Patents

Literature

47results about How to "The foaming process is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

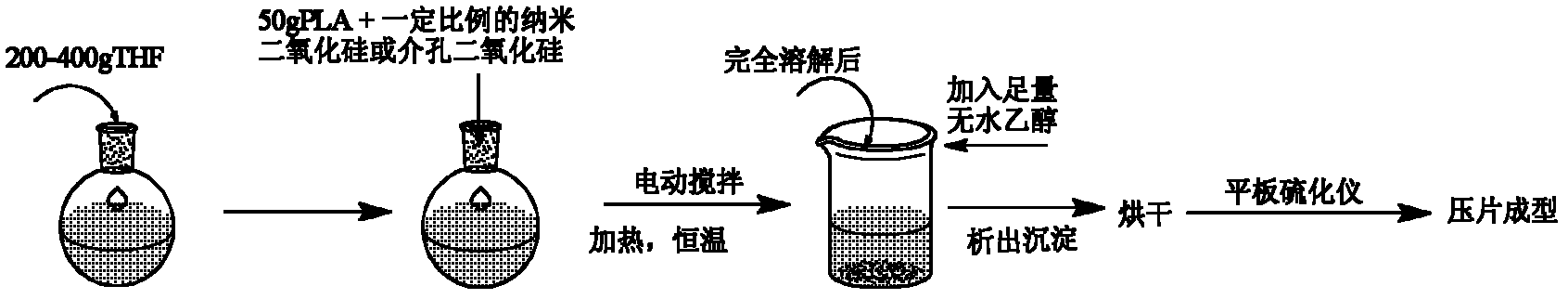

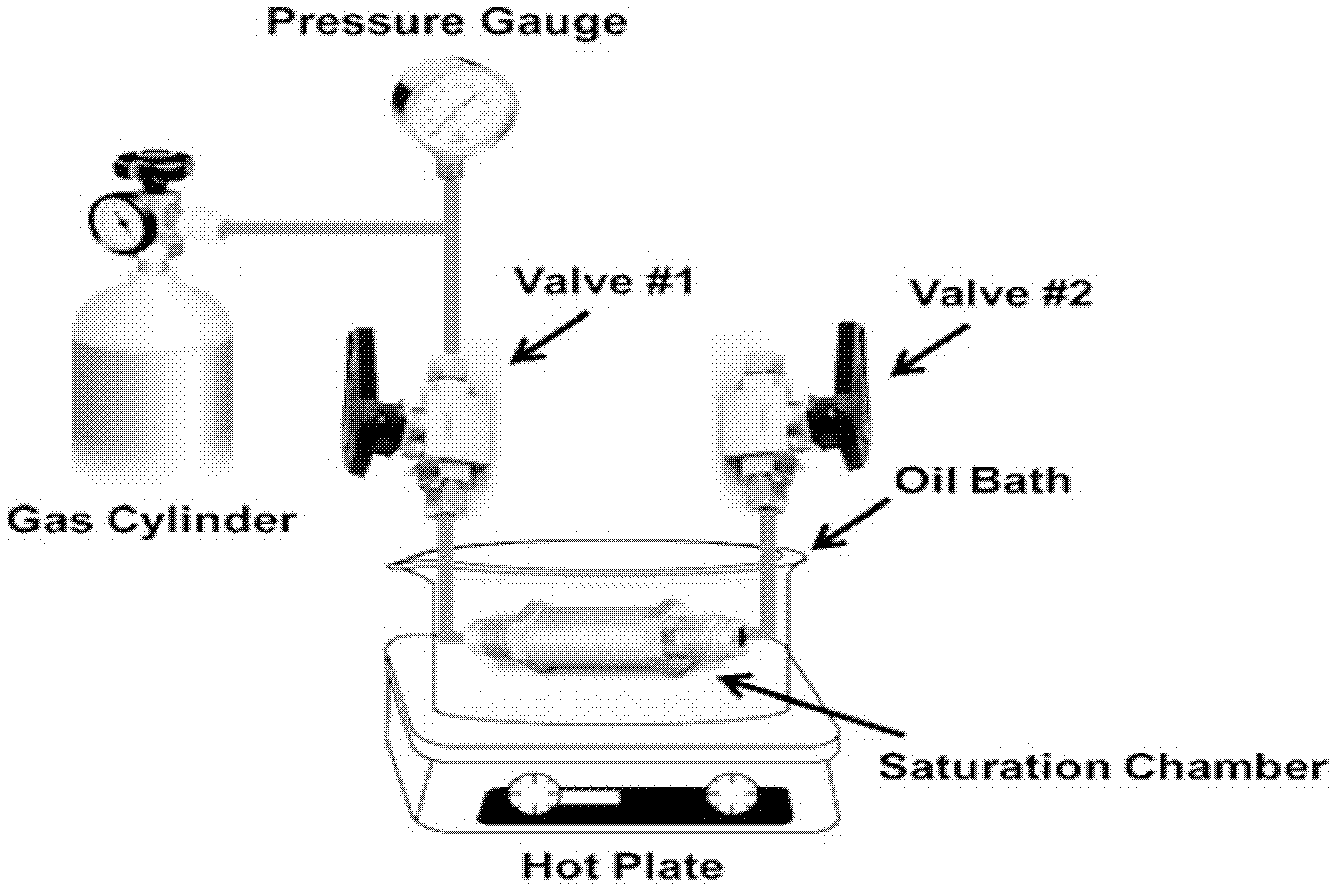

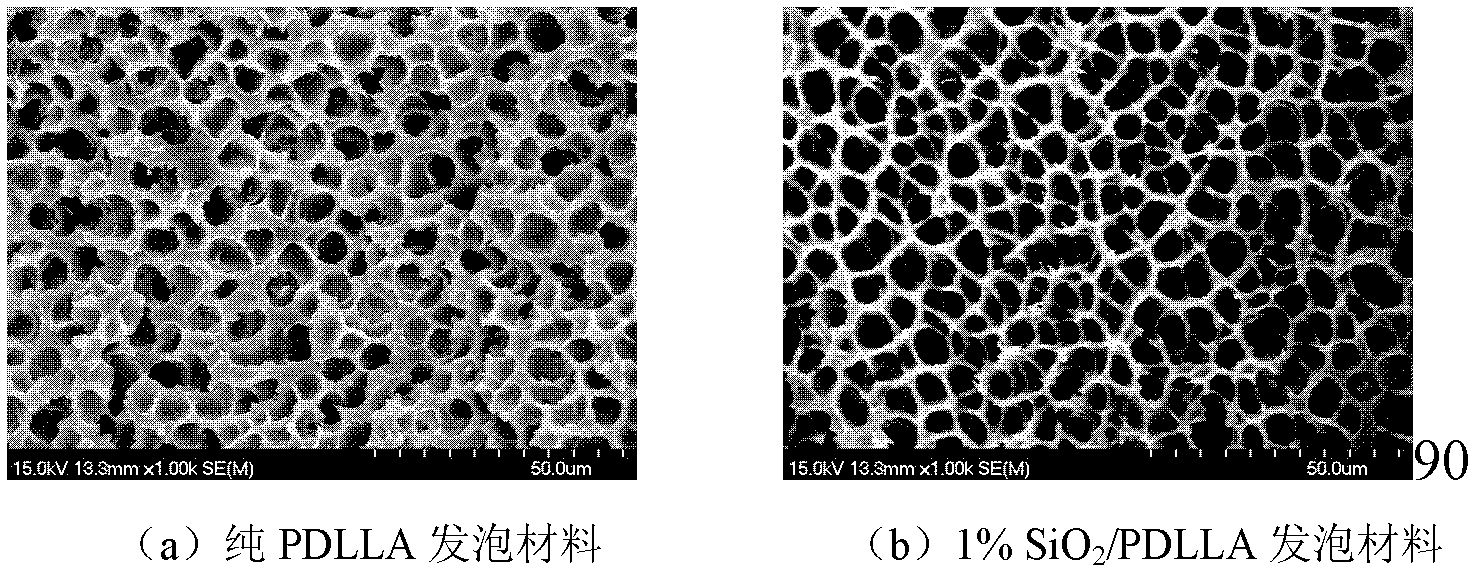

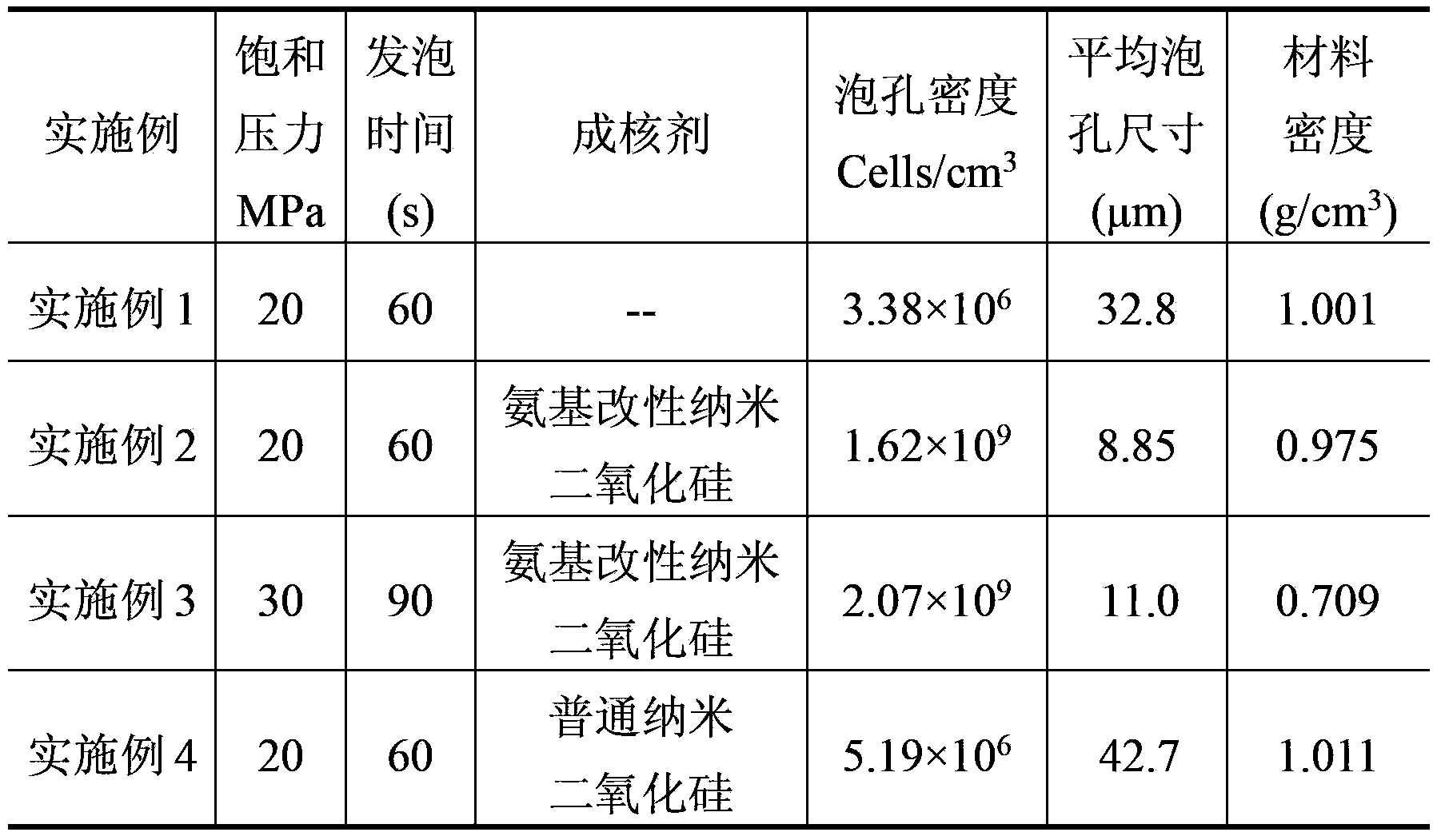

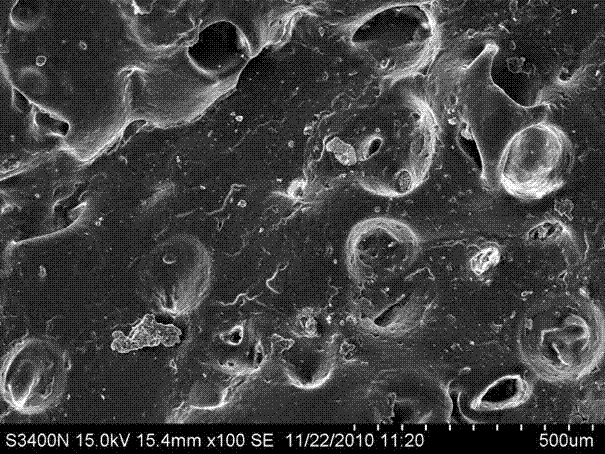

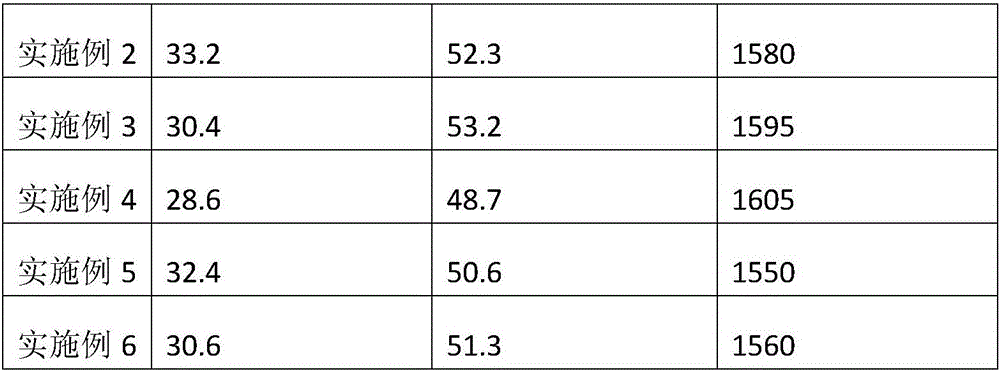

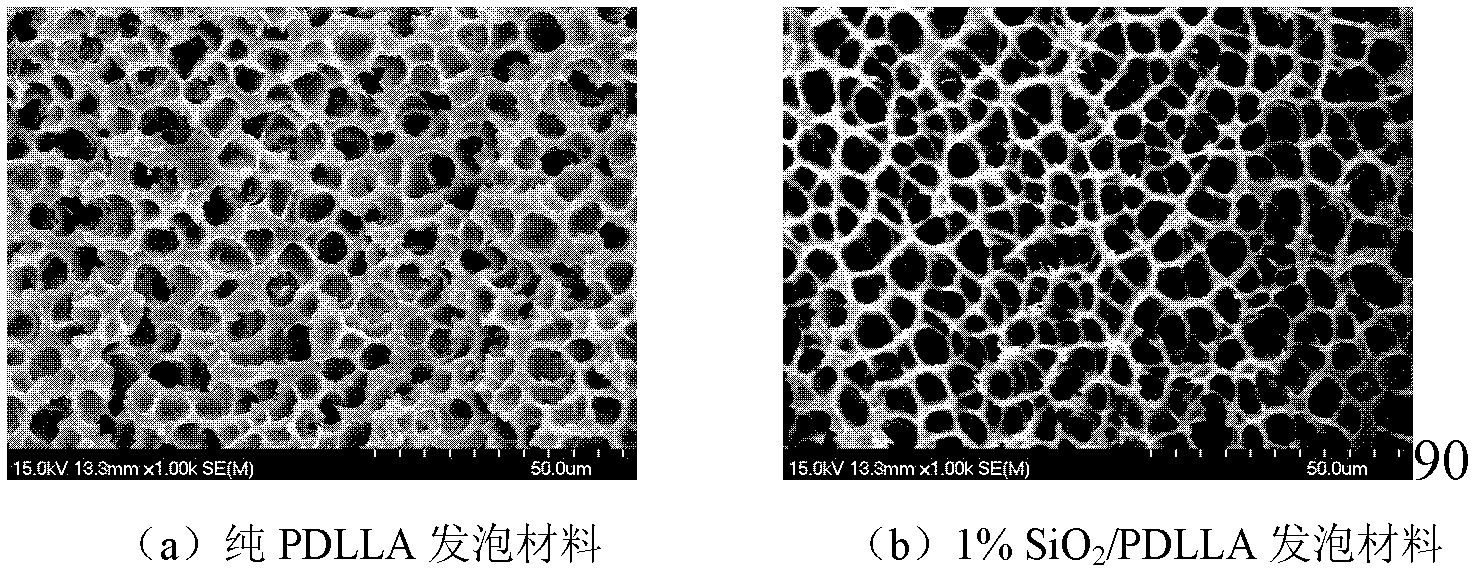

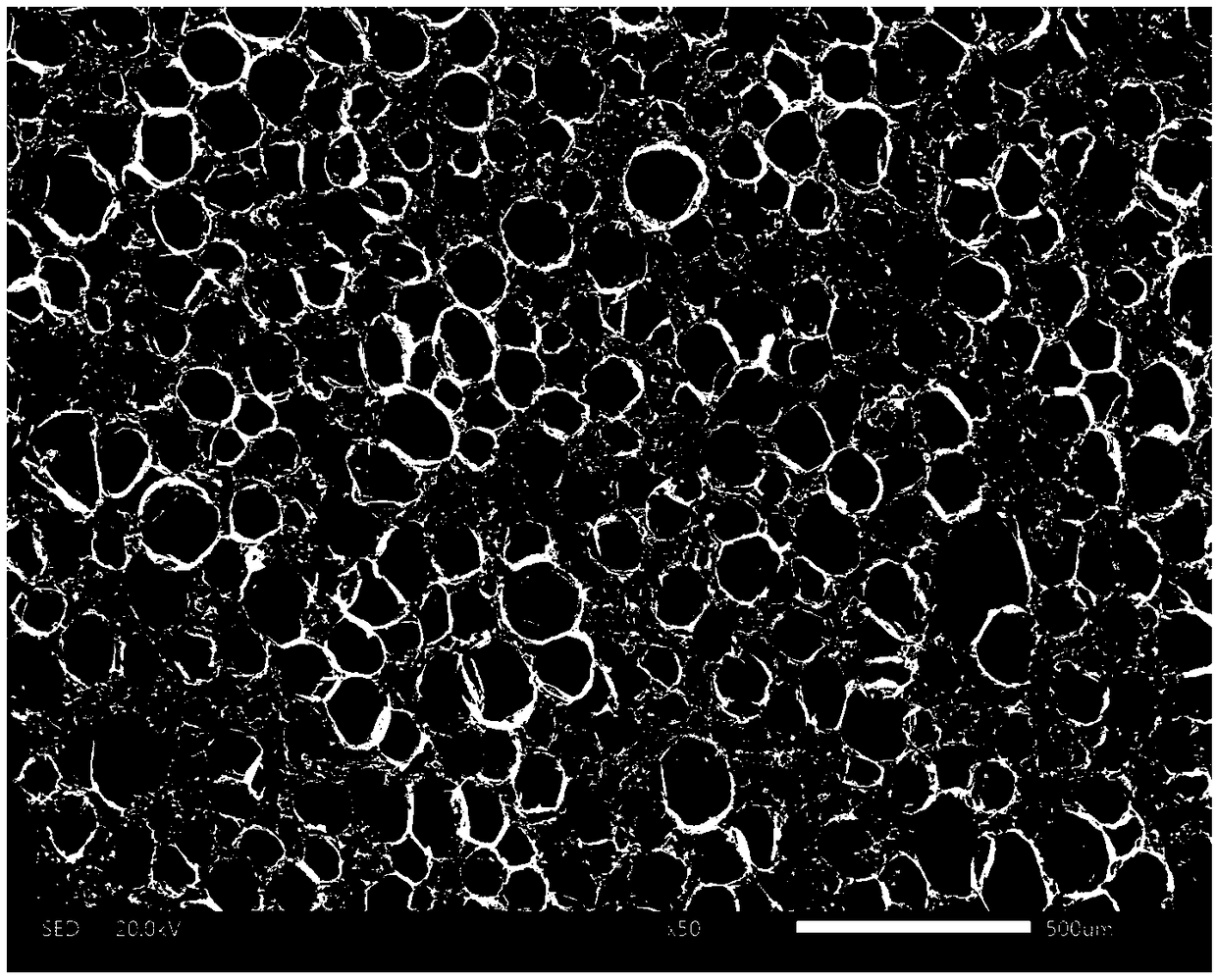

Method for preparing meso-porous silica/polylactic acid foamed material by supercritical CO2 foaming

The invention discloses a method for preparing a meso-porous silica / polylactic acid foamed material by supercritical CO2 foaming, and the method prepares a polylactic acid foamed material by using meso-porous silica as a nucleating agent; the foaming process is simple; foams of the obtained foamed material have a uniform foam size and high density.

Owner:弗润德力新材料宁夏股份有限公司

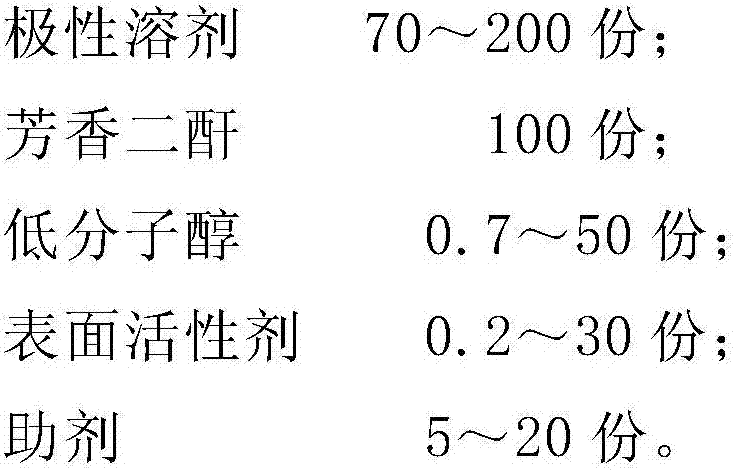

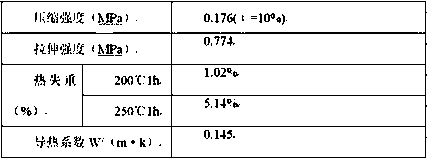

Lightweight sound-absorption heat-insulation polyimide foamed material, and preparation method thereof

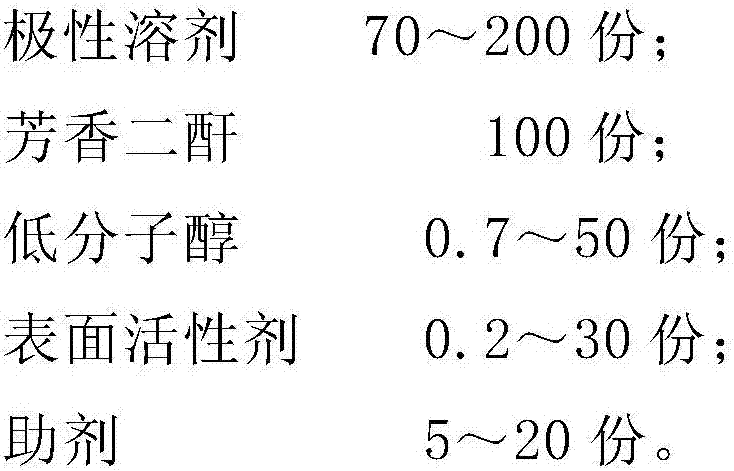

The invention discloses a lightweight sound-absorption heat-insulation polyimide foamed material, and a preparation method thereof. The preparation method comprises following steps: an aromatic dianhydride, a low molecular alcohol, a surfactant, and an auxiliary agent are mixed at a certain ratio, and are reacted in a polar solvent so as to obtain a foam precursor solution; the foam precursor solution is reacted with isocyanate in a mould, and semi-free foaming is carried out so as to obtain a foam intermediate; microwave radiation treatment, and heating curing in an aging oven are carried outso as to obtain the lightweight sound-absorption heat-insulation polyimide foamed material. The preparation route is short; the preparation method is simple; the foam precursor solution is low in viscosity and high in stability, is suitable for casting and extrusion process; the foaming process is simple, and is convenient to control; defects such as cracking, collapsing, nonuniformity, and incomplete material imidization are avoided; the obtained lightweight sound-absorption heat-insulation polyimide foamed material is high in stability and strength, is low in density, possesses excellent sound absorption and heat insulation performance, and can be widely used in fields such as aerospace, ship, automobile, refrigeration house, and other special application fields.

Owner:康达新材料(集团)股份有限公司

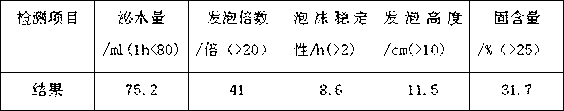

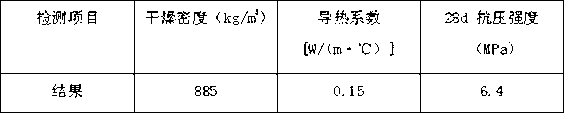

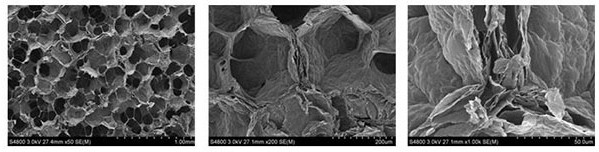

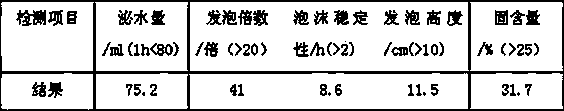

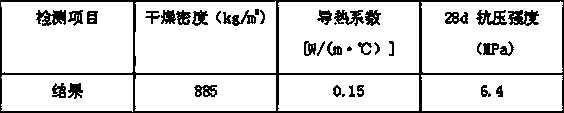

Egg yolk cement foaming agent and lightweight foaming cement concrete thereof

The invention discloses a yolk cement concrete foamer and light-weight foaming cement concrete, which comprises the following steps: 1) blending cement, ceramic micro-powder and water evenly according to certain quality; making cement concrete slurry; 2) blending yolk, stabilizer, disperser, conservative and water according to certain weight rate; forming even compact seal-pore foam; weighing certain bulk of foam to add into the cement concrete slurry; stirring evenly; casting; mounding; curing.

Owner:寿延

Inorganic filler modified polyurethane foam material and preparation method thereof

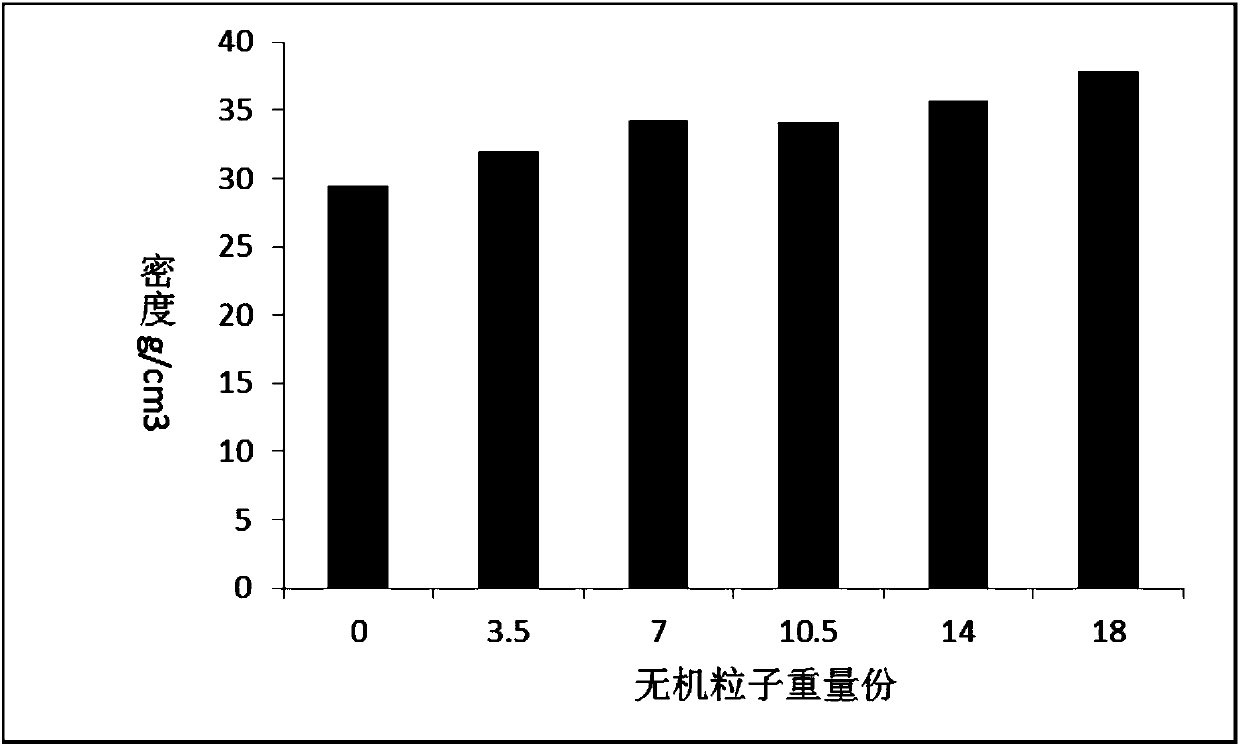

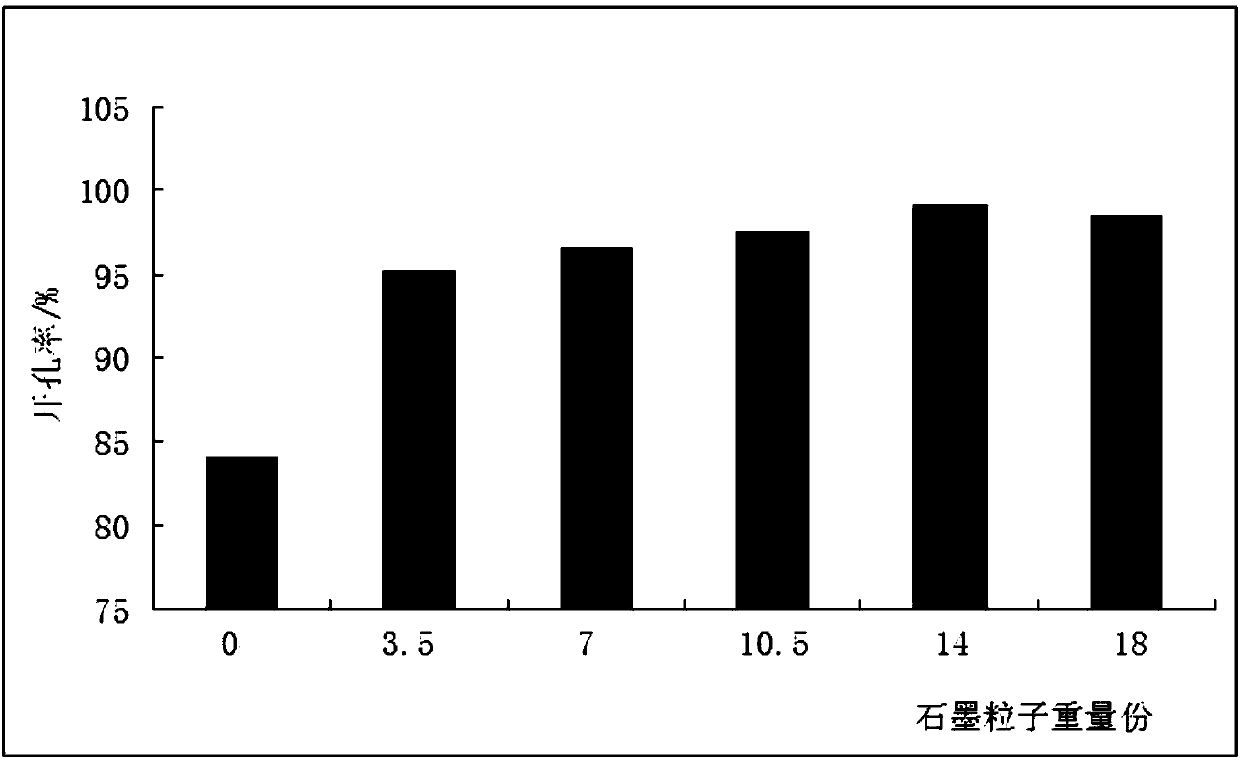

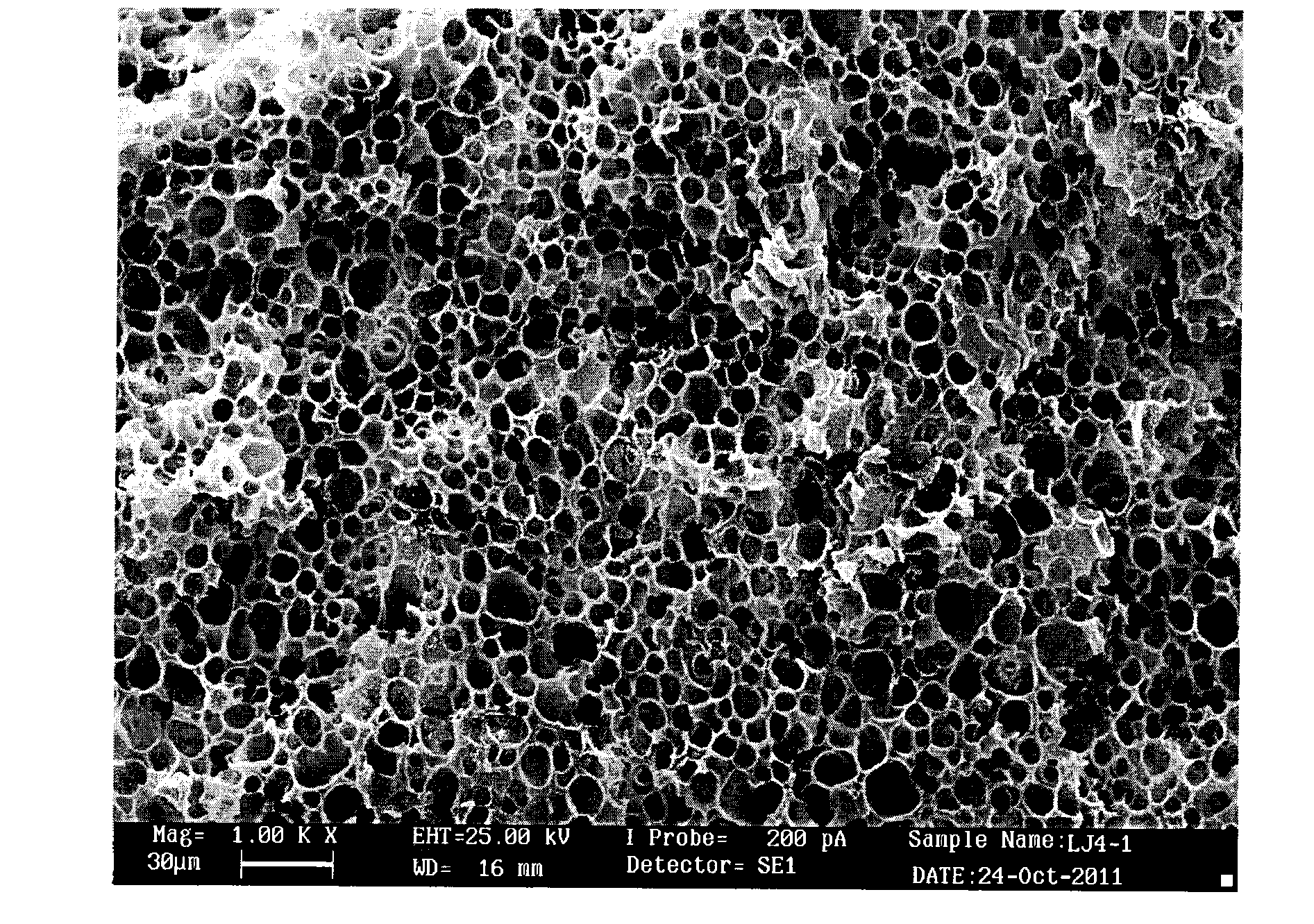

InactiveCN107722230AImprove adsorption capacityImprove mechanical propertiesInorganic particleAlcohol

The invention provides an inorganic filler modified polyurethane foam material and a preparation method thereof, and belongs to the field of macromolecular foam materials. The inorganic filler modified polyurethane foam material is prepared from polyhydric alcohols, deionized water, catalysts, surface active agents, inorganic particles and isocyanate compounds. The preparation method comprises thefollowing steps that 1, polyhydric alcohols and isocyanate are preheated separately; 2, polyhydric alcohols, deionized water, catalysts, surface active agents and inorganic particles are mixed proportionally to be uniform; 3, the mixture is stirred with isocyanate compounds at high speed; 4, free foaming is performed, and the inorganic filler modified polyurethane foam material is obtained. The inorganic filler modified polyurethane foam material adopts deionized water as the foaming agent, is environmentally friendly, due to the high opening rate of polyurethane foams, a channel can be provided for sewage flowing, the adhesion property of microorganisms can be improved due to biocompatibility of filler, and the material has the advantages that the method is simple, the cost is low and the requirement for equipment is low.

Owner:BEIJING DRAINAGE TECH CO LTD

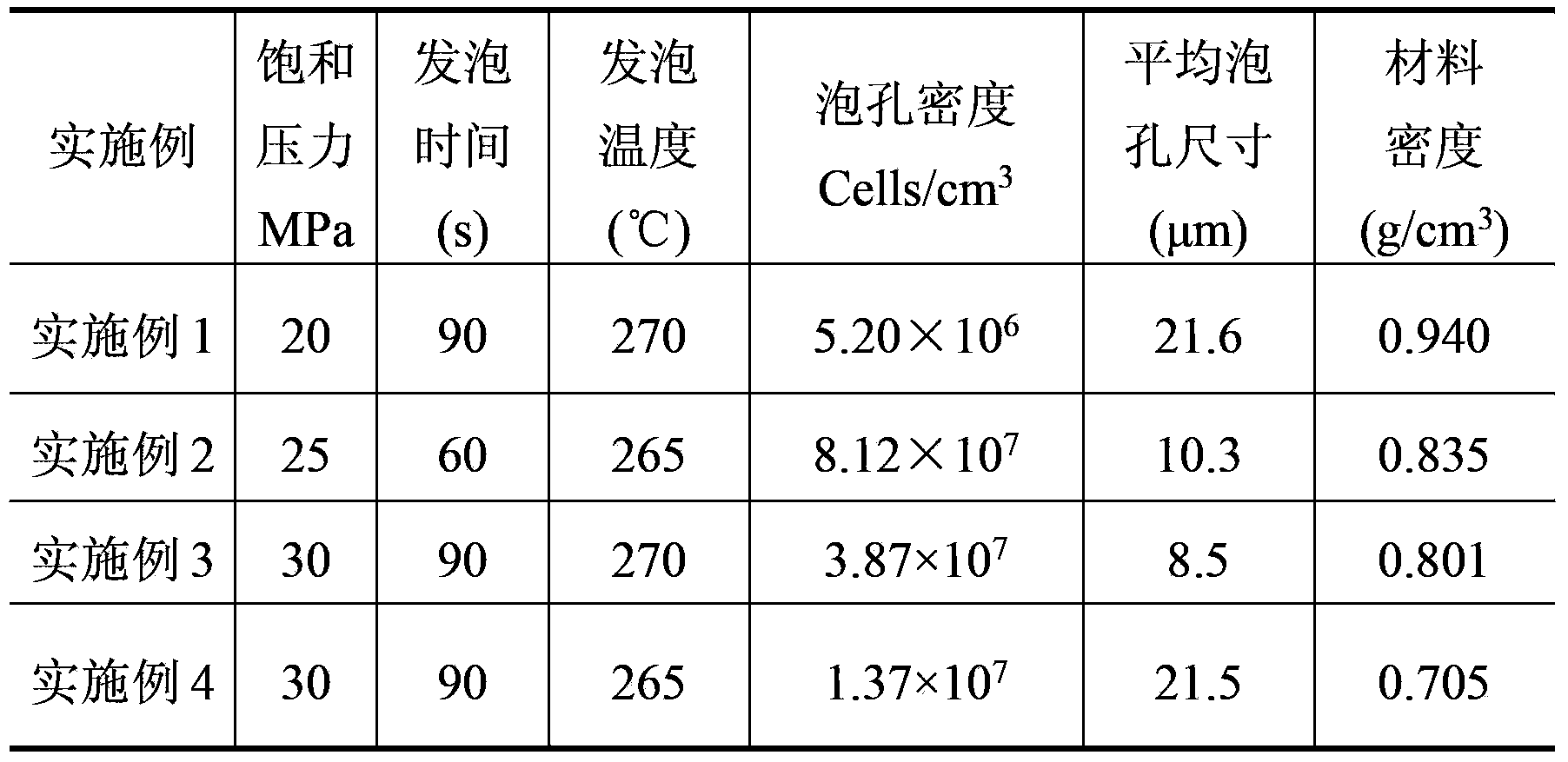

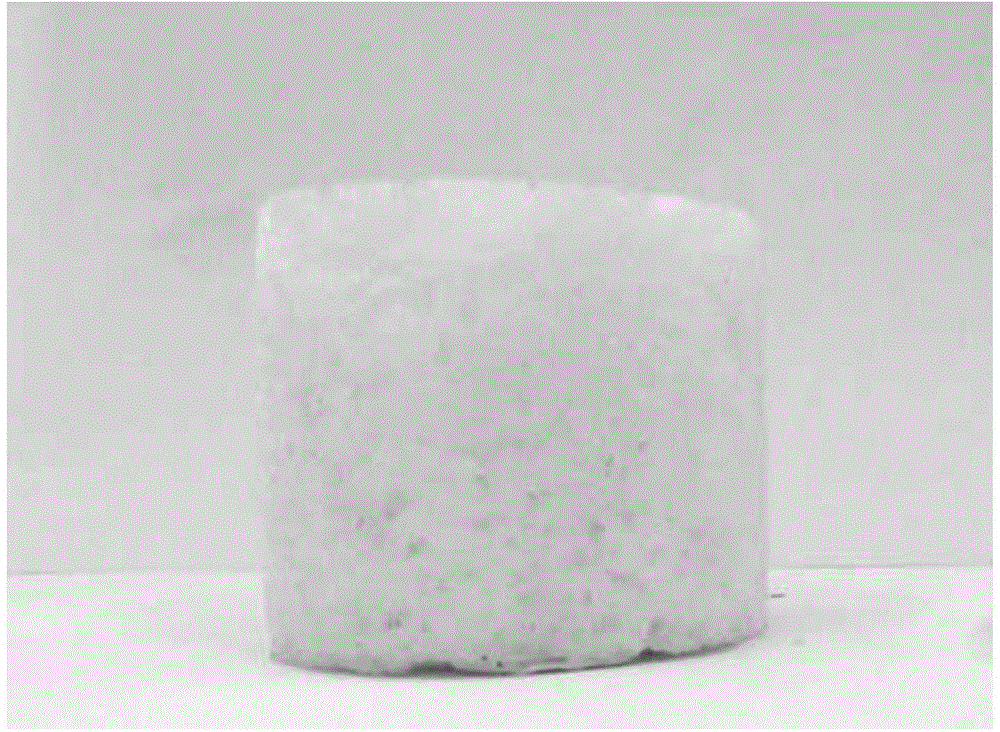

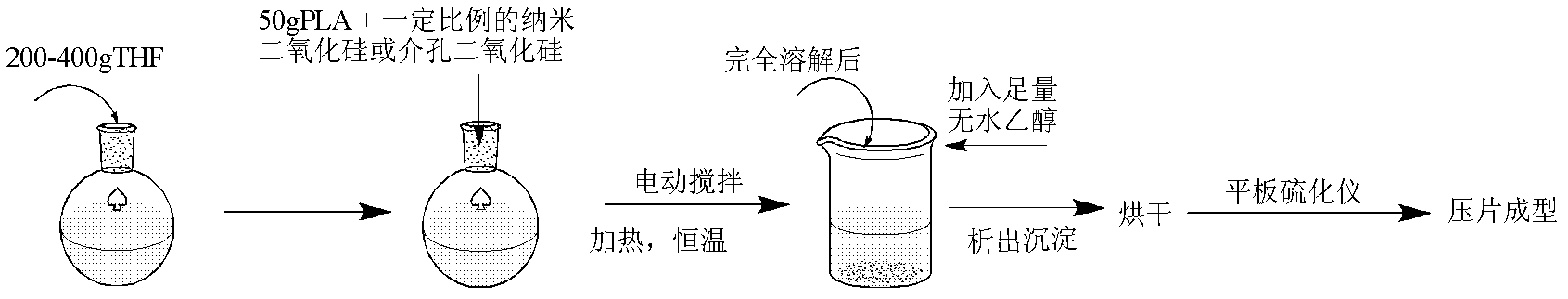

Supercritical CO2 micro-foaming polylactic acid/wood-flour composite material and preparation method thereof

The invention provides a supercritical CO2 micro-foaming polylactic acid / wood-flour composite material and a preparation method of the supercritical CO2 micro-foaming polylactic acid / wood-flour composite material, and relates to a micro-foaming composite material and a preparation method of the micro-foaming composite material, solving the problems of common wood-plastic composite material that the density is high, the impact strength is low, and the resulting waste is easy to pollute the environment. The preparation method comprises the following steps: getting raw materials such as polylactic acid, wood flour, a coupling agent, a toughening agent and a lubricant; mixing the raw materials in a high-speed mixer based on a certain ratio; melting and blending by a two-roll mill; preparing a sample by compression molding; then swelling the sample by adopting the supercritical carbon dioxide as the foaming agent; and finally quickly releasing the pressure, thus obtaining the micro-foaming polylactic acid / wood-flour composite material. The supercritical CO2 micro-foaming polylactic acid / wood-flour composite material has the advantages that the temperature for foaming is low, the pressure is held within a short time, a cellular structure is easy to control, and the prepared micropore composite material is small in aperture and high in cellular density; and the supercritical CO2 micro-foaming polylactic acid / wood-flour composite material is a green and environment-friendly foaming material with good performance.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Modified soy protein foaming agent for concrete

The invention discloses a modified soy protein foaming agent for concrete. The foaming agent consists of the following raw materials, by weight: 10-15 parts of a modified soy protein powder, 1-5 parts of hexadecyl trimethyl ammonium bromide, 1-5 parts of sodium dodecyl benzene sulfonate, 1-3 parts of rhamnolipid, 1-5 parts of Arabia gum, 1-5 parts of carrageenan, 0.1-1 part of hydrogen peroxide, 0.05-0.2 part of protease solution and 100-150 parts of water. The modified soy protein foaming agent for concrete provided by the invention can effectively improve the foaming capacity, foam stability, concrete compatibility, and various performances of the foam concrete, and provide technical support for preparation of novel wall material. The invention has advantages of simple product preparation process, low production cost, simple foaming process, high foaming rate of the foaming agent and good foam stability.

Owner:安徽艾柯泡塑股份有限公司

Method for preparing polyetherketone foaming material by using supercritical CO2

The invention discloses a method for preparing a polyetherketone foaming material by using supercritical CO2. The method specifically comprises: taking fluid CO2 in supercritical state as a physical foaming agent to perform physical foaming on polyetherketone, saturating a polyetherketone sheet material in an autoclave, and realizing foaming on the saturated polyetherketone sheet material in high-temperature oil bath to obtain a closed-cell foamed material with uniform cell distribution, wherein the cell size can be changed through the technological conditions. By taking polyetherketone as the raw material and using the green environment-friendly foaming method, the obtained high-temperature resistant polymer is not only guaranteed in the original excellent performances, but also substantially reduced in production cost, and is a foaming material with a wide application prospect.

Owner:大连疆宇新材料科技有限公司

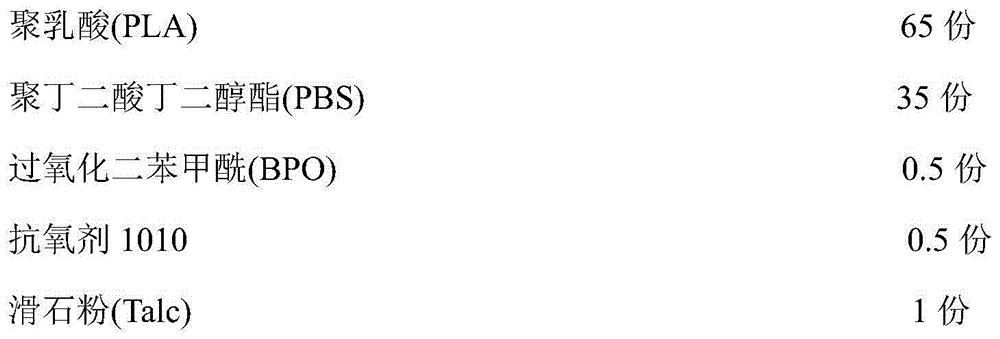

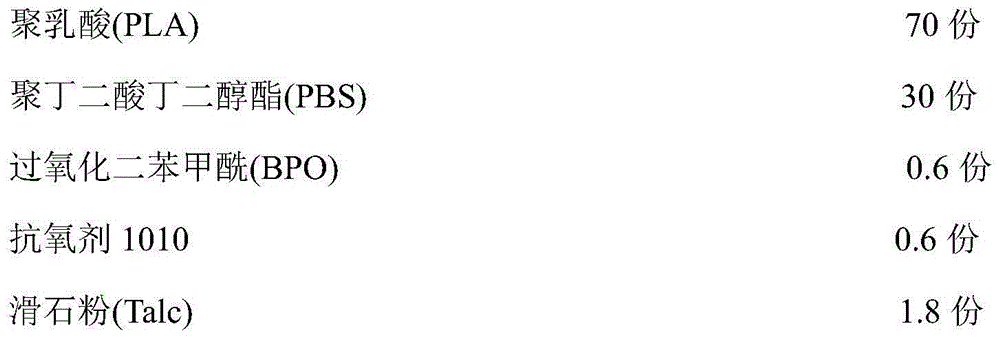

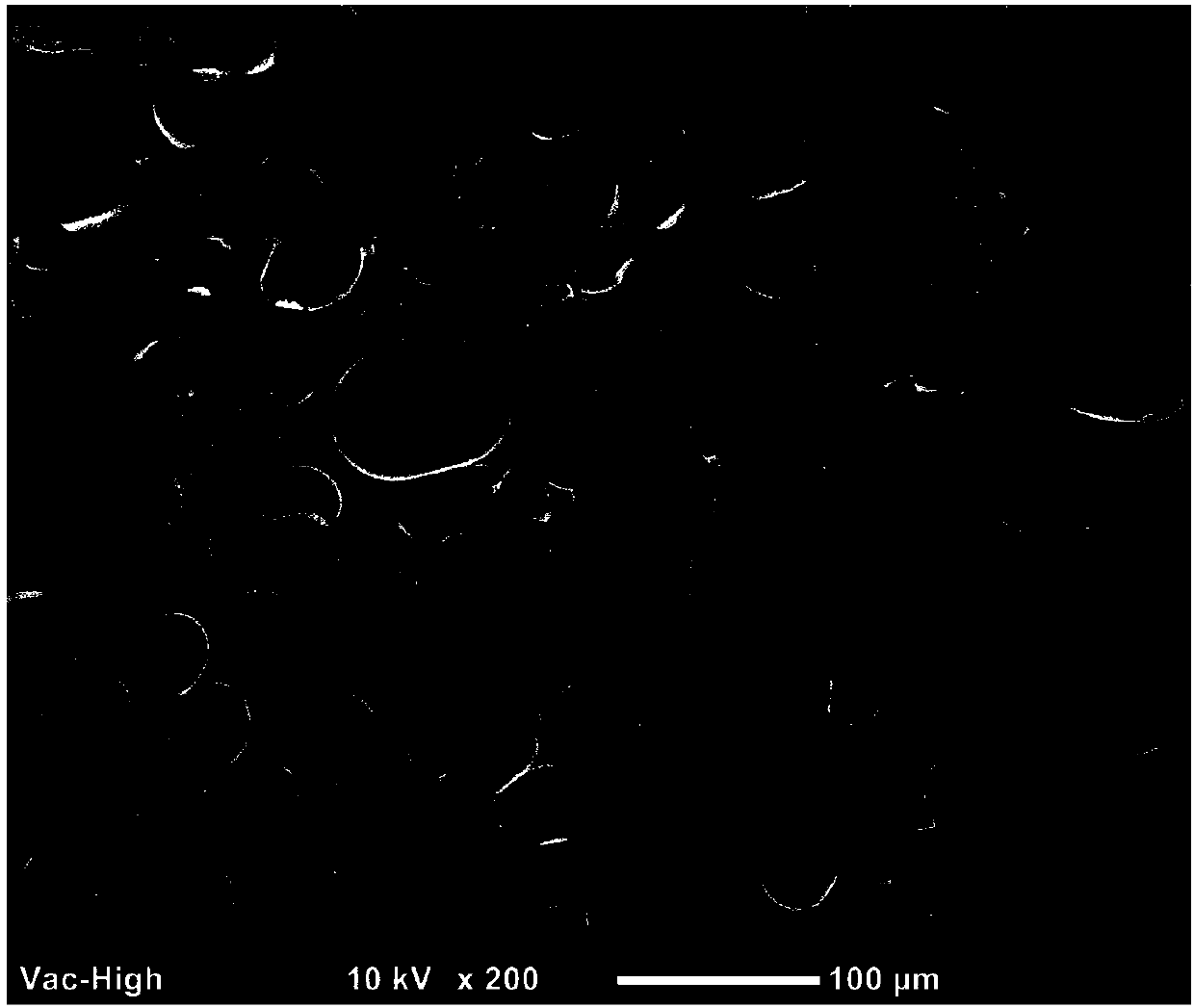

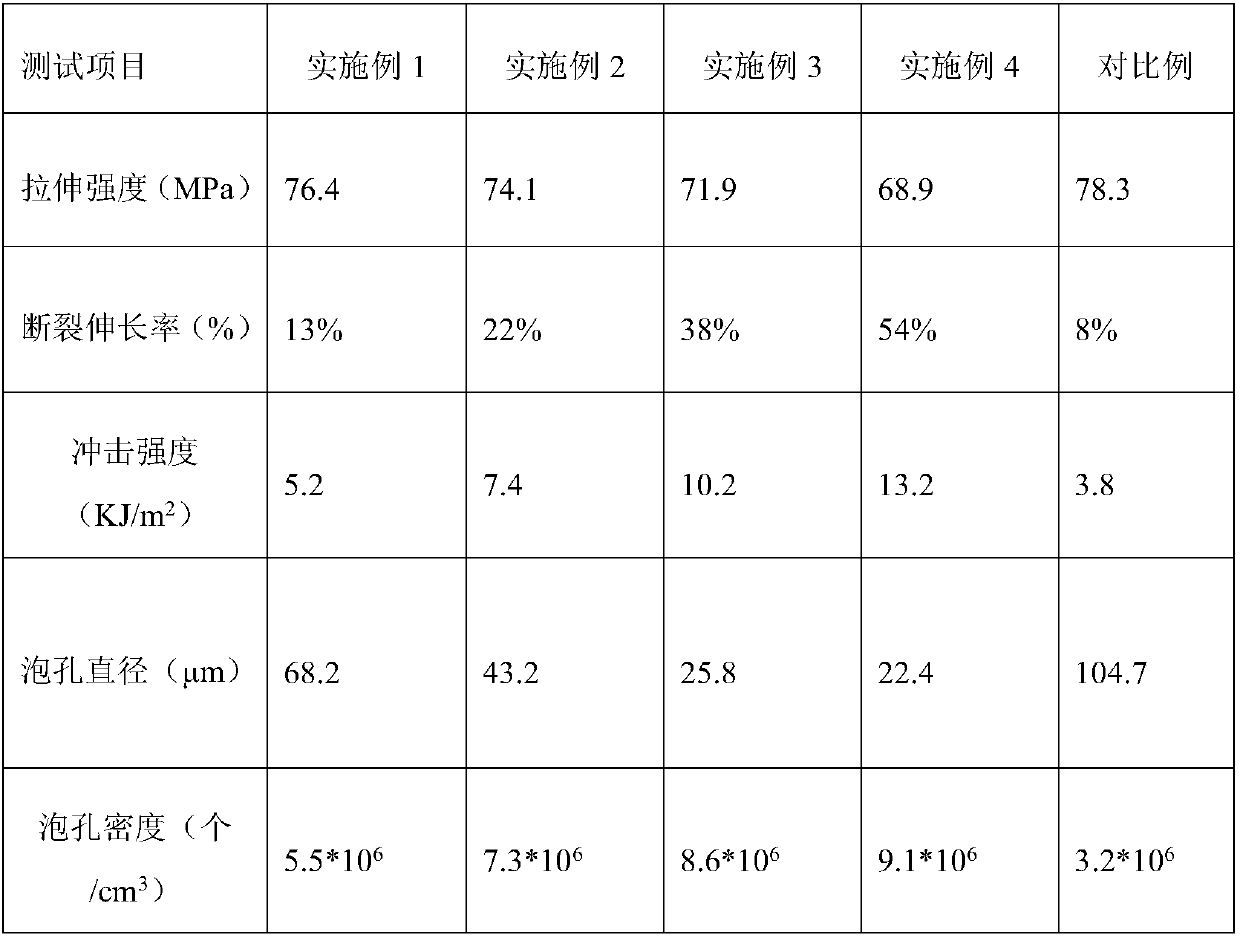

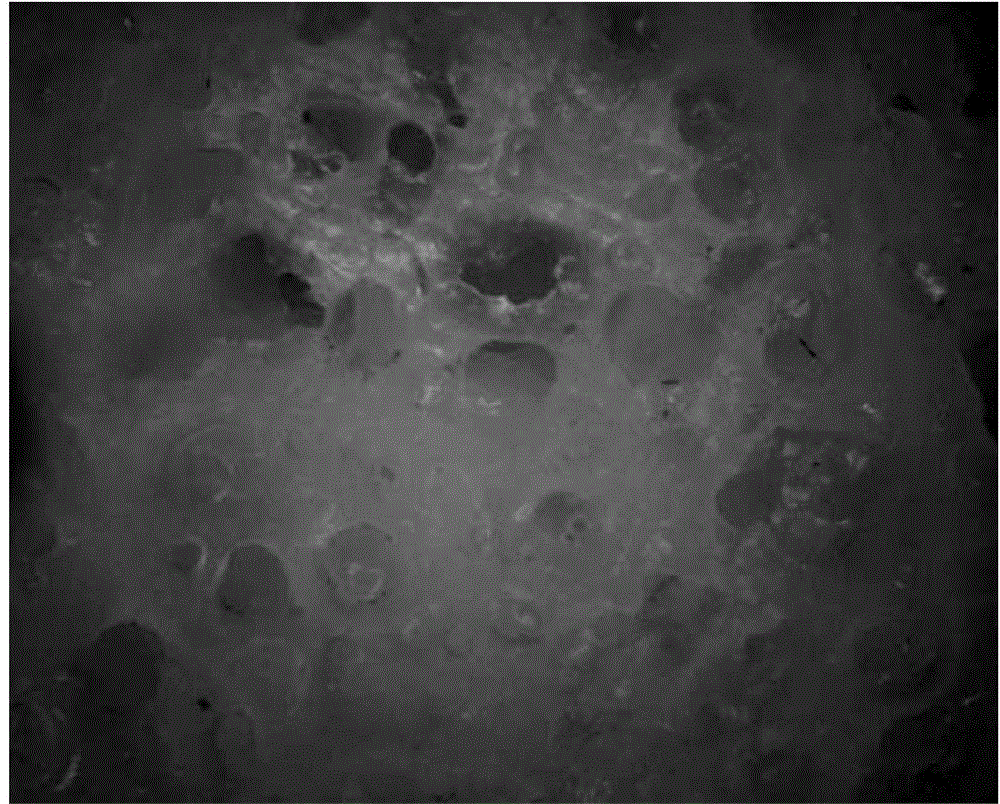

Micro-foamed plylactic acid material and preparation method thereof

The invention discloses a micro-foamed plylactic acid material and a preparation method thereof. The disadvantages of high application cost, poor toughness, small quantity of molecular branched chains, unstable processing, easy molecular chain fracture, low melt viscosity and strength, and unfavourable foaming molding of polylactic acid are overcome in the invention. The method comprises the following steps: preparing a dibenzoyl peroxide tackified polydactyl acid / poly(butylene succinate) composite material through a melt blending technology, preparing a sample through compression molding, swelling the sample with supercritical carbon dioxide as a foaming agent, and rapidly releasing pressure to obtain the micro-foamed plylactic acid material. The preparation method has the advantages of low temperature foaming, high speed pressure relief, simple foaming process and short time, and the micro-foamed plylactic acid material prepared in the invention has the advantages of uniform cell dimension, large cell density and small material density.

Owner:常州龙骏天纯环保科技有限公司 +1

Method and material for preparing polylactic acid-natural rubber porous material by micropore injection molding foaming

The invention belongs to the technical field of micropore injection molding foaming, and discloses a method and a material for preparing a polylactic acid-natural rubber porous material by micropore injection molding foaming. Grafts are prepared through emulsion polymerization; dried polylactic acid particles and glycidyl methacrylate-natural rubber grafts are mixed in proportion, and are molten and mixed by adopting a double-screw extruder for extrusion and granulation; the micropore injection molding foaming is performed on the mixed particles by adopting an injection molding machine with agas compression unit; and with a supercritical CO2 fluid as a foaming agent, a polylactic acid / natural rubber porous material is obtained. Polylactic acid is roughened and modified by adopting naturalrubber; and the method of grafting glycidyl methacrylate on the natural rubber is used for improving polarity of the natural rubber and compatibility with the polylactic acid. The foaming process issimple; the obtained foaming material is more uniform in bubble size and distribution; and meanwhile, the foaming material is better in toughness.

Owner:贵州黔城黔测检测技术有限公司

Preparation method and driving method of shape-memory polycaprolactone foam

The invention relates to a preparation method and a driving method of shape-memory polycaprolactone foam. The invention relates to the field of functional polymer materials, in particular to the preparation method and the driving method of the shape-memory polycaprolactone foam. The invention is intended to solve the problems of complex process, low production efficiency, high cost and uneasy control existing in conventional preparation methods. The preparation method includes the following steps: (1) polycaprolactone is dissolved into dichloromethane, stirring is performed at room temperature until the polycaprolactone is dissolved completely, benzamide peroxide is then added, stirring is performed at room temperature until the benzamide peroxide is dispersed uniformly, and thereby polycaprolactone solution is obtained; (2) the polycaprolactone solution obtained in step 1 is poured into a mold, and is then put into a microwave oven to be heated, and thereby the shape-memory polycaprolactone foam is obtained. The driving method is as follows: under the condition of microwave heating, the shape-memory polycaprolactone foam can be restored to an initial shape within 98s.

Owner:HARBIN INST OF TECH

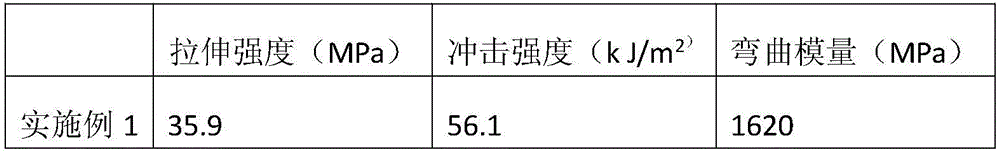

Homo-polypropylene/carbon fiber/montmorillonite composite material and preparation method thereof

The invention relates to a homo-polypropylene / carbon fiber / montmorillonite composite material and a preparation method of the homo-polypropylene / carbon fiber / montmorillonite composite material. The homo-polypropylene / carbon fiber / montmorillonite composite material is prepared from the following raw materials in parts by weight: 85 to 95 parts of homo-polypropylene, 5 to 10 parts of carbon fibers, 2 to 3 parts of organic montmorillonite, and 3 to 5 parts of foaming masterbatches, the foaming masterbatches are prepared from the following raw materials in parts by weight: 60 to 70 parts of polyethylene, 20 to 30 parts of foaming agents, 1 to 3 parts of foam stabilizers, 3 to 5 parts of nucleating agents, 0.5 to 1.5 parts of zinc oxide, 0.5 to 1 part of a titanate coupling agent NDZ-201, 3 to 5 parts of PE wax and 0.5 to 1 part of zinc stearate. According to the homo-polypropylene / carbon fiber / montmorillonite composite material disclosed by the invention, the mechanical properties are excellent, the tensile strength reaches 36.9 MPa, the impact strength reaches 55.1 kJ / m<2>, and the flexural modulus reaches 1590 MPa. The foaming material has best foaming and biggest cell density, the cell density reaches 2.3*10<7> / cm3, and the porosity of the foaming material is 17.7%.

Owner:GUANGZHOU JUZHU GENERAL TECH INST CO LTD

Production method of polyether ketone and modified nano silicon dioxide foaming materials and by supercritical carbon dioxide

The invention discloses a production method of polyether ketone and modified nano silicon dioxide foaming materials and by supercritical carbon dioxide. The production method comprises the following steps of enabling fluid carbon dioxide in the supercritical state to be utilized as physical foaming agents and modified nano silicon dioxide to be utilized as nucleating agents to perform physical foaming on polyether ketone; enabling polyether ketone and modified nano silicon dioxide sheets to be saturated in an autoclave; achieving foaming of the saturated polyether ketone sheets in a high temperature oil bath to obtain closed-cell foaming materials with uniformly distributed foaming cells, wherein the size of the foaming cells can change through process conditions. According to the production method of the polyether ketone and modified nano silicon dioxide foaming materials and by the supercritical carbon dioxide, the polyether ketone is utilized as raw materials and the green and environment-friendly foaming method is utilized to obtain high temperature resistant polymers, so that the original excellent performance is guaranteed, the production cost is greatly reduced, and accordingly the polyether ketone and modified nano silicon dioxide foaming materials are wide in application prospect.

Owner:大连疆宇新材料科技有限公司

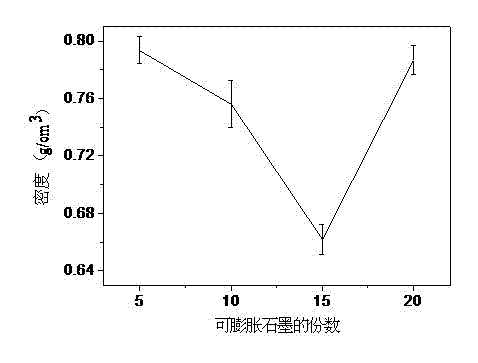

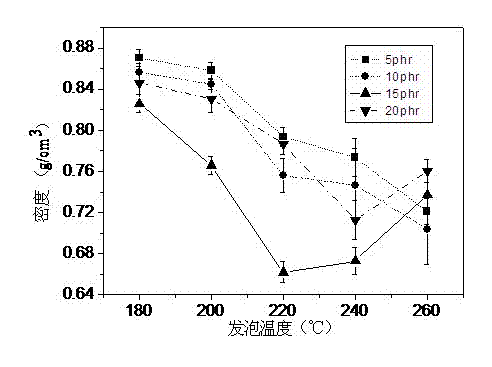

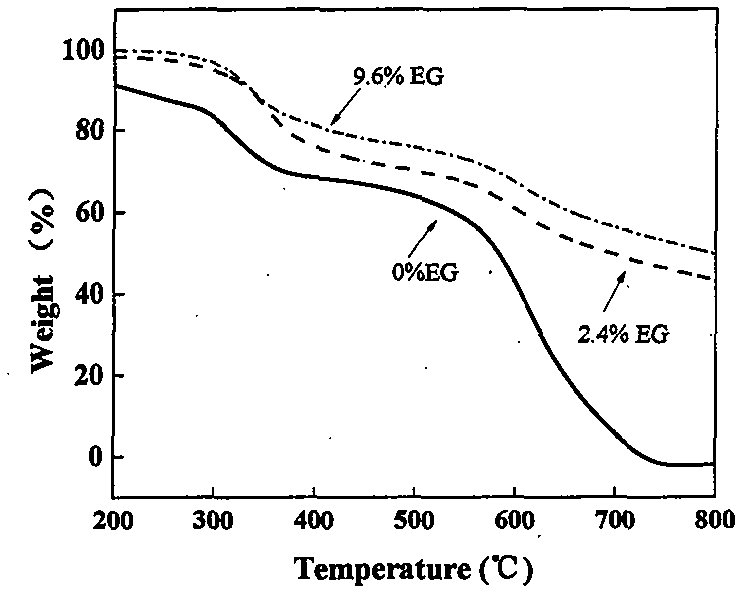

Preparation method of low temperature expandable graphite/polymer foam material

InactiveCN102286159ADoes not affect foamabilityThe foaming process is simplePolymer scienceFoaming agent

The invention discloses a method for preparing a low-temperature expandable graphite / polymer foam material. The preparation method is as follows: after the polymer and the low-temperature expandable graphite are fully dried, they are mixed according to a certain ratio to obtain an expandable polymer; Bubbles can generate foamable polymers; the present invention uses low-temperature expandable graphite as a foaming agent; the cost is low, and after being prepared into foamable polymers, it can be placed for a long time before foaming operations and still have expandable properties. bubble performance.

Owner:GUANGDONG UNIV OF TECH

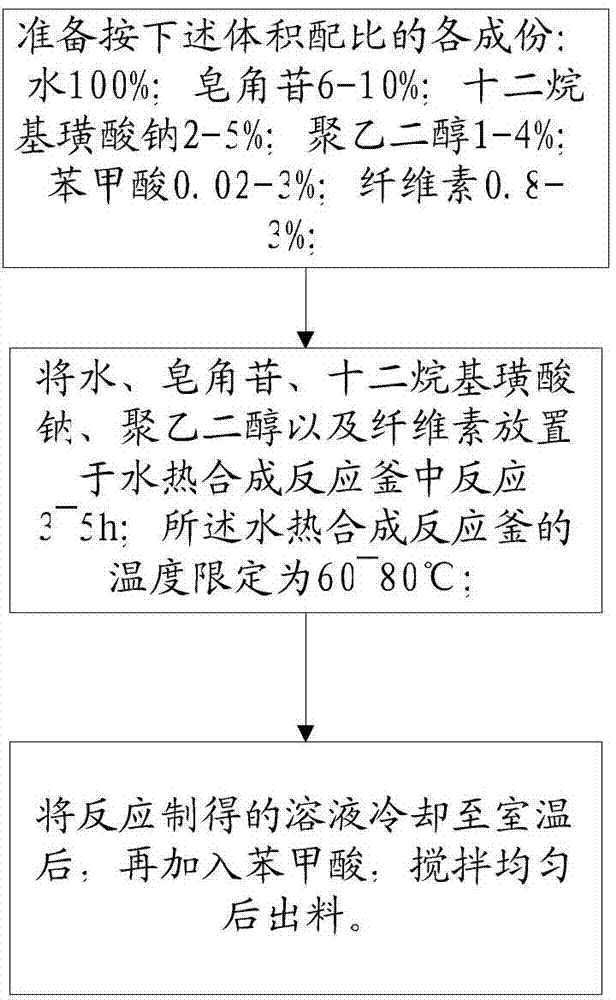

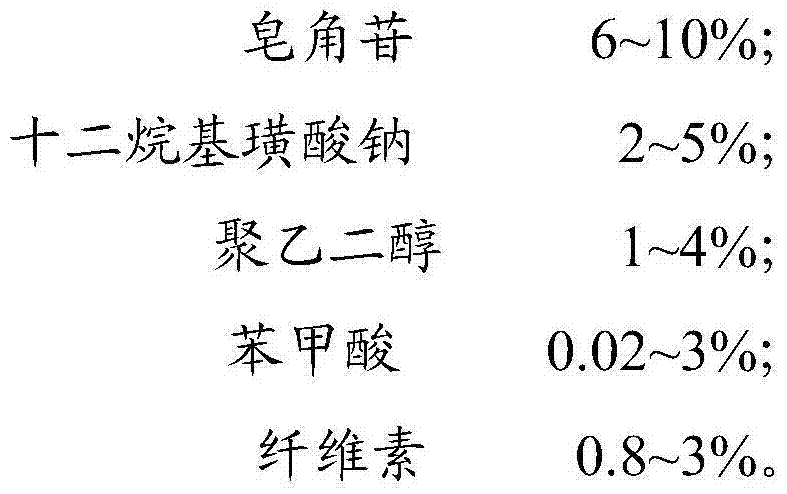

Foam concrete foaming agent and preparation method thereof

The invention provides a foam concrete foaming agent which comprises the following raw materials in percentage by weight: 100% of water, 6%-10% of saponin, 2%-5% of sodium dodecyl sulfate, 1%-4% of polyethylene glycol, 0.02%-3% of benzoic acid and 0.8%-3% of cellulose. The invention further provides a preparation method of the foam concrete foaming agent. The surfactants, namely the sodium dodecyl sulfate and the polyethylene glycol are adopted, so that a foaming effect of the foaming agent is uniform and can be further improved; moreover, the benzoic acid is capable of effectively overcoming the shortcoming of easiness in mildewing of the foaming agent and prolonging the storage cycle of the foaming agent.

Owner:FUJIAN CONSTR ENG GRP BUILDING MATERIAL SCI & TECH DEV

Polypropylene microcellular foam composite material and preparation method thereof

The invention relates to a polypropylene microcellular foam composite material and a preparation method thereof. The polypropylene microcellular foam composite material is prepared from, by weight, 85-95 parts of polypropylene, 5-10 parts of carbon fibers and 3-5 parts of foaming masterbatch, wherein the foam masterbatch is prepared from, by weight, 60-70 parts of polyethylene, 20-30 parts of a foaming agent, 3-5parts of a nucleating agent, 0.5-1.5 parts of zinc oxide, 0.5-1 part of a titanate coupling agent NDZ-201, 3-5 parts of PE wax and 0.5-1 part of zinc stearate. According to the polypropylene microcellular foam composite material prepared through the method, the mechanical property is superior, the tensile strength reaches 35.9 MPa, the impact strength reaches 56.1 kJ / m<2>, and the bending modulus reaches 1,620 MPa.

Owner:GUANGZHOU JUZHU GENERAL TECH INST CO LTD

Method for preparing meso-porous silica/polylactic acid foamed material by supercritical CO2 foaming

The invention discloses a method for preparing a meso-porous silica / polylactic acid foamed material by supercritical CO2 foaming, and the method prepares a polylactic acid foamed material by using meso-porous silica as a nucleating agent; the foaming process is simple; foams of the obtained foamed material have a uniform foam size and high density.

Owner:弗润德力新材料宁夏股份有限公司

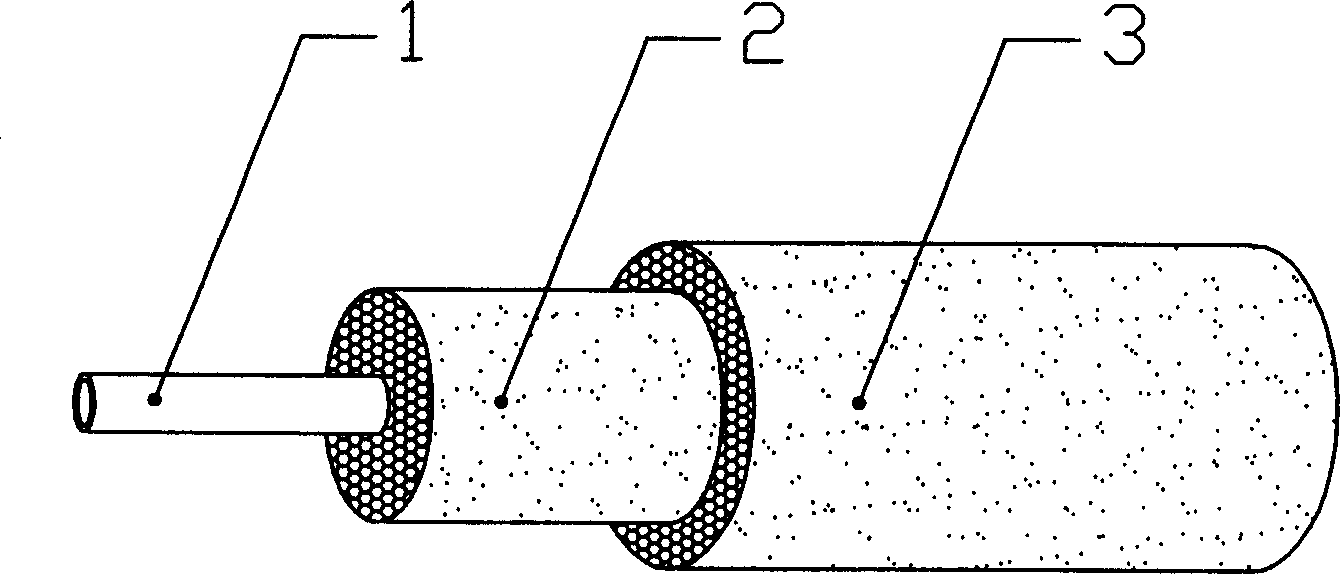

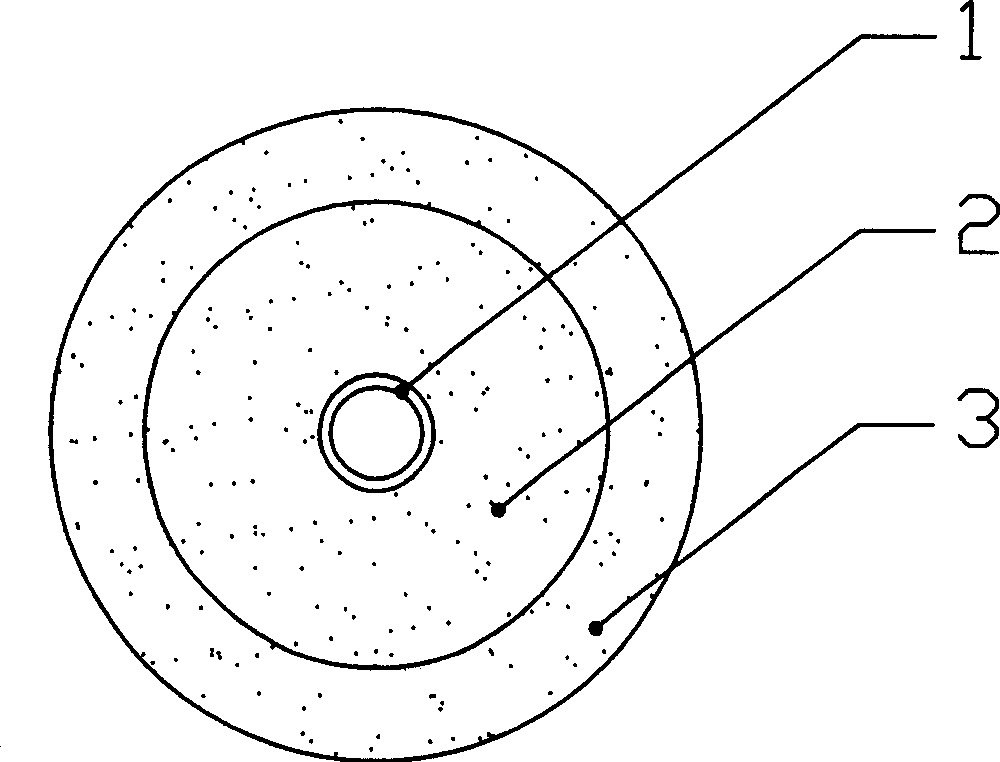

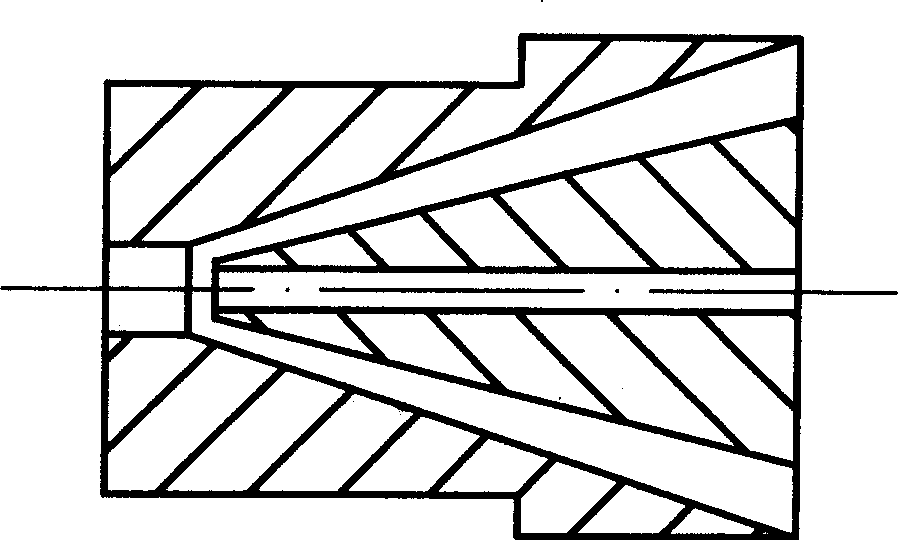

Preparation of signal transmission coaxial cable and physic foaming insulation layer and mould

InactiveCN1822245ARelieve pressureReduce high pressureCoaxial cables/analogue cablesInsulating conductors/cablesCable transmissionUltrasound attenuation

Said invention relates to improvement to signal transmission coaxial cable, featuring cable internal conductor outer physics sparkle insulating layer being secondary extruding composed double layer compound sparkle insulation. Due to adopting secondary physics sparkle extrusion laminating, said invention not only solves inside and outside cooling down misproportion problem and resulted fault of once extruded moulding of thick physics sparkle insulation, greatly raising radial and longitudinal sparkle hole uniformity without bunlla hole and cuniculus. For example the leakance RF coaxial cable sparkle degree can be raised to more than 78 per cent, reducing cable dielectric constant and dielectric loss tangent value, reducing cable transmission attenuation, voltage standing wave ratio less than 1.15 with fine product consistency. Said invented insulation physics sparkle forming method and mould is suitable for signal transmission coaxial cable sparkle insulation with greater than 10 mm sparkle insulation thickness.

Owner:JIANGSU HENGXIN TECH CO LTD

Graphene and epoxy resin composite foam material and preparation method thereof

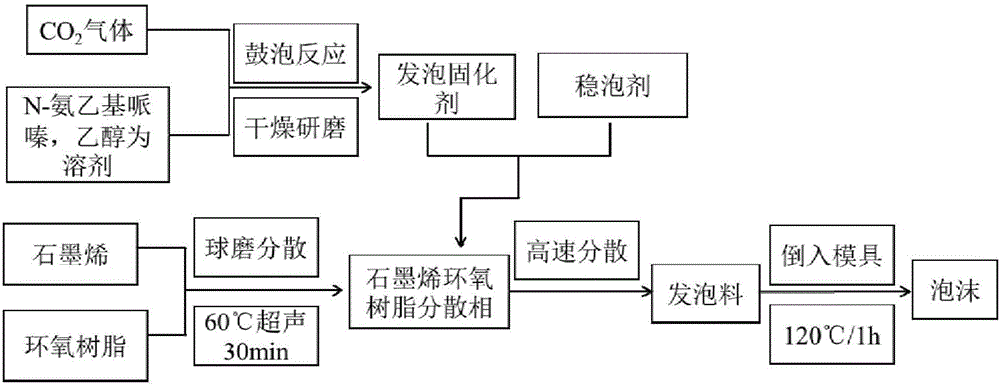

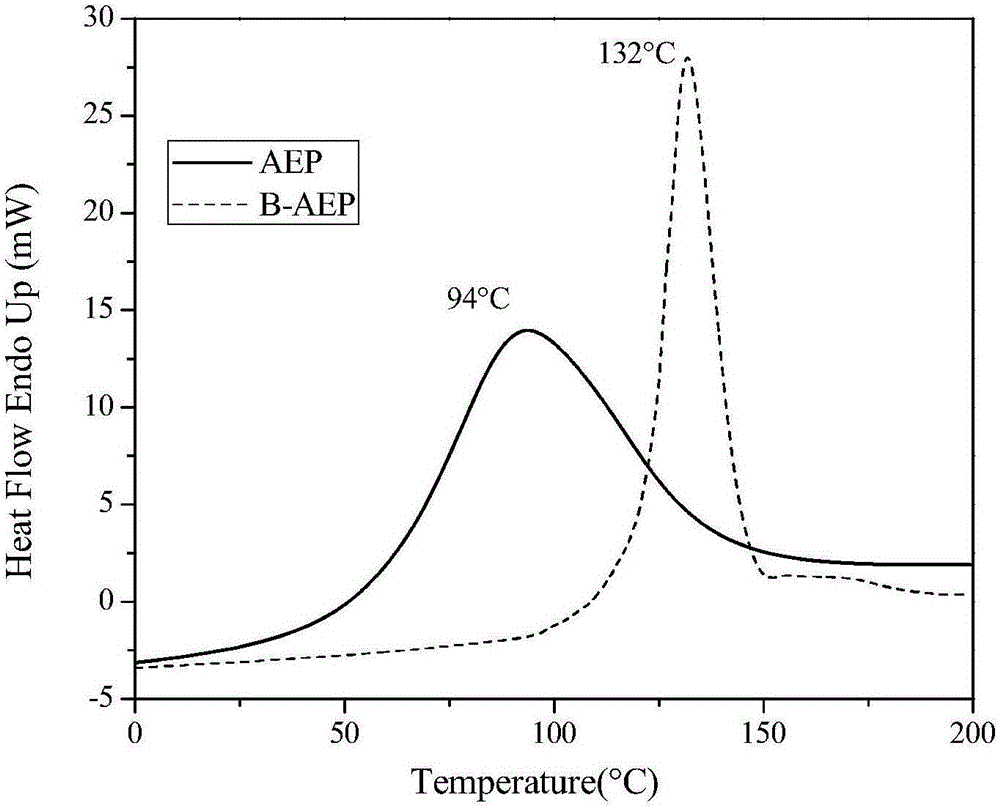

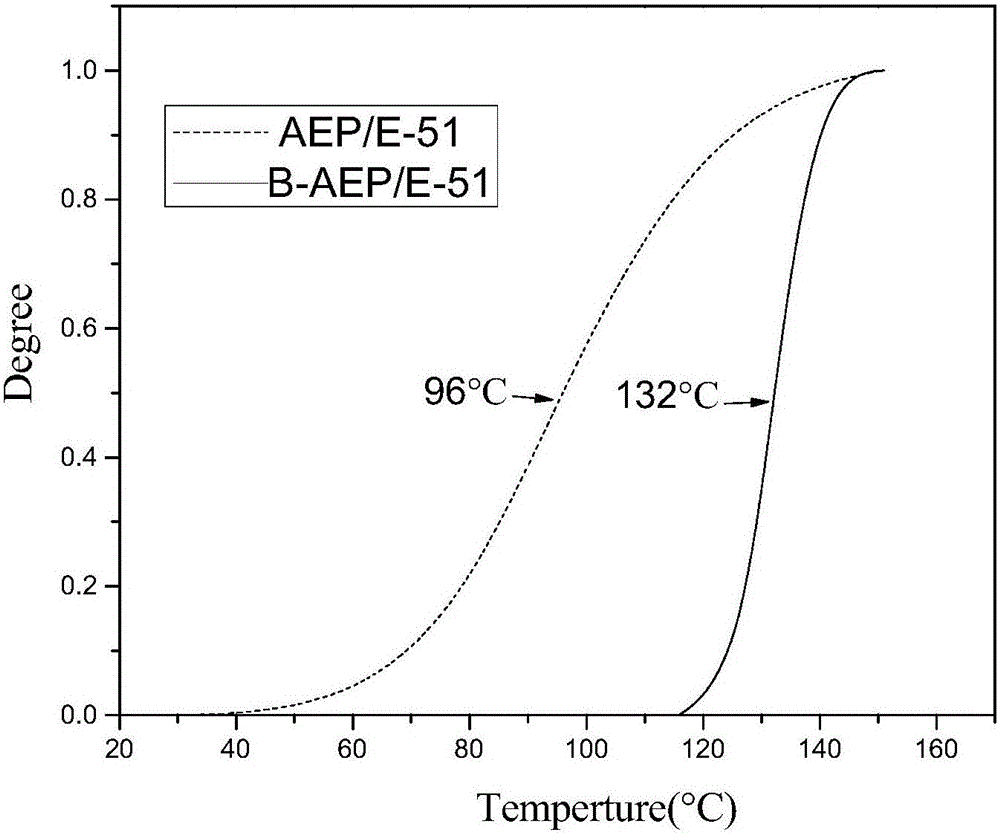

The invention provides an environment-friendly and simple method for preparing graphene and epoxy resin composite foam material by single-component foaming, comprising: allowing N-aminoethylpiperazine (AEP) and CO2 to react to obtain a latent curing-foaming agent (B-AEP); ball-milling epoxy resin and graphene, ultrasonically dispersing at 55-60 DEG C for 30-35 min, cooling to room temperature, adding the curing-foaming agent and a foam stabilizer, stirring to obtain single-component foam, pouring into a preheated mold, and curing at 120-125 DEG C to obtain the graphene and epoxy resin composite foam material. The prepared foam material has excellent storage stability, good foam pore structure, excellent compressibility and good antistatic property.

Owner:滁州斯英铂聚合材料有限公司

Supercritical CO2 micro foamed polylactic acid/wooden powder composite material

The invention discloses a supercritical carbon dioxide micro foamed polylactic acid / wooden powder composite material and a preparation method thereof. The invention relates to a micro foamed compositematerial and a preparation method thereof. In view of the problems of large density and low impact strength of normal wood plastic composite materials, and the environmental problems easily caused byrejected materials thereof and the like, polylactic acid, wooden powder, coupling agent, toughening agent and lubricant are adopted as raw materials of the supercritical carbon dioxide micro foamed polylactic acid / wooden powder composite material. The raw materials are mixed in a high speed mixer according to a certain proportion, melting blending is conducted through a double-roller open mill, compression moulding is conducted to prepare samples, then supercritical carbon dioxide is used as a foaming agent to swell the samples, and finally micro porous polylactic acid / wooden powder compositematerials are acquired by conducting rapid pressure releasing. The material has the advantages that the foaming temperature is low, the holding pressure time is short, the pore structure is easy to control, and the prepared micro porous composite material is small in pore diameter and large in pore density and will be a green environmentally friendly foamed material with excellent performance.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

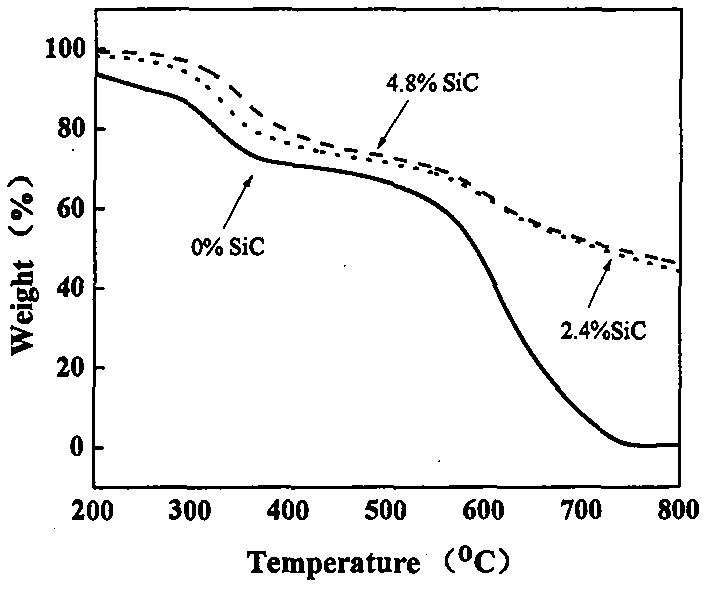

Inorganic-filler-filled high-temperature-resistant foam material and preparation method thereof

InactiveCN109553743AImprove flame retardant and high temperature resistanceOvercome the disadvantages of destroying the ozone layer of the atmosphereTemperature resistanceFire retardant

The invention provides an inorganic-filler-filled high-temperature-resistant foam material and a preparation method thereof, and relates to the field of high-molecular foam materials. The inorganic-filler-filled high-temperature-resistant foam material is prepared from dianhydride, polyol and isocyanate. The preparation method comprises mixing inorganic particles (silicon carbide, expandable graphite, vermiculite, graphene oxide and the like) with a prepolymer for polymerizing, and performing heat treatment at the later stage. According to the method, deionized water is adopted as a foaming agent, the inorganic particles are used as high-temperature-resistant and flame-retardant phases, the obtained foam has high thermal stability and flame retardancy, and the dimensional stability is alsoimproved. The high-temperature-resistant foam material is filled with an inorganic filler, a fluorine-containing foaming agent and a toxic flame retardant are not used, and the foaming process is environment-friendly. Compared with other high-temperature-resistant foam, the deionized water as a foaming agent is environment-friendly, and the inorganic particles are used as a flame retardant are free of harmful gas, and the inorganic-filler-filled high-temperature-resistant foam material good in high temperature resistance, simple in forming method and wide in application and development prospect.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

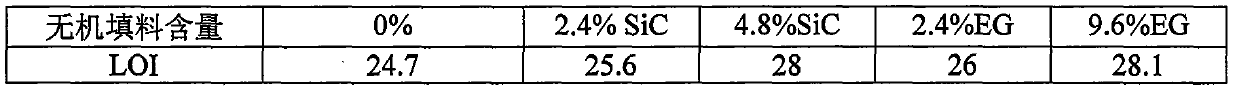

One-time manufacturing method of colorful TPU foamed particles through double-screw equipment

ActiveCN110355970AReduce changes in physical propertiesThe foaming process is simpleCarbon dioxideLeft handed

The invention discloses a one-time manufacturing method of colorful TPU foamed particles through double-screw equipment. The method comprises the following steps of (1) proportioning raw materials comprising, by weight, 100 parts of TPU resin, 2-5 parts of POE-g-MAH and 1-3 parts of organic pigments; (2) conducting stirring and mixing; (3) conducting heating and melting; (4) injecting gas, specifically, arranging left-handed threads in a sixth area of a double-screw and injecting nitrogen or carbon dioxide gas to the sixth area; (5) evenly mixing the gas and the molted materials, specifically,arranging engagement blocks from a sixth area to a ninth area of the double-screw to enable the injected gas, the organic pigments, the TPU resin and the POE-g-MAH The invention be mixed evenly; (6)conducting cooling extrusion; and (7) conducting cooling and shaping. Through the method, the colorful TPU foamed particles are manufactured at a time, the forming process is simplified, and the costis reduced. Physical property changes, caused by repeated heating and processing, to the TPU resin originally are reduced. The method is suitable for mass production. Moreover, the color and forming density of the colorful TPU foamed particles can be adjusted at random. The method has the good promotion and utilization value.

Owner:东莞市元普智造科技有限公司

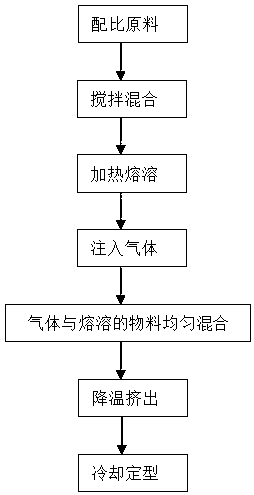

Sound absorption black body foam material and preparation method thereof

ActiveCN112919928AImproved sound absorptionFacilitate large-scale useCeramicwarePolymer sciencePlasticulture

The invention provides a multi-stage foam sound absorption black body material for the first time, graphene aerogel is introduced into a commercialized polymer foam skeleton by using a solvent plasticizing foaming technology, so that ultrathin graphene drums are embedded into the foam skeleton, and when sound waves enter the foam black body, a large number of graphene drums generate a violent resonance effect, so that attenuation of the sound waves is rapidly achieved, and in combination with friction loss of a porous structure of the polymer foam to the sound waves, the sound absorption black body foam material has excellent sound absorption performance in a broadband range. The scheme is based on a commercial foam material, the method is simple, the cost is low, and the potential of wide industrial application is achieved.

Owner:ZHEJIANG UNIV

Modified soy protein foaming agent for concrete

The invention discloses a modified soy protein foaming agent for concrete. The foaming agent consists of the following raw materials, by weight: 10-15 parts of a modified soy protein powder, 1-5 parts of hexadecyl trimethyl ammonium bromide, 1-5 parts of sodium dodecyl benzene sulfonate, 1-3 parts of rhamnolipid, 1-5 parts of Arabia gum, 1-5 parts of carrageenan, 0.1-1 part of hydrogen peroxide, 0.05-0.2 part of protease solution and 100-150 parts of water. The modified soy protein foaming agent for concrete provided by the invention can effectively improve the foaming capacity, foam stability, concrete compatibility, and various performances of the foam concrete, and provide technical support for preparation of novel wall material. The invention has advantages of simple product preparation process, low production cost, simple foaming process, high foaming rate of the foaming agent and good foam stability.

Owner:安徽艾柯泡塑股份有限公司

An egg yolk cement foaming agent and a lightweight foaming cement concrete thereof

The invention discloses a yolk cement concrete foamer and light-weight foaming cement concrete, which comprises the following steps: 1) blending cement, ceramic micro-powder and water evenly according to certain quality; making cement concrete slurry; 2) blending yolk, stabilizer, disperser, conservative and water according to certain weight rate; forming even compact seal-pore foam; weighing certain bulk of foam to add into the cement concrete slurry; stirring evenly; casting; mounding; curing.

Owner:寿延

Expandable silicone rubber sheet and preparation method thereof

The invention discloses an expandable silicone rubber sheet and a preparation method thereof. The expandable silicone rubber sheet is prepared from the following components in parts by weight: 100 parts of silicone rubber, 10 to 30 parts of white carbon black, 100 to 150 parts of filler, 3 to 5 parts of vulcanizing agent, 6 to 10 parts of foaming agent and 3 to 8 parts of hydrogenated silicone oil. The preparation method of the expandable silicone rubber sheet comprises the following steps: putting and mixing the silicone rubber and the white carbon black in proportion in an open mill, then sequentially adding the filler, the vulcanizing agent, the foaming agent and the hydrogenated silicone oil, and mixing, thus preparing the expandable silicone rubber sheet. The expandable silicone rubber sheet disclosed by the invention can be used as a filling material for filling a gap of a structural member, and the gap of the structural member can be spontaneously filled during a temperature rising process through foaming; compared with a foamed silicone rubber filling material prepared by a traditional method, the preparation method has the advantages that advanced foaming is not required,the expandable silicone rubber sheet and the structural member are integrally formed, filling is compact, the foaming is uniform, and the like.

Owner:WUHAN UNIV OF TECH

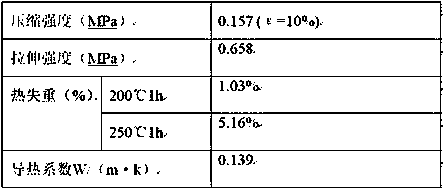

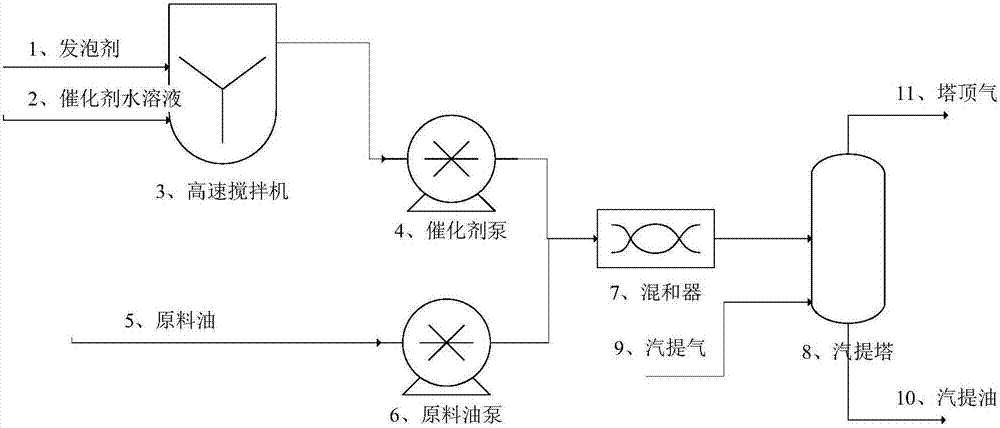

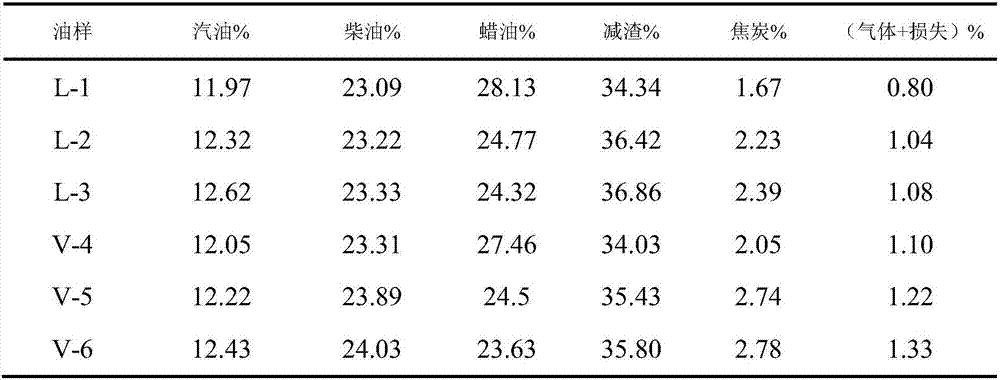

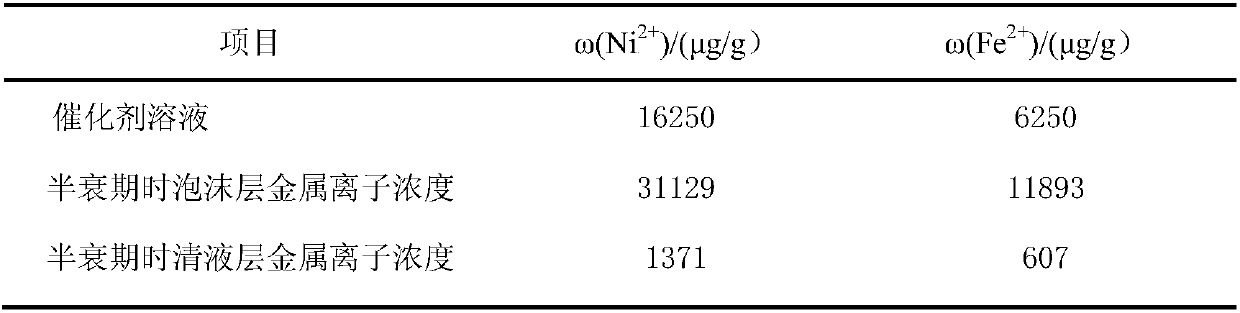

Dispersion method of suspension bed hydrogenation water-soluble catalyst

InactiveCN107345157AReduce moisture contentDisperse evenly and finelyHydrocarbon oils treatment control/regulationTreatment with moving solid particlesFoaming agentActive component

The invention discloses a dispersion method of a suspension bed hydrogenation water-soluble catalyst. The method comprises the following steps: adding foaming agents into a water-soluble catalyst solution; stirring for 1 second to 6000 seconds under conditions that the rotation speed is 500r / min to 15000r / min and the stirring temperature is 5 DEG C to 50 DEG C until the water-soluble catalyst solution is divided into two layers, wherein an upper layer is a stable-foam-state catalyst dispersion system while a lower layer is a clear solution or suspension liquid; taking the stable-foam-state catalyst dispersion system out and adding the stable-foam-state catalyst dispersion system into a heavy oil raw material for being stirred to obtain a mixture; carrying out steam stripping on the obtained mixture and then enabling the mixture to enter into a reaction system. The dispersion method of the suspension bed hydrogenation water-soluble catalyst disclosed by the invention is simple in foaming process, and only a proper amount of foaming agents are added into an aqueous solution or the suspension liquid of the catalyst and then stirring is carried out so as to obtain a finished product. Through enrichment of the catalytic active components by foam, the moisture content of the dispersion system is reduced, so that the load in subsequent steam stripping and dehydration processes is reduced; catalyst particles can be more uniformly and finely dispersed in crude oil.

Owner:SINOPEC YANGZI PETROCHEM +1

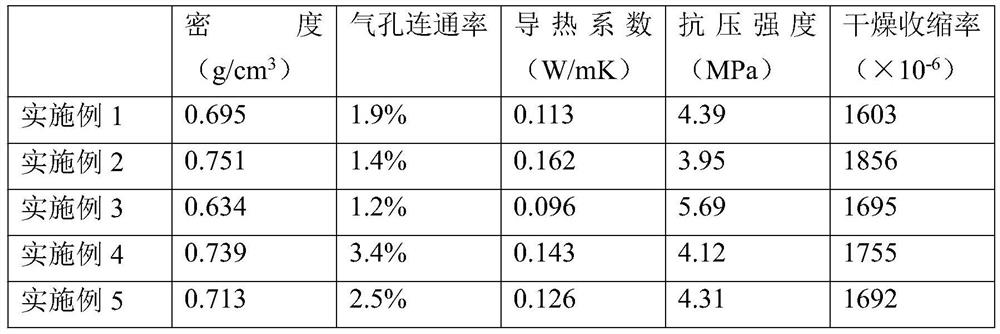

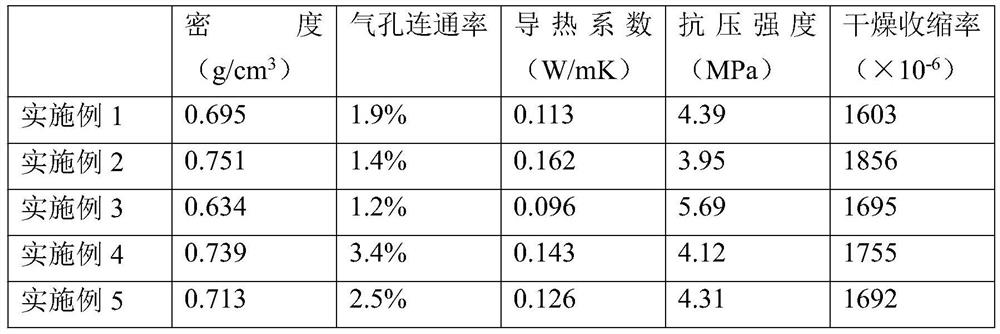

Regenerated powder-based inorganic gelling material toughening and cracking foaming agent and its application

The invention discloses a recycled powder-based inorganic gelling material toughening and cracking-reducing foaming agent and its application. The composition of the foaming agent includes: a foaming component composed of recycled glass fiber reinforced plastic powder and strong alkali powder. Among the foaming components, strong The percentage by weight of the alkali powder in the regenerated FRP powder is 0.5-20%. The glass powder in the regenerated glass powder reacts with sodium hydroxide to make it active and become a part of the gelling material. Among them, the resin particles in the recycled FRP powder have better toughness than that of the cementitious material, which can realize the toughening and crack reduction of the cementitious material. Other very few fillers can be used as microfillers. The foaming agent of the present invention is simple to prepare. There is no need to pre-foam during use, the foaming process is simple, it is easy to mix with inorganic gelling materials, the bubbles produced are uniform and stable, and it has a greater strengthening and toughening effect on inorganic gelling materials. The resulting foamed material has low density, low pore connectivity, good thermal insulation performance, and high strength and crack resistance.

Owner:HEBEI UNIV OF TECH

Regenerated powder-based inorganic cementing material toughening and crack-reducing foaming agent and application thereof

The invention discloses a regenerated powder-based inorganic cementing material toughening and crack-reducing foaming agent and application, the foaming agent comprises a foaming component composed of regenerated glass fiber reinforced plastic powder and strong base powder, and the strong base powder in the foaming component accounts for 0.5-20 wt% of the regenerated glass fiber reinforced plastic powder. Glass powder in regenerated glass steel powder reacts with sodium hydroxide, so that the regenerated glass steel powder has activity and becomes a part of a cementing material. Resin particles in the regenerated glass fiber reinforced plastic powder have higher toughness than a cementing material, and toughening and crack reduction of the cementing material can be achieved. A small part of other fillers can be used as a micro-filler. The foaming agent disclosed by the invention is simple to prepare. Pre-foaming is not needed in the using process, the foaming process is simple, mixing with an inorganic cementing material is easy, generated bubbles are uniform and stable, and the reinforcing and toughening effects on the inorganic cementing material are large. The prepared foaming material is low in density, low in air hole communication rate, good in heat preservation and insulation performance, high in strength and resistant to cracking.

Owner:HEBEI UNIV OF TECH

Dispersion method of suspension bed hydrogenation catalyst

InactiveCN107619678AThe foaming process is simpleReduce moisture contentHydrocarbon oils treatment control/regulationTreatment with moving solid particlesFoaming agentActive component

The invention relates to a dispersion method of a suspension bed hydrogenation catalyst, wherein the suspension bed hydrogenation catalyst is formed by a water-soluble catalyst and an oil-soluble catalyst. The dispersion method includes: adding a foaming agent to the water-soluble catalyst, and placing an obtained solution in a high-speed stirrer for stirring to enrich foam to obtain a foaming system; dissolving the oil-soluble catalyst in a surfactant solution prior to dropwise dropping into the foaming system to obtain CLA (colloidal liquid aphron); adding the obtained CLA into heavy-oil material for stirring to allow a mixture to enter a reaction system via stream stripping. The method is simple in foaming process, subsequent stripping dehydration process load can be reduced by reducingdispersion system moisture content through enrichment of catalytic active components by the foam, catalyst granules can be evenly and finely dispersed in raw oil, and the dispersion effect is betterthan that of a traditional mode.

Owner:SINOPEC YANGZI PETROCHEM +1

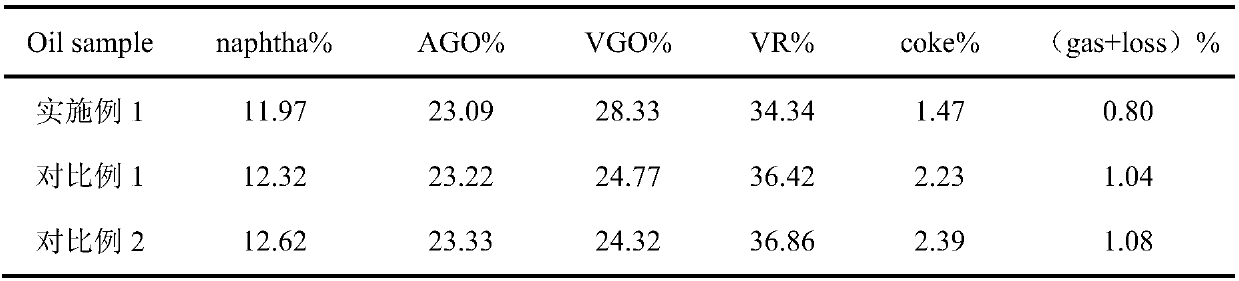

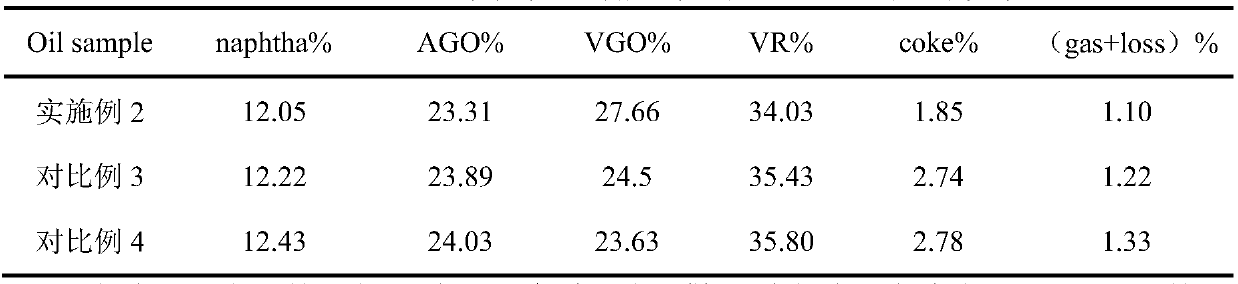

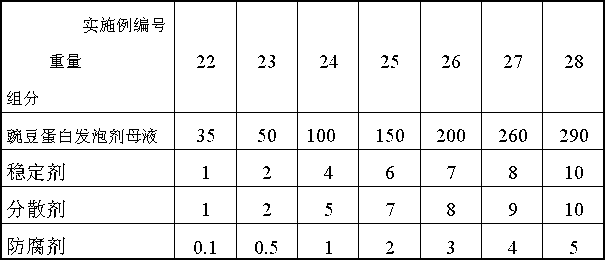

Pea protein concrete foaming agent and preparation method thereof

InactiveCN102173644BEasily available in large quantitiesLow priceCeramicwareFoam concreteFoaming agent

The invention discloses a pea protein concrete foaming agent and a preparation method thereof. The preparation method is characterized by comprising the steps of: mixing 10 weight parts of pea protein, 0.1 to 1 weight part of papain and 200 weight parts of water, carrying out hydrolysis reaction for 0.5 to 24 hours under the temperature of 10 DEG C to 100 DEG C, deactivating enzyme, and filtering, wherein filtering liquid is a prepared mother solution of the pea protein concrete foaming agent; and uniformly mixing 30 to 200 weight parts of the mother solution of the pea protein concrete foaming agent, 1 to 10 weight parts of stabilizing agent, 1 to 10 weight parts of dispersing agent, 0.1 to 5 weight parts of preservative according to weight proportion to prepare the pea protein concrete foaming agent. The preparation method disclosed by the invention has advantages of readily available raw materials, low production cost, and favorable environmental friendliness, and is easy for realizing large-scale industrial production. A foaming process is simple, and the pea protein concrete foaming agent can efficiently enhance the foaming capacity, foaming stability and concrete consistencyand also efficiently enhance various performances of foaming concrete.

Owner:SICHUAN HUASHI GREEN HOMELAND BUILDING MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com