Method for preparing meso-porous silica/polylactic acid foamed material by supercritical CO2 foaming

A foaming technology of mesoporous silica and polylactic acid, which is applied in the field of supercritical CO2 foaming to prepare mesoporous silica/polylactic acid foaming materials, can solve problems that have never occurred before, and achieve high cell density and foaming. The effect of simple foaming process and uniform cell size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

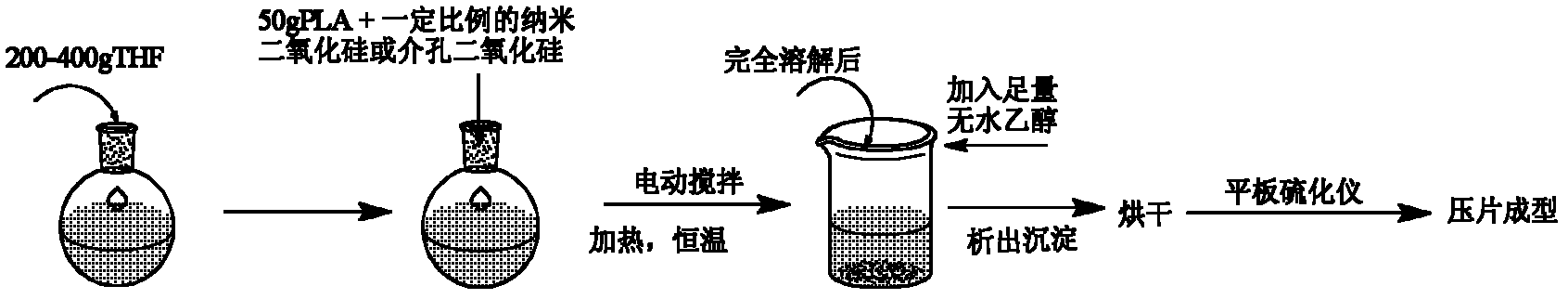

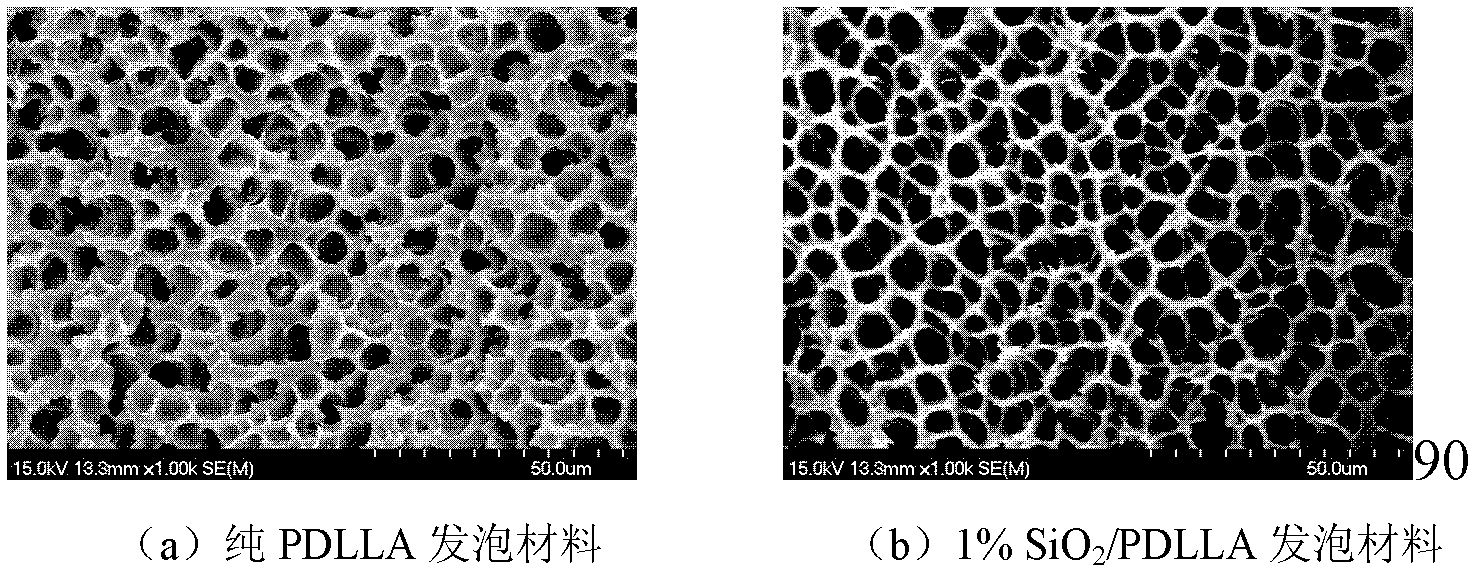

[0033] The raw material components are 50g of racemic polylactic acid (PDLLA, NatureWork), 0.5g of mesoporous silica (accounting for 1% of the total weight, the pore diameter is 8.0nm, and the specific surface area is 890m 2 / g, pore volume 1.42m 3 / g), tetrahydrofuran 300g (THF, analytically pure).

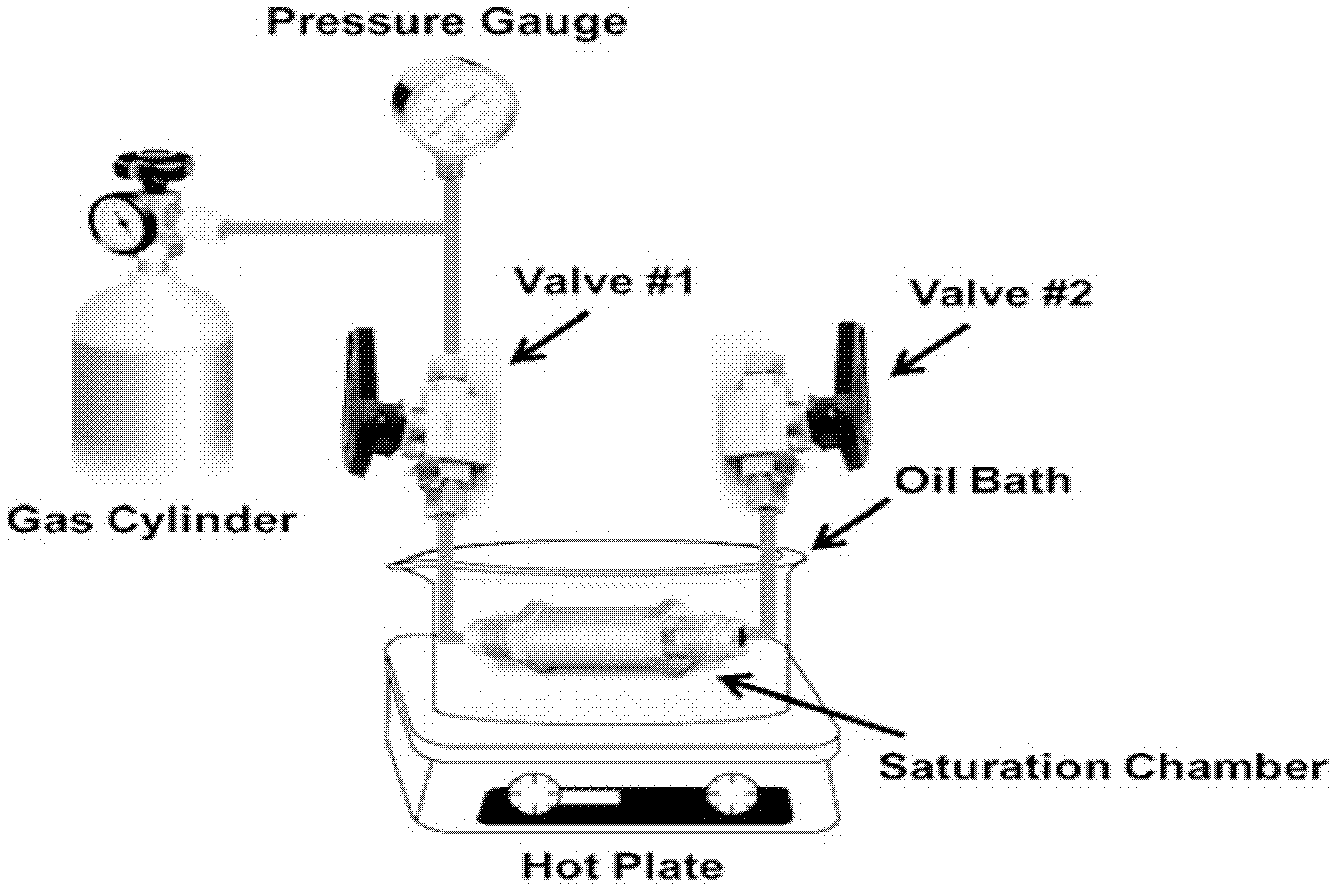

[0034] Add polylactic acid and mesoporous silica to tetrahydrofuran, heat the solution to 60°C, stir thoroughly for 2 hours, add 360mL ethanol to the solution to precipitate a rough mixture; then wash the obtained rough mixture with ethanol, dry at 40°C, and use a plate The vulcanizer is molded, the temperature of the flat vulcanizer is 175°C, the pressure is 10MPa, and the holding time is 8min; the molded sample is placed in supercritical CO 2 Swell in the fluid, the swelling process takes 10 hours, the swelling temperature is 120°C, and the swelling pressure is 15Mpa; finally, the CO in the material is decompressed at a pressure relief rate of 4MPa / s. 2 Supersaturated, foamed...

Embodiment 2

[0038] The raw material components are calculated by weight ratio: 50g of racemic polylactic acid (PDLLA, NatureWork), 1.5g of mesoporous silica (accounting for 3% of the total weight, with a pore diameter of 10.0nm and a specific surface area of 950m 2 / g, pore volume 1.57m 3 / g), tetrahydrofuran 350g (THF, analytically pure).

[0039] Add polylactic acid and mesoporous silica to tetrahydrofuran, heat the solution to 65°C, stir thoroughly for 1.5h, add 400mL ethanol to the solution to precipitate a rough mixture; then wash the obtained rough mixture with ethanol, dry at 60°C, and use The flat vulcanizer is molded, the temperature of the flat vulcanizer is 175°C, the pressure is 10MPa, and the holding time is 7min; the molded sample is placed in supercritical CO 2 Swell in the fluid, the swelling process takes 10 hours, the swelling temperature is 122°C, and the swelling pressure is 14Mpa; finally, the CO in the material is decompressed at a pressure relief rate of 4MPa / s. ...

Embodiment 3

[0043] The raw material components are calculated by weight ratio: 50g of racemic polylactic acid (PDLLA, NatureWork), 2.6g of mesoporous silica (accounting for 5% of the total weight, with a pore diameter of 14.0nm and a specific surface area of 967m 2 / g, pore volume 1.72m 3 / g), tetrahydrofuran 250g (THF, analytically pure).

[0044] Add polylactic acid and mesoporous silica to tetrahydrofuran, heat the solution to 50°C, stir thoroughly for 3 hours, add 425mL ethanol to the solution to precipitate a rough mixture; then wash the obtained rough mixture with ethanol, dry at 50°C, and use a plate The vulcanizer is molded, the temperature of the flat vulcanizer is 185°C, the pressure is 12MPa, and the holding time is 6min; the molded sample is placed in supercritical CO 2 Swell in the fluid, the swelling process takes 12 hours, the swelling temperature is 126°C, and the swelling pressure is 15Mpa; finally, the CO in the material is decompressed at a pressure relief rate of 3M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com