Sound absorption black body foam material and preparation method thereof

A foam material and foam technology, applied in the field of sound-absorbing black body foam material and its preparation, can solve the problems of high cost of graphene, sheet slip, loss of ultra-thin vibration characteristics of graphene, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

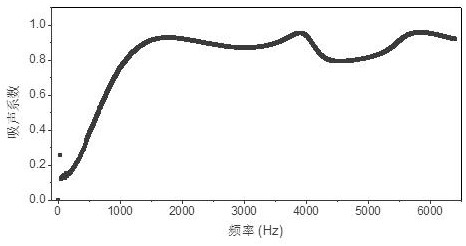

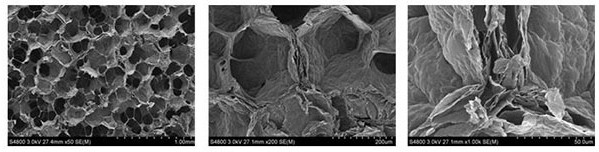

[0026] Melamine foam (pore size 50-200um) with a thickness of 20mm was immersed in 10mg / ml aqueous graphene oxide (purchased from Hangzhou Gaoxi Technology Co., Ltd., with an average size of 20um) for 2 hours, and then the dried foam was hydrated to 30% Hydrazine was foamed for 2 hours, and after natural drying, a high-performance multi-stage foam sound-absorbing black body material was obtained, such as image 3 As shown, the wall thickness of graphene in the secondary foam structure is 20nm, the average sound absorption coefficient at 100-10000Hz is 0.78, and the average sound absorption coefficient at 200-6000Hz is 0.86.

Embodiment 2

[0028] With embodiment 1, wherein the pore diameter of melamine foam is 50-200um, and thickness is 30mm, the obtained high-performance multistage foam sound-absorbing blackbody material, wherein the wall thickness of graphene in the secondary foam structure is 20nm, at 100-10000Hz The average sound absorption coefficient is 0.8, and the average sound absorption coefficient at 200-6000Hz is 0.89.

Embodiment 3

[0030] With embodiment 2, wherein the polyurethane foam that melamine foam is replaced by pore diameter is 10-100um, the obtained high-performance multistage foam sound-absorbing black body material, wherein the wall thickness of graphene in the secondary foam structure is 15nm, in 100-100um The average sound absorption coefficient at 10000Hz is 0.75, and the average sound absorption coefficient at 200-6000Hz is 0.83.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com