Pea protein concrete foaming agent and preparation method thereof

A technology of pea protein and foaming agent, applied in ceramic products, other household utensils, applications, etc., can solve the problems of low strength of products, limited source of raw materials, high production cost, etc., achieve simple preparation process, improve various properties, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

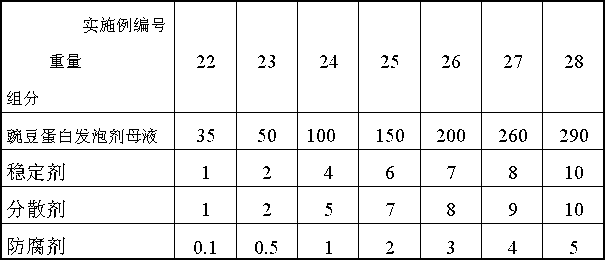

Examples

Embodiment 1

[0037] A preparation method of a pea protein concrete foaming agent, comprising the following steps:

[0038] a. Preparation of pea protein foaming agent stock solution:

[0039] 10 Kg pea protein, 2Kg Ca(OH) 2 and 200 L of water in proportion, mixed in a reaction kettle, heated to 80 ° C, hydrolyzed for 4 hours, entered into a filter for filtration, and the filtrate is the obtained pea protein foaming agent mother liquor;

[0040] b. Preparation of pea protein concrete foaming agent:

[0041] Take the pea protein foaming agent mother liquor, cetyl trimethyl ammonium bromide, sodium lauryl sulfate, carrageenan, sodium p-hydroxybenzene sulfonate prepared in step (a), according to the pea protein foaming agent mother liquor : Stabilizer (Cetyltrimethylammonium Bromide and Sodium Lauryl Sulfate): Dispersant (Gum Arabic): Preservative (Sodium p-hydroxybenzenesulfonate) 100:2 and 0.1:4:0.3 After mixing and compounding in the appropriate weight ratio, stir evenly at a high speed...

Embodiment 2

[0045] A preparation method of a pea protein concrete foaming agent, comprising the following steps:

[0046] a. Preparation of pea protein foaming agent stock solution:

[0047] 20 Kg pea protein, 2Kg Ca(OH) 2 and 200 L of water in proportion, mixed in a reaction kettle, heated to 80 ° C, hydrolyzed for 4 hours, entered into a filter for filtration, and the filtrate is the obtained pea protein foaming agent mother liquor;

[0048] b. Preparation of pea protein concrete foaming agent:

[0049] Take the pea protein foaming agent mother liquor, lauryl trimethyl ammonium bromide, sodium lauryl sulfate, gum arabic, sodium p-hydroxybenzene sulfonate prepared in step (a), according to the pea protein foaming agent mother liquor : Stabilizers (Lauryl Trimethylammonium Bromide and Sodium Lauryl Sulfate): Dispersing Agents (Gum Arabic): Preservatives (Sodium p-hydroxybenzenesulfonate): 100:1 and 0.1:2: After mixing and compounding in a weight ratio of 0.25, stir evenly at a high sp...

Embodiment 3

[0053] A preparation method of a pea protein concrete foaming agent, comprising the following steps:

[0054] a. Preparation of pea protein foaming agent stock solution:

[0055] 20 Kg pea protein, 2Kg Ca(OH) 2 and 200 L of water in proportion, mixed in a reaction kettle, heated to 80 ° C, hydrolyzed for 4 hours, entered into a filter for filtration, and the filtrate is the obtained pea protein foaming agent mother liquor;

[0056] b. Preparation of pea protein concrete foaming agent:

[0057] Take the pea protein foaming agent mother liquor, sodium lauryl sulfate, gelatin, and sodium p-hydroxybenzene sulfonate prepared in step (a), according to the pea protein foaming agent mother liquor: stabilizer (sodium lauryl sulfate): Dispersing agent (gelatin): preservative (sodium p-hydroxybenzenesulfonate) in a weight ratio of 100:2 and 0.1:4:0.1. After mixing and compounding, stir at a high speed to form a uniform and dense foam, that is, to prepare peas Protein concrete foaming...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com