Patents

Literature

153results about How to "Promote the process of industrialization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pleurotus eryngii cultivation method and cultivation material thereof

InactiveCN101717298AHigh biological conversion ratePromote the process of industrializationHorticultureFertilizer mixturesBiologyGypsum

The invention discloses a pleurotus eryngii cultivation method and a cultivation material thereof. The cultivation material comprises the following components in parts by weight: 30 to 40 parts of corncobs or cornstalk, 0 to 60 parts of cotton seed shells, 8 to 10 parts of wheat bran, 5 to 8 parts of kapok seed powder, 5 to 8 parts of cornmeal, 1 to 2 parts of plaster powder and 1 to 3 parts of lime powder. The traditional formula using pure cotton seed shells as the mail materials is changed, and the optimized high-yield formula using the corncobs or cornstalk, kapok seed shells and the like is developed. The invention reduces the production cost, further standardizes the fore treatment of the cultivation material and the reasonable and scientific formula, provides the functions of sterilization and disinfection and obtains high yield and good quality of rare mushrooms through cultivation by using the stalk of crops.

Owner:SHANDONG FANGLV AGRI SCI & TECH

Samarium-cobalt sintered magnet material and preparation method thereof

InactiveCN101882494ALower temperature coefficient of remanenceLower flux temperature coefficientMagnetic materialsRare earthCobalt

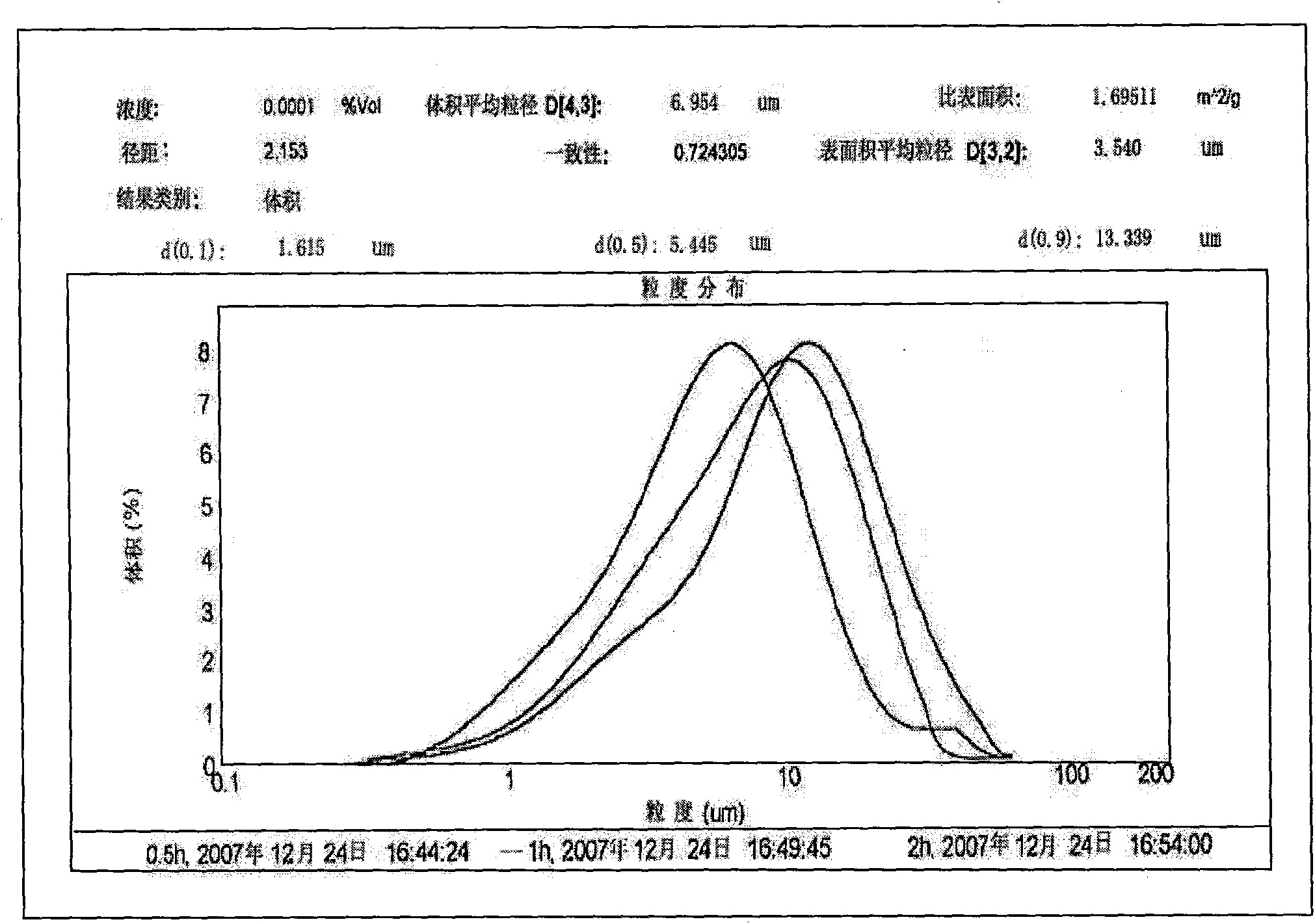

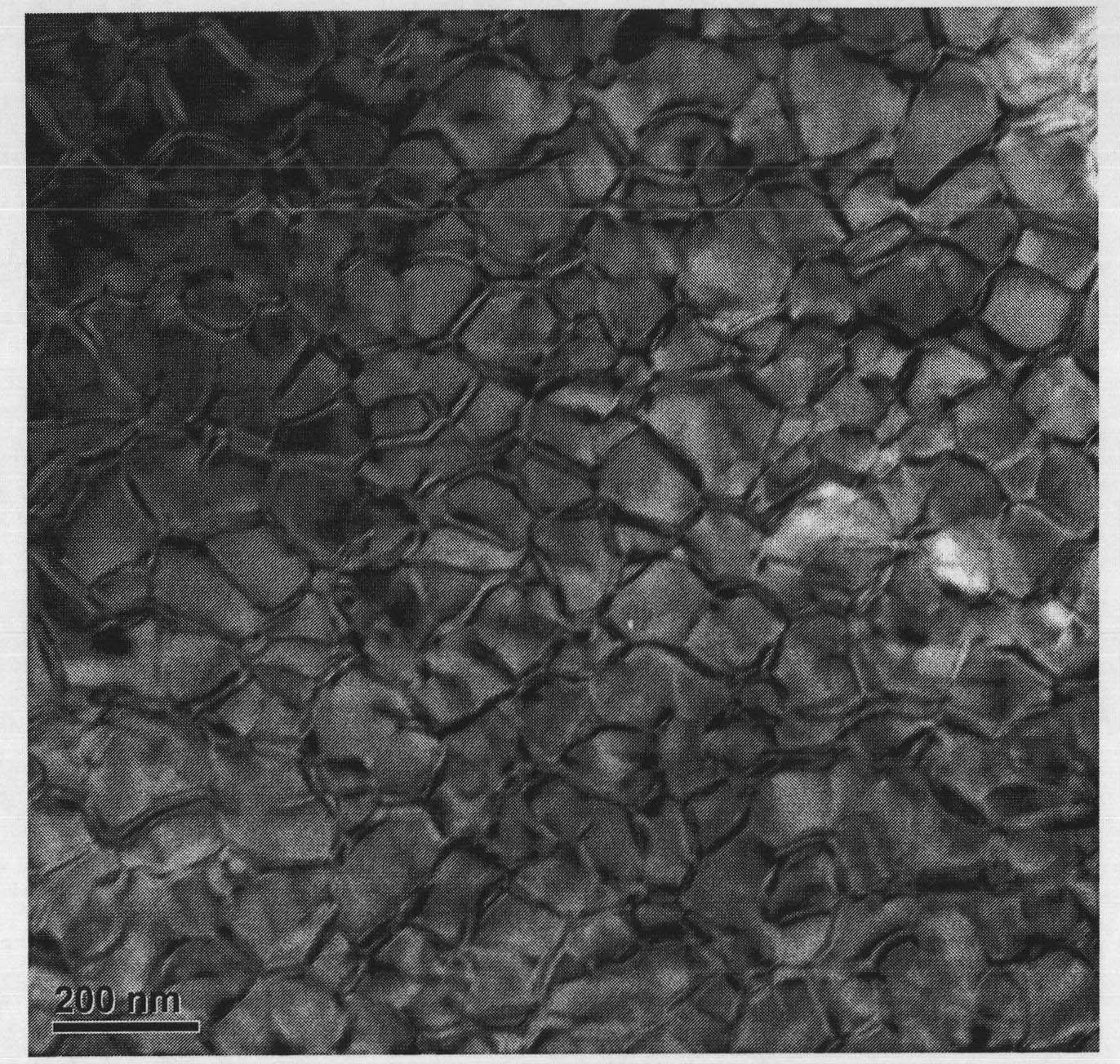

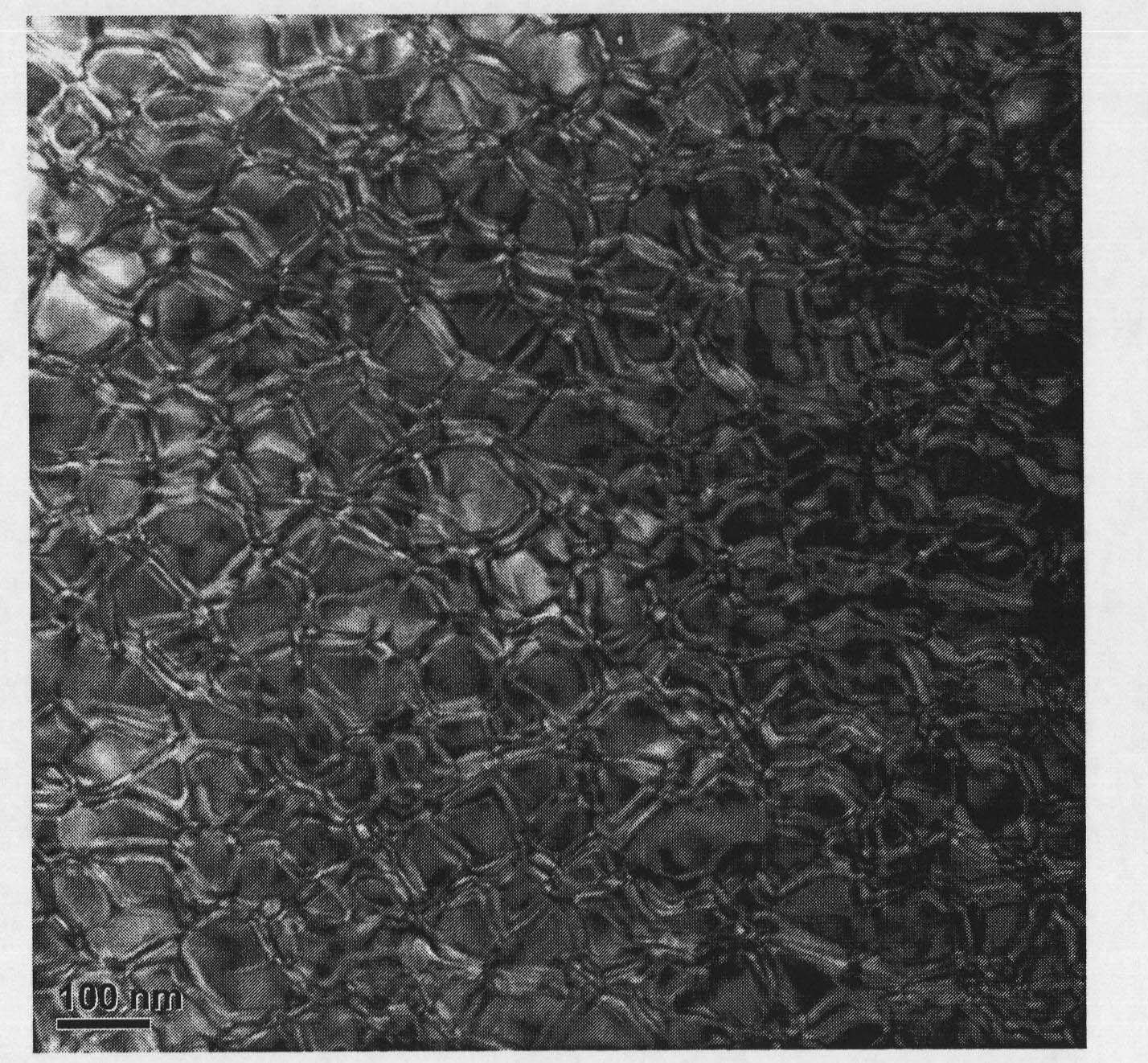

The invention discloses a 2:17 type samarium-cobalt sintered magnet material and a preparation method thereof. The 2:17 type samarium-cobalt sintered magnet material comprises the following raw materials in percentage by mass: 10 to 25 percent of samarium, 45 to 55 percent of cobalt, 10 to 20 percent of iron, 3 to 9 percent of copper, 1 to 3 percent of zirconium and 5 to 15 percent of at least one heavy rear earth element. Due to the selection and the proportion of the raw materials and the innovation of the sintering process, a microstructure of the magnet material is optimized, and the aims of reducing the temperature coefficient of a magnet and simultaneously maintaining higher magnetic energy product of the magnet are fulfilled, wherein the magnetic energy product of the prepared magnet is 14 to 25 MGsOe, the residual magnetism temperature coefficient is about -0.005 to -0.03 percent per DEG C, and a lower magnetic flux temperature coefficient is maintained in an environment at the temperature of between -35 and 300 DEG C.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Vegetation recovery method for nonferrous metal mining wasteland

ActiveCN102972197APrevent heavy metals from spreading and polluting the environmentImprove efficiencySoil lifting machinesArtificial islandsTerrainIon

The invention provides a vegetation recovery method for a nonferrous metal mining wasteland, which comprises the following steps: 1), terrain consolidation; 2), heavy metal stabilizing disposal; 3), shallow acid-base improvement and flexible impervious isolation: spraying the mixture of an acid-base modifier, a vegetative matrix and resin to a wasteland surface; 4), setting a section of drainage ditch; and 5), laying a vegetation cushion: laying a vegetation cushion on a slope surface and fixing the vegetation cushion with an anchor rod. The method provided by the invention combines the terrain consolidation, the heavy metal stabilizing disposal, the shallow acid-base improvement, the surface layer impervious isolation, wasteland vegetation recovery and other technologies to prevent heavy metal ions from relocating and diffusing to pollute the environment; the wasteland vegetation system is recovered; and the vegetation recovery method is high in standardization and industrialization level, is 2 to 3 times higher than a conventional soil replacement spray-sowing greening method in efficiency, low in governance cost, suitable for the popularization and application of ecological environmental management of large-area nonferrous metal mining wastelands, and remarkable and stable in effect.

Owner:江苏绿之源生态建设有限公司

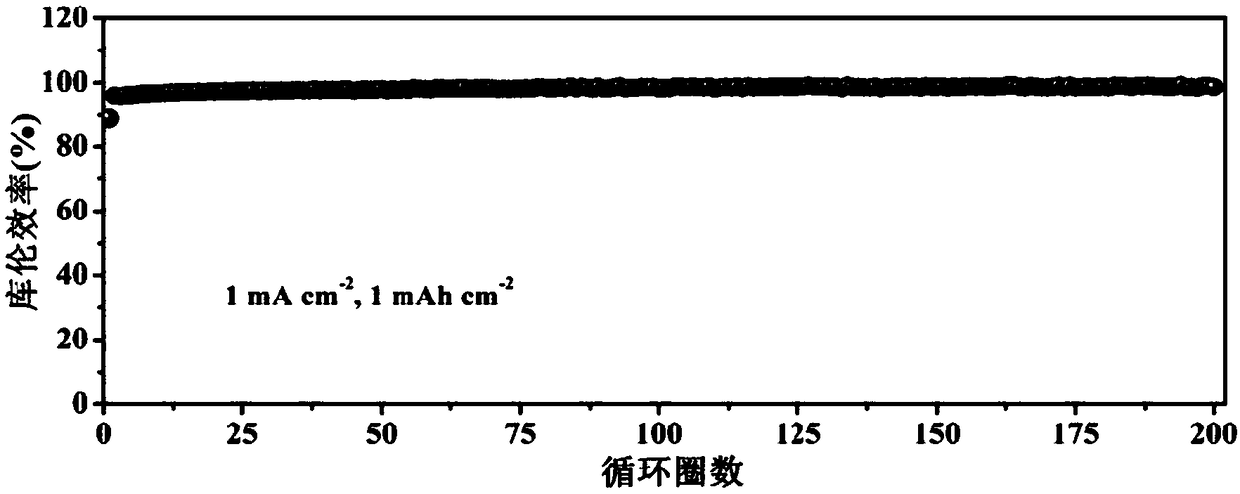

Lithium metal battery lithium negative electrode surface modification method, and lithium metal battery

ActiveCN108448058ASimple processEasy to operateElectrode manufacturing processesCell seperators/membranes/diaphragms/spacersHigh energyShielding gas

The invention discloses a lithium metal battery lithium negative electrode surface modification method, and a lithium metal battery. The modification method comprises the following steps: a lithium metal negative electrode is impregnated in or coated with a fluorine-containing ionic liquid in a dry protection gas atmosphere, is fluorinated, and is taken out to make a protection layer rich in lithium fluoride formed on the surface of the metal lithium negative electrode in order to obtain a lithium fluoride coated metal lithium negative electrode. The lithium fluoride protection layer obtainedby surface fluorination is very uniform and dense, and can reduce the consumption of lithium metal and an electrolyte and inhibit the formation of lithium dendrites in order to make the metal lithiumnegative electrode have a high specific discharge capacity, a long cycle life and a good safety, so the stability and the high efficiency of the lithium metal battery in a long cycle process are achieved, use requirements of a high-energy and high-power power battery are met, the industrialization process of the lithium metal battery is facilitated, and lithium metal battery has a wide applicationprospect.

Owner:SOUTH CHINA UNIV OF TECH

Method and device for removing hydrogen sulphide from mixture gas containing low-concentration hydrogen sulphide

ActiveCN101062460AEliminate bad odorSolve absorptionDispersed particle separationProduct gasLow density

The invention provides a H2s removing method from the gas mixture, comprising a provision of absorption of liquid, with the solution selected from N-methyl diethanolamine, aminoethanol and their mixture, under 0. 05-0. 30MPa absolute pressure, keeping the 18-42deg.C absorption liquid contact with the 20-52deg.C low density H2S gas, absorbing mixture gas through countercurrent and vortex, lowering the mixture gas H2S into 10ppm or even lower, separating the mixture gas for swirl gas and liquid separation. It also provides a low density H2S gas mixture to remove it.

Owner:EAST CHINA UNIV OF SCI & TECH

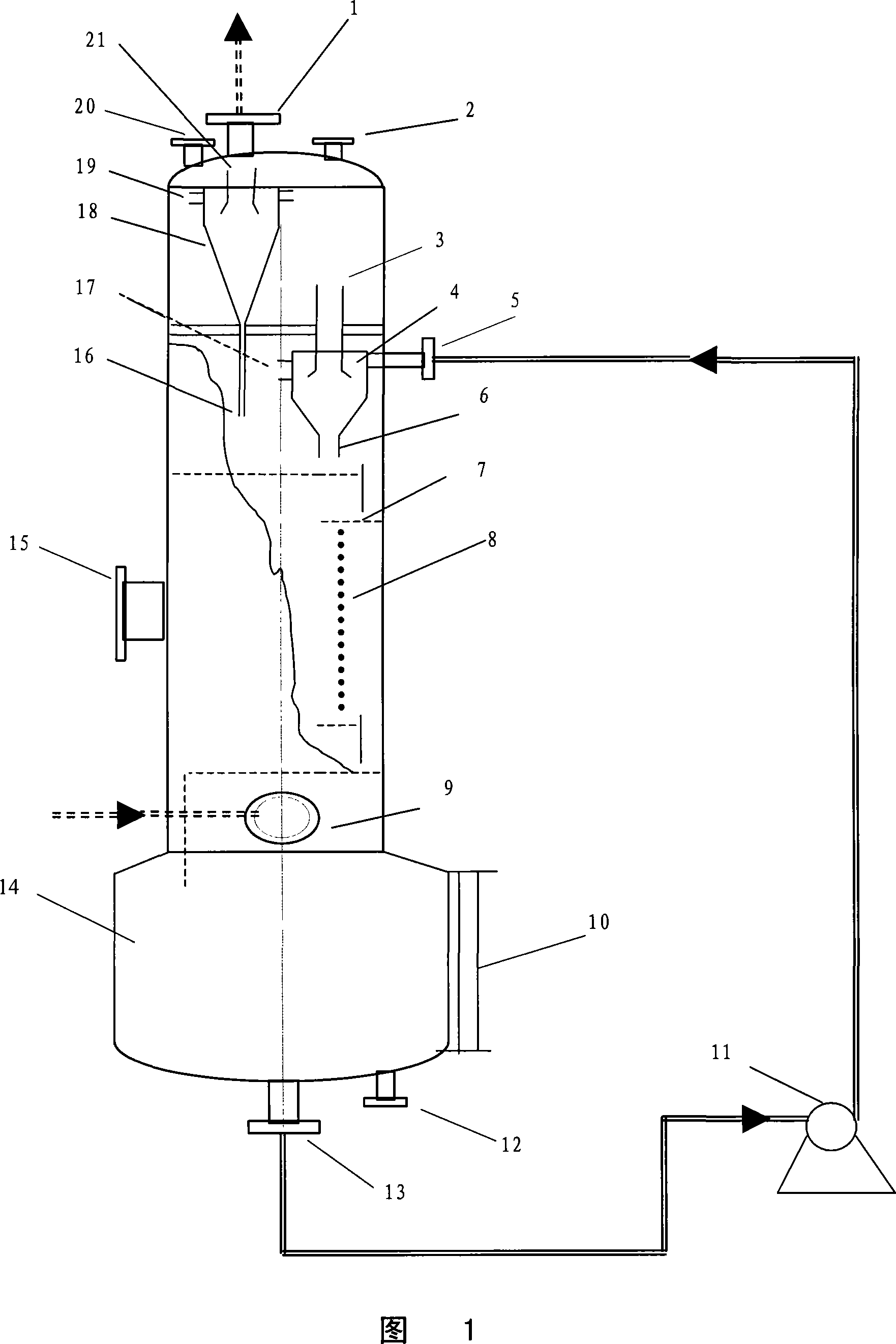

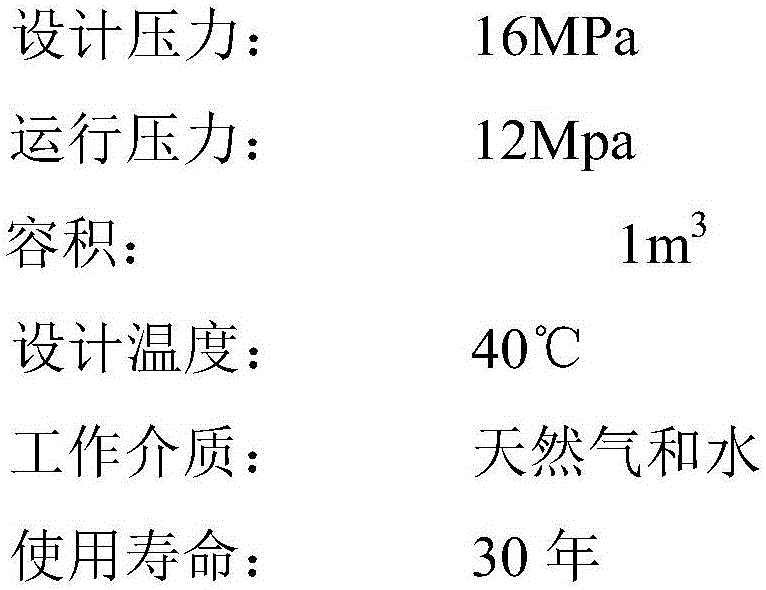

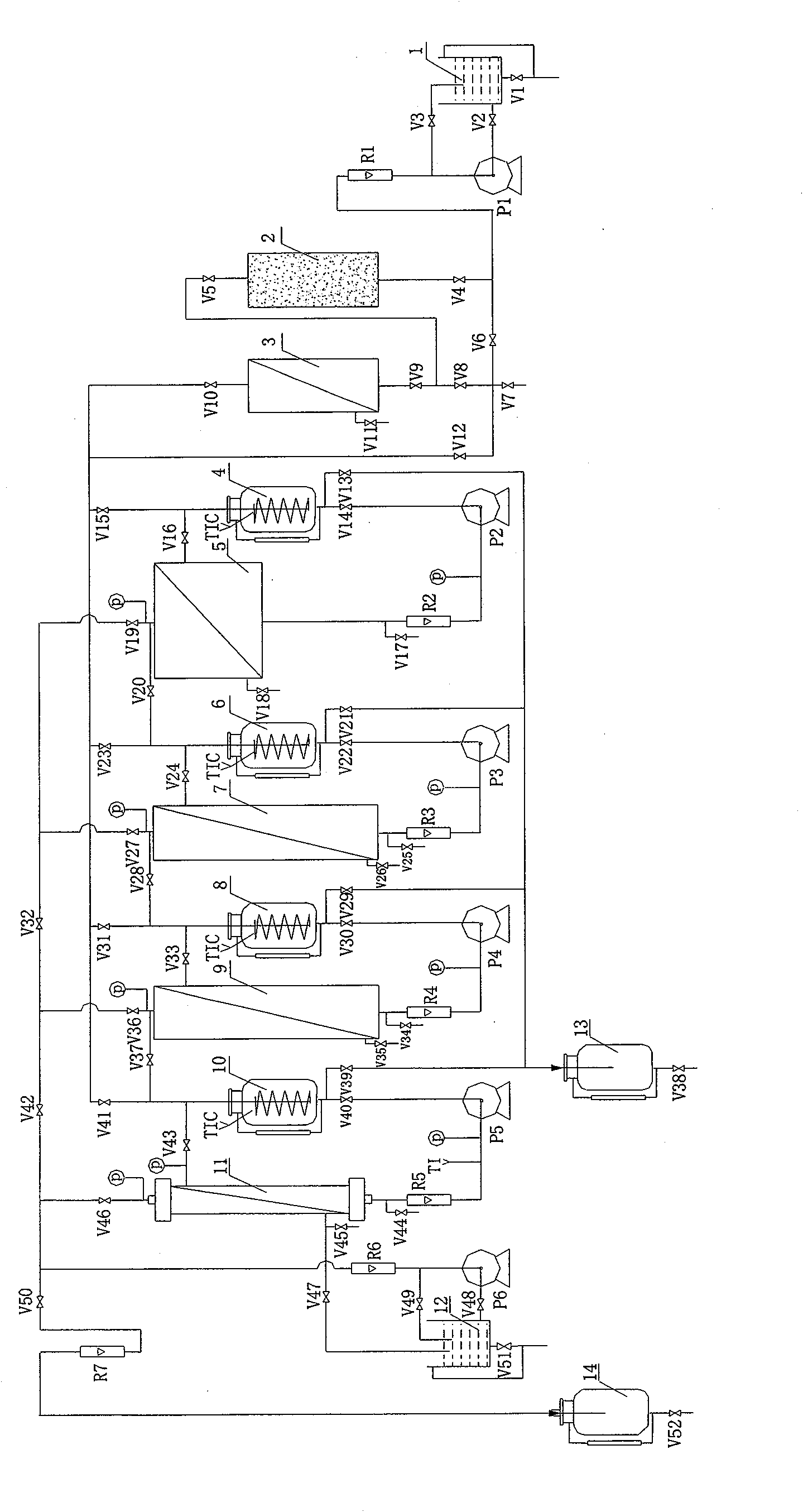

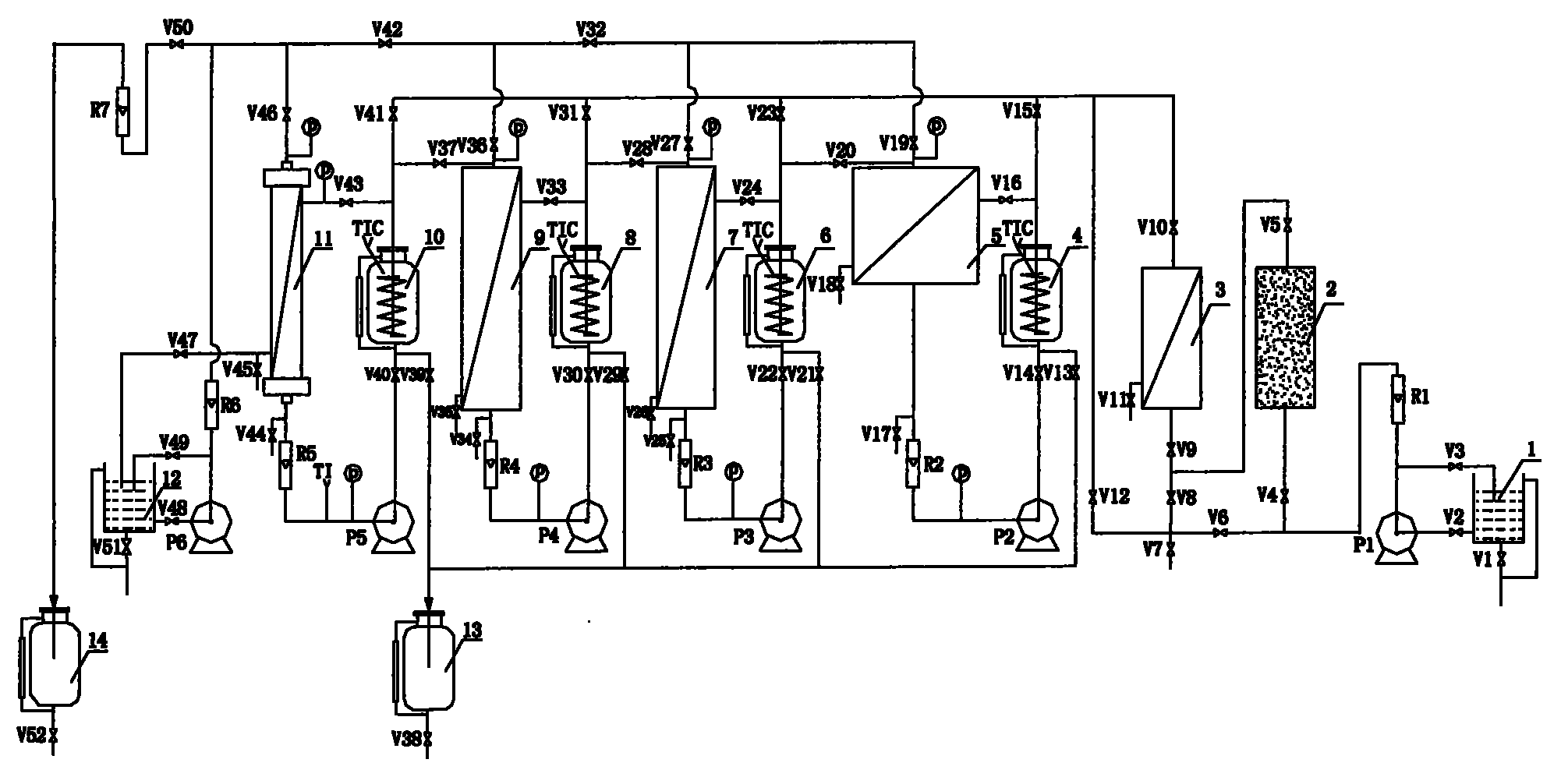

Rapid synthesis device for natural gas hydrate

InactiveCN106010698AHigh synthesis efficiencyPromote the process of industrializationGaseous fuelsGas cylinderControl system

The invention provides a rapid synthesis device for natural gas hydrate. The rapid synthesis device comprises a gas supply pipeline, a liquid supply pipeline, a stirring device and a data acquisition control system. The gas supply pipeline is used for conveying gas in a gas cylinder into a reaction kettle and is communicated with a gas inlet a in the bottom of the reaction kettle through an outlet of the gas cylinder via a pipeline. The liquid supply pipeline is used for conveying water in a water tank into the reaction kettle and is communicated with a liquid phase inlet c of the reaction kettle through an outlet of the water tank via a pipeline, and a plunger pump is arranged on the communicating pipeline. The stirring device is formed by installing a stirrer in the reaction kettle, propeller blades are adopted for a stirring and smashing paddle of the stirrer, and a smashing tooth cone is installed below the blades. By means of the rapid synthesis device for natural gas hydrate, the synthesis efficiency of natural gas hydrate can be improved, and thus the industrialization process of natural gas hydrate is promoted.

Owner:SOUTHWEST PETROLEUM UNIV

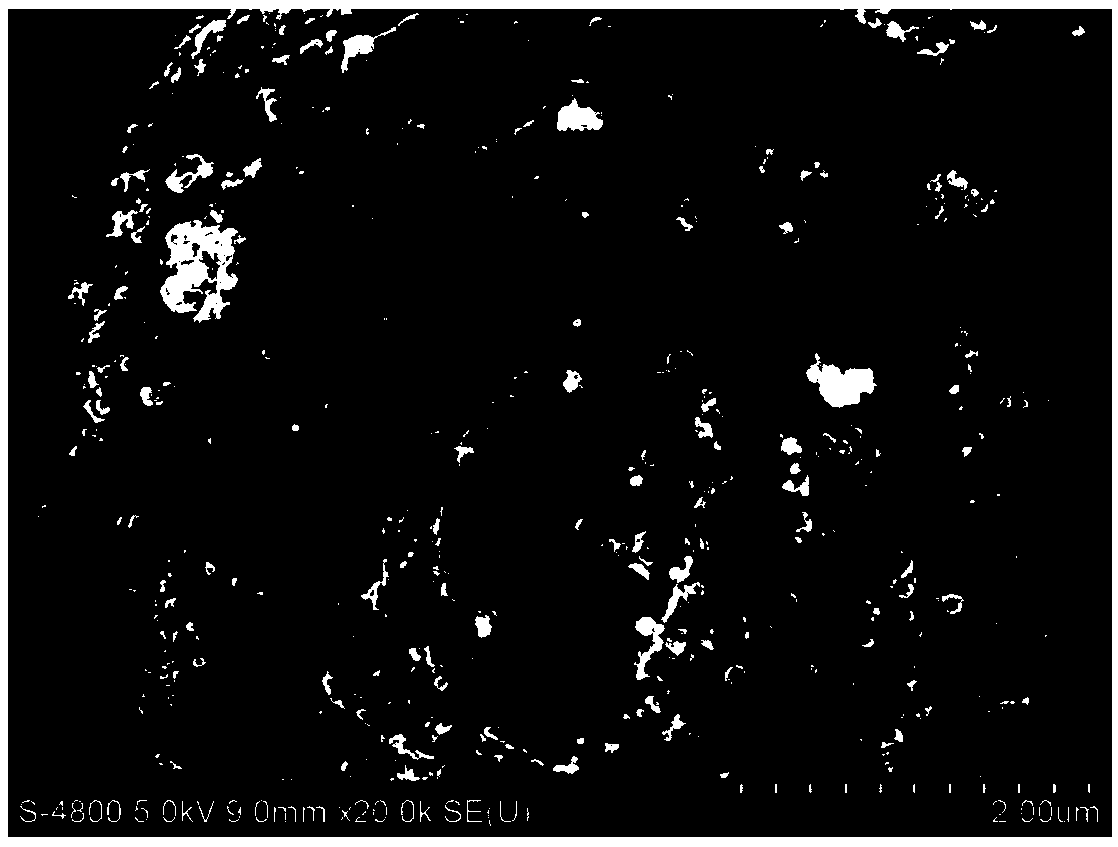

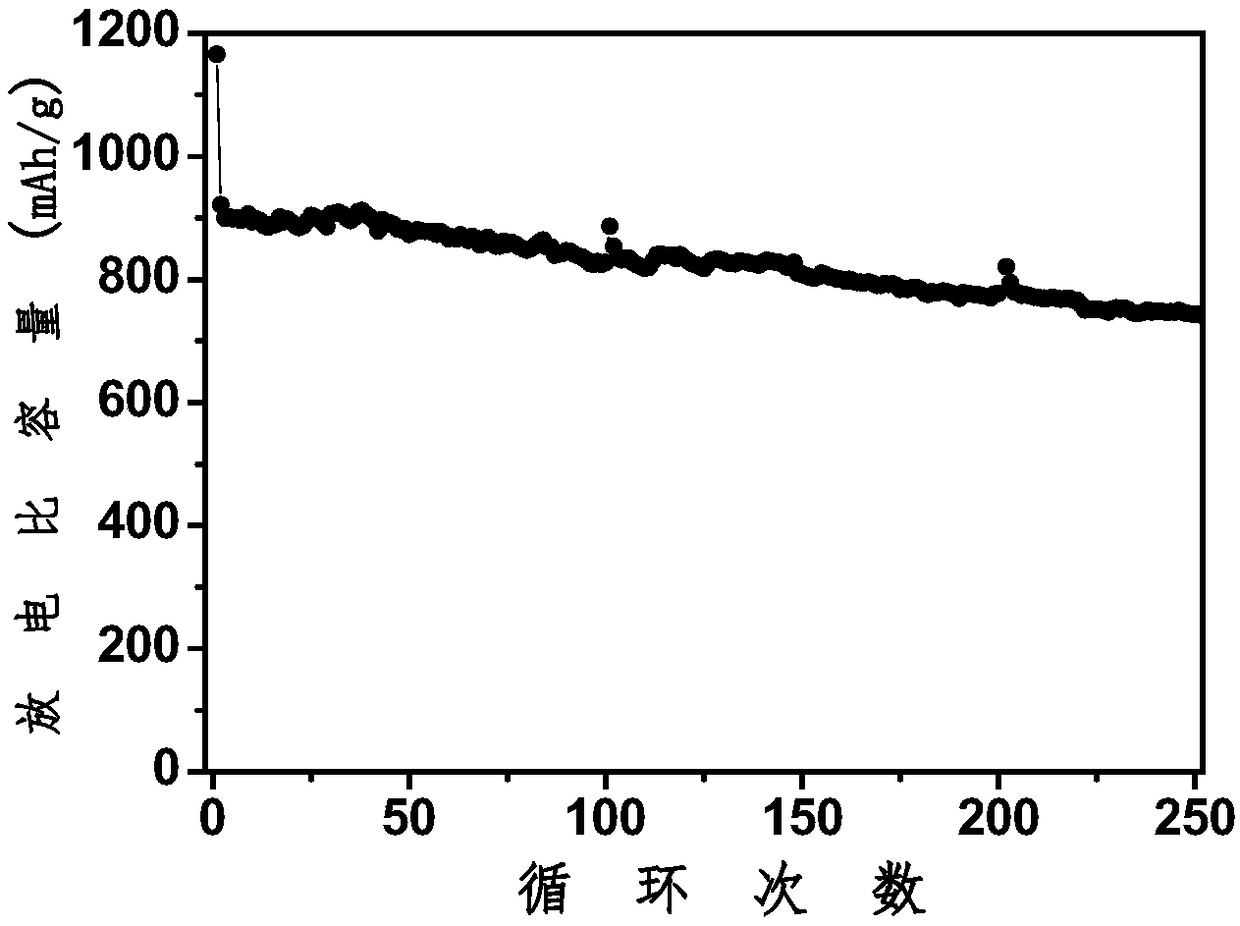

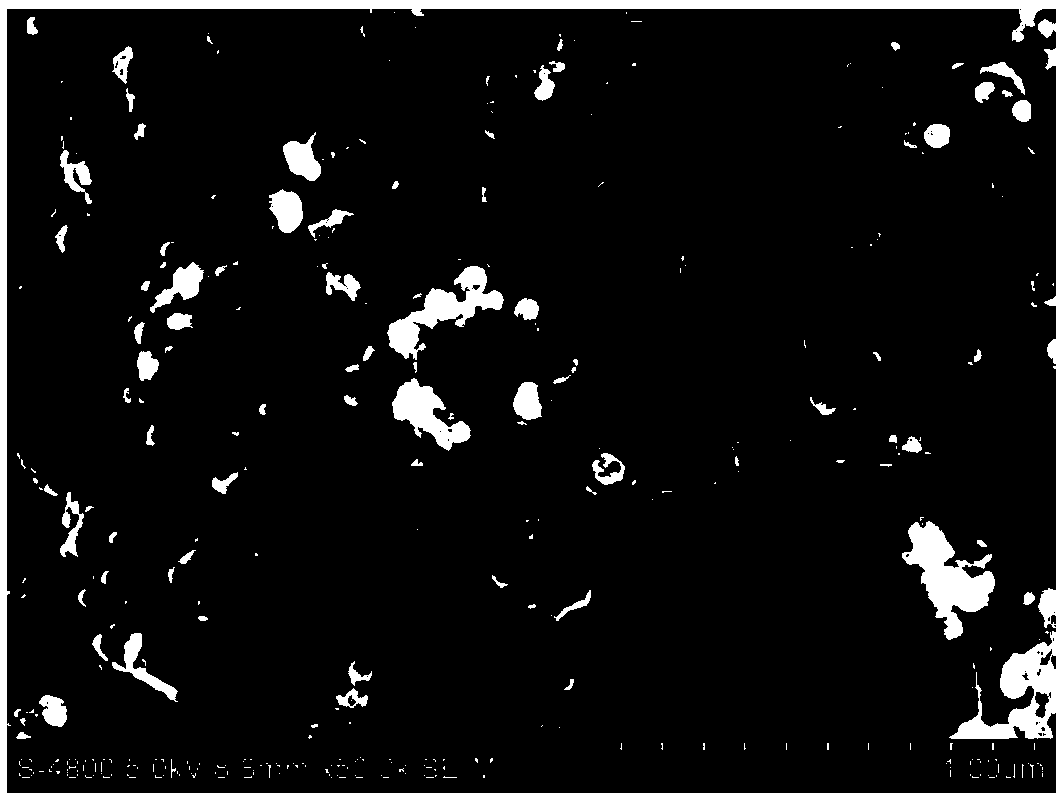

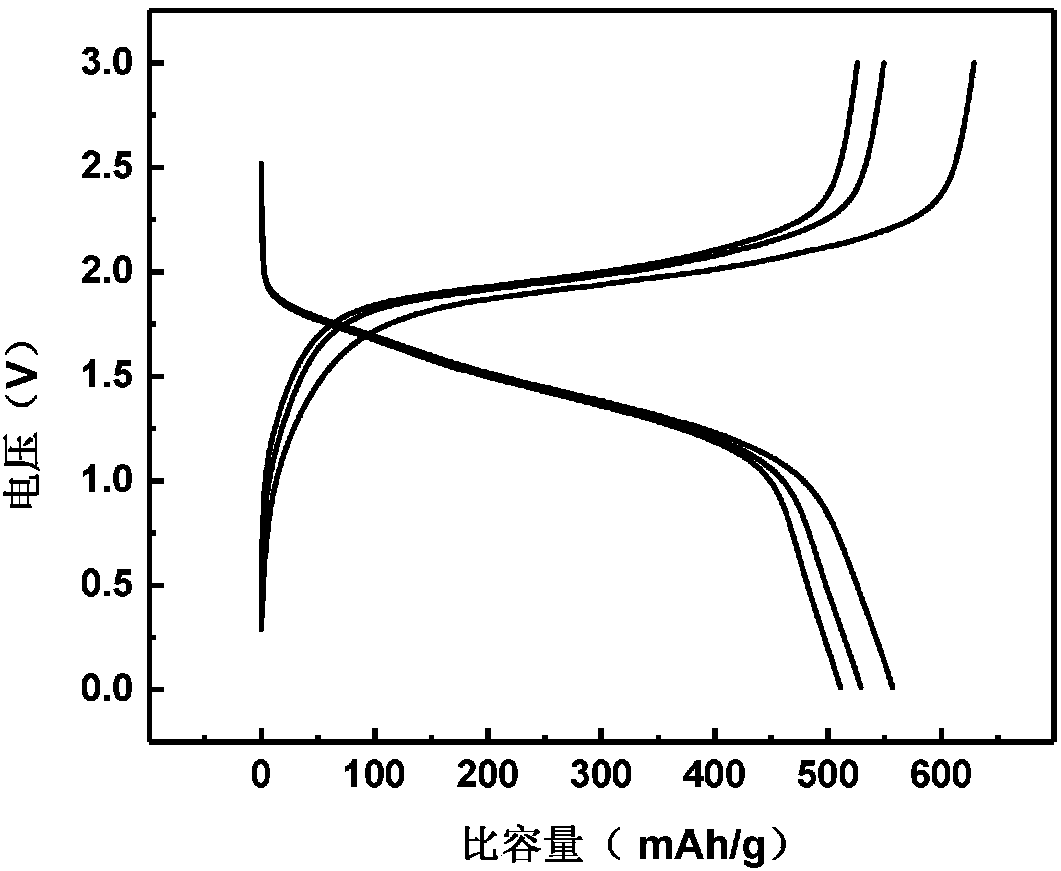

High-capacity carbon-silicon negative electrode active material and preparation and application methods thereof

ActiveCN109301215AHigh specific capacityImprove cycle lifeCell electrodesSecondary cellsFiberCarbon fibers

The invention discloses a high-capacity carbon-silicon negative electrode active material and preparation and application methods thereof. The high-capacity carbon-silicon negative electrode active material achieves a specific capacity of 800-1500 mAh / g and is formed by mixing carbon-silicon materials and graphite materials, wherein the carbon-silicon materials are microspherical particles prepared by performing ball milling spray-drying and thermal treatment processes on nanosilicon, crystalline flake graphite, carbon nanotubes and a carbon source, the nanosilicon is dispersed on the surfaceof the crystalline flake graphite, the carbon nanotubes are inserted into pores formed between the carbon nanotubes and the crystalline flake graphite, pyrolytic carbon of the carbon source is coatedon the surface of the nanosilicon and the surface and pores of the spherical particles formed by the nanosilicon, the crystalline flake graphite and the carbon nanotubes; the weight of silicon-carbonmaterials is 25%-80% of the total weight of the high-capacity carbon-silicon negative electrode active material. When uniformly mixed with conducting agent and bonding agent, the high-capacity carbon-silicon negative electrode active material can be coated or deposited onto copper foils, foamed nickel, foamed copper or carbon fiber paper as the negative electrode of a lithium ion battery. The preparation method of the high-capacity carbon-silicon negative electrode active material is simple in process, low in cost, applicable to amplified preparation of long-circulation carbon-silicon materials.

Owner:SHAANXI COAL & CHEM TECH INST

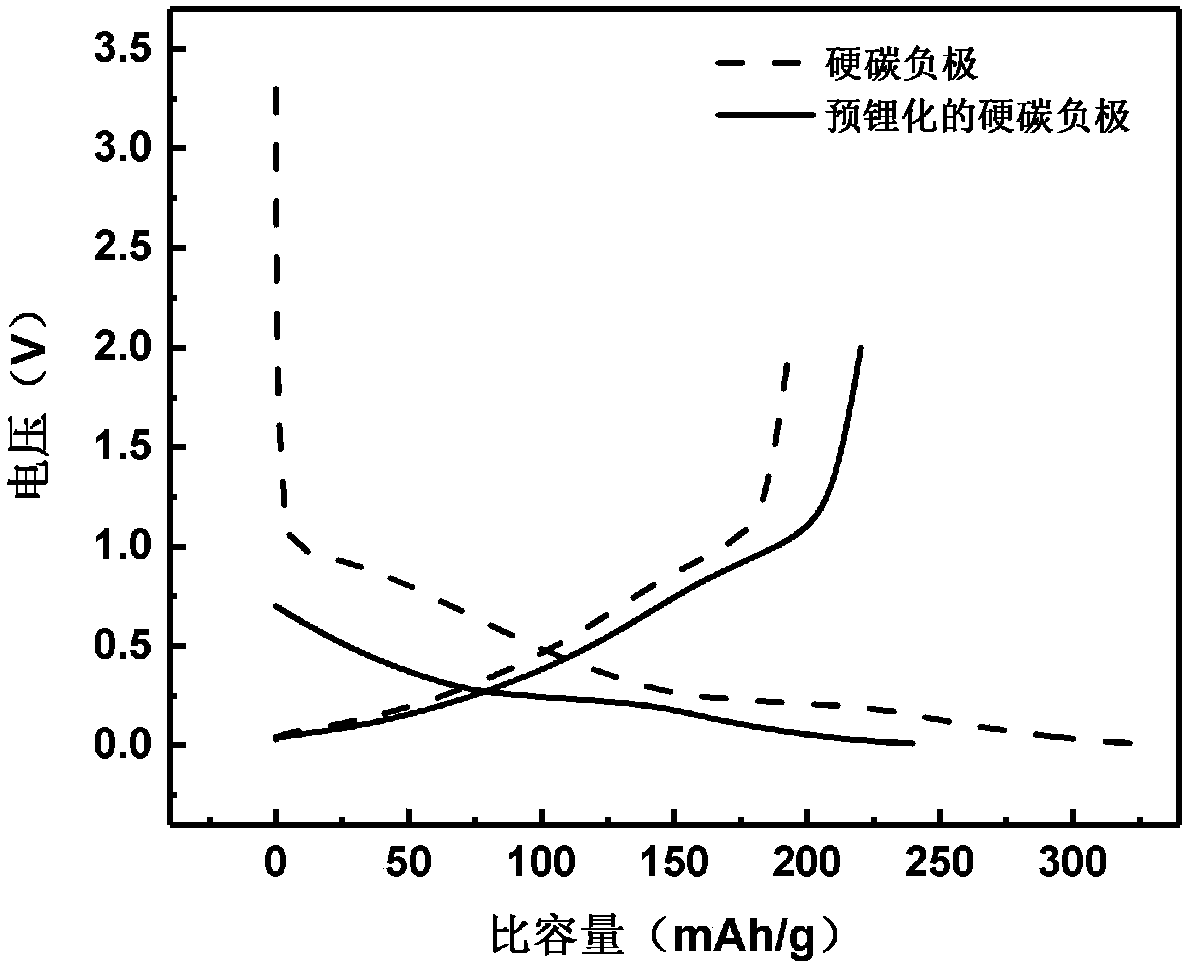

Lithium ion battery negative electrode and pre-lithiation method and application thereof

InactiveCN110120496APromote the process of industrializationIncrease energy densitySecondary cellsNon-aqueous electrolyte accumulator electrodesLithium electrodeLithium ion battery anode

The invention discloses a lithium ion battery negative electrode and a pre-lithiation method thereof, and application of the lithium ion battery negative electrode in a battery. In an inert atmosphere, the negative electrode of the lithium ion battery is allowed to react with an aryl lithiation reagent, and the first-cycle irreversible capacity of the negative electrode is removed to obtain higherfirst-cycle capacity. The aryl lithiation reagent is milder than a common lithiation reagent under the condition that the same pre-lithiation effect is achieved. The method has the advantages of normal-temperature reaction, short reaction time, simple process, controllable lithiation depth, high safety and easy industrialization.

Owner:WUHAN UNIV

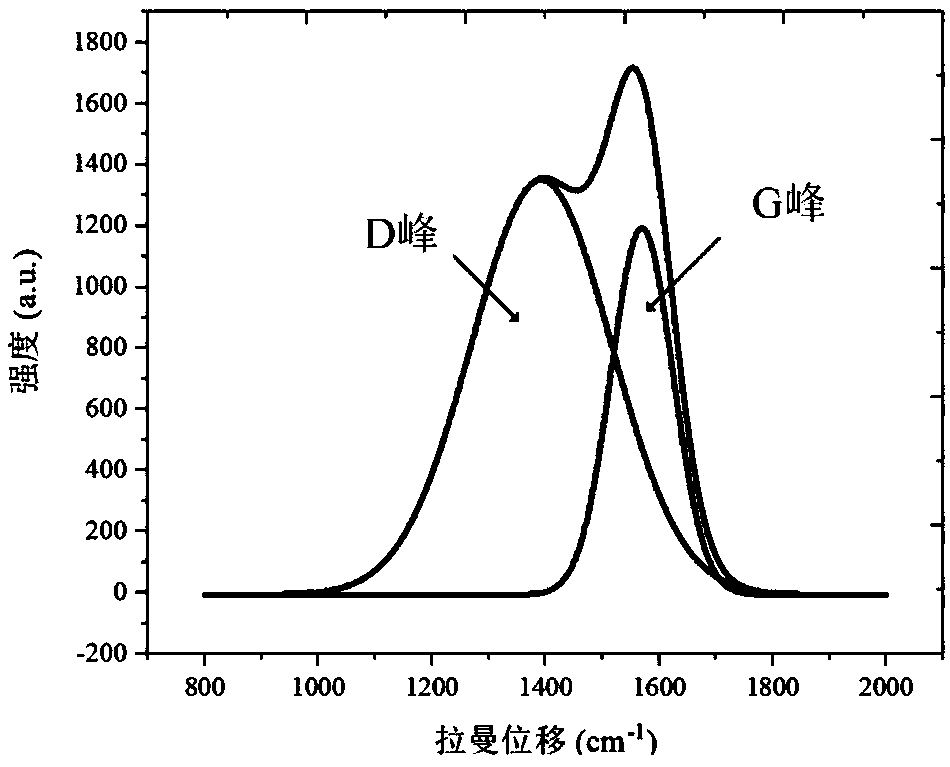

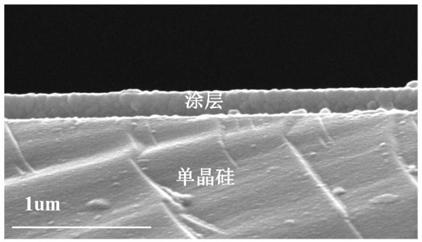

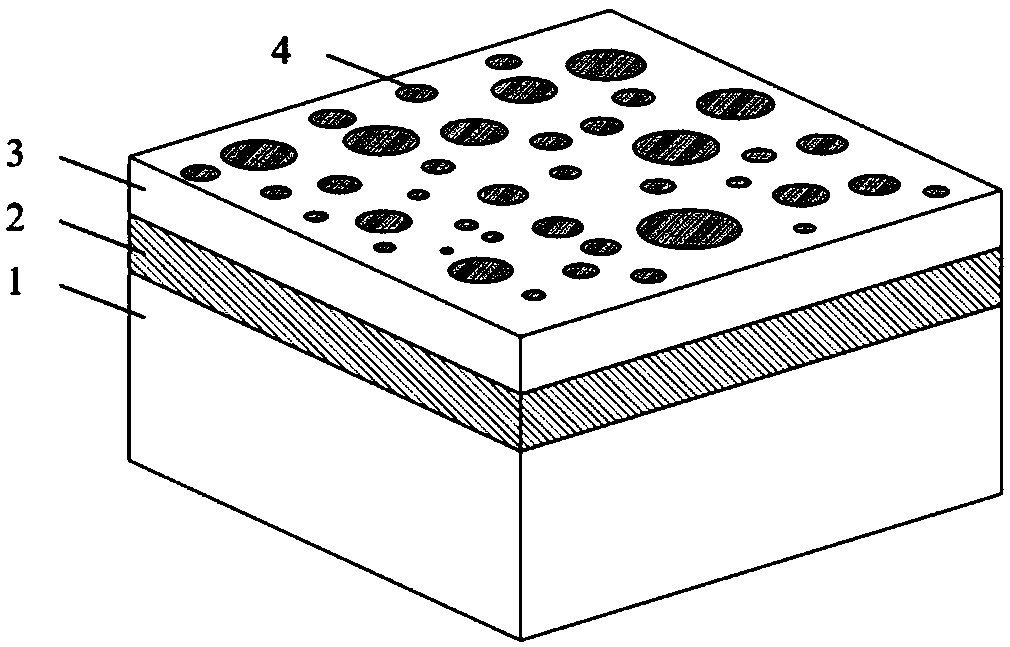

A graphite microcrystalline carbon coating for a metal bipolar plate of a fuel cell and application thereof

ActiveCN109037723ALow costImprove conductivityElectric discharge tubesVacuum evaporation coatingSputteringFuel cells

The invention relates to a graphite microcrystalline carbon coating for a metal bipolar plate of a fuel cell and application thereof, wherein the coating is coated on the surface of the metal bipolarplate, the graphite microcrystalline carbon coating is a graphite-like coating, and the coating comprises 5-50 wt% of graphite microcrystalline, and has good compactness. On the basis of conventionalmagnetron sputtering technology, carbon coatings with high conductivity, corrosion resistance and stability can be prepared by changing the energy of deposited particles by changing the target sputtering power, sputtering magnetic field strength and coating deposition temperature, thus changing the structure of carbon coatings. In accordance with that prior art, As that preparation cost of the coat is not increased, the contact resistance between the metal bipolar plate of the fuel cell and the gas diffusion lay can be reduced, the corrosion resistance of the carbon coating in the acidic environment of the fuel cell and the stability of the conductivity after long-time testing can be improved, and the invention has important significance for promoting the commercialization process of the fuel cell.

Owner:SHANGHAI JIAOTONG UNIV

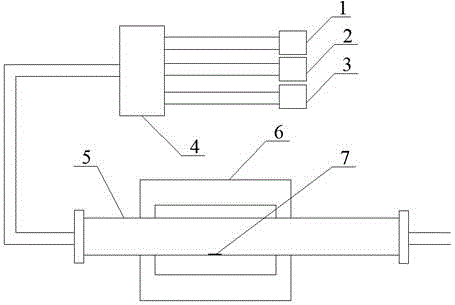

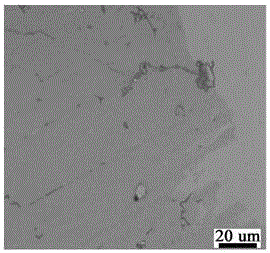

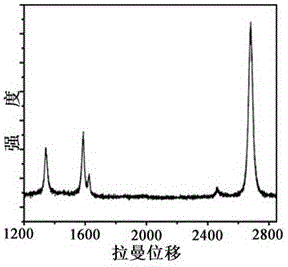

Method for preparing graphene thin film by chemical vapor deposition at normal pressure and low temperature

InactiveCN106587030AImprove catalytic abilityHigh catalytic activityGrapheneChemical vapor deposition coatingCvd grapheneEnergy consumption

The invention discloses a method for preparing a graphene thin film by chemical vapor deposition at normal pressure and low temperature. According to the method, a metal substrate is subjected to high-temperature annealing treatment firstly and then temperature-reduction annealing treatment; and next, the graphene thin film is obtained on the surface of the metal substrate through the chemical vapor deposition method. By virtue of the method, the catalysis activity of the metal substrate is improved, so that the growth temperature of graphene is lowered, and the energy consumption and cost of industrial production of the graphene thin film are lowered consequently; and compared with a conventional chemical vapor deposition method for synthesizing the graphene thin film, the method disclosed by the invention is simple in process, the carbon source is wide in source, the prepared graphene thin film is high in quality, and the number of layers is uniform and controllable.

Owner:CHONGQING UNIV

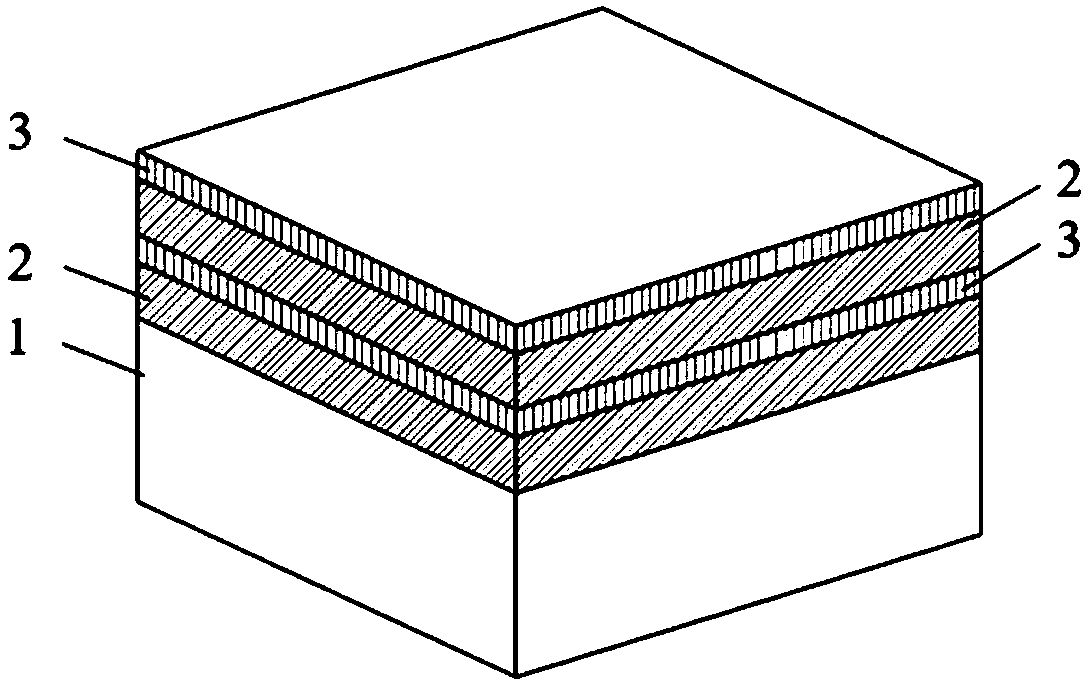

Conductive and corrosion-resistant coating for metal bipolar plate of fuel cell

ActiveCN109346743AImprove conductivityAccelerated corrosionCollectors/separatorsState of artFuel cells

The invention relates to a conductive and corrosion-resistant coating for a metal bipolar plate of a fuel cell. The coating comprises a precious metal part, and a conductive and corrosion-resistant non-precious metal part, wherein a precious metal accounts for 10-90wt% of the coating; and a precious metal coating is doped with a corrosion-resistant non-precious metal material through different modes. The precious metal in the coating is used for ensuring high conductivity, corrosion resistance and stability of the metal bipolar plate; under the premise that good coating performance is ensured,the added corrosion-resistant non-precious metal is used for reducing the amount of the precious metal in the coating, so that the coating cost is reduced; compared with the prior art, the coating provided by the invention has the advantages that through the different doping modes, excellent physical and chemical properties of the precious metal can be utilized to ensure better performance of themetal bipolar plate, and the coating preparation cost can be greatly reduced; and therefore, the coating is of great significance in promoting fuel cell industrialization.

Owner:SHANGHAI JIAO TONG UNIV +1

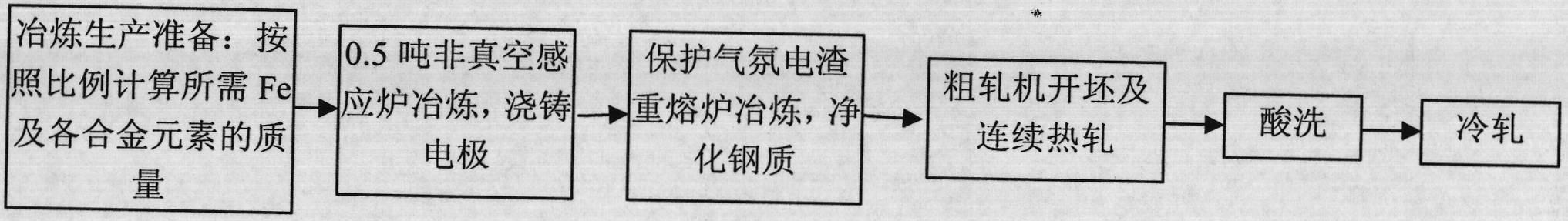

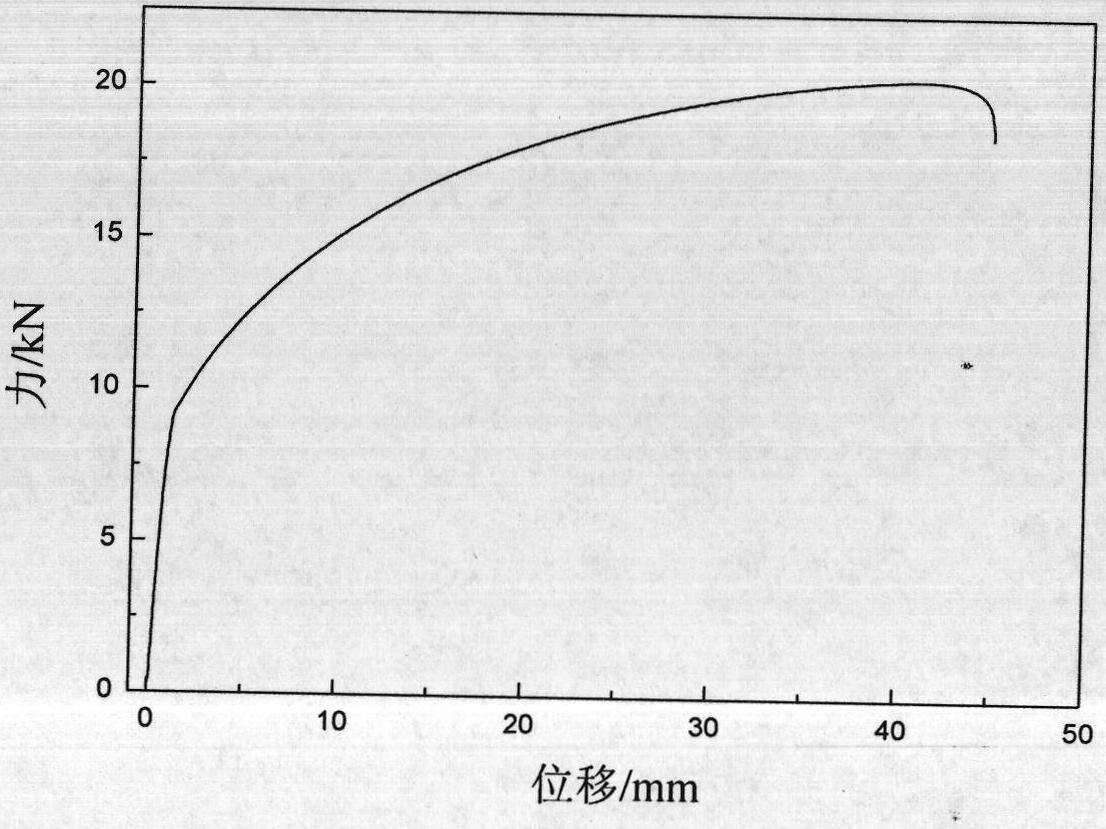

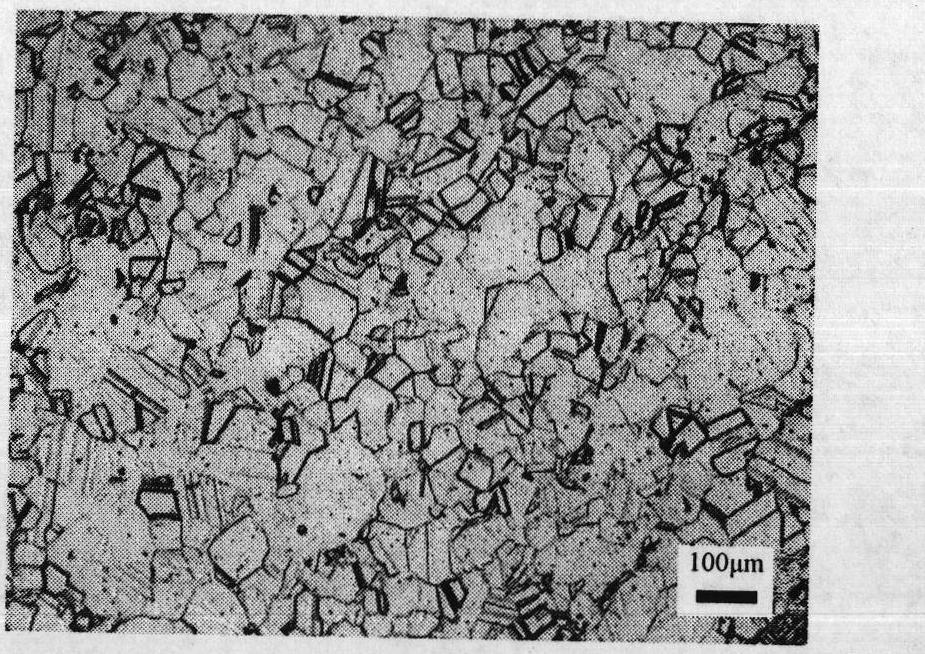

Pilot scale production method of low-carbon Fe-Mn-Al-Si series TWIP (Twining Induced Plasticity) steel

InactiveCN102690938ASolve the smelting process control methodSolve the rolling process control methodIncreasing energy efficiencyElectric furnaceSlagElectro-slag remelting

The invention provides a pilot scale production method of low-carbon Fe-Mn-Al-Si series TWIP (Twining Induced Plasticity) steel, mainly comprising two technical processes of smelting and rolling the TWIP steel, wherein a smelting link in the pilot scale production of the TWIP steel is finished by a combined smelting manner of a 0.5-ton non-vacuum induction furnace and a 2.5-ton electro-slag refining furnace. The TWIP steel is produced by the combined smelting manner of the 0.5-ton non-vacuum induction furnace and the 2.5-ton electro-slag refining furnace and the manner is basically confirms to an accrual large production condition; the conventional situation of utilizing a 10-Kg experiment furnace to smelt the TWIP steel is changed and an industrial progress of the TWIP steel is propelled; and smelting and rolling technical parameters in the pilot scale production are provided.

Owner:ZHONGBEI UNIV

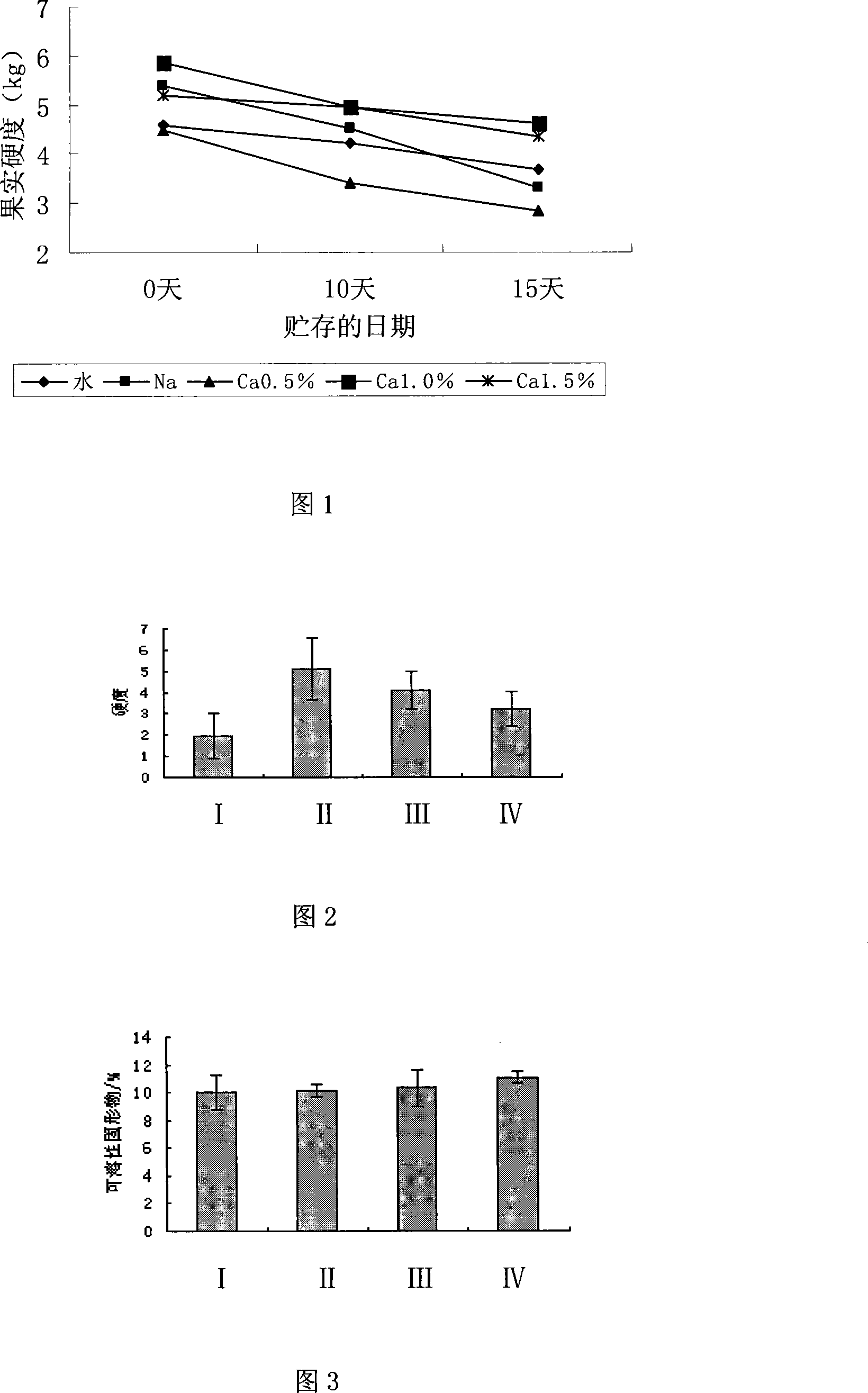

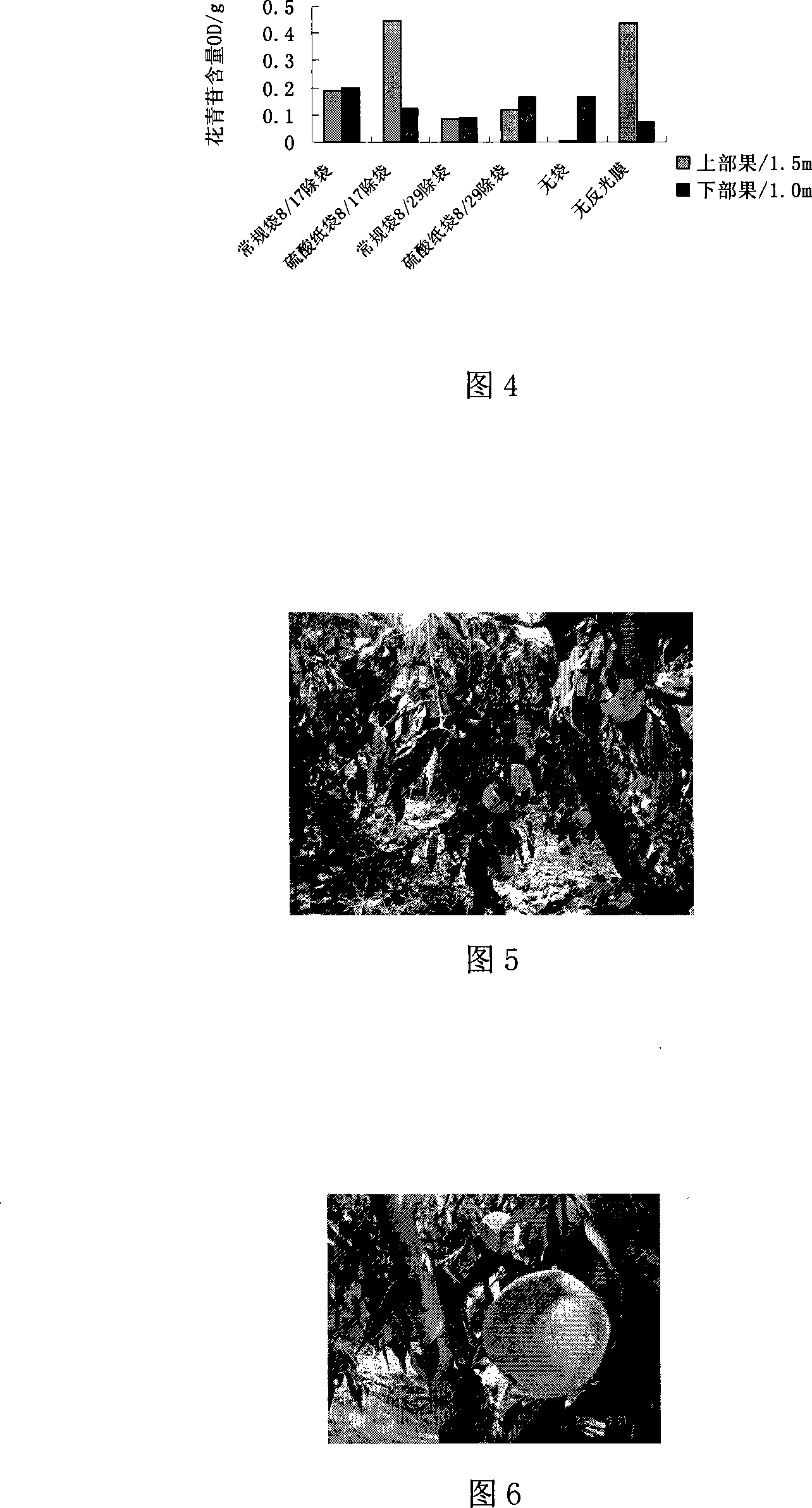

Method for fruits biological freezing point preservation and the storehouse

InactiveCN101204173AGuaranteed storage qualityEasy to combineFruits/vegetable preservation by coatingFruits/vegetable preservation by freezing/coolingPre coolingProduct processing

The invention relates to a fresh-keeping method and a fresh-keeping storehouse of a biological freezing point for fruits belonging to an agricultural products processing field. The fresh-keeping method of the biological freezing point for the fruits includes the steps: spraying calcium salt in the process of cultivating, sleeving a transparent bag or spreading a reflecting film to improve hardness and sugar degree of the fruits; carrying out rapid cooling before putting in the fresh-keeping storehouse in a pre-cooling room; after putting in the fresh-keeping storehouse, processing with a preservative; then regulating the temperature to a critical point of the freezing point with humidity of over 90%; adopting stage heating after leaving the fresh-keeping storehouse. Preservation period of late maturing peach is prolonged to 3 months; the fruits processed by the steps are fresh as before and the phenomenon such as browning, softening and rotting do not exist. The cost of the supporting fresh-keeping storehouse constructed based on the invention is about 1.2 times of that of a low temperature cold storage and 1 / 2-2 / 3 times of that of an air conditioned storehouse with the same volume; fresh-keeping effect is remarkably superior to the low temperature cold storage and the air conditioned storehouse; the invention can promote the creativity and development of relevant industries such as a transport case and a transport vehicle of the biological freezing point as well as the relevant culture of the biological freezing point; the invention is a technology with a wide prospect and favorable economic benefits.

Owner:CHINA AGRI UNIV

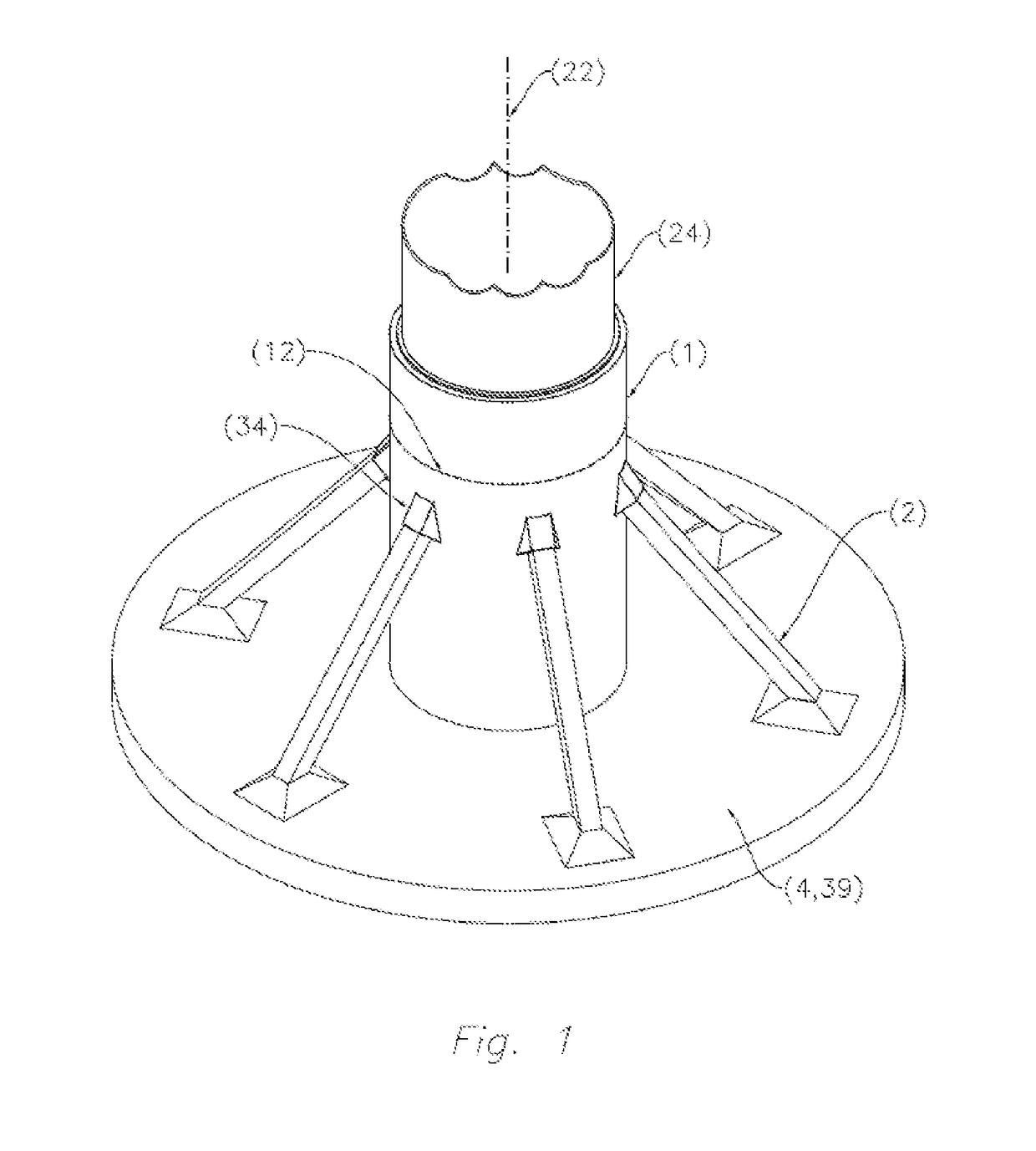

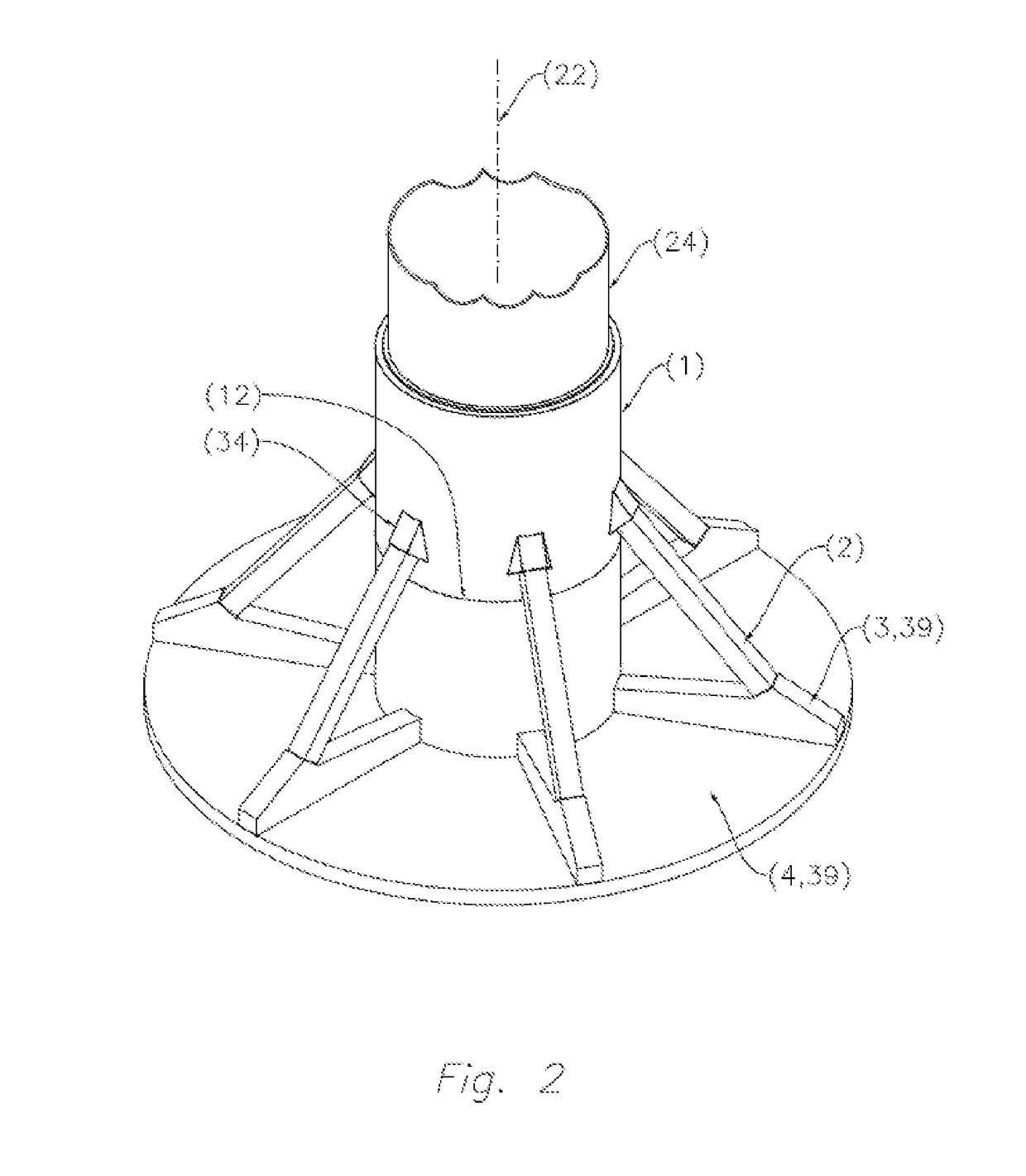

Foundations system for towers and method for installing the foundations system for towers

ActiveUS20170152641A1Low costReducing maximum amount of materialWind motor supports/mountsFoundation engineeringPre stressPre stressing

Foundation system for towers, especially for onshore wind turbines, comprising a central shaft buried or partially buried, preferably hollow and formed by dowels made from precast concrete, an essentially flat lower slab and completely buried, and lateral support means in the form of inclined struts that are joined at their upper end with the central shaft and at its lower end with the lower slab, and that are preferably entirely buried. The wind tower is located on the partly buried main shaft. The foundation system may comprise other lower elements connected with the lower slab, such as radial ribs or peripheral beams. The struts are preferably prefabricated elements incorporating an efficient and economical connection system by pre-stressing. The foundation system maximizes the fraction of the weight of the foundation by gravity generated by soil or ballast material, allowing an important economy in the structural materials of the foundation.

Owner:ESTEYCO ENERGIA

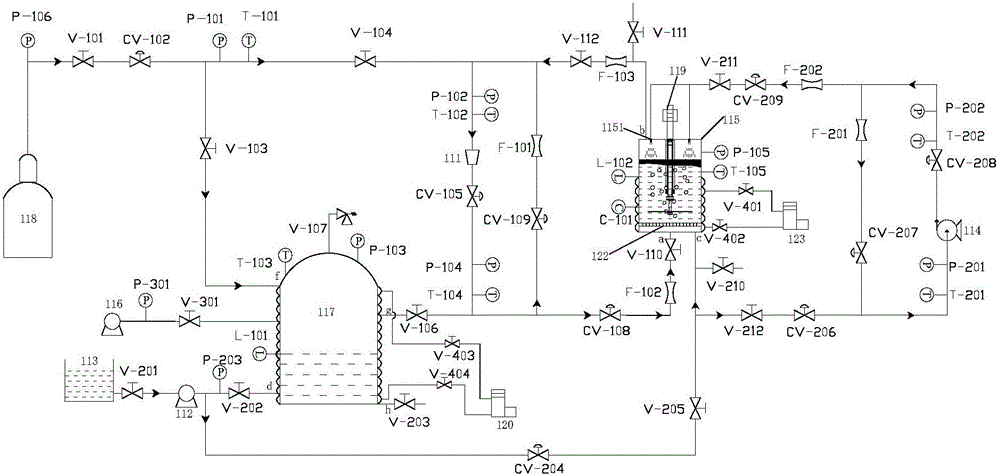

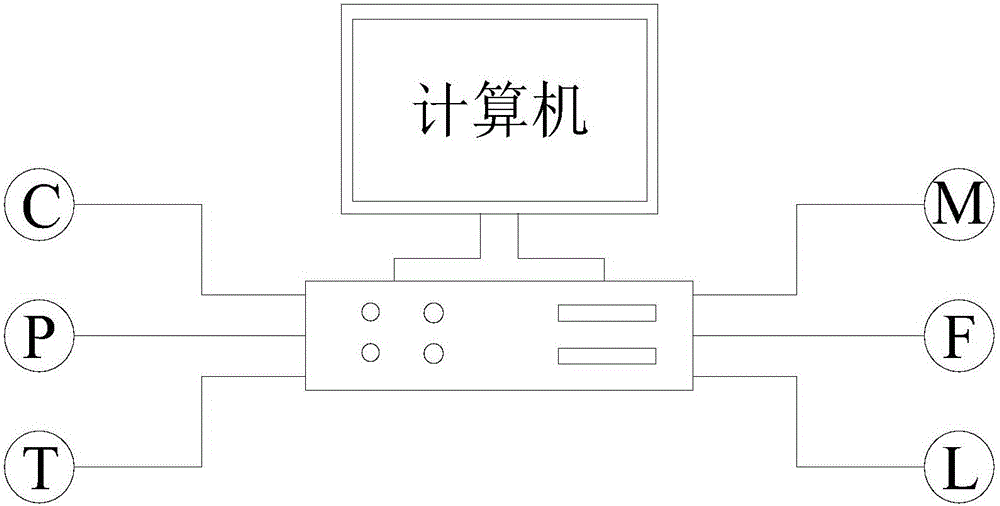

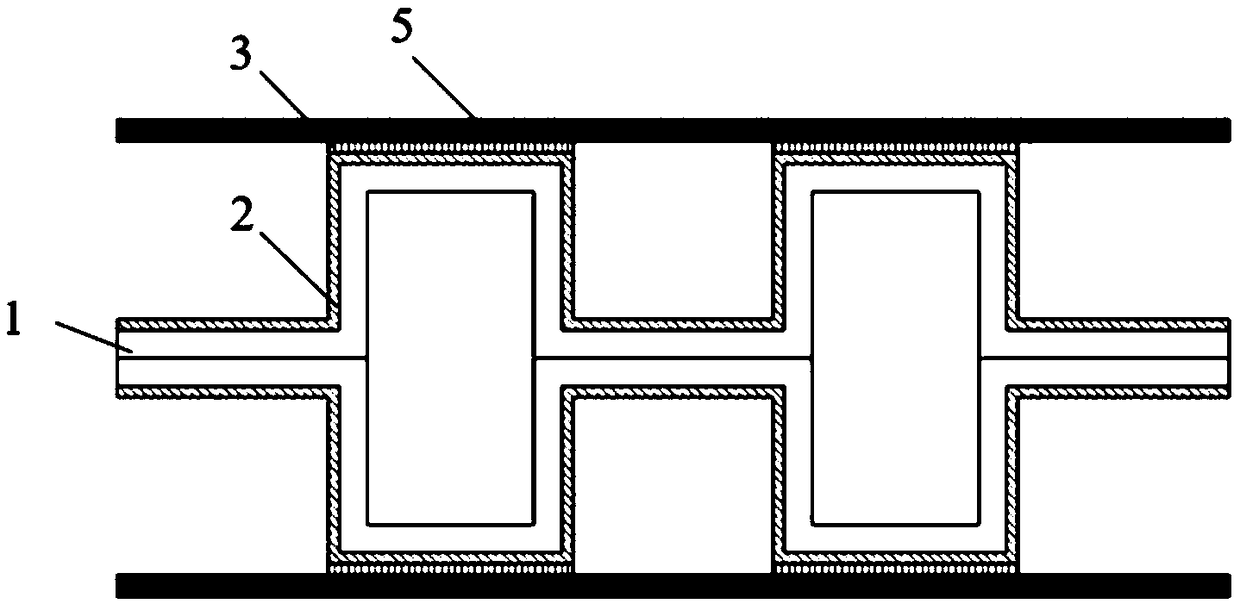

Multifunctional membrane separation device for treating pulping and paper-making waste water and separation method thereof

ActiveCN101934197AMeet separation processing requirementsImprove experimental efficiencySemi-permeable membranesAutomatic controlReverse osmosis

The invention relates to a multifunctional membrane separation device for treating pulping and paper-making waste water and a separation method thereof. The device is provided with four groups of membrane assemblies which respectively correspond to four membrane separation processes, wherein each group of membrane assemblies are connected with an inflow pipeline, an outflow pipeline and a circulating backflow pipeline, the inflow pipeline is connected with a blow down pipeline and a chemical washing pipeline, and the outflow pipeline is connected with a backwashing pipeline; different membrane assemblies can be singly used, serially used or used in parallel; each inflow pipeline is connected with a storage pot type heat exchanger to achieve the purpose of simultaneously carrying out temperature regulation and feed buffering; and a pressure sensor is arranged in front of a reverse osmosis membrane assembly for automatically controlling and separating required constant pressure. The device can realize the following working modes: the single working of the membrane assemblies; the serial working of the membrane assemblies; the parallel working of the membrane assemblies; the chemicalwashing of the membrane assemblies; the backwashing of the membrane assemblies; and the blow down of the membrane assemblies. The device can meet the requirement on the membrane separation of variouskinds of pulping and paper-making waste water with different components and properties and has the advantages of high experiment efficiency and small data error.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD

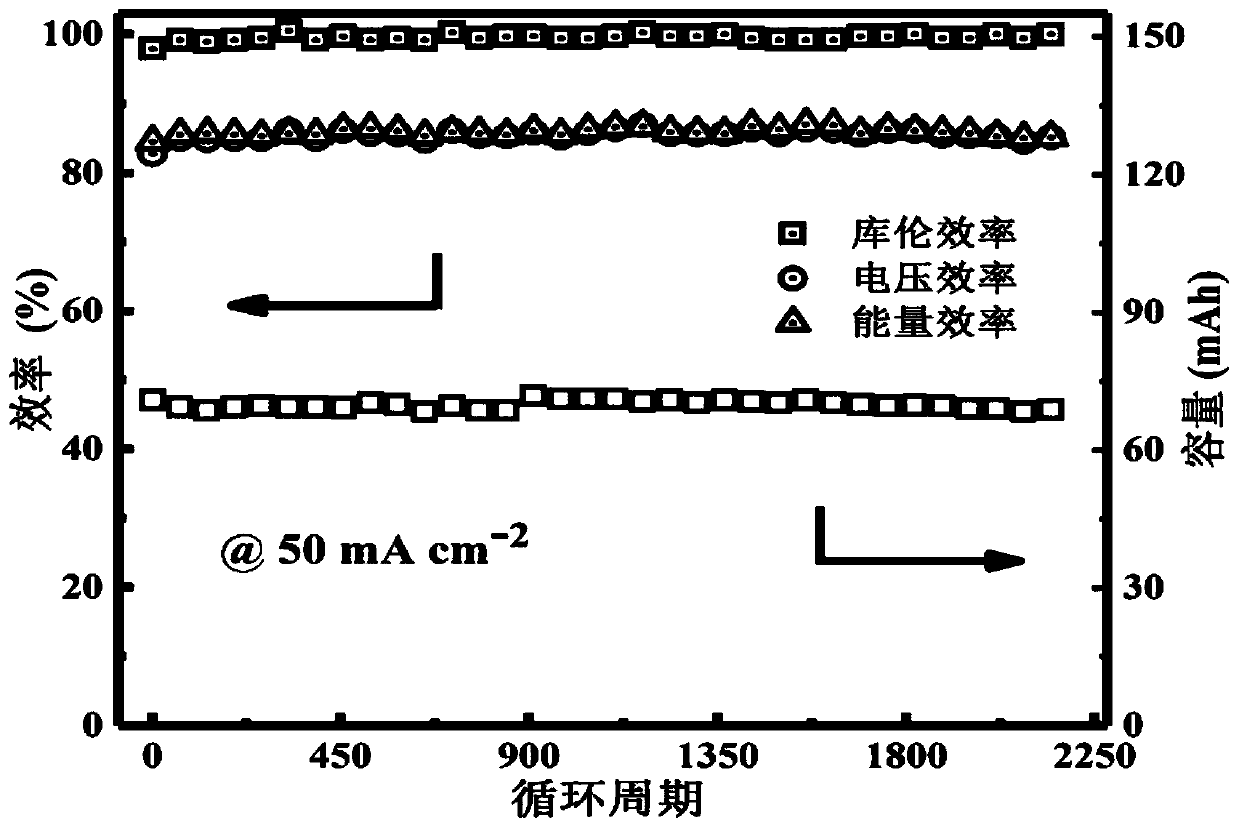

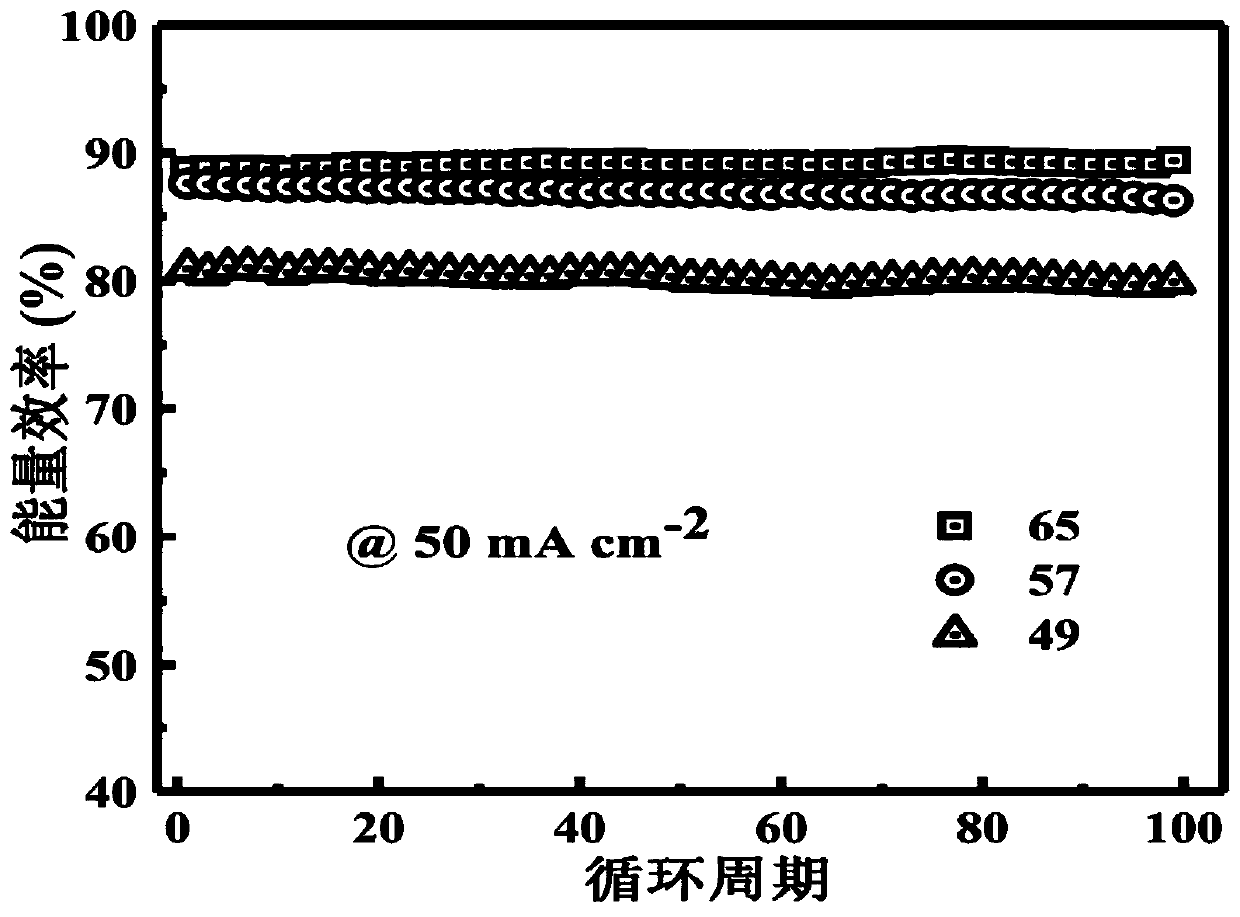

Preparation method of ion exchange membrane for alkaline redox flow battery

InactiveCN110534682AHigh ion selectivityHigh proton conductivityCell electrodesRegenerative fuel cellsKetoneCarbon felt

The invention relates to the field of alkaline redox flow battery energy storage, in particular to a preparation method of an ion exchange membrane for an alkaline redox flow battery, which is mainlyused for solving the problem of the high price of a Nafion diaphragm in the alkaline redox flow battery at the present stage, so that the cost of the redox flow battery is greatly reduced. An alkalineaqueous solution of ferricyanide (such as Na3[Fe(CN)6], K3[Fe(CN)6], (NH4)3[Fe(CN)6] and the like) is used as a positive electrolyte, and a strong alkaline solution (such as KOH, NaOH and the like) is used as a negative electrolyte; graphite felt and carbon felt are selected as positive electrode materials, and a zinc plate is selected as a negative electrode material; and the ionized sulfonatedpolyether ether ketone (SPEEK) diaphragm is used as an ion exchange membrane to assemble the battery. Therefore, the alkaline redox flow battery system with low cost and high performance is obtained.The flow battery system provided by the invention has the advantages of the high open-circuit voltage, the low cost, the high efficiency, the good cycling stability, safety, reliability and the like,and has a wide application prospect.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

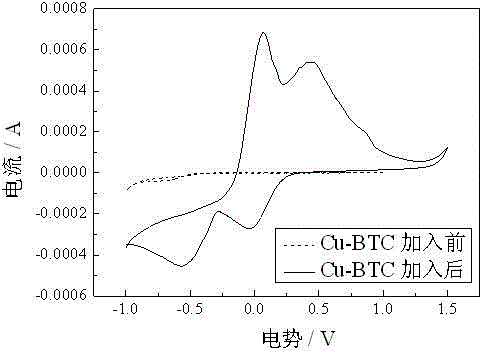

Preparation method of metal organic polymer material

InactiveCN103451717AMild reaction conditionsSimple processPolycrystalline material growthFrom normal temperature solutionsElectrolytic agentMetallic electrode

The invention discloses a preparation method of a metal organic polymer material. The preparation method comprises the following steps: in an electrolytic cell, using ionic liquid as electrolyte, using a metal electrode or a titanium-based oxide electrode as an anode, using a titanium plate as a cathode, turning on a power supply, controlling the temperature and current density to carry out electric synthesis, carrying out solid-liquid separation, washing the product through a solvent, and then, washing the product through chloroform, and drying the product to obtain the metal organic polymer material; and finally, removing organic ligands, metal salt ions and solvent molecules out of pores of the synthesized metal organic polymer material and from surfaces of the pores to prepare the metal organic polymer material. The method of the invention is carried out under normal temperature and normal pressure, thereby having the advantages of mild reaction conditions, simple process, easiness for controlling the reaction, no secondary pollution, etc and is clean, sanitary and friendly to the environment.

Owner:TAIYUAN UNIV OF TECH

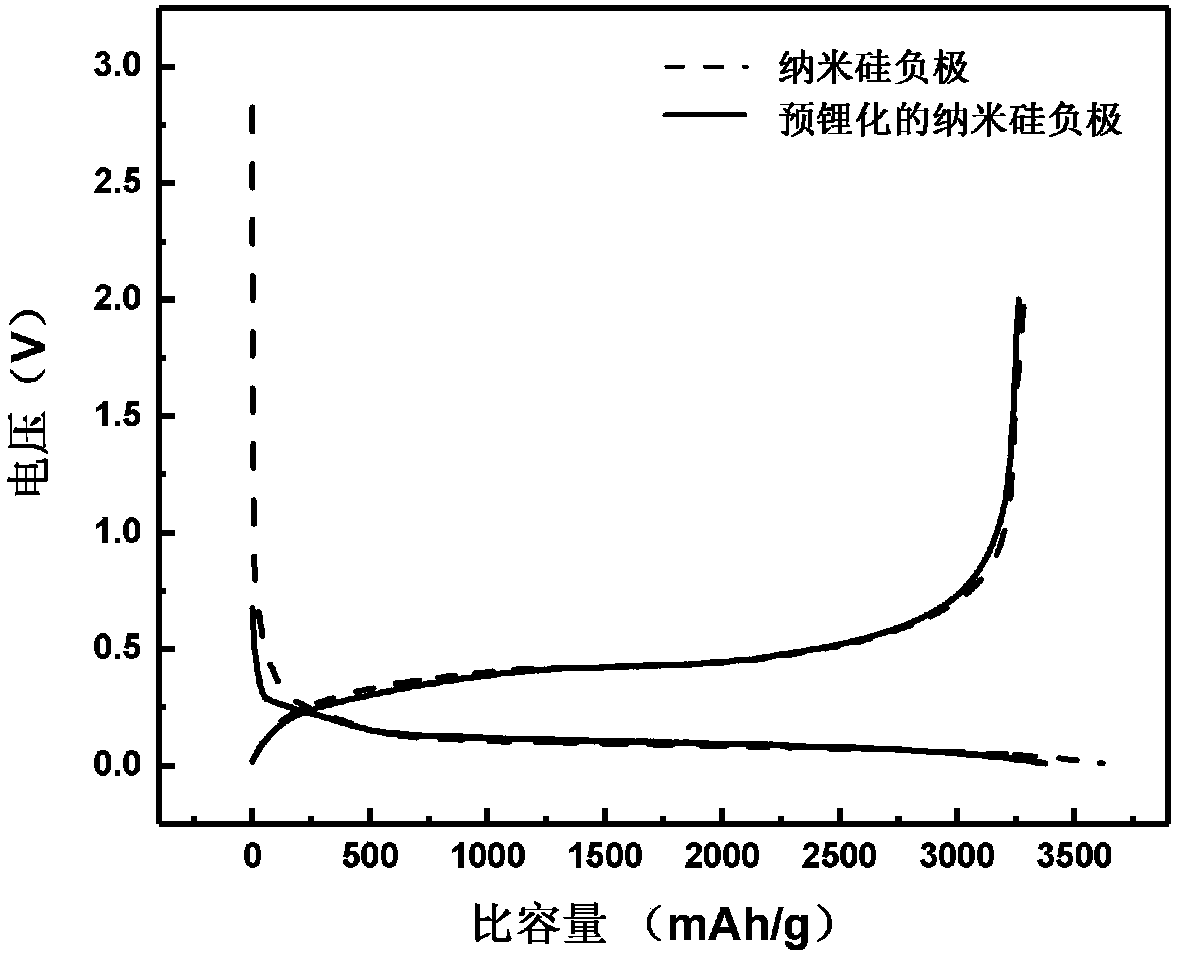

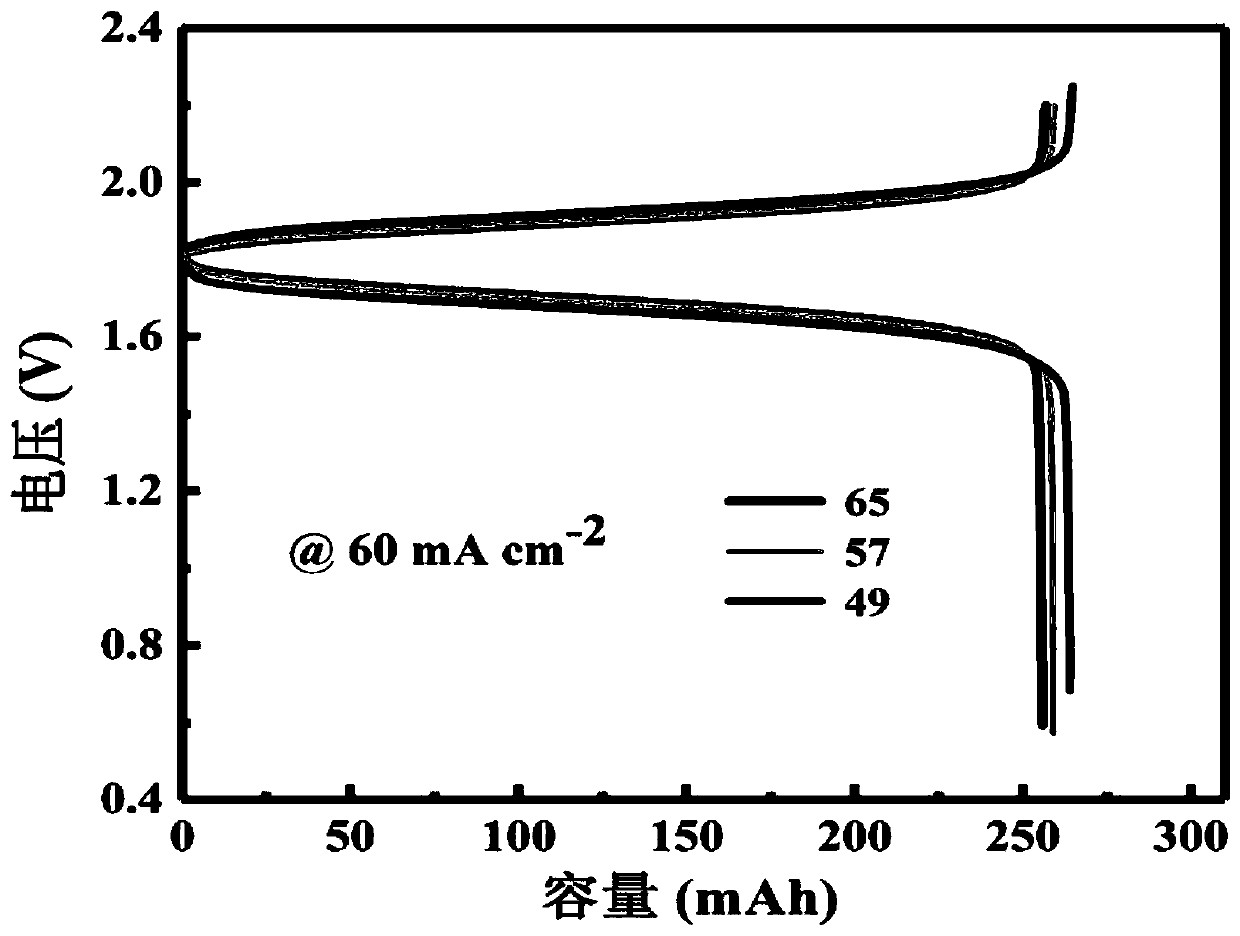

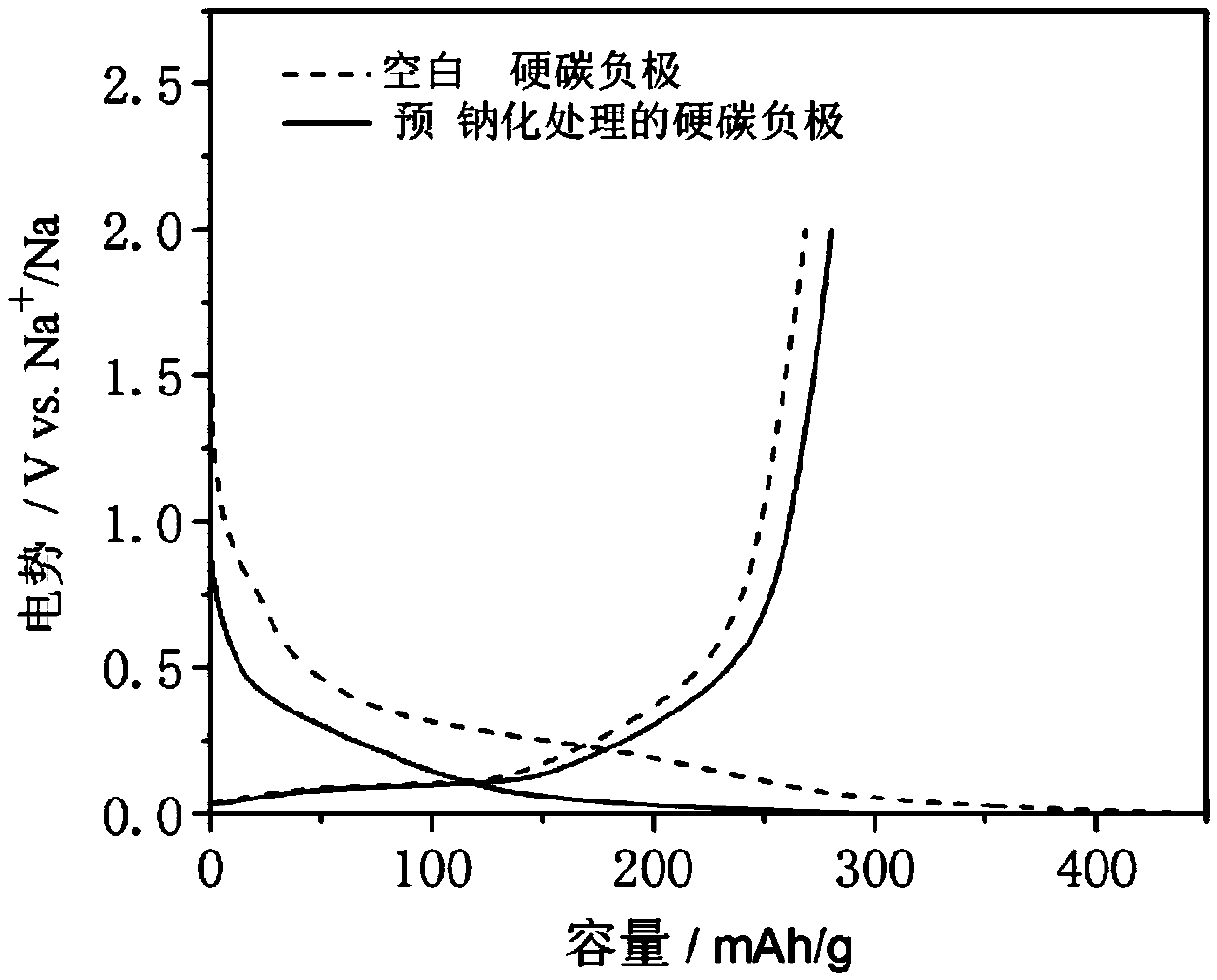

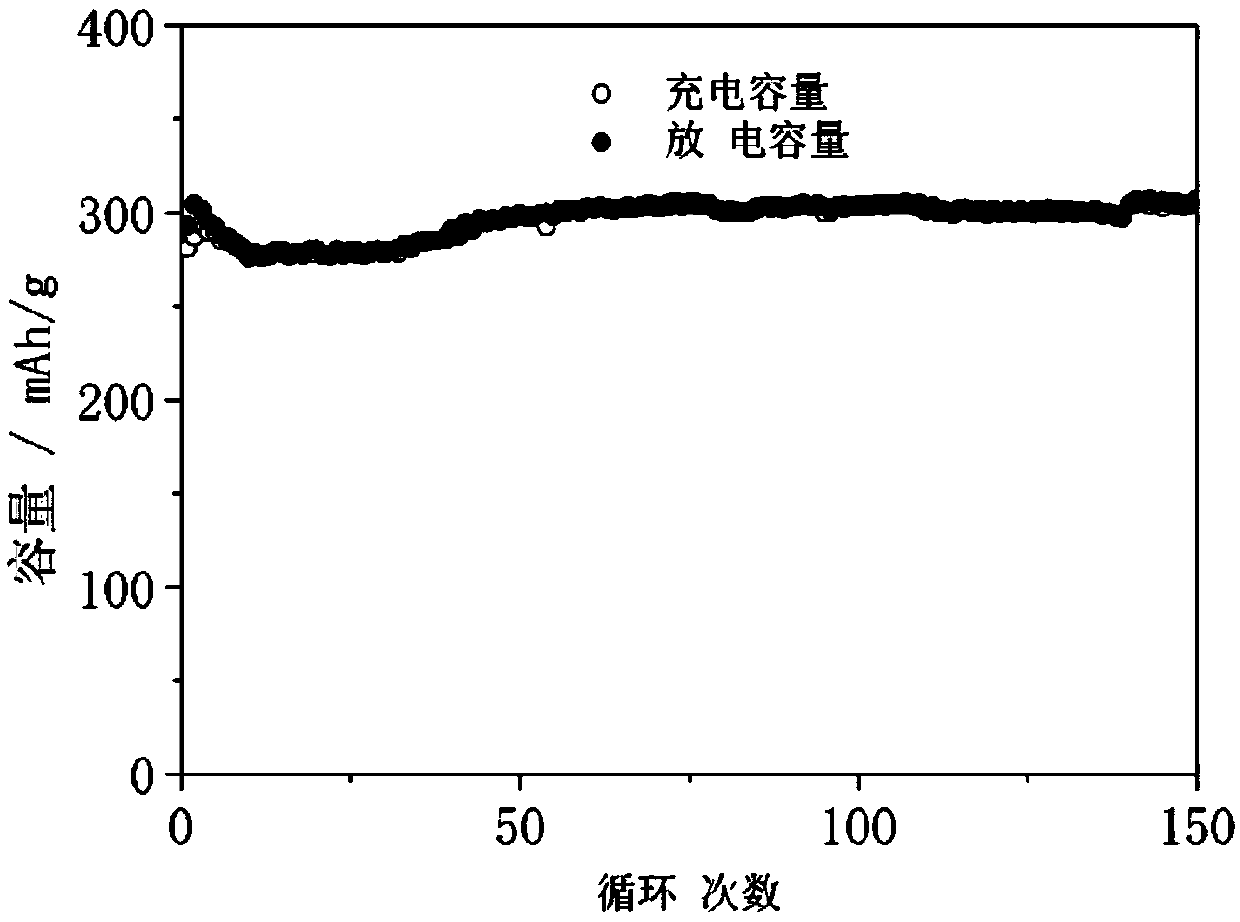

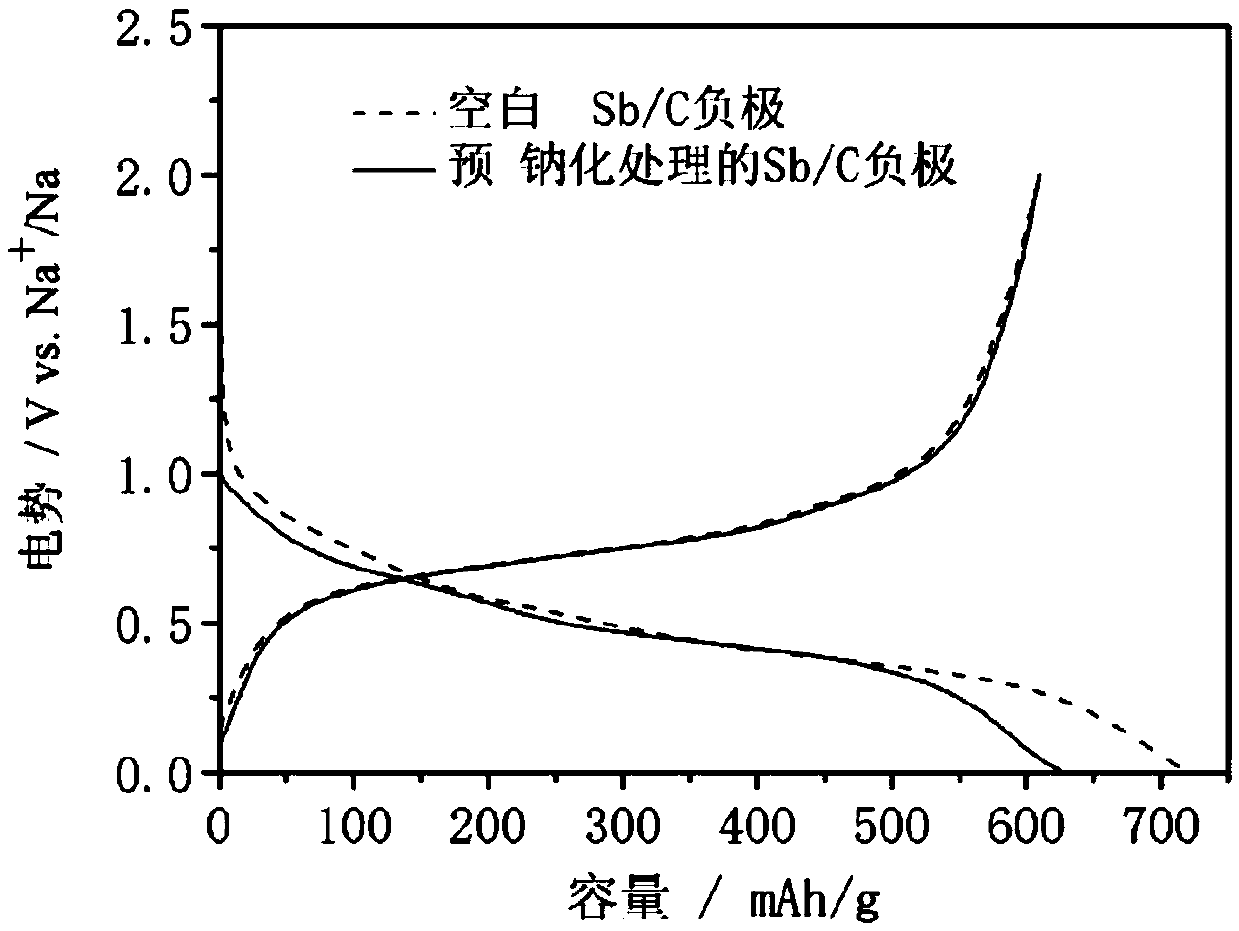

Sodium ion battery negative electrode pre-sodium modification method, obtained negative electrode material and sodium ion battery

InactiveCN109546134APromote the process of industrializationIncrease energy densitySecondary cellsNegative electrodesHigh energySodium-ion battery

The invention provides a sodium ion battery negative electrode pre-sodium modification method, an obtained negative electrode material and a sodium ion battery. A sodium ion battery negative electrodematerial is enabled to react with an aryl sodium solution, wherein an aryl sodium reagent is a polycyclic conjugated aryl sodium compound. Irreversible capacity existing in a first-cycle discharge process of the negative electrode material can be eliminated, and the first-cycle coulombic efficiency of a negative electrode is greatly improved. The method can be carried out at normal temperature, and is short in reaction time, simple in process, controllable in reaction depth, high in safety and easy to industrialize. Meanwhile, the energy density and the cycling stability of the sodium ion whole battery assembled by matching the pre-sodium-modified negative electrode and the sodium storage positive electrode are greatly improved, so that the possibility is provided for the practical development of a high-energy-density sodium battery system.

Owner:WUHAN UNIV

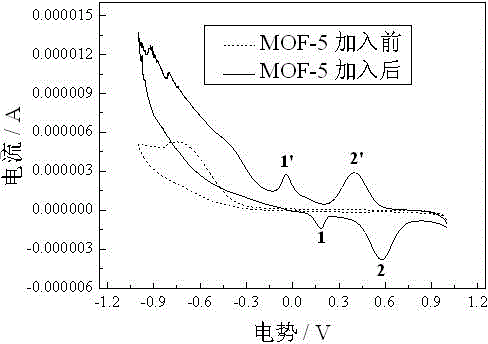

Method for hydrogen production and storage through catalysis of water splitting by MOF composite electrode

ActiveCN104131309AHigh hydrogen storage capacityRealize online storageElectrode shape/formsElectricityComposite electrode

The invention relates to a method for hydrogen production and storage through catalysis of water splitting by an MOF (metal-organic framework) composite electrode. The method utilizes the unsaturated metal sites and the porous structure of MOF to conduct electrocatalysis on water splitting so as to produce hydrogen, and the produced hydrogen is stored in an MOF porous material on line, thus realizing integration of hydrogen production and storage. The method greatly reduces the hydrogen production overpotential, is simple in operation and is easy to control, storage and release of hydrogen are realized through charge and discharge, the absorption and desorption conditions are mild, the current efficiency is greater than or equal to 75%, and the electrochemical hydrogen storage capacity can reach 920mAh / g. The method provided by the invention realizes synchronization of hydrogen production and storage, and greatly promotes the research and industrialization process of the water splitting technology for hydrogen production and storage.

Owner:TAIYUAN UNIV OF TECH

Preparation method of titanium dioxide dense film for dye-sensitized solar cell

InactiveCN101697321APromote the process of industrializationImprove performanceLight-sensitive devicesSolid-state devicesSulfateSlurry

In the invention, industrial-grade titanyl sulfate is used as a titanium source to prepare aqueous titanium dioxide collosol which is suitable for film coating, the titanium dioxide collosol is rotationally coated to form a film, and after high-temperature heat treatment, a high-performance nano-titanium dioxide dense film is obtained. The combination degree between the titanium dioxide film and a matrix is improved and the contact between an electrolyte with a photoanode is effectively prevented so as to reduce electronic complex. Thus, the battery performance is improved substantially, and due to low slurry cost, the industrialization process of the dye-sensitized solar cell is promoted.

Owner:IRICO

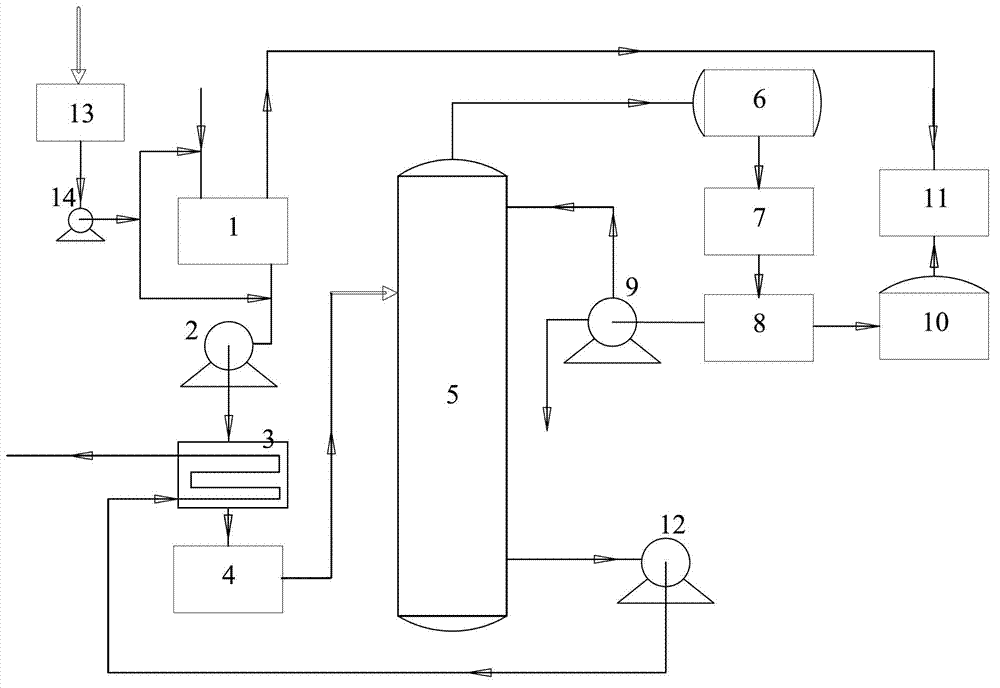

Pressure-reduction, alkali-addition and ammonia-distillation system

InactiveCN102765842ASimple processLess investmentWater contaminantsMultistage water/sewage treatmentDistillationWater quality

The invention discloses a pressure-reduction, alkali-addition and ammonia-distillation system. The system comprises a residual ammonia water tank, an ammonia distillation tower, a finished product ammonia water tank and a vacuum pumping system; by the improvements of using a metering pump to simultaneously adding an alkali liquor in an alkali liquor tank into pipes arranged at the front end and the back end of the residual ammonia water tank, and connecting the residual ammonia water tank and the vacuum pumping system with a tail gas recycling device, the use conditions of negative pressure ammonia distillation process are prepared. According to the pressure-reduction, alkali-addition and ammonia-distillation system, only an alkali-addition position needs to be adjusted without changing former ammonia distillation process and devices, the quality of ammonia distillation waste water can satisfy the demand of next process, so that the process is simple and the investment is low; the switch of pressure-reduction ammonia-distillation and normal pressure ammonia-distillation is not affected; the pressure-reduction ammonia-distillation process is improved; and the industrial process of the pressure-reduction ammonia-distillation is promoted. With the simplest process changes and lowest investment, the pressure-reduction, alkali-addition and ammonia-distillation system improves the quality of the ammonia distillation waste water, promotes the research process of the pressure-reduction ammonia-distillation, and is in favor of promoting the popularization and application of the pressure-reduction ammonia-distillation process.

Owner:JIGANG GRP

Method used for preparing lithium ion battery positive pole material fluophosphate vanadium lithium

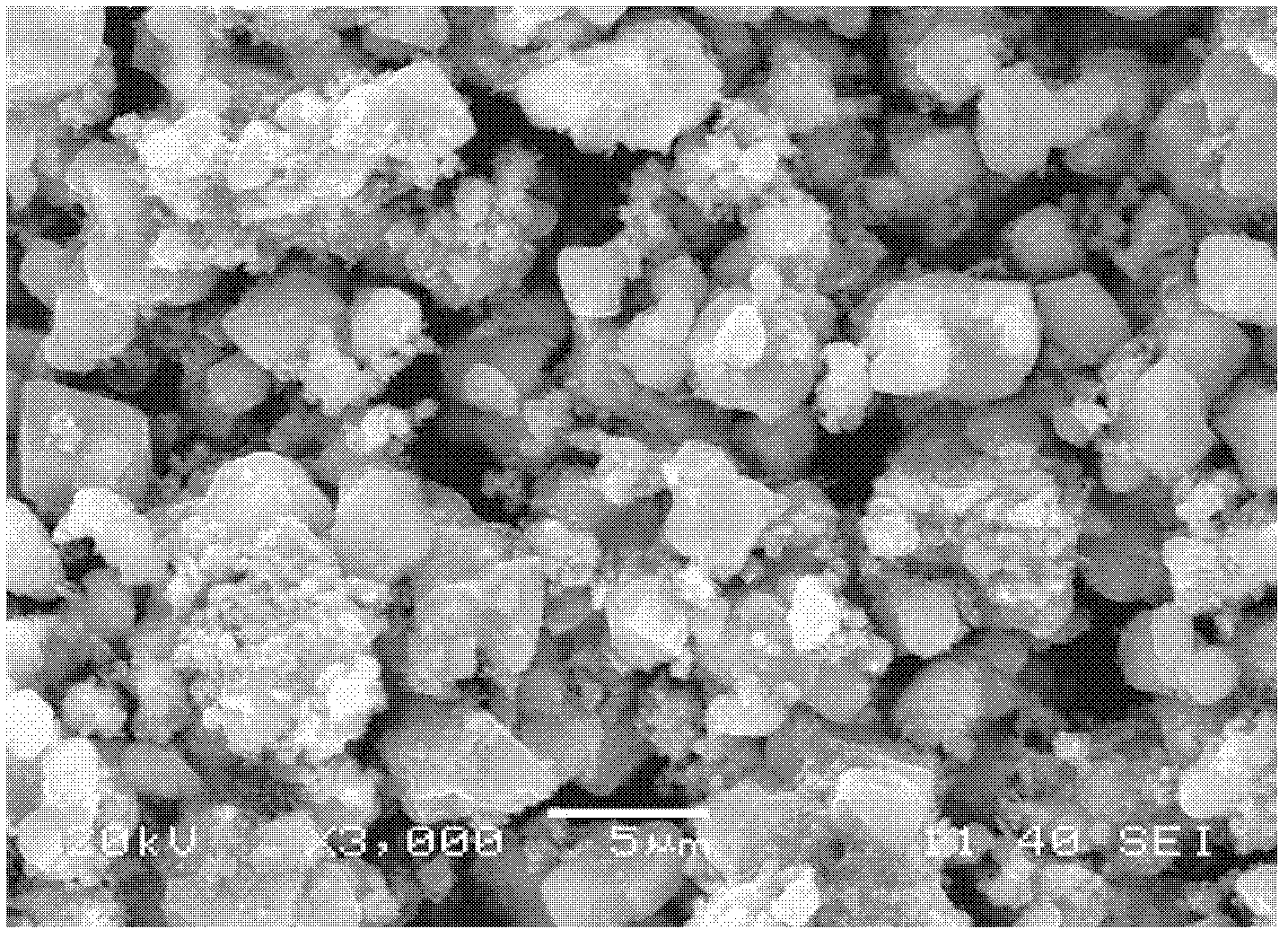

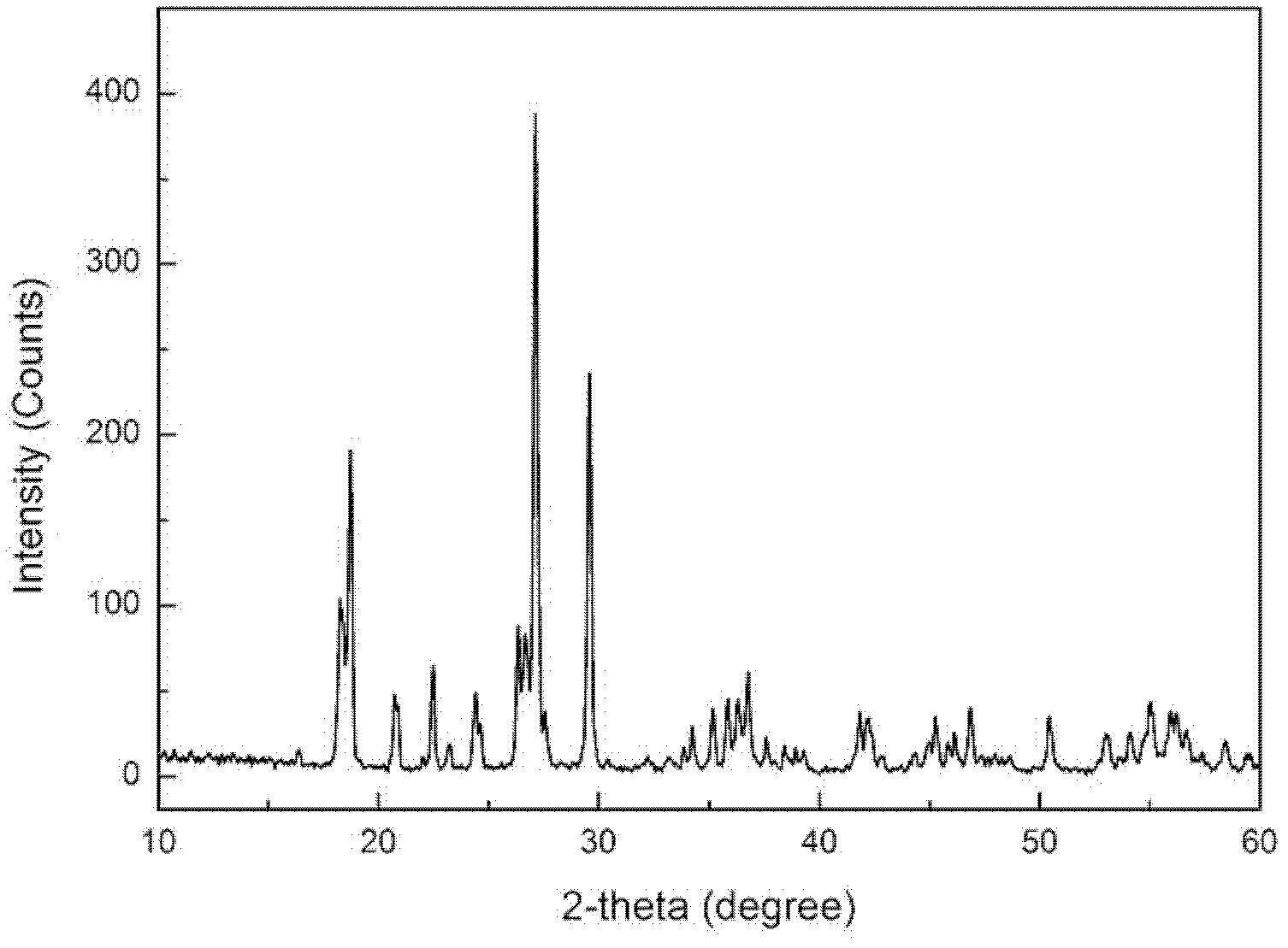

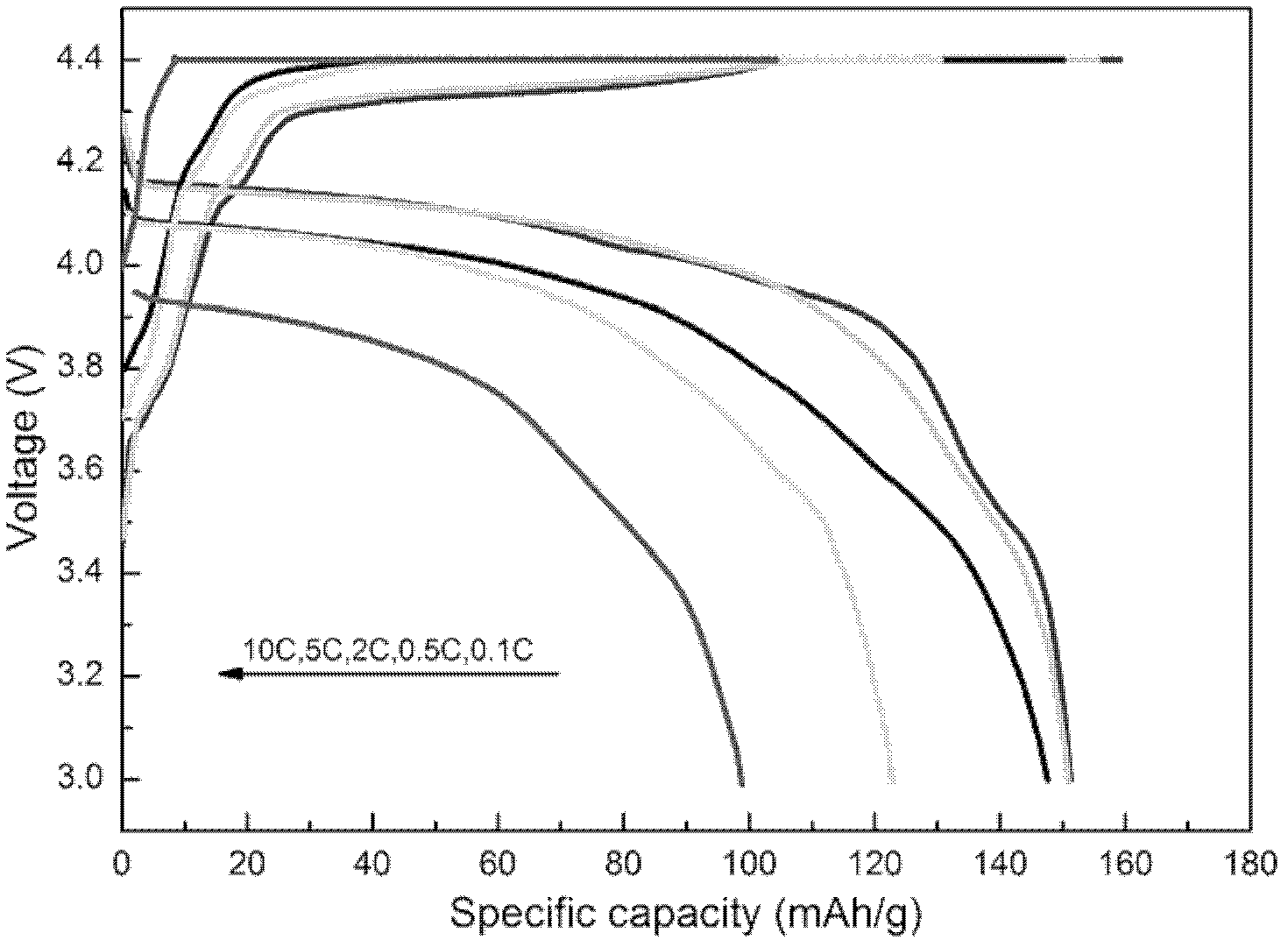

ActiveCN102354752AUniform particlesImprove electrochemical performanceCell electrodesPhysical chemistryBiological activation

The invention discloses a method used for preparing lithium ion battery positive pole material fluophosphate vanadium lithium. The method is characterized in that a normal temperature reduction-heat treating method is adopted to prepare a lithium ion battery positive pole material LiVPO4F; the method comprises the following steps: mixing a lithium source, a vanadium source, a fluorine source and a phosphorus source according to the mol ratio of a lithium element, a vanadium element, a fluorine element, and a phosphorus element of 1:1:1:1, adding a reducer, wherein the dosage of the reducer is 1-5 times of that of the theory dosage; carrying out mechanical activation for 0.5-20 hours under the normal temperature condition, and reducing a high-price vanadium to a trivalence vanadium so as to prepare tiny amorphism LiVPO4F of small grains; and heating to 600-800 DEG C in non-oxidizing atmosphere and keeping constant temperature for 0.5-20 hours, thereby obtaining the positive pole material fluophosphate vanadium lithium. The electrochemistry performance of the prepared fluophosphate vanadium lithium is excellent. The fluophosphate vanadium lithium provided by the invention has the advantages of short flow, simple process, lower energy consumption and small production cost, and is easy to realize large scale production and the like.

Owner:CENT SOUTH UNIV

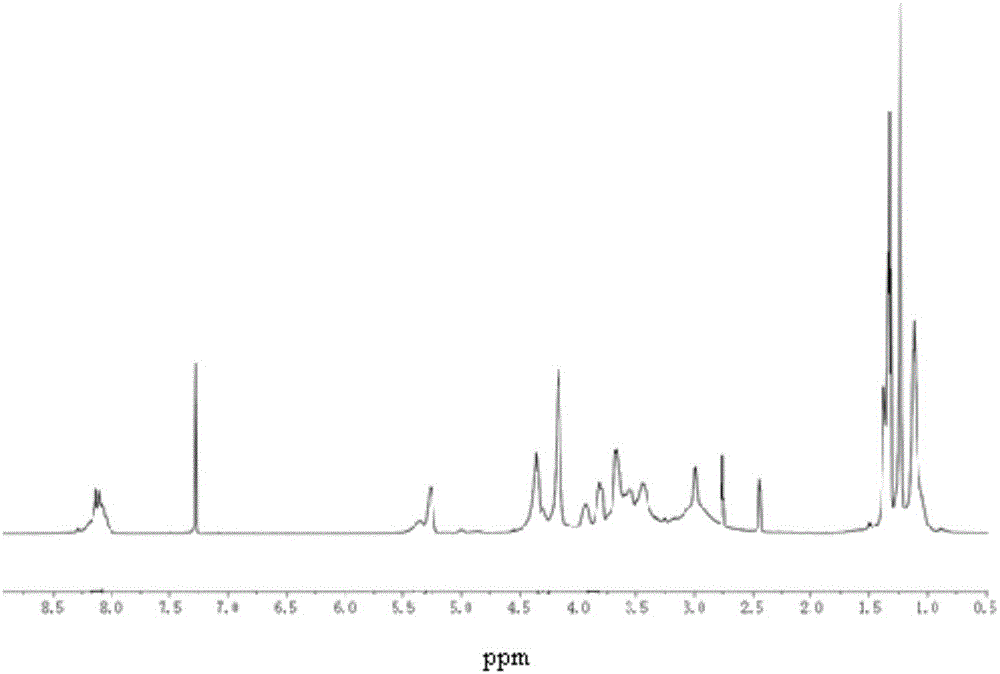

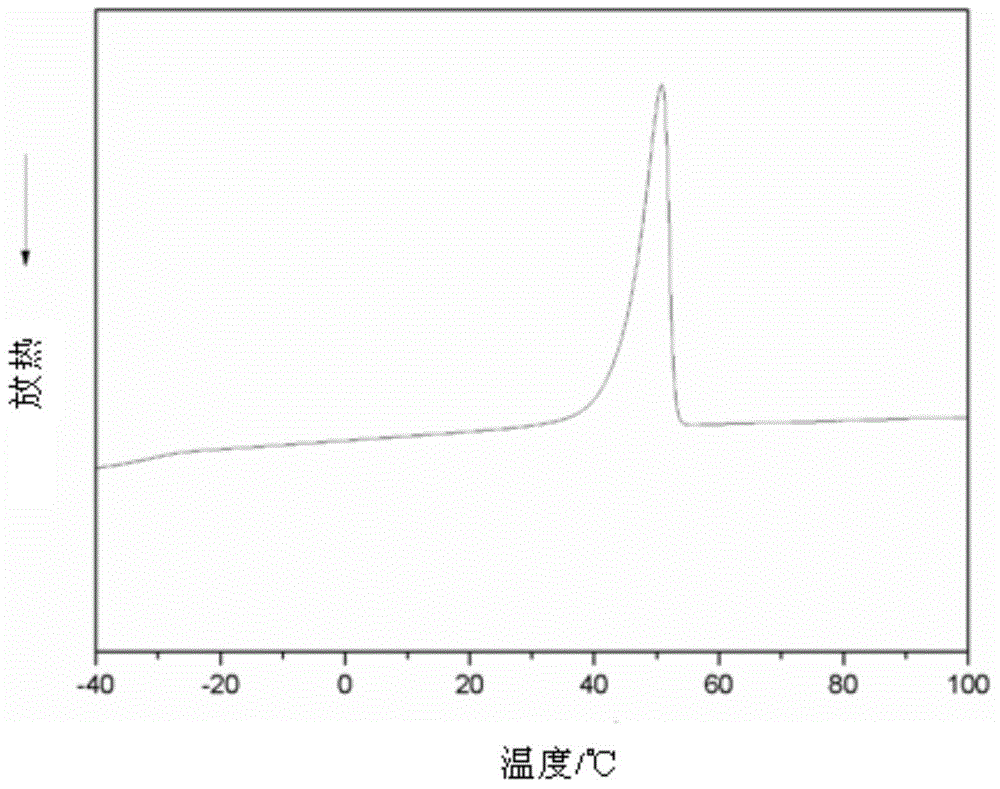

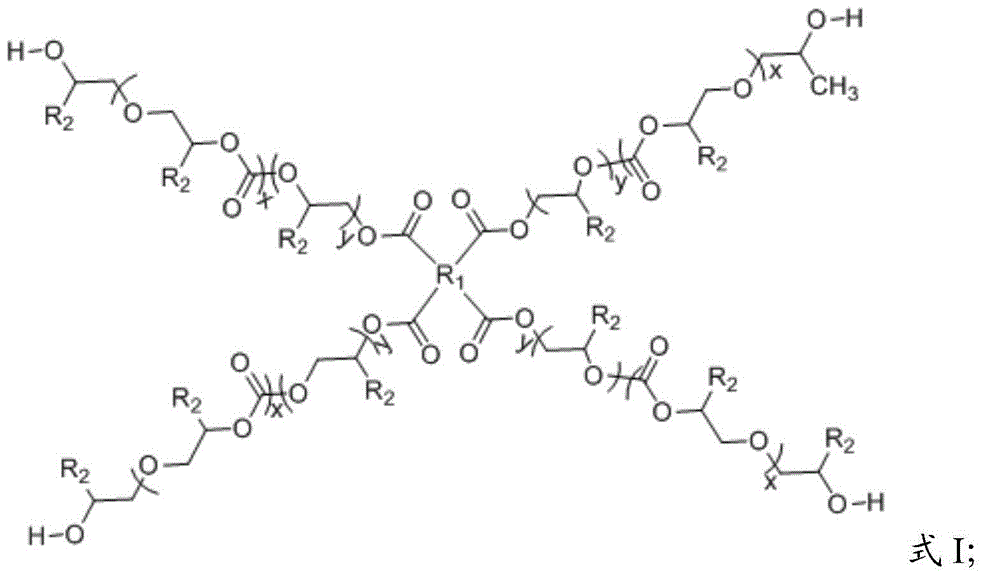

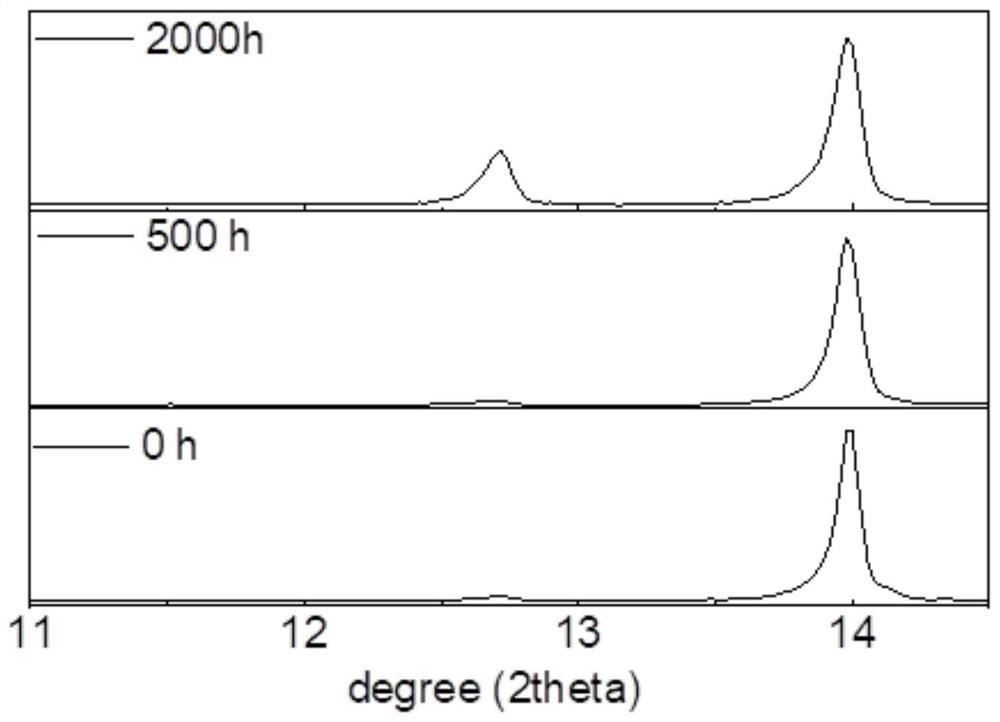

Poly (carbonate-ether)tetrahydric alcohol, preparation method of poly (carbonate-ether)tetrahydric alcohol and carbon dioxide based shape memory polyurethane

The invention provides poly (carbonate-ether)tetrahydric alcohol with a structure as formula I. The invention provides carbon dioxide based shape memory polyurethane which is prepared with a preparation method comprising steps as follows: poly (carbonate-ether)tetrahydric alcohol, crystallized dihydric alcohol and diisocyanate react, and the carbon dioxide based shape memory polyurethaneis obtained. The poly (carbonate-ether)tetrahydric alcohol is taken as a macromolecule crosslinking agent, can accurately control the molecular weight, has characteristics of polyether polyol and polyester polyol and can accurately control the molecular weight as well as the content of a carbonic ester unit and ether bond, and the shape memory and the shape restorability of the carbon dioxide based shape memory polyurethane prepared from the poly (carbonate-ether)tetrahydric alcohol serving as the raw material can be adjusted. Besides, the production cost of the poly (carbonate-ether)tetrahydric alcohol is reduced due to introduction of carbon dioxide, and the carbon dioxide based shape memory polyurethane has large-scale application prospect; and the poly (carbonate-ether)tetrahydric alcoholis taken as the raw material for synthesizing shape memory polyurethane, and the industrialization process of the shape memory polyurethane is promoted.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Graphene bonded copper wire and preparation method thereof

InactiveCN106816423AImprove conductivityImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesCopper wireCvd graphene

The invention provides a graphene bonded copper wire and a preparation method thereof. The graphene bonded copper wire comprises a copper wire and a graphene layer which packages the copper wire. The diameter of the copper wire is 0.016-0.050mm. The thickness of the graphene layer is 0.001-0.2 [mu]m. The preparation method comprises the following steps of S1, oxidizing crystalline flake graphite and preparing graphene oxide aqueous solution; S2, applying the graphene oxide aqueous solution on the surface of a bonding copper wire; S3, restoring the graphene oxide for obtaining the graphene, and directly packaging the bonding copper wire; and S4, applying annealing solution on the surface of the graphene bonded copper wire and performing drying. The graphene bonded copper wire and the preparation method thereof settle problems of easy copper wire oxidation and adhesion of external packaging wires. Furthermore the graphene bonded copper wire and the preparation method further have advantages of realizing environment-friendly performance, improving conductivity and heat radiation performance of the material. The graphene bonded copper wire and the preparation method improve an industrialization process of the copper base bonded wire.

Owner:SHANDONG KEDADINGXIN ELECTRONICS TECH

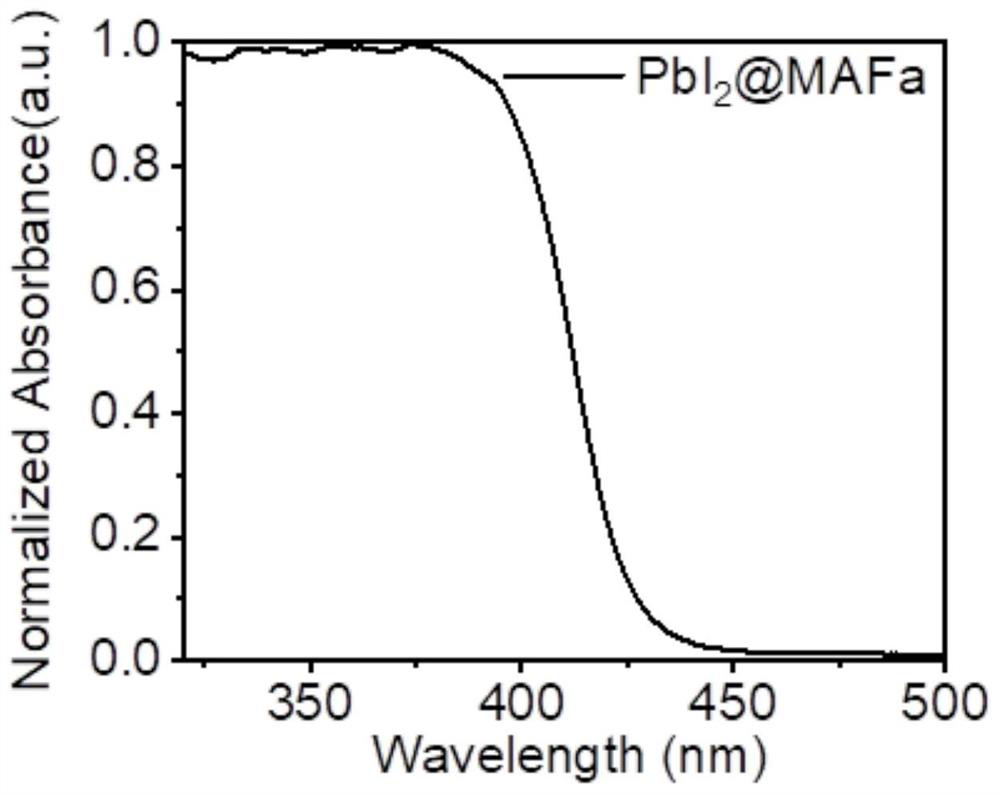

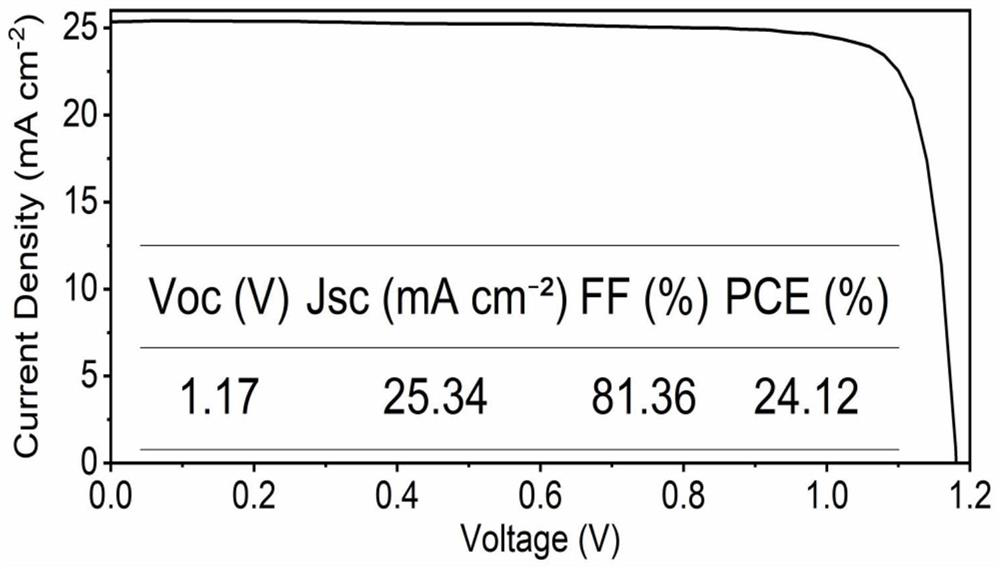

Efficient and stable perovskite solar cell based on novel ionic liquid methylamine formate as well as preparation method and application of perovskite solar cell

ActiveCN111952456ANarrow bandgapReduce defectsSolid-state devicesSemiconductor/solid-state device manufacturingMetallic electrodeElectrical battery

The invention relates to an efficient and stable perovskite solar cell prepared by dissolving lead halide PbX2 (X = Cl, Br, I), lead acetate, lead sulfate and the like based on novel ionic liquid methylamine formate as well as a preparation method and application of the perovskite solar cell, and belongs to the field of optoelectronic materials and devices. The preparation method comprises the following steps: dissolving PbI2 into a methylamine formate solvent according to the concentration of 1-1.5 M, spin-coating PbI2 on an ITO substrate deposited with SnO2 by using a heating spin-coating method, annealing to form a compact, uniform and stable PbI2 film, spin-coating a cation solution on the PbI2 film, annealing to form stable formamidine lead iodine perovskite, and completely operatingthe whole process in air. And then spin-coating a Spiro-OMeTAD hole transport layer on the thin film, and evaporating a modification layer MoO3 and a metal electrode by using a vacuum evaporation technology to complete the preparation of the device.

Owner:NANJING TECH UNIV

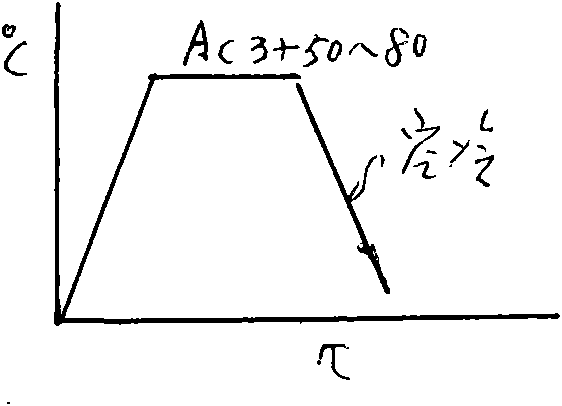

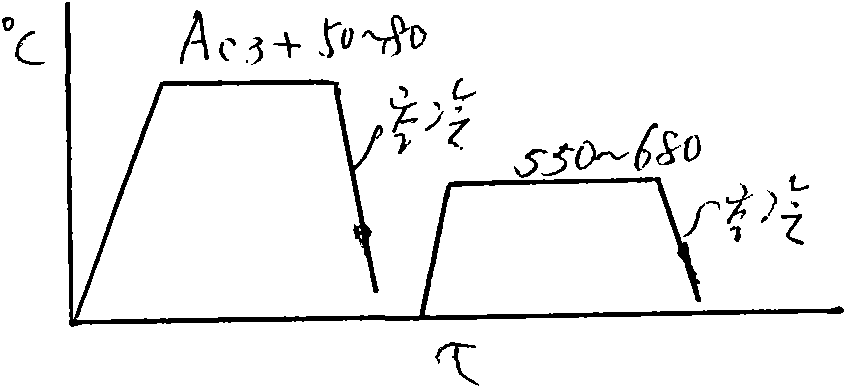

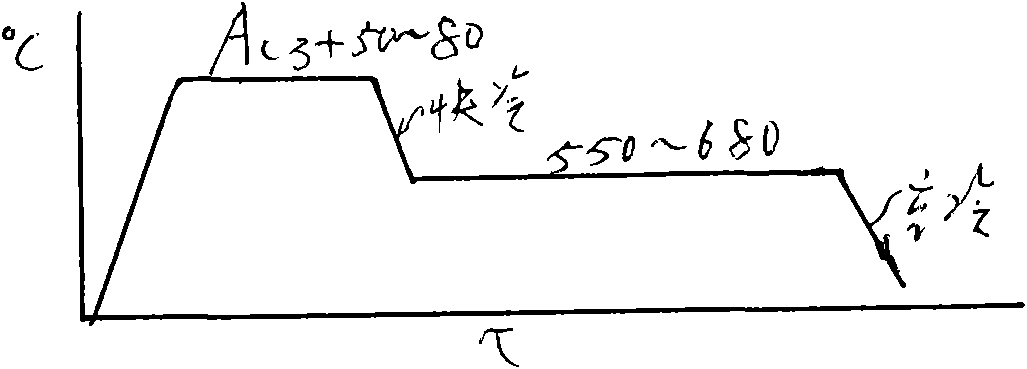

Gear blank isothermal annealing process and isothermal annealing production line

InactiveCN101886163AEnsure consistencyReduce heat lossFurnace typesIncreasing energy efficiencyProduction lineHardness

The invention relates to a heating treatment process for scale production of gear blanks and a corresponding heating treatment production line. The invention eliminates the integral recrystallization heating of the gear blanks, and gears can stably obtain a metallographic structure with excellent cutting performance and an expected hardness value no matter using a forging waste heat isothermal annealing process or an isothermal annealing process conducted after the blank is cooled of the invention.

Owner:天津市天瑞硬化工程有限公司

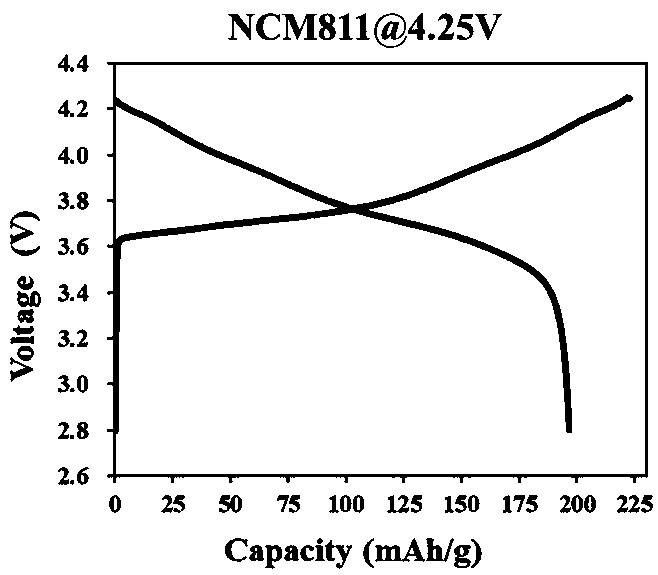

Preparation method of ternary positive electrode material of lithium-rich manganese-based coating layer

PendingCN110668507AImprove performanceImprove electrochemical stabilityCell electrodesNickel compoundsElectrolytic agentPhysical chemistry

The invention discloses a preparation method of a ternary positive electrode material of a lithium-rich manganese-based coating layer. The preparation method comprises the following steps: synthesizing a nickel-rich ternary positive electrode material on the basis of a conventional coprecipitation method, and coating a lithium-rich manganese-based layer on the nickel-rich ternary positive electrode material by a solvothermal method. According to a microscopic core-shell structure, the high-capacity characteristic of the lithium-rich manganese-base layer and the structural stability of the ternary positive electrode material are perfectly combined, so that the material optimal performance is achieved. And finally, the material is coated with an AlF3 coating for protecting the material fromreacting with electrolyte, so that the performance of the material is more stably. The morphology and particle size of the material can be controlled, and the method is simple, controllable and suitable for industrial production.

Owner:HUBEI WANRUN NEW ENERGY TECH DEV

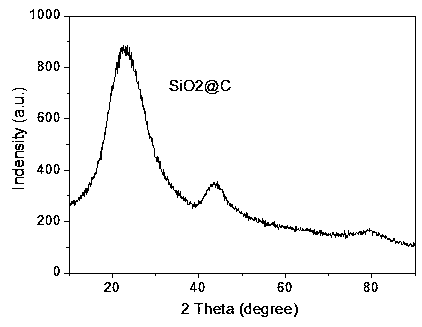

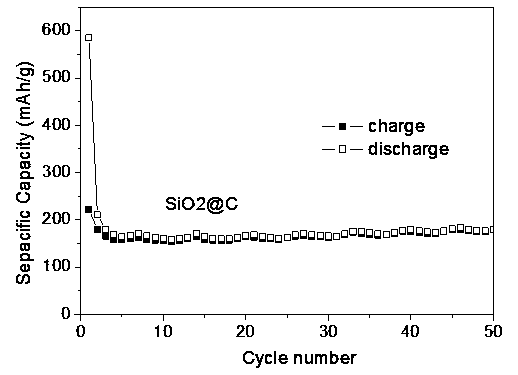

Preparation method and application of in-situ carbon-coated silicon dioxide carbon composite material

InactiveCN111029554AImprove conductivityImprove stabilitySecondary cellsNegative electrodesCarbon compositesCarbon coating

The invention provides a preparation method and application of an in-situ carbon-coated silicon dioxide carbon composite material. The method comprises the following steps: mixing and dissolving a carbon source, a surfactant and alkali liquor, adding an organic silicon source, stirring, transferring a solution into a reaction kettle, carrying out high-temperature and high-pressure hydrothermal reaction to obtain a black precipitate, drying the black precipitate, putting the dried substance into a furnace, introducing shielding gas, and carrying out reaction at high temperature to obtain the product silicon dioxide-carbon composite material. The process is simple and feasible, the raw materials are rich and cheap, and the obtained silicon dioxide material is uniform in particle distribution, uniform in carbon coating and high in conductivity and can be applied to the field of lithium battery negative electrode materials.

Owner:HUBEI WANRUN NEW ENERGY TECH DEV

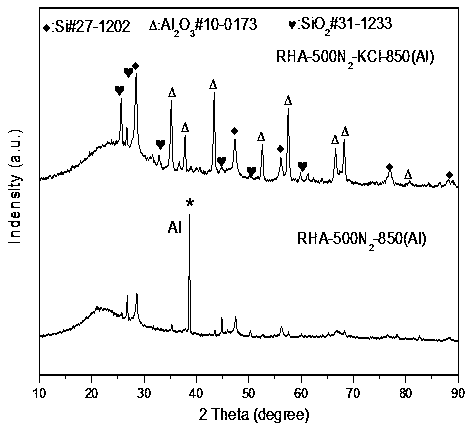

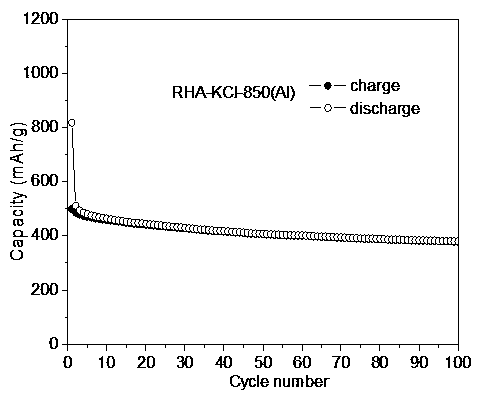

Preparation method and application of high-safety biomass silicon synthesized SiOx@C material

ActiveCN110867567AImprove stabilityImproved magnification performanceNegative electrodesSecondary cellsCarbon coatingCarbonization

The invention provides a preparation method of a high-safety biomass silicon synthesized SiOx@C material. The method comprises the following steps: pickling rice hull ash, carbonizing a proper amountof the rice hull ash in an inert atmosphere, uniformly mixing and ball-milling the carbonized product, metal powder and molten salt, putting the mixture into a furnace, introducing inert gas, carryingout a high-temperature reaction, and pickling to clean byproducts to obtain the product of the SiOx@C material. The method is simple and feasible in process, rich and cheap in raw materials and higher in safety compared with magnesiothermic reduction, and the obtained SiOx@C particles have porous structures, are uniform in carbon coating and good in rate capability and can be applied to the fieldof lithium battery negative electrode materials.

Owner:HUBEI WANRUN NEW ENERGY TECH DEV

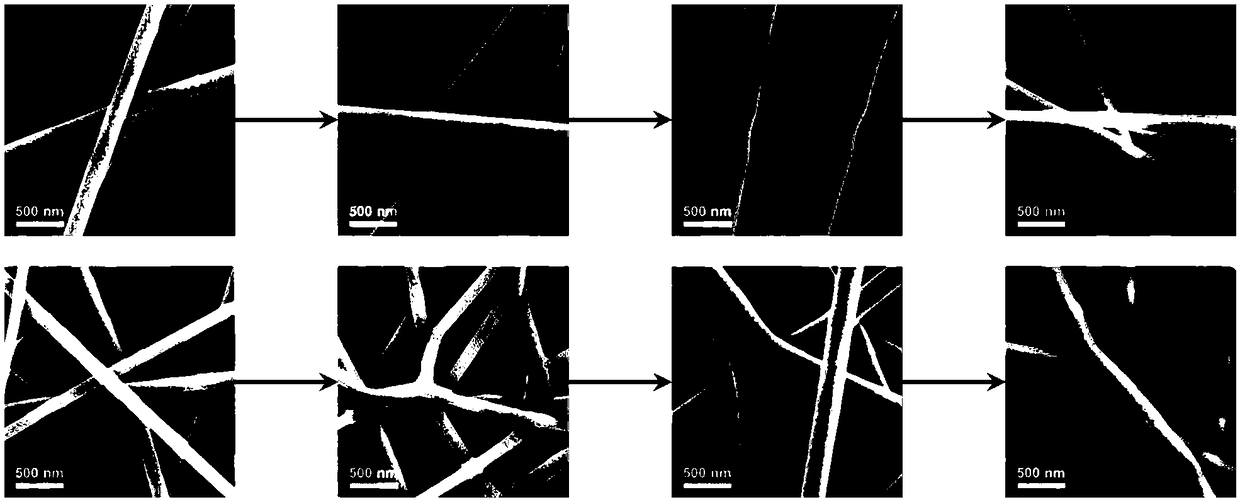

Method for preparing carbon nanofibers from wearing acrylic fibers or waste wearing acrylic fibers

The invention relates to a method for preparing carbon nanofibers from wearing acrylic fibers or waste wearing acrylic fibers, and belongs to the technical field of preparation of the carbon nanofibers. The method includes performing washing, impurity removal and drying pretreatment on the wearing acrylic fibers or the waste wearing acrylic fibers, then re-dissolving the acrylic fibers by good solvents, adding metal salt for modifying, controlling modification temperature and time to obtain spinning precursors, and performing spinning, pre-oxidation and carbonation on the spinning precursors to obtain the carbon nanofibers. The metal salt for modification refers to one or two or more of cobalt acetate, manganese acetate, zinc acetate, ferric acetate, nickelous acetate, copper acetate, magnesium acetate, sodium acetate, cobalt chloride, zinc chloride, manganese chloride, ferric chloride, copper chloride, cuprous chloride or stannous chloride. Raw materials applied to the method are waste. The method has the advantages that cyclization reaction triggering mechanisms of the acrylic fibers during pre-oxidation can be changed, cyclization reaction starting temperatures of the acrylic fibers can be lowered remarkably at the same time, energy conservation and environmental protection can be achieved, and production costs can be reduced remarkably.

Owner:ZHEJIANG SCI-TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com