation polyurethane composite heat insulation plate

InactiveCN105924942AHigh strengthImprove heat resistanceSynthetic resin layered productsEpoxyInsulation layer

The invention discloses a high-strength and high-flame retardation polyurethane composite heat insulation plate. The high-strength and high-flame retardation polyurethane composite heat insulation plate comprises two backing layers and a polyurethane heat insulation layer positioned between the two backing layers, the polyurethane heat insulation layer is made of a high-performance polyurethane foam material, and raw materials of the high-performance polyurethane foam material comprise a component A and a component B according to a weight ratio of 2:1.2-2.3; raw materials of the component A comprise polyether polyol, pentamethyldiethylenetriamine, trimethylolpropane, pentaerythritol, polyethylene glycol, an organic bismuth catalyst, cyclohexane, water, an organosilicon foaming stabilizer, amino modified carbon nanotubes, expanded perlite, hollow glass micro-beads, silicon whiskers, nanometer aluminum hydroxide, trichloroethyl phosphate, piperazine pyrophosphate, a phosphamide fire retardant, epoxy resin and polyvinyl chloride; and raw materials of the component B comprise diphenylmethane diisocyanate and hexamethylene diisocyanate.

Owner:ANHUI GUANGYAN NEW MATERIAL TECH

Continuous process for making polyetherimide foam materials and articles made therefrom

A continuous process of making polyetherimide foam materials and articles that include these foam materials. The continuous process is a foam extrusion process that uses selected blowing agents, equipment design and processing conditions to continuously produce extruded foam with a substantially uniform cell size in a wide range of cell densities. Subsequent heating may be used in certain embodiments to remove any residual components from the foam, such as any blowing agents or nucleating agents. Due to the greater densities as well as the characteristics inherent in polyetherimide articles, the resulting foam materials are suitable for a much broader range of applications. The continuous process provides a more cost effective product while also avoiding the use of Freon and / or other agents potentially harmful to the environment.

Owner:SABIC INNOVATIVE PLASTICS IP BV

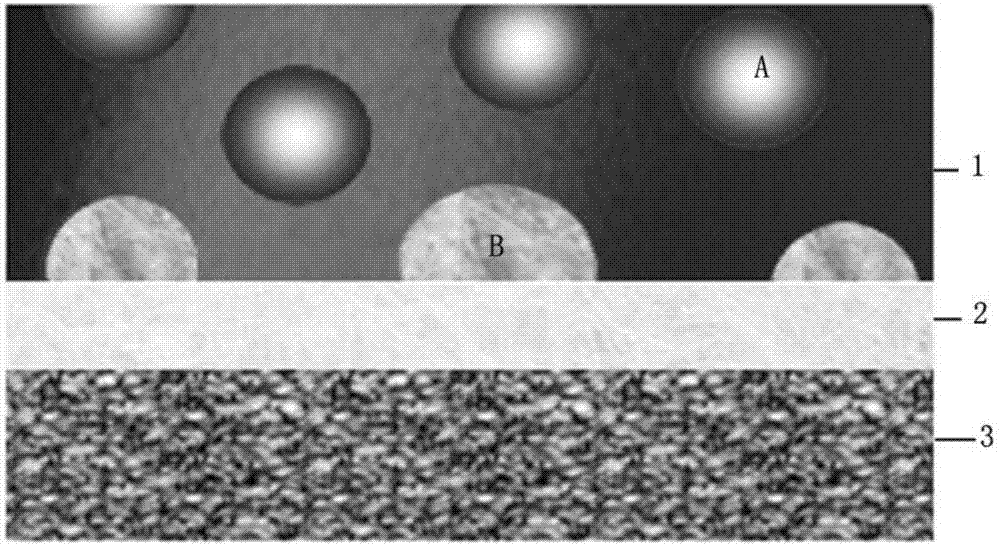

Tread rubber material for snow tire

The invention relates to a tread rubber material for a snow tire. 0.2wt%-4.0wt% of pre-expanded submicrospheres are dispersed in the tread rubber material; further, the tread rubber material in the formula is prepared from components in parts by weight as follows: 100.0 parts of rubber, 60.0-90.0 parts of reinforcing filler, 3.0-8.0 parts of an active agent, 0.0-6.4 parts of a sulfur-containing organosilicon compound, 0.5-4.5 parts of an anti-aging agent, 1.0-2.5 parts of protective wax, 20.0-45.0 parts of rubber operating oil, 0.8-2.5 parts of sulfur (in terms of pure sulfur content), 0.8-3.5 parts of an accelerant, 1.0-7.0 parts of pre-dispersing master batch of the pre-expanded submicrospheres and 0.1-0.4 parts of an anti-scorching agent. According to the tread rubber material for the snow tire, the pre-expanded submicrospheres are utilized to replace a chemical foaming agent, cell size and distribution are uniform, and outstanding on-ice slipping resistance can be realized in the whole life cycle of the tire; the formal design is flexible, the raw material selection range is enlarged, the processing conditions are easy, the safety is improved, and the quality is stable.

Owner:SAILUN GRP CO LTD

Polylactic acid foaming composite material as well as preparation method and application thereof

The invention belongs to the technical field of biodegradable foaming materials, and discloses a polylactic acid foaming composite material as well as a preparation method and application thereof. The polylactic acid foaming composite material comprises the following components in parts by weight: 100 parts of polylactic acid resin, 5-15 parts of other biodegradable materials, 0.5-3 parts of a bio-based nucleating agent, 0.5-4 parts of a chain extender and 0.1-1 part of a lubricant. The preparation method comprises the steps of mixing, extruding, drawing and pelletizing the components to prepare a polylactic acid foaming master batch; and putting the polylactic acid foaming master batch into a high-pressure reaction kettle, introducing a fluid serving as a foaming agent into the high-pressure reaction kettle, controlling the temperature of the high-pressure reaction kettle to be 40-200 DEG C and the pressure of the high-pressure reaction kettle to be 8-20 MPa, keeping the temperature and the pressure for 30-120 minutes, releasing gas in the reaction kettle, reducing the pressure to normal pressure, and taking out polylactic acid foaming particles from the reaction kettle, so as to obtain the particles, namely, the polylactic acid foaming composite material.

Owner:GUANGDONG UNIV OF TECH

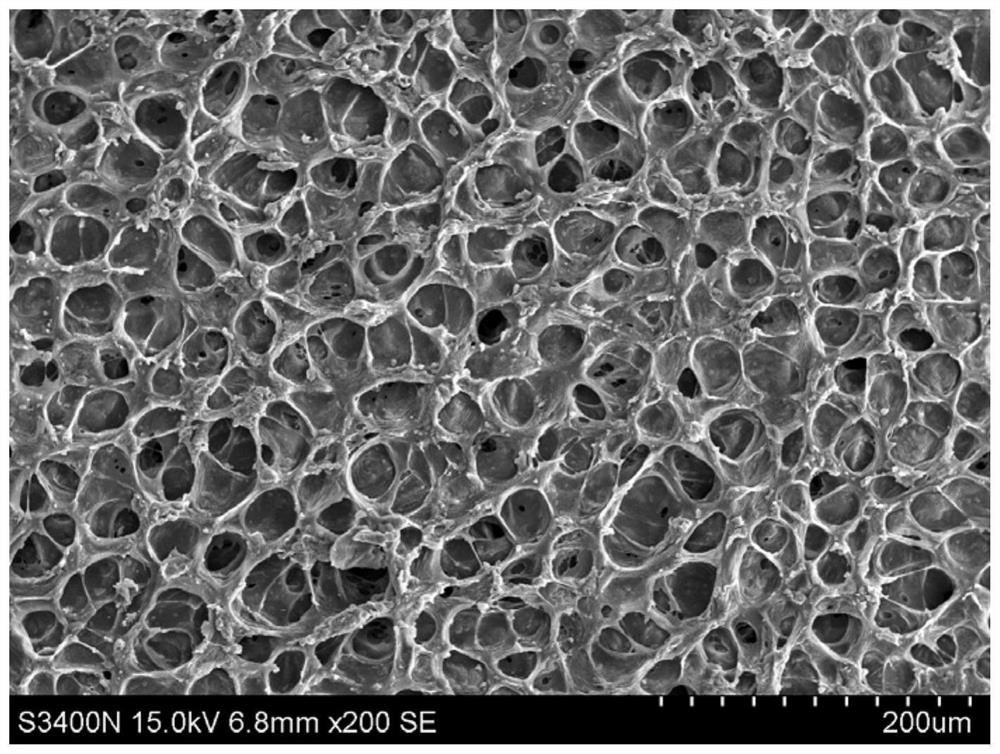

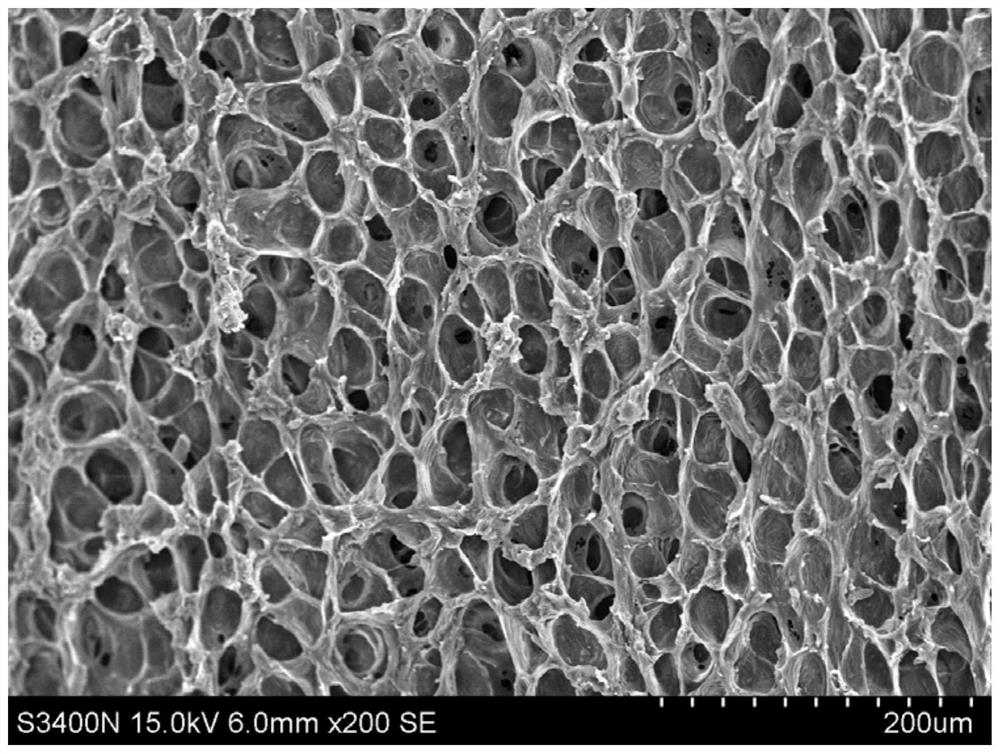

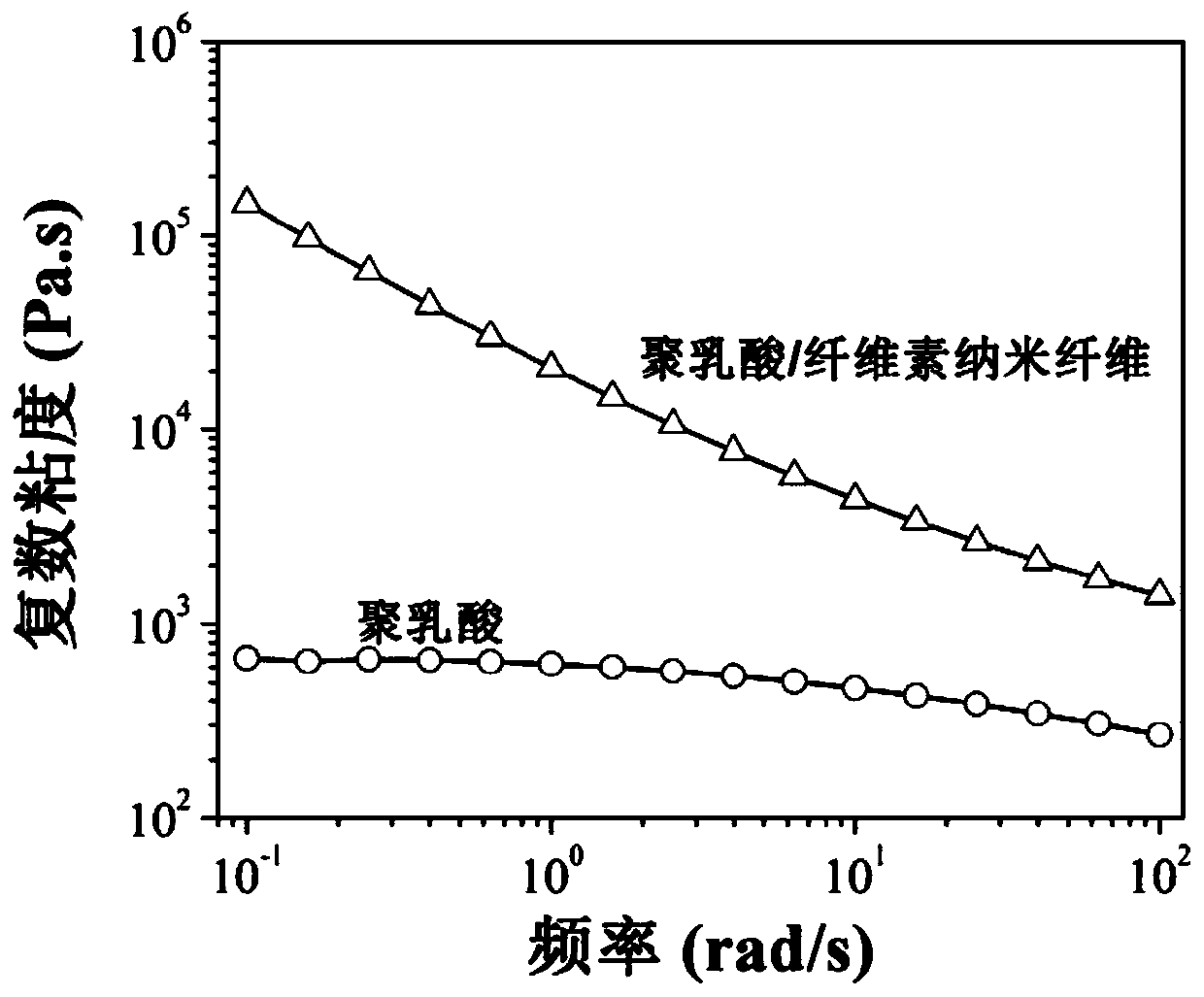

Supercritical fluid injection molding foaming polylactic acid foam material and preparation method thereof

ActiveCN111286070AIncrease cell densityHigh crystallinityLayered productsCellulose pulp after-treatment modificationCelluloseFoaming agent

The invention discloses a supercritical fluid injection molding foaming polylactic acid foam material and a preparation method thereof. The light high-strength polylactic acid foam material is prepared by modifying biological filler cellulose nanofibers, and the crystallization property and melt property of the polylactic acid material are improved by using the cellulose nanofibers as a nucleatingagent. The prepared cellulose nanofiber modified polylactic acid composite material is uniformly mixed with a supercritical fluid foaming agent in a microcellular foaming injection molding machine, and microcellular injection foaming molding is carried out through a mold opening and closing foaming device to obtain the full-bio-based polylactic acid foaming material. The microcellular foaming cellulose nanofiber / polylactic acid composite material which is uniform in cell size, high in cell density and good in performance is prepared, and the preparation method has the outstanding advantages of being high in production efficiency, high in operability, stable, reliable, easy for industrial production and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Low-smoke low-toxicity flame-retardant hard polyurethane foam material and preparation method thereof

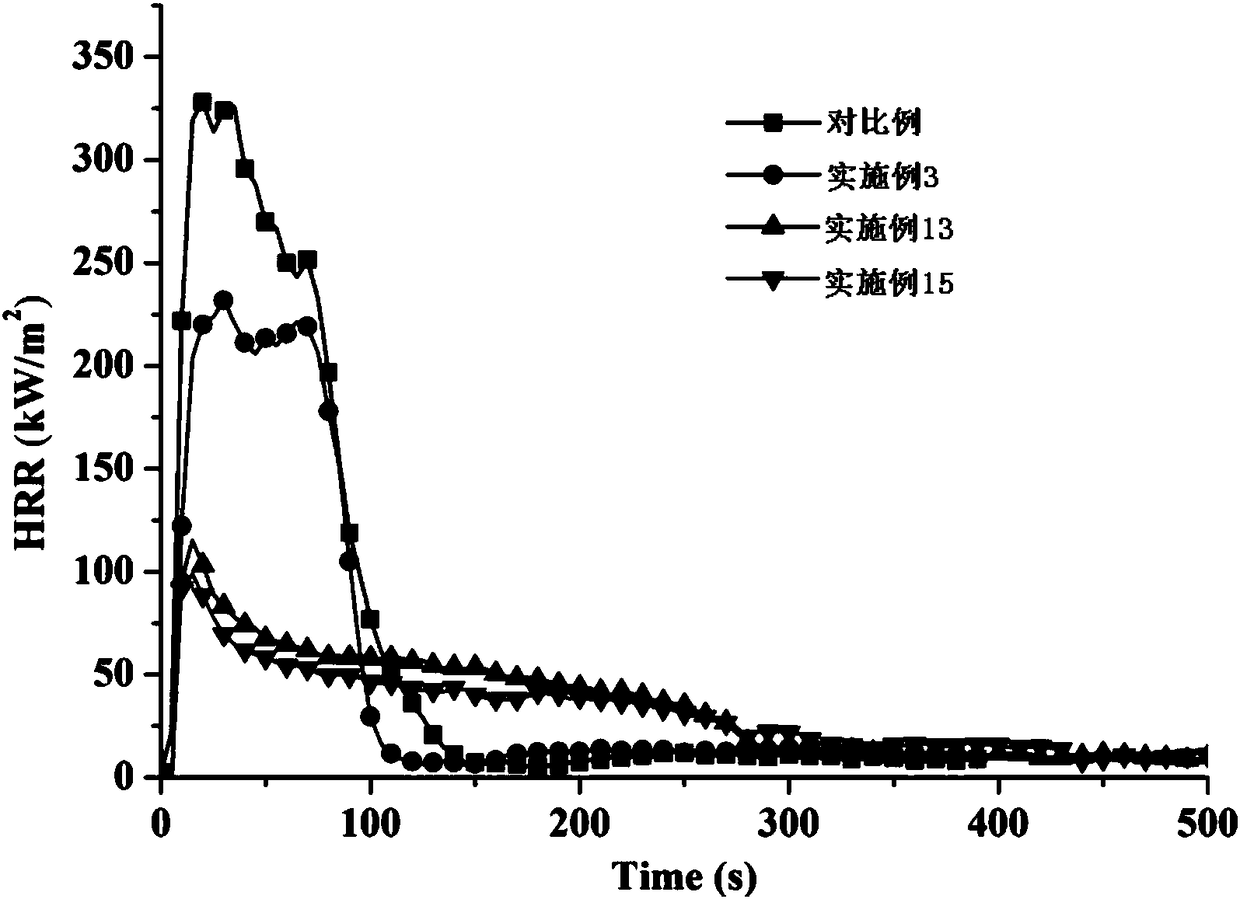

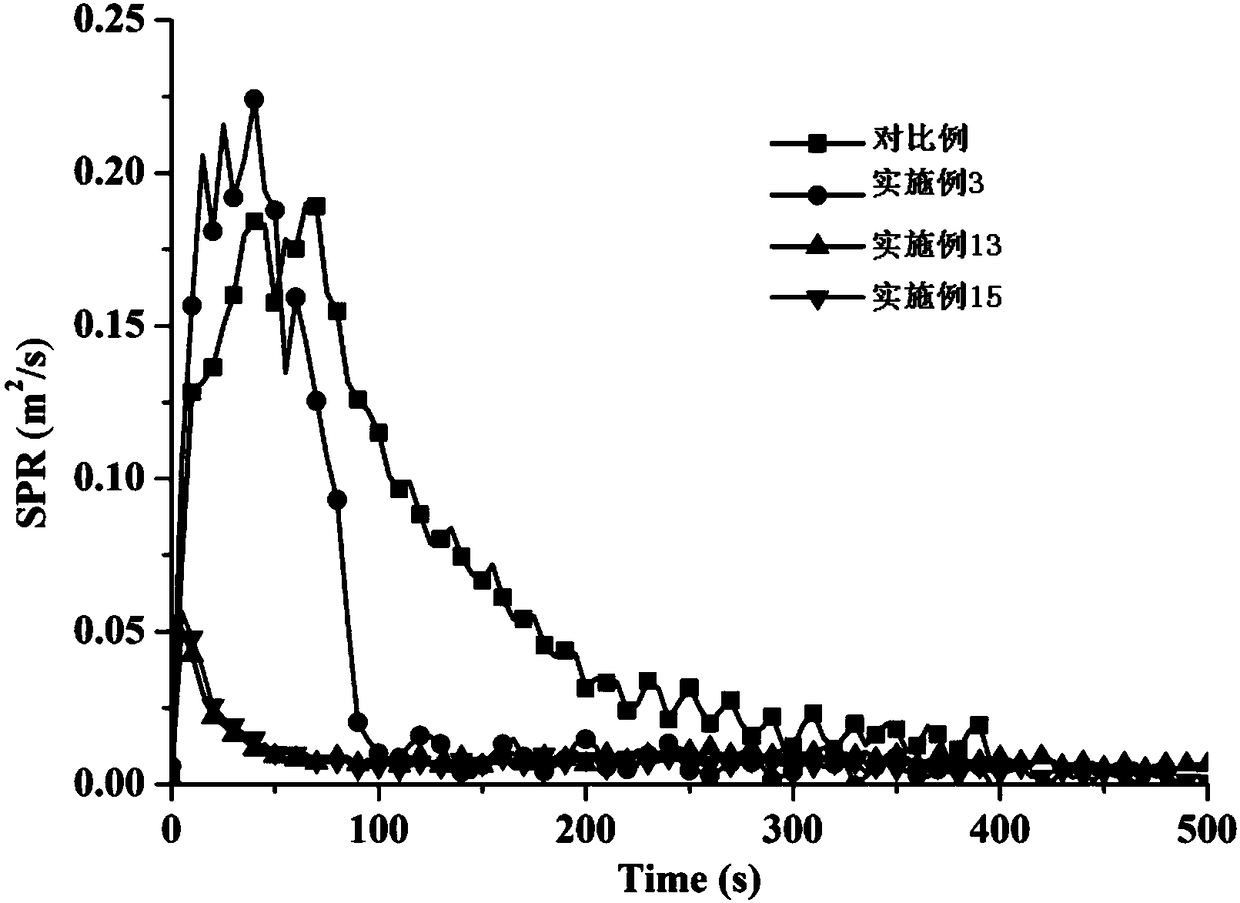

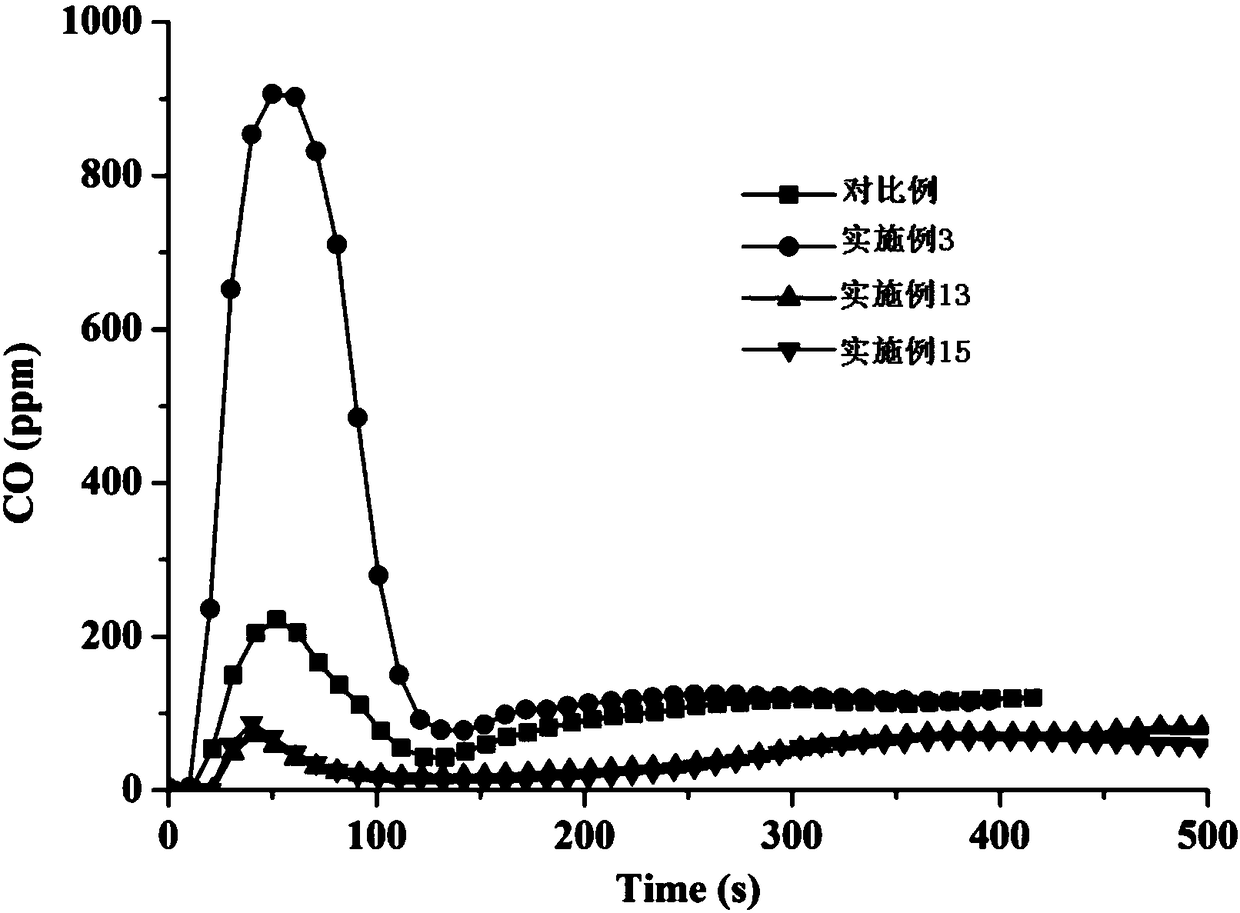

InactiveCN109111558AHigh flame retardant efficiencyAchieving the goal of smoking suppression and reducing toxicityToxic gasFoaming agent

The invention discloses a low-smoke low-toxicity flame-retardant hard polyurethane foam material, which comprises 100 parts of polyol, 140-260 parts of isocyanate, 0-35 parts of phosphate, 0-50 partsof flame retardant polyol, 10-45 parts of an inorganic flame retardant complex, 2-5 parts of a foaming agent, 0.5-2 parts of a catalyst, and 0.5-5 parts of a foam stabilizer, wherein the amounts of the phosphate and the flame retardant polyol are not both 0. According to the present invention, the phosphate provides the gas-phase flame retardant effect, the flame retardant polyol is the reactive flame retardant, and can reduce the addition amounts of the phosphate and the inorganic flame retardant while provide the flame retardant effect, and the inorganic flame retardant complex mainly provides effects of condensed phase fire retardation, smoke suppression and toxicity reducing, such that the hard polyurethane foam material with advantages of excellent fire retardation, low smoke generation and low toxic gas generation can be obtained on the basis of the low flame retardant adding amount through the matched use of the three flame retardants; and the low-smoke low-toxicity flame-retardant hard polyurethane foam material has characteristics of good flame retardant performance, low smoke and low toxicity, and the preparation method has characteristics of simpleness, convenience, lowcost and easy operation, and is suitable for industrial production.

Owner:TIANJIN FIRE RES INST

Expanded thermoplastic polyurethane beads and preparation method and application thereof

The present invention relates to expanded thermoplastic polyurethane beads, a preparation method for same, and an application thereof. The expanded thermoplastic polyurethane beads consists of components of the following parts by weight: 100 parts of a thermoplastic polyurethane, 1-10 parts of a cell size stabilizer, and 1-35 parts of a melt viscosity modifier. The preparation method for the expanded thermoplastic polyurethane beads is also disclosed. The bead is produced by employing a volatile blowing agent to immerse the thermoplastic polyurethane, comprising the pore size stabilizer and the melt viscosity modifier, in an aqueous suspension, and is then followed by the foaming process. Utilization of the expanded thermoplastic polyurethane beads of the present invention allows for preparation of a foam product. The expanded thermoplastic polyurethane beads prepared per the present invention has uniform cell sizes and a high product yield. At the same time, the expanded thermoplastic polyurethane bead provides a great sintering performance even at a relatively low vapor pressure, a molded foam product has a small deformation, a low dimensional shrinkage ratio relative to a mold, great dimensional stability, and an aesthetically appealing appearance.

Owner:MIRACLL CHEM

Method for producing latex foamed product by using low-protein latex

PendingCN110982131AReduce allergies and other hazardsImprove foam stabilityPolymer scienceFoaming agent

The invention relates to the technical field of latex foamed products, in particular to a method for producing a latex foamed product by using low-protein latex. The natural latex foamed product is prepared from the following raw materials in parts by weight: 100 parts of latex, 2-5 parts of a vulcanizing agent, 0.5-6 parts of a foaming agent, 1-5 parts of a foam stabilizer, 0.5-1.5 parts of a gelatinizing agent, 3-5 parts of an active agent, 3-12 parts of an auxiliary agent and 1-15 parts of a filler. The natural latex in the preparation raw materials of the natural latex foamed product provided by the invention is low-protein natural latex, and has the characteristics of nature, environmental protection, no pollution, no toxicity, antianaphylaxis and the like. Proper amounts of the foamstabilizer and the active agent are added in the production and preparation process of the latex foamed product; meanwhile, the production process parameters are changed, so that the prepared latex foamed product has good foam stability, uniform foam pore size, regular and stable pore structure, few internal defects and the like, the prepared foamed product has good resilience, and the tensile strength, elongation at break, resilience rate and the like are remarkably improved.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI

Production method of polyether ketone and modified nano silicon dioxide foaming materials and by supercritical carbon dioxide

The invention discloses a production method of polyether ketone and modified nano silicon dioxide foaming materials and by supercritical carbon dioxide. The production method comprises the following steps of enabling fluid carbon dioxide in the supercritical state to be utilized as physical foaming agents and modified nano silicon dioxide to be utilized as nucleating agents to perform physical foaming on polyether ketone; enabling polyether ketone and modified nano silicon dioxide sheets to be saturated in an autoclave; achieving foaming of the saturated polyether ketone sheets in a high temperature oil bath to obtain closed-cell foaming materials with uniformly distributed foaming cells, wherein the size of the foaming cells can change through process conditions. According to the production method of the polyether ketone and modified nano silicon dioxide foaming materials and by the supercritical carbon dioxide, the polyether ketone is utilized as raw materials and the green and environment-friendly foaming method is utilized to obtain high temperature resistant polymers, so that the original excellent performance is guaranteed, the production cost is greatly reduced, and accordingly the polyether ketone and modified nano silicon dioxide foaming materials are wide in application prospect.

Owner:大连疆宇新材料科技有限公司

Lightweight polypropylene material containing microcapsule foaming agent

InactiveCN105860249AHigh foaming ratioUniform cell sizeMicroballoon preparationMicrocapsule preparationPolyurethane elastomerFoaming agent

The invention discloses a lightweight polypropylene material containing a microcapsule foaming agent. The lightweight polypropylene material is prepared from, by weight, 100 parts of polypropylene resin, 1-10 parts of nucleating agent, 5-15 parts of microcapsule foaming agent and 10-20 parts of polyurethane elastomer, and the polypropylene resin is the polypropylene resin which is of a C6-C8 long chain branch structure. The foamed polypropylene is high in foaming ratio, uniform in cell size, small in material density, excellent in mechanical property of the material, and a formed body obtained through foamed polypropylene is excellent in surface quality and good in size stability.

Owner:SUZHOU RUNJIA ENGINEER PLASTIC

Method for preparing meso-porous silica/polylactic acid foamed material by supercritical CO2 foaming

The invention discloses a method for preparing a meso-porous silica / polylactic acid foamed material by supercritical CO2 foaming, and the method prepares a polylactic acid foamed material by using meso-porous silica as a nucleating agent; the foaming process is simple; foams of the obtained foamed material have a uniform foam size and high density.

Owner:弗润德力新材料宁夏股份有限公司

A kind of foamed thermoplastic polyurethane artificial leather and preparation method thereof

ActiveCN105714574BUniform cell sizeHigh closed cell rateLayered product treatmentSynthetic resin layered productsFiberMasterbatch

The invention relates to foaming thermoplastic polyurethane artificial leather and a preparation method thereof. The foaming thermoplastic polyurethane artificial leather is obtained by compositing a surface layer, a foaming layer and a bottom layer from top to bottom sequentially, wherein the surface layer is prepared from thermoplastic polyurethane particles A through a calendering process, the foaming layer is prepared from thermoplastic polyurethane particles B, a lubricating agent and color masterbatch through a supercritical carbon dioxide foaming, extrusion calendering combined mode, and the bottom layer is obtained in the mode that fiber cloth is dipped in waterborne PU resin to be dried. The foaming thermoplastic polyurethane artificial leather product is high in closed pore rate which is larger than or equal to 90%, good in abrasion resistance, elasticity and hand feeling, the production process is environmentally friendly, product quality is stable, and the foaming thermoplastic polyurethane artificial leather is suitable for industrial continuous production.

Owner:MIRACLL CHEM

Supercritical CO2 micro foamed polylactic acid/wooden powder composite material

The invention discloses a supercritical carbon dioxide micro foamed polylactic acid / wooden powder composite material and a preparation method thereof. The invention relates to a micro foamed compositematerial and a preparation method thereof. In view of the problems of large density and low impact strength of normal wood plastic composite materials, and the environmental problems easily caused byrejected materials thereof and the like, polylactic acid, wooden powder, coupling agent, toughening agent and lubricant are adopted as raw materials of the supercritical carbon dioxide micro foamed polylactic acid / wooden powder composite material. The raw materials are mixed in a high speed mixer according to a certain proportion, melting blending is conducted through a double-roller open mill, compression moulding is conducted to prepare samples, then supercritical carbon dioxide is used as a foaming agent to swell the samples, and finally micro porous polylactic acid / wooden powder compositematerials are acquired by conducting rapid pressure releasing. The material has the advantages that the foaming temperature is low, the holding pressure time is short, the pore structure is easy to control, and the prepared micro porous composite material is small in pore diameter and large in pore density and will be a green environmentally friendly foamed material with excellent performance.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

Foaming technology of inorganic nanoparticle modified polypropylene

The invention discloses a foaming technology of inorganic nanoparticle modified polypropylene. The technology comprises the steps of 1, conducting melt blending extrusion on uniformly mixed polypropylene PP and inorganic nanoparticles to obtain polypropylene / nanoparticle granules of which diameter is 2-4 mm and length is 2-5 mm; 2, putting the polypropylene / nanoparticle granules into a high pressure reactor, pumping carbon dioxide into the high pressure reactor, raising the temperature to an infiltration temperature of 170-180 DEG C, continuing to pump carbon dioxide into the high pressure reactor until a saturation pressure reaches 20-28 MPa, and maintaining the pressure for 20-50 min; 3, reducing the high temperature to a foaming temperature of 105-165 DEG C, maintaining pressure constant in a temperature raising process, and conducting heat preservation for 40-90 min; 4, decompressing to an ordinary pressure in 10 seconds, taking out a foaming material to put into an ice and water mixture to be subjected to quenching. According to the technology, by adding nanosilicon dioxide or nano mica granules into PP, the foaming capacity of polypropylene is strengthened, and the size of a foam hole is uniform.

Owner:WUXI MINGSHENG STRONG BLOWER

Low-thermal-conductivity polyimide foam material and preparation method thereof

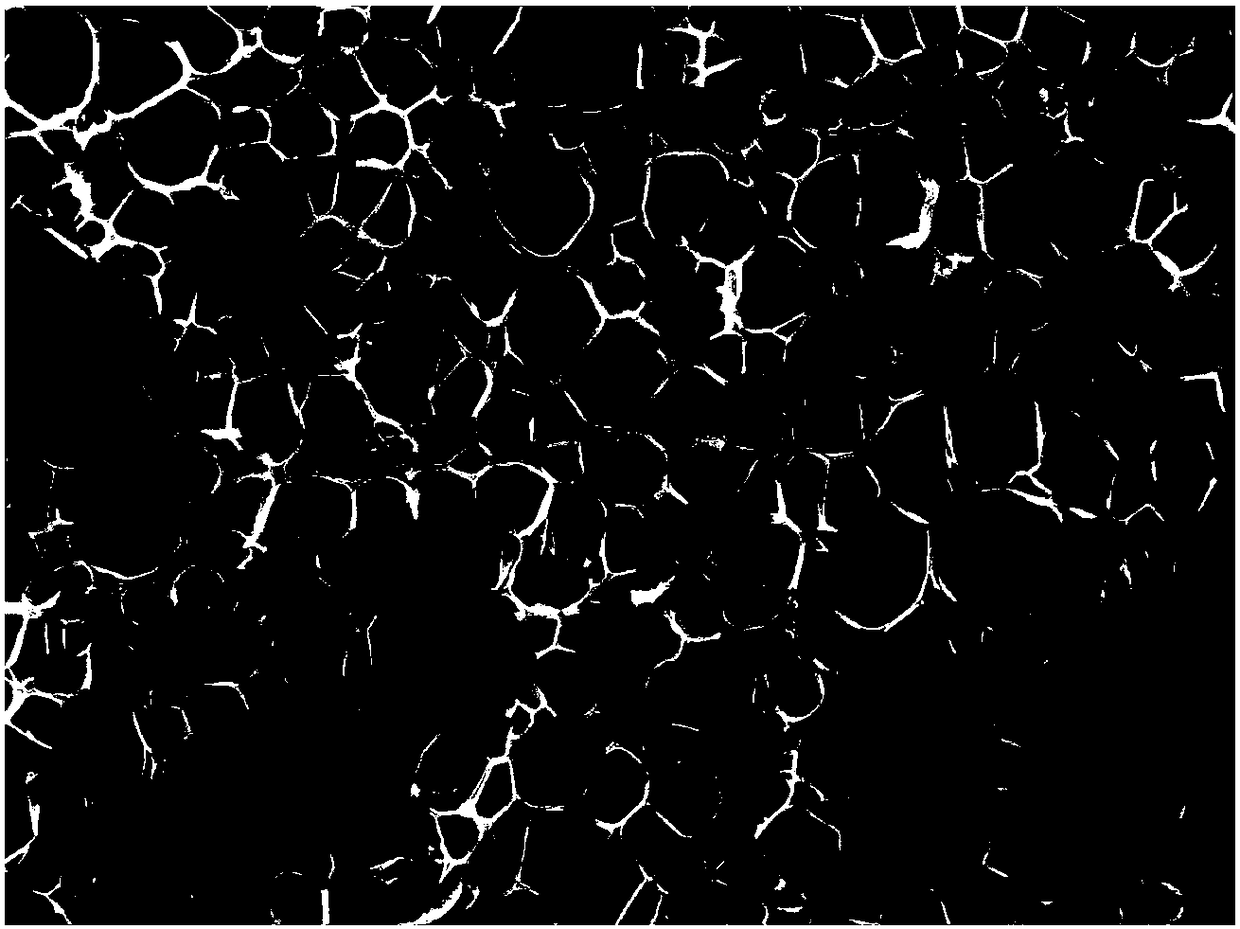

The invention discloses a low-thermal-conductivity polyimide foam material and a preparation method thereof. The method comprises the following steps: mixing aromatic dianhydride with a polar solvent,dissolving under a heating condition, adding low-molecular-weight alcohol, and continuously heating to carry out esterification on each component to obtain an esterification precursor solution; adding a catalyst, a foaming agent, a surfactant, polymer polyol and a foaming agent, uniformly dispersing to obtain a foaming white material, finally adding isocyanate into the white material, quickly stirring for uniform dispersion, then putting the mixture into a mold, foaming and molding, and heating and curing after foaming is finished to obtain the polyimide foam material. The polyimide foam material prepared by the method has the advantages of low heat conductivity coefficient, high limit oxygen index, good flame retardance, uniform cell size, controllable density and high mechanical strength, and can be widely applied to the fields of aerospace, military ships and warships, building insulation, vehicle construction and the like.

Owner:GUIZHOU AEROSPACE TIANMA ELECTRICAL TECH

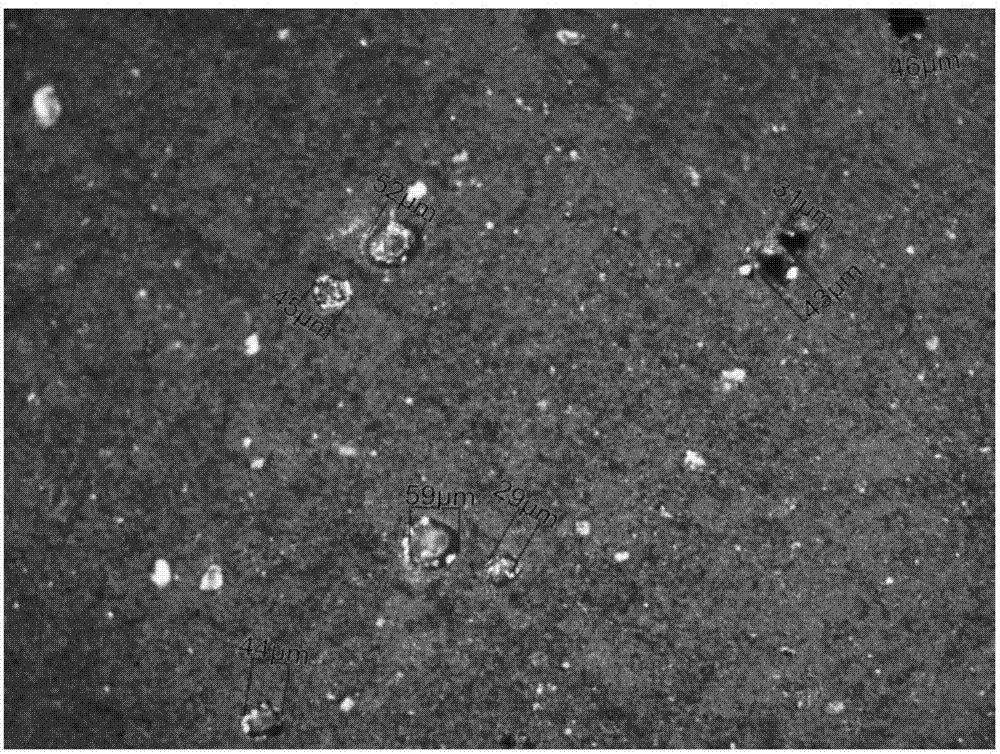

2,5-furandicarboxylic-acid-based polyester foam material and preparation method thereof

The invention relates to a 2,5-furandicarboxylic-acid-based polyester foam material and a preparation method thereof. The preparation method comprises the following steps: (a) placing 2,5-furandicarboxylic-acid-based polyester plastic in a mold, pressing the same into a laminated preform, and quenching the laminated preform; (b) placing the quenched preform and a first foaming agent in a closed container without contact, wherein the first foaming agent is at least one of chloroform, acetone, diethyl ether, pentane and hexafluoroisopropanol; (c) introducing a second foaming agent into the closed container, wherein the second foaming agent is at least one of carbon dioxide and nitrogen, and the temperature in the closed container is maintained at 40 DEG C to 65 DEG C, so that the first foaming agent is changed into a gas state from a liquid state, the pressure in the closed container is 1 MPa to 6 MPa, and the pressure maintaining time is 4 h to 15 h; (d) removing the gas in the closed container, taking the preform out and placing in a foaming medium to be foamed, and cooling to obtain the 2,5-furandicarboxylic-acid-based polyester foam material with the cell size of 5 microns to 50microns and the expansion multiple of 2 to 15 times.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

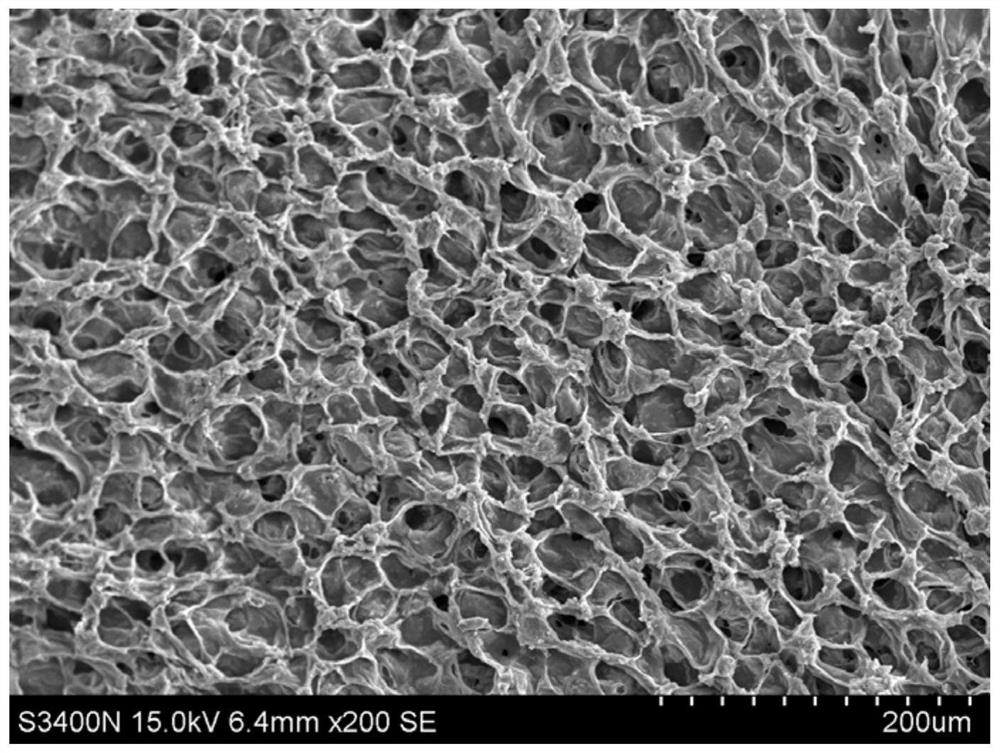

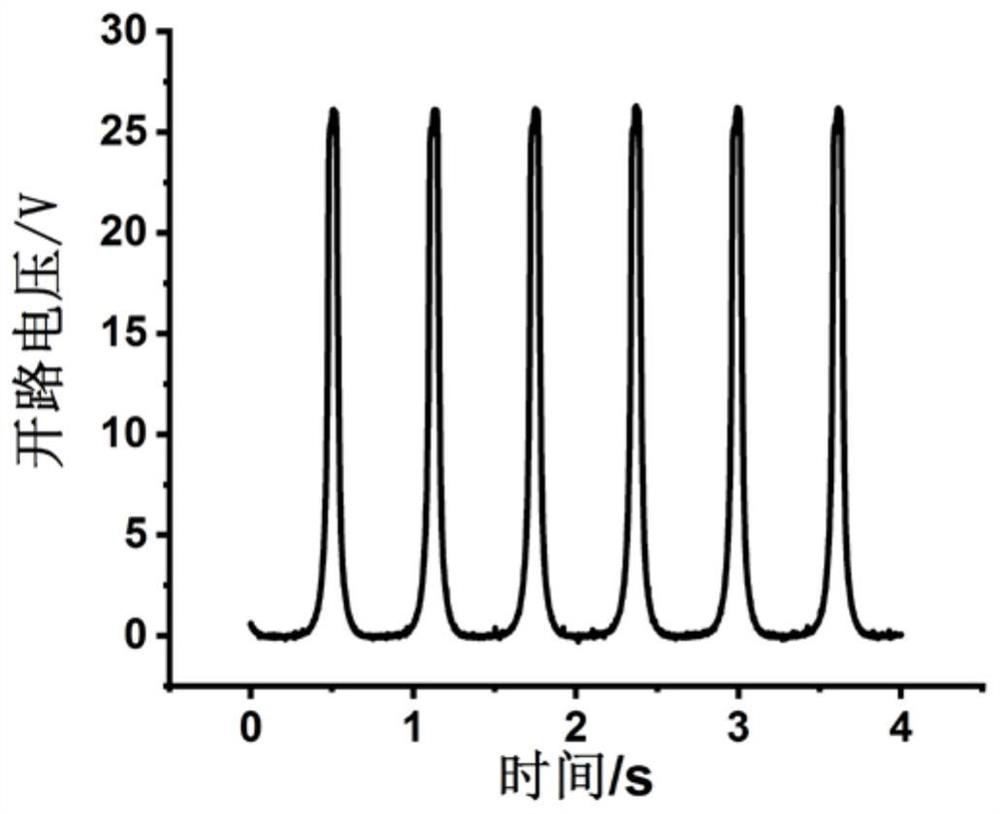

Method for preparing open-cell ZIF-8/polymer composite foam material by using solid-phase shearing and milling technology

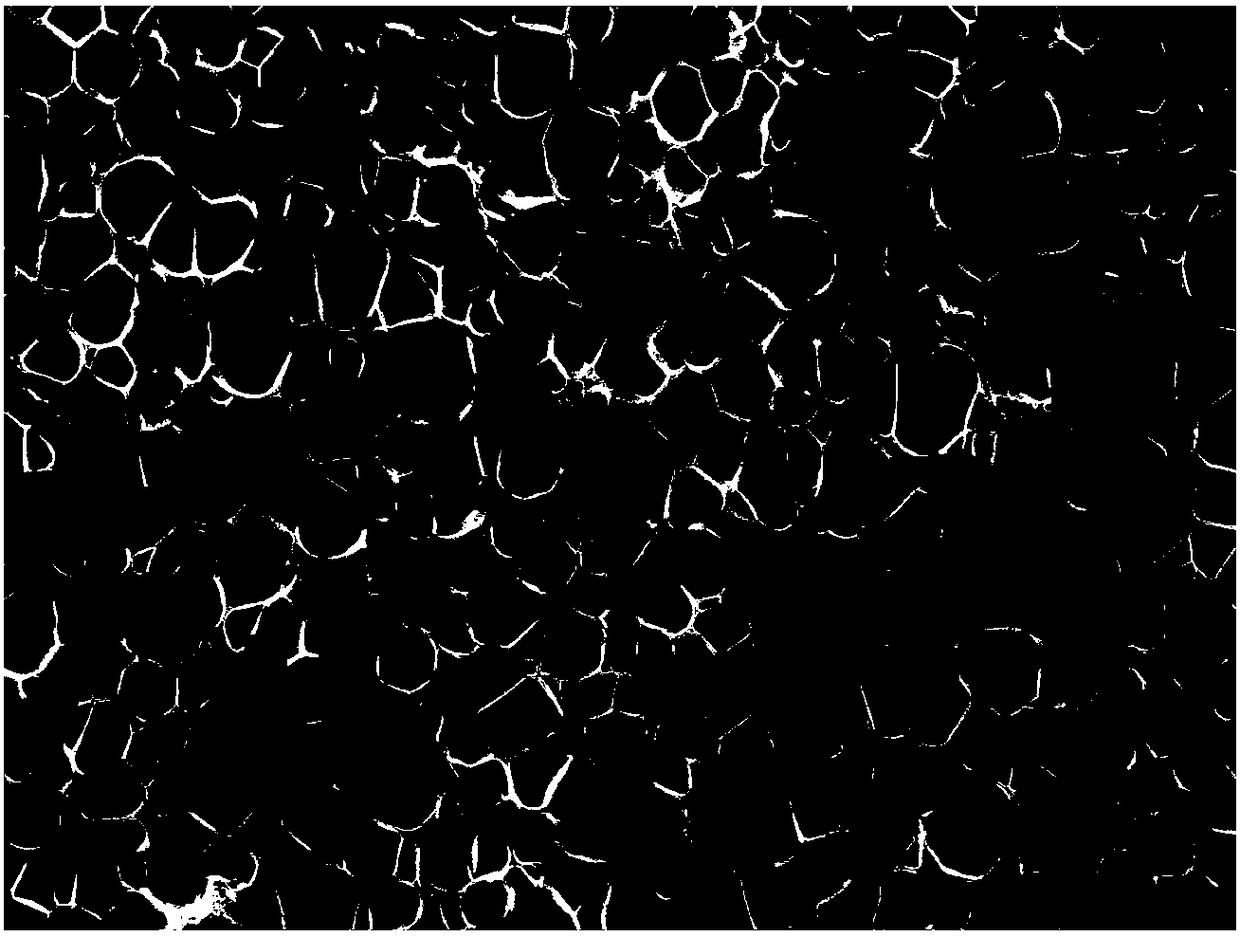

ActiveCN112940342AUniform particle size distributionUniform cell sizeProsthesisNanocapsulesPolymer scienceFreeze-drying

The invention provides a method for preparing an open-cell ZIF-8 / polymer composite foam material by using a solid-phase shearing and milling technology. The method comprises the following steps: mixing 40-60 parts of piezoelectric polymer granules and 60-40 parts of water-soluble salt granules in total 100 parts, adding the mixture into a millstone type mechanochemical reactor for milling and crushing, then preparing a block body by using a forming process, adding a water-soluble salt into a block, soaking the block into deionized water until the water-soluble salt is completely dissolved, soaking the obtained piezoelectric polymer foam into a ZIF-8 diluted solution, and standing and freeze-drying to obtain the ZIF-8 / polymer composite foam material. The ZIF-8 / polymer composite foam material obtained by the method has better mechanical property and flexibility, and when the ZIF-8 / polymer composite foam material is used as a foam bone material, the piezoelectric effect can be exerted under the stress effect while an osteogenesis space is maintained in an oral stress environment, and continuous micro-current stimulation promotes osteogenesis in an operation area.

Owner:SICHUAN UNIV

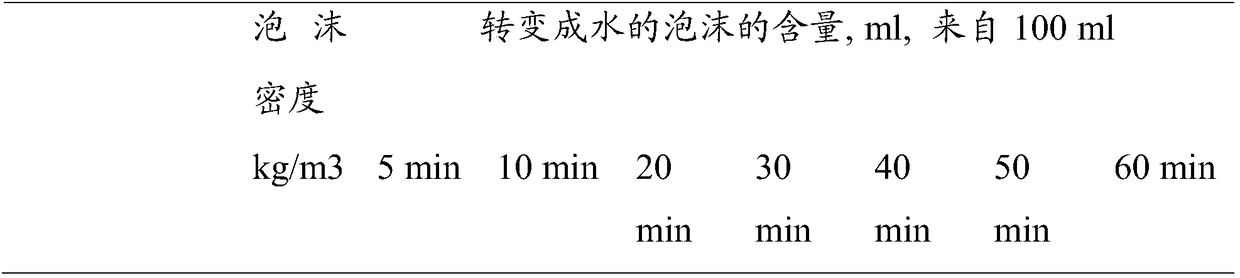

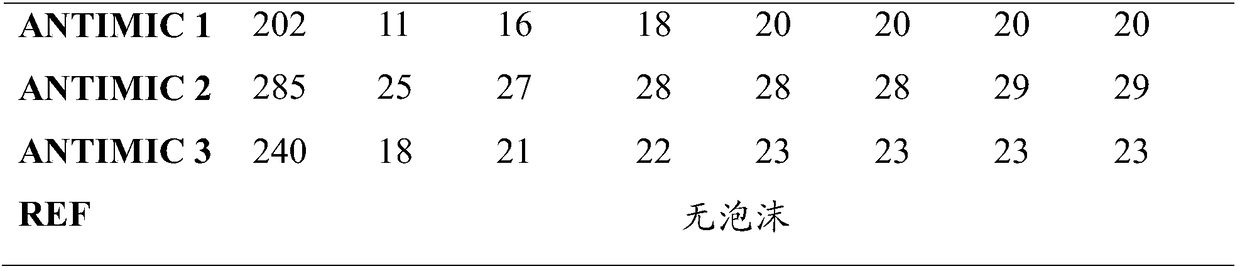

Process for creating a foam utilizing an antimicrobial starch within a process for manufacturing a paper or board product

PendingCN109415874AUniform cell sizeAvoid problems in treatment plantsPaper coatingPaper/cardboardCardboardPulp and paper industry

The present invention relates to a new process for creating foam in a process for manufacturing a paper or board product. According to the present invention, certain types of antimicrobial starch is used in the creation of the foam.

Owner:STORA ENSO OYJ

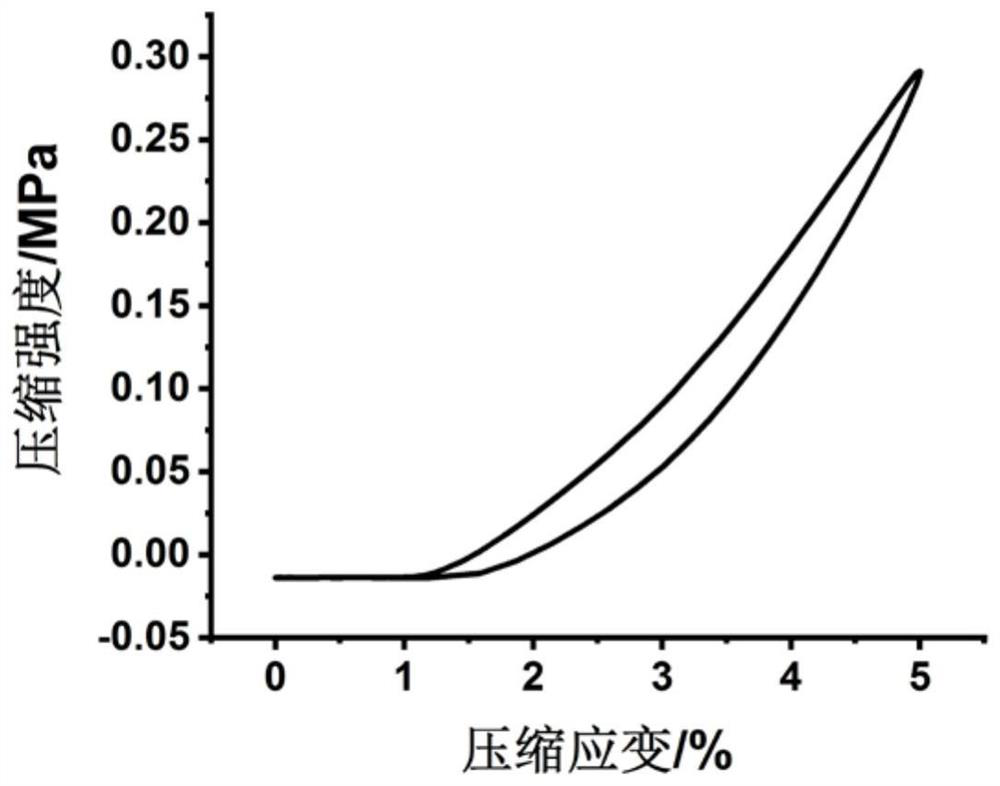

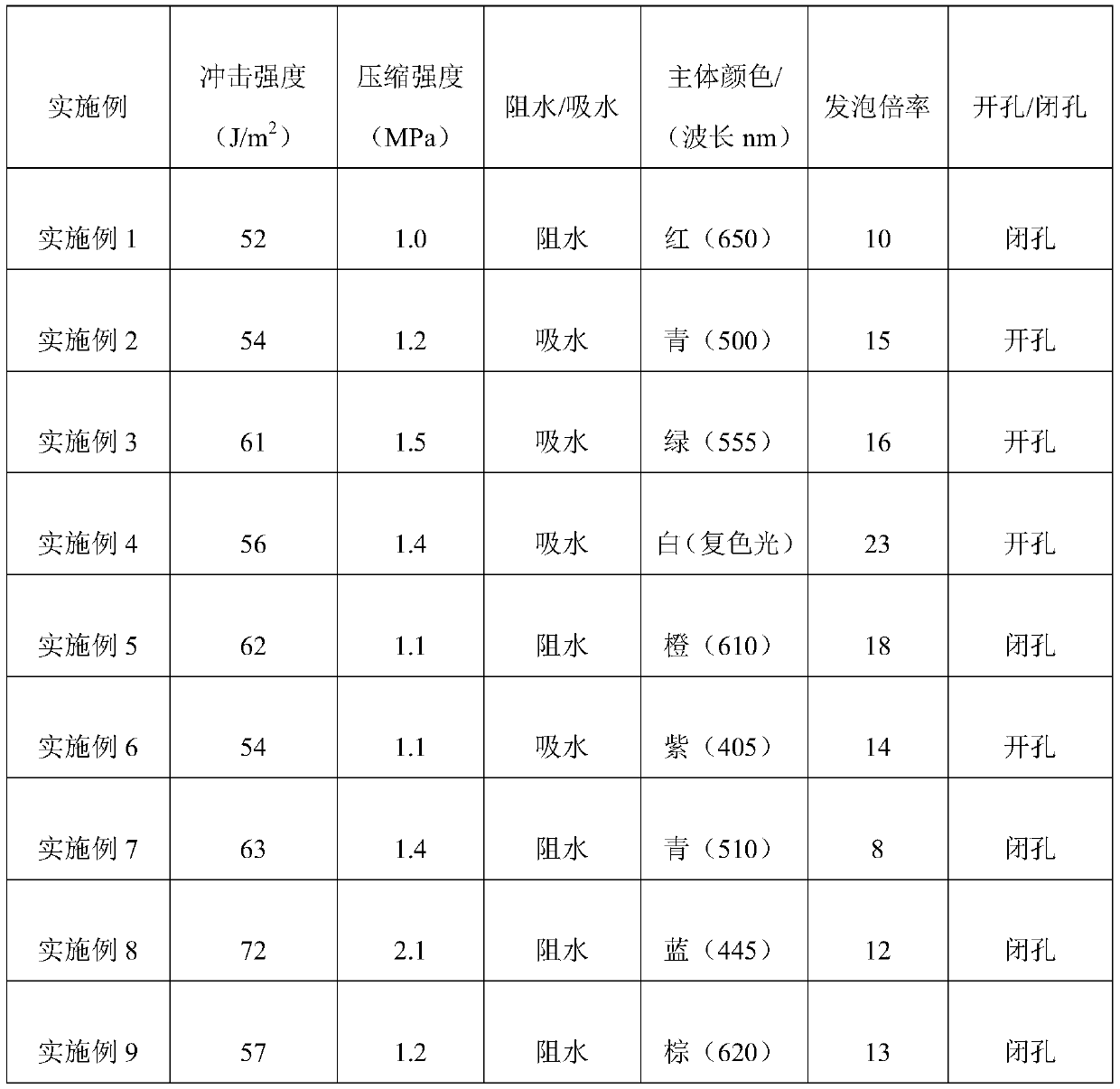

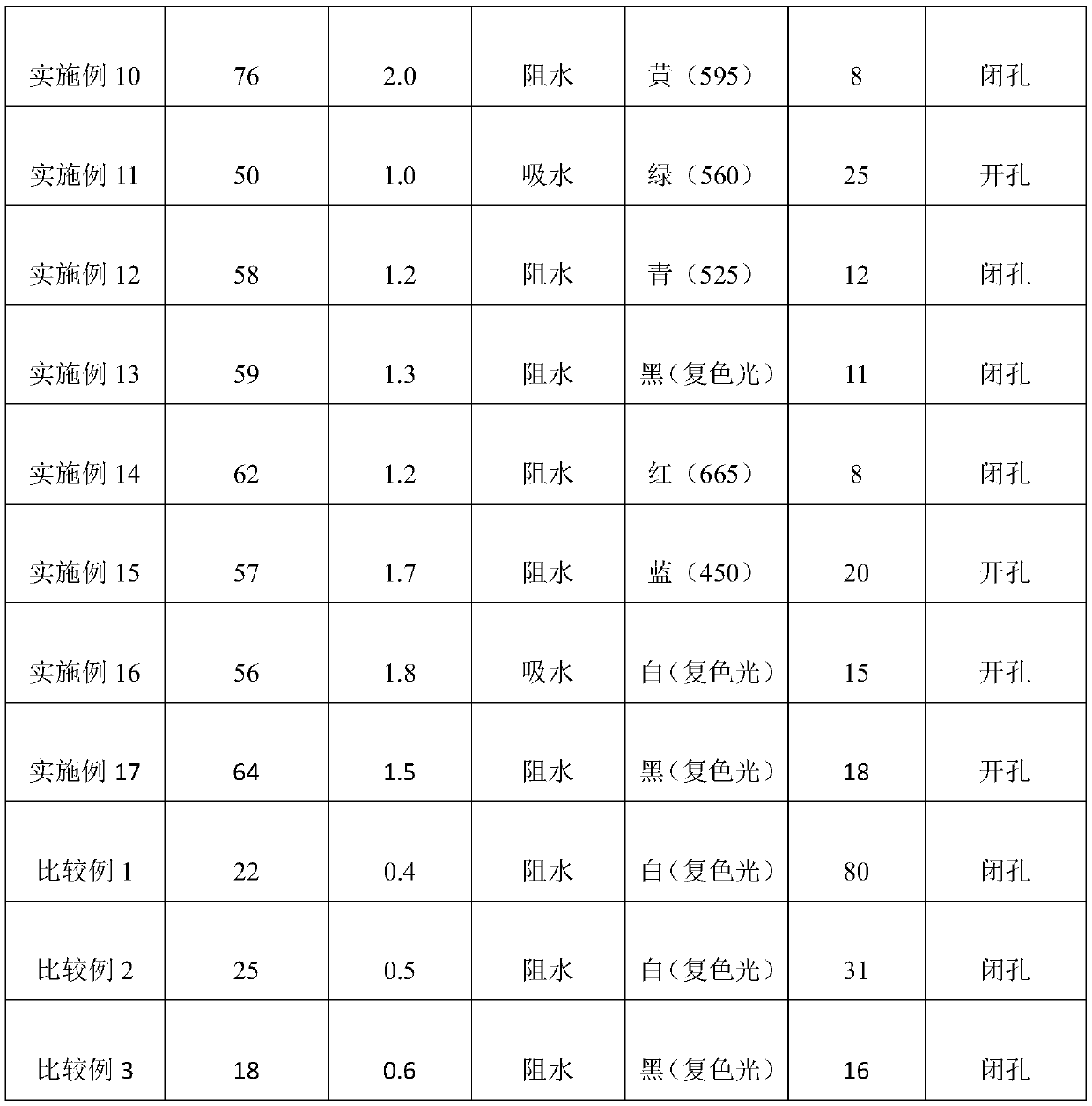

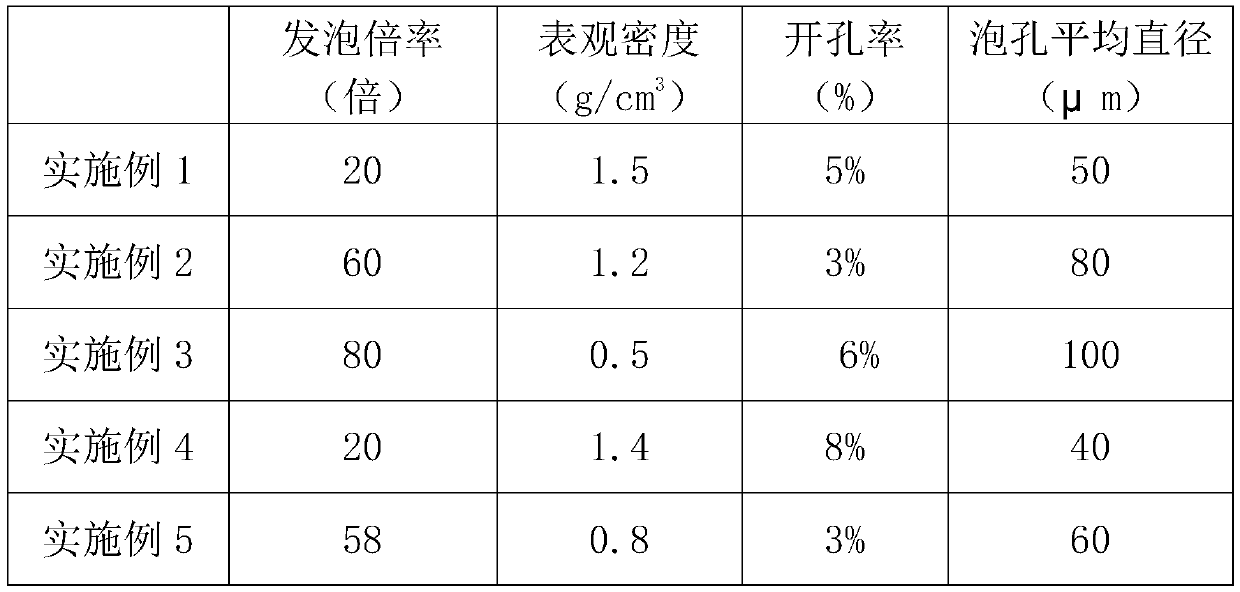

Foaming material, preparation method thereof and foaming product

The invention relates to a luminescent material, a preparation method thereof and a foaming product, the foaming material is mainly prepared from poly-4-methyl-1-pentene and a reinforcing agent through a supercritical foaming process, and the particle size of the reinforcing agent is 40-100 nm. The foaming material has excellent impact strength and compression strength.

Owner:NINGBO CHANGYANG TECH

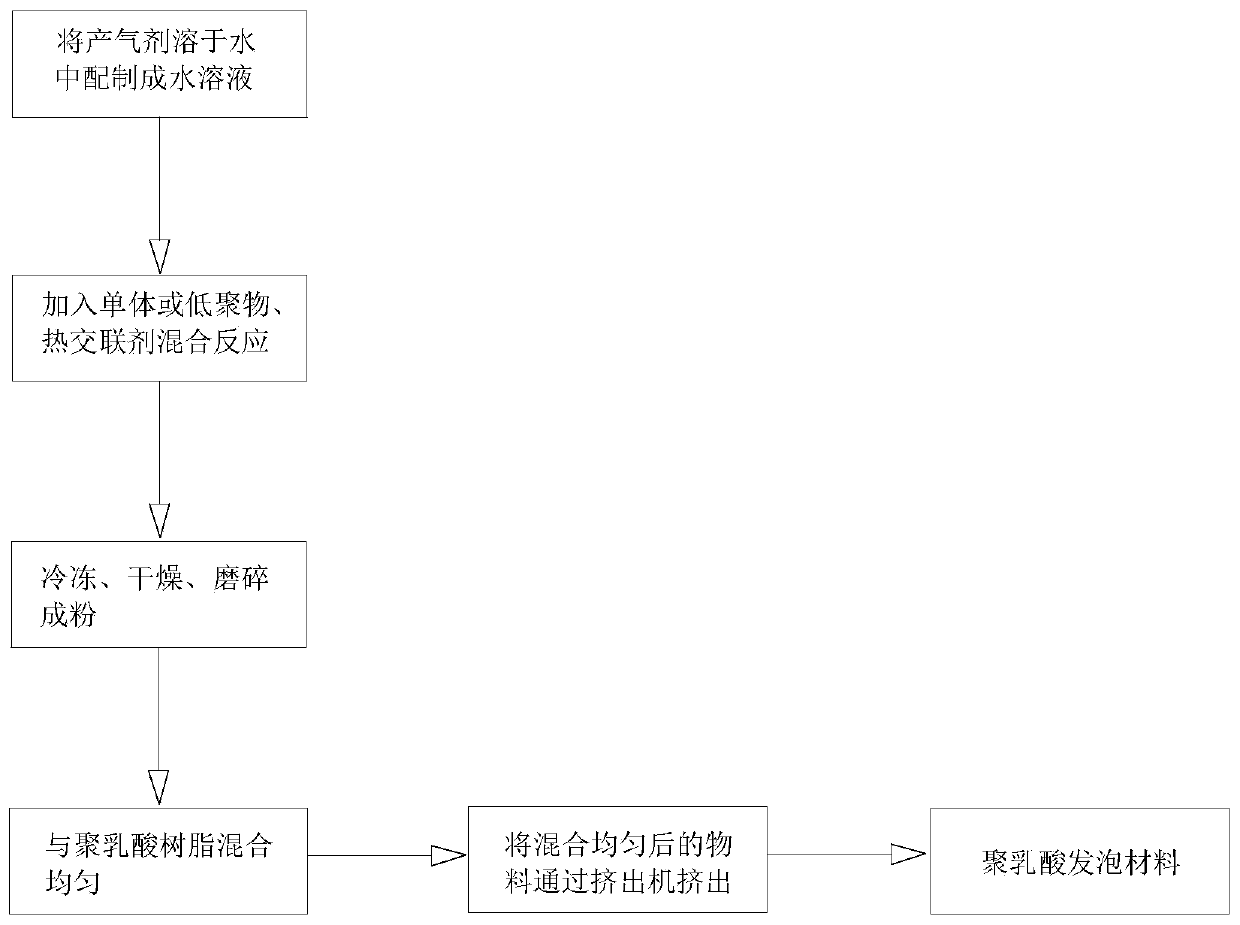

Polylactic acid foaming method

The invention discloses a polylactic acid foaming method. The polylactic acid foaming method comprises the following steps that A, a gas-generating agent is dissolved into water to prepare a solution;B, monomer or oligomer, a thermal crosslinking agent are mixed with the aqueous solution of the step A to obtain an initial reaction mixed solution, and after the initial reaction mixed solution is frozen and dried in a freeze drying device, grinding is conducted; C, polylactic acid resin and the ground initial reaction mixture powder obtained in the step B are uniformly mixed; D, the uniformly mixed material in the step C is added into an extruder, process parameters of the extruder are set for melt extrusion, the gas-generating agent is heated and generated expansion during the extrusion process, and a polylactic acid melt displays a foaming state; and E, the polylactic acid melt in the step D is extruded through the extruder and the polylactic acid foaming material is obtained after cooling and shaping. The foaming method is simple and efficient, no special equipment is needed, the cost is low, the operation is easy, the control is easy, and the obtained foaming material is stablein quality, uniform in the foam size, and high in the foaming rate.

Owner:佛山碧嘉高新材料科技有限公司

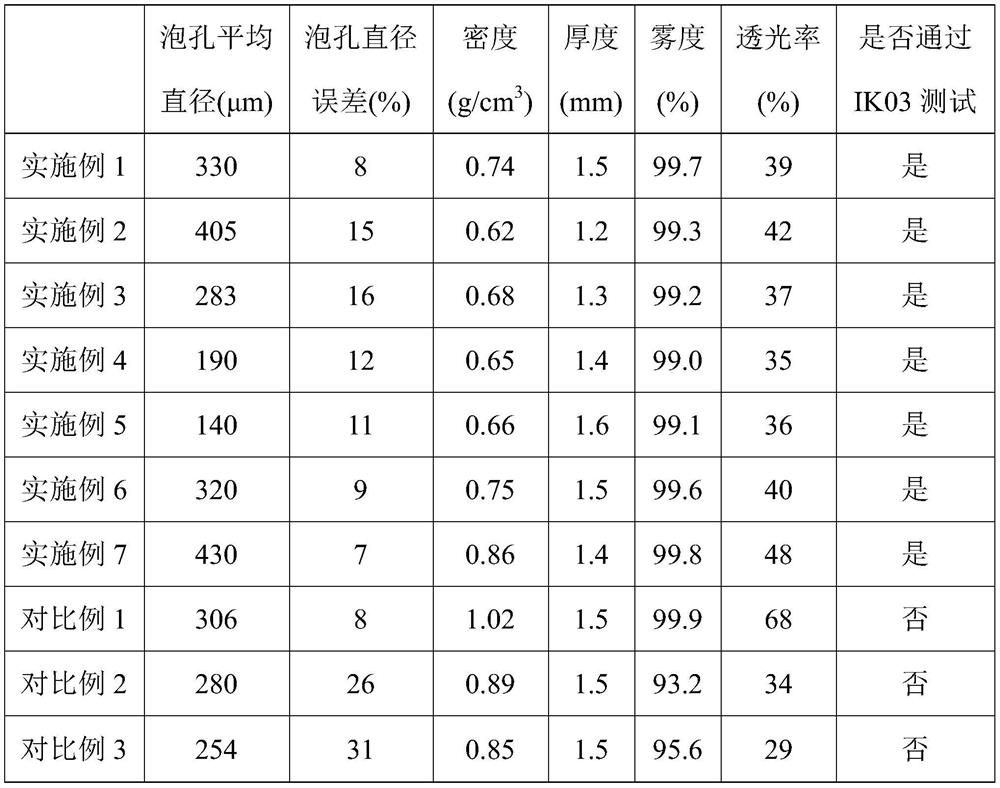

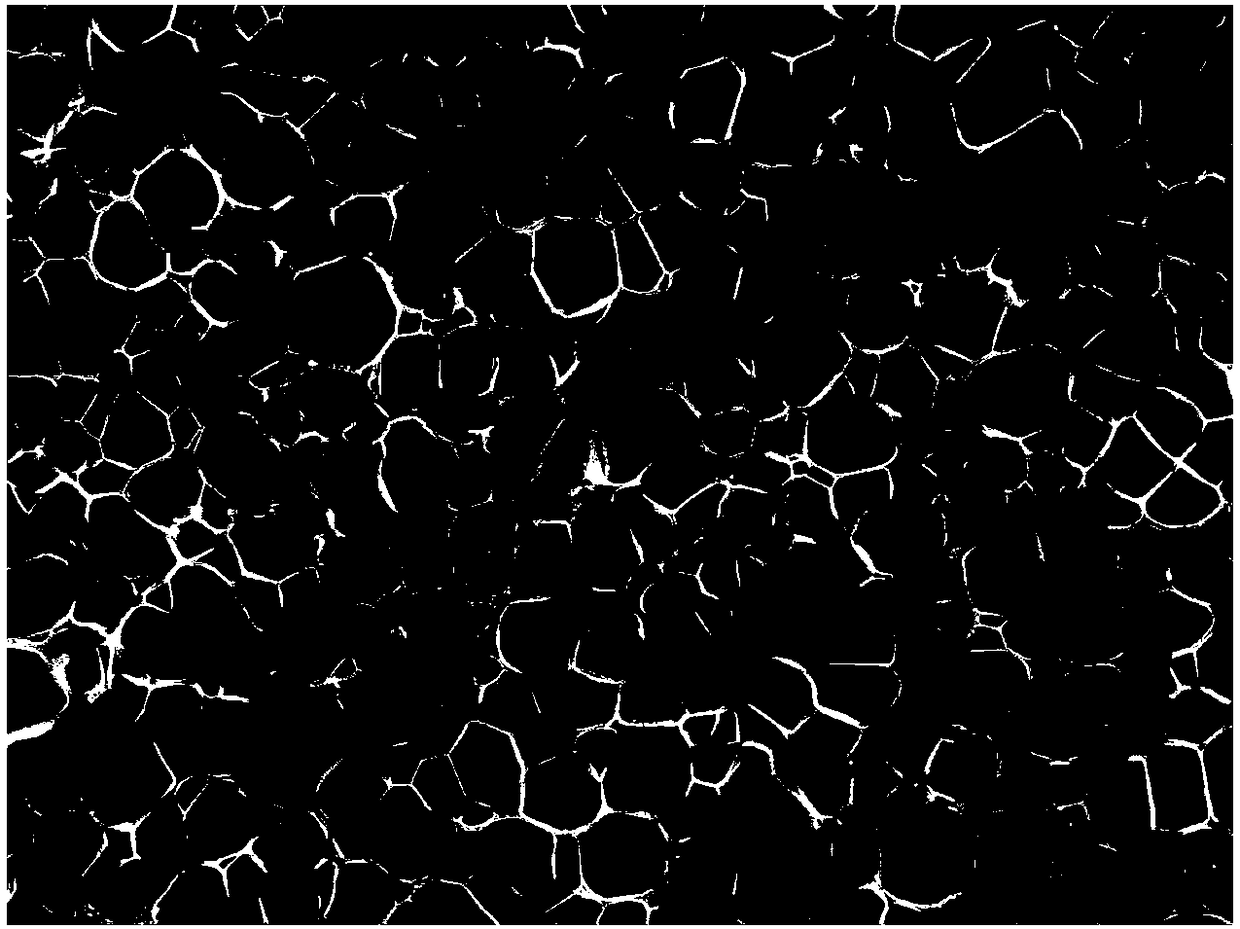

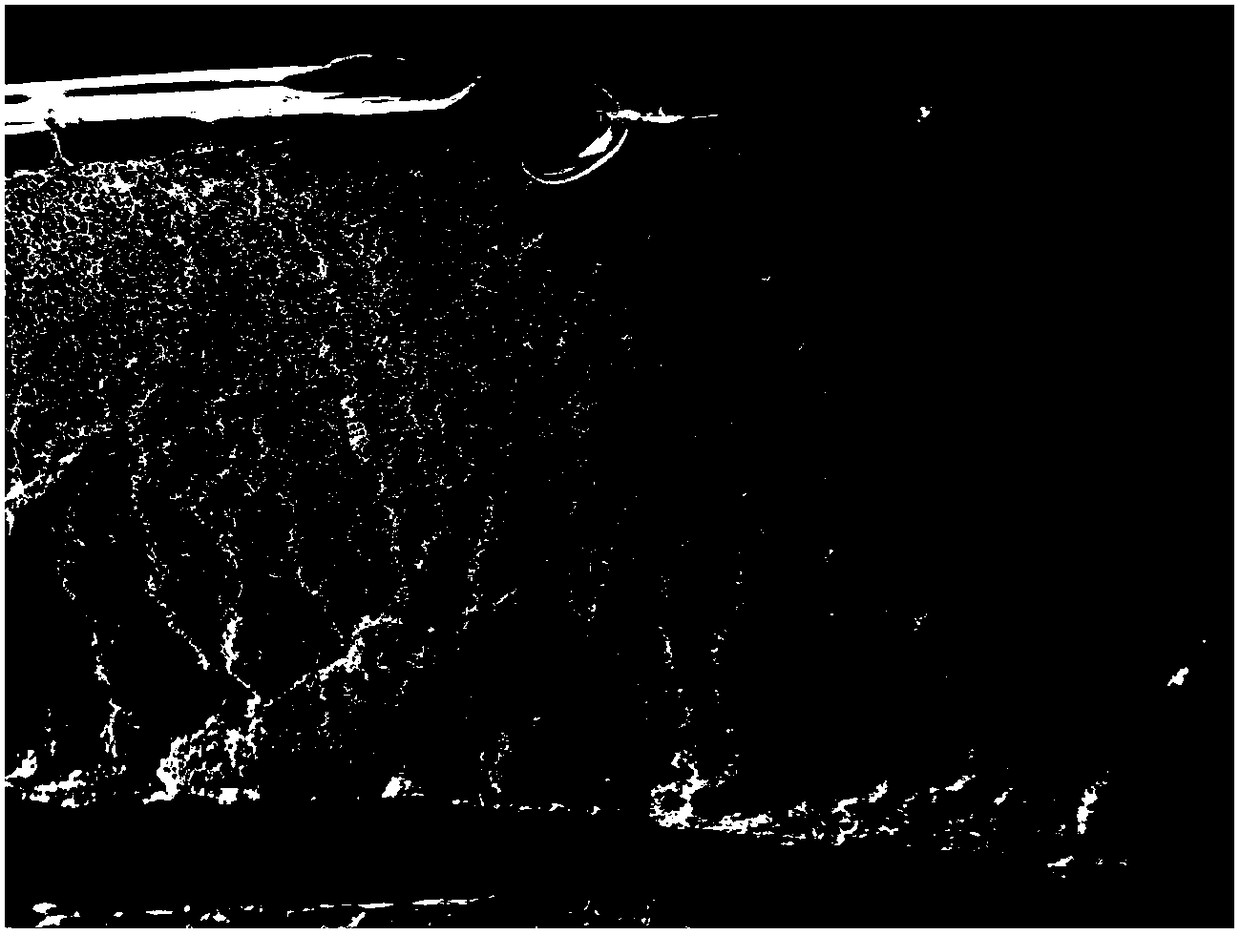

Foaming light diffusion plate, preparation method and application thereof

PendingCN113896936AUniform cell sizeOverall light weightDiffusing elementsBulk chemical productionComposite materialCarbonyl group

The invention relates to a foaming light diffusion plate, a preparation method and application thereof. The preparation method of the foaming light diffusion plate comprises the following steps: mixing and melting polystyrene, a polymer containing carbonyl and a nucleating agent to obtain a blend, wherein the melting temperature of the polymer containing carbonyl is smaller than or equal to 200 DEG C; and injecting supercritical carbon dioxide into the blend, and then extruding and foaming to obtain the foaming light diffusion plate. According to the invention, the preparation method of the foaming light diffusion plate is clean and harmless, the mass of the light diffusion plate can be effectively reduced, and the prepared foaming light diffusion plate is uniform in cell size, uniform in density, good in optical performance and mechanical performance, capable of passing an IK03 protection grade test and wide in application prospect.

Owner:ZHEJIANG CARBON VISION TECH CO LTD

Expanded thermoplastic polyurethane beads and preparation method and application thereof

The present invention relates to expanded thermoplastic polyurethane beads, a preparation method for same, and an application thereof. The expanded thermoplastic polyurethane beads consists of components of the following parts by weight: 100 parts of a thermoplastic polyurethane, 1-10 parts of a cell size stabilizer, and 1-35 parts of a melt viscosity modifier. The preparation method for the expanded thermoplastic polyurethane beads is also disclosed. The bead is produced by employing a volatile blowing agent to immerse the thermoplastic polyurethane, comprising the pore size stabilizer and the melt viscosity modifier, in an aqueous suspension, and is then followed by the foaming process. Utilization of the expanded thermoplastic polyurethane beads of the present invention allows for preparation of a foam product. The expanded thermoplastic polyurethane beads prepared per the present invention has uniform cell sizes and a high product yield. At the same time, the expanded thermoplastic polyurethane bead provides a great sintering performance even at a relatively low vapor pressure, a molded foam product has a small deformation, a low dimensional shrinkage ratio relative to a mold, great dimensional stability, and an aesthetically appealing appearance.

Owner:MIRACLL CHEM

2, 5-furan diformyl copolyester foam material and preparation method thereof

The invention relates to a 2, 5-furan diformyl copolyester foam material and a preparation method thereof. The preparation method comprises the steps of (a) putting 2,5-furan diformyl copolyester plastic into a mold, pressing into a laminated preform, and quenching the laminated preform; (b) putting the quenched preform and a first foaming agent into a sealed container without contacting, whereinthe first foaming agent is at least one of chloroform, acetone, diethyl ether, pentane and hexafluoroisopropanol; (c) feeding a second foaming agent into the sealed container, wherein the second foaming agent is at least one of carbon dioxide and nitrogen; keeping the temperature in the sealed container to be 40 DEG C to 65 DEG C, enabling the first foaming agent to change into a gas state from aliquid state, and keeping the pressure in the sealed container to be 2MPa to 5MPa, wherein the pressure keeping time is 5h to 10h; (d) releasing a gas in the sealed container, taking the preform out,putting into a foaming medium for foaming, and cooling to obtaining the 2,5-furan diformyl copolyester foam material with the cell size being 5 microns to 50 microns and the expansion rate being 2 times to 15 times.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

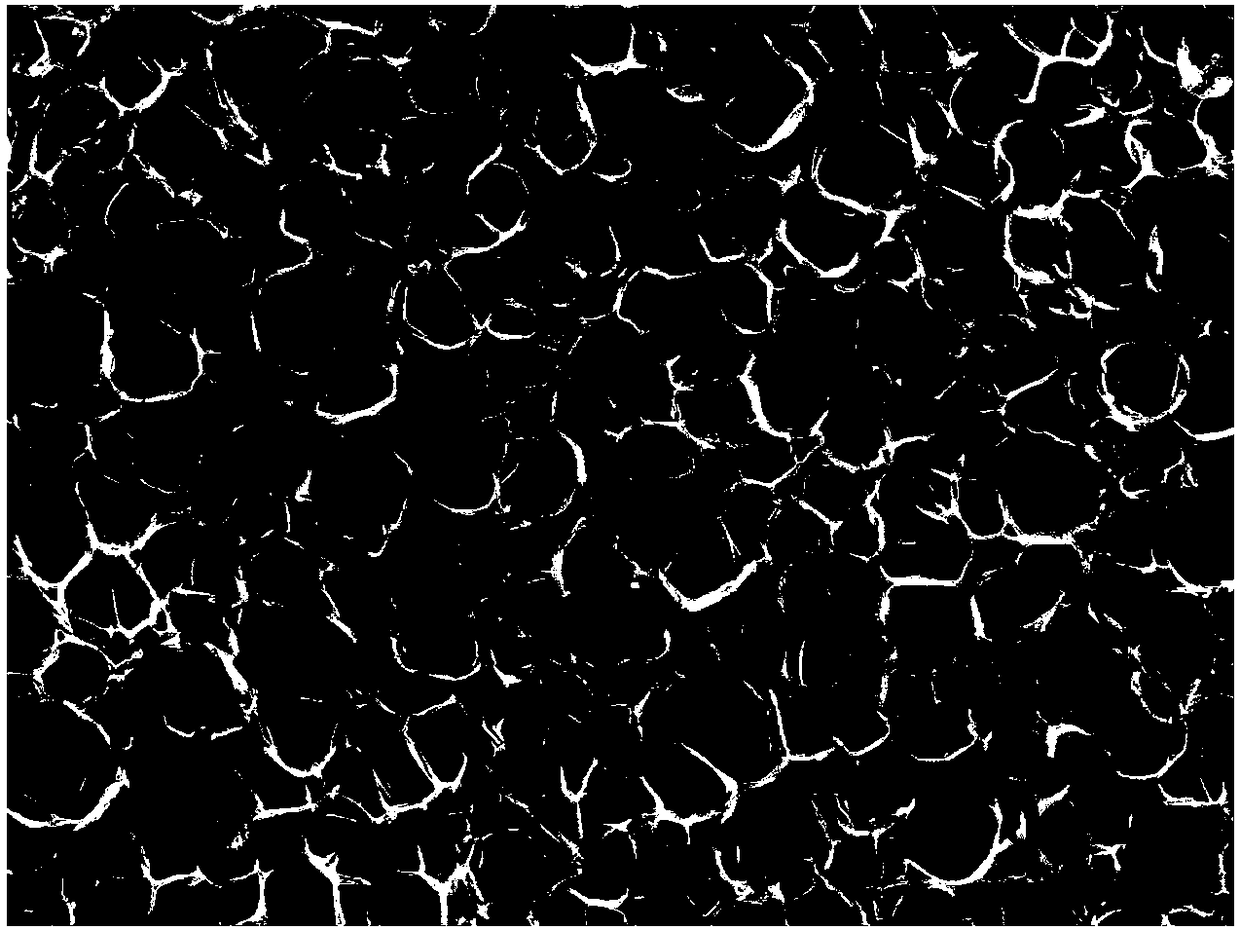

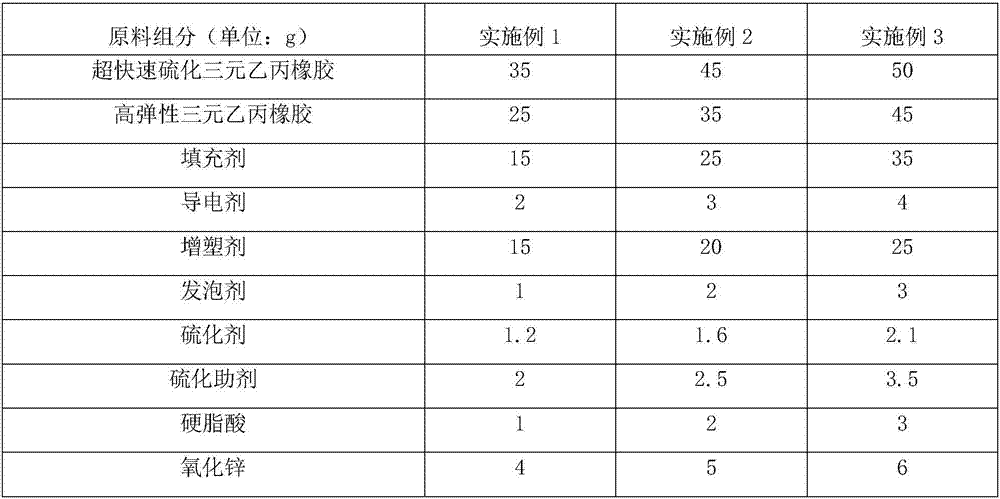

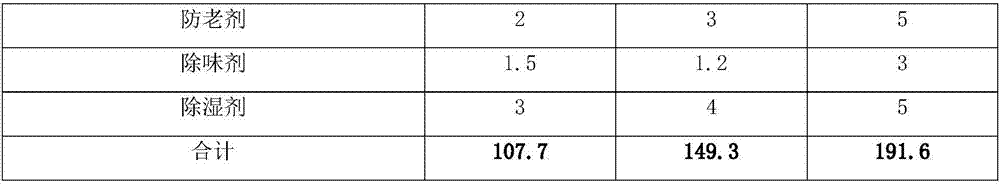

High-elasticity and uniform-cell size foamed rubber hose composition for charging roller and preparation method of foamed rubber hose composition

InactiveCN107118450AIncreased degree of vulcanizationFast heatingTubular articlesVulcanizationPolymer science

The invention belongs to the technical field of synthetic rubber and particularly relates to a high-elasticity and uniform-cell size foamed rubber hose composition for a charging roller and a preparation method of the foamed rubber hose composition. The high-elasticity and uniform-cell size foamed rubber hose composition is prepared from the following components in parts by weight: 10-50 parts of an ultra-fast vulcanized ethylene propylene diene monomer, 10-50 parts of a high-elasticity ethylene propylene diene monomer, 12-35 parts of a filler, 2-10 parts of a conductive agent, 10-25 parts of a plasticizer, 1-4 parts of a foaming agent, 3-6 parts of a vulcanizing agent and vulcanizing assistant, 1-3 parts of stearic acid, 4-7 parts of zinc oxide, 1-5 parts of an anti-aging agent, 1-3 parts of a deodorant an 3-5 parts of a dehumidizer. The preparation method of the foamed rubber hose composition is extruding continuous microwave vulcanization. The high-elasticity and uniform-cell size foamed rubber hose composition has the beneficial effects that post thermal stabilization treatment is not needed, the production efficiency is high and the prepared product is high in elasticity; the produced sponge-layer foamed rubber hose for the charging roller is high in elasticity, uniform in cell size, stable in foamed rubber hose size and resistance and relatively low in cost; a charging roller product is uniform in charging and stable in performance; the service life of the charging roller is prolonged; and good quality of a charging roller print product is ensured.

Owner:NANJING ORIENTLEADER TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com