Pilot scale production method of low-carbon Fe-Mn-Al-Si series TWIP (Twining Induced Plasticity) steel

A technology of fe-mn-al-si and molten steel, applied in the direction of furnace type, furnace, energy efficiency, etc., can solve the problem of less research on hot rolling process, lack of hot and cold rolling process control methods, and lack of TWIP steel Issues such as production smelting process and parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The method of the present invention will be described in further detail below in conjunction with the specific embodiments of the accompanying drawings.

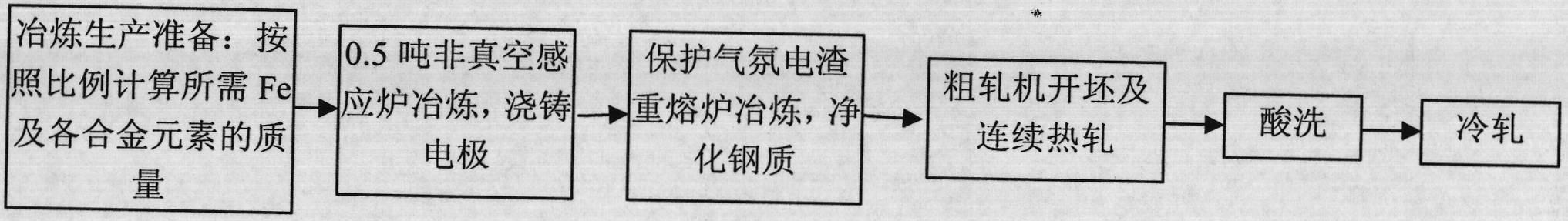

[0030] The technical scheme flow chart of the present invention is as figure 1 As shown, the pilot production of TWIP steel with Fe-24Mn-1.5Al-1.0Si-0.05C as the target composition mainly includes two processes of smelting and rolling of TWIP steel. The details of each process and related parameters are as follows:

[0031] 1) Smelting process control and process parameters

[0032] According to the current production status and actual situation of my country's iron and steel enterprises, the smelting link in the pilot production of TWIP steel is completed by the combined smelting of 0.5 tons of non-vacuum induction furnace and 2.5 tons of electroslag remelting furnace.

[0033] A1 non-vacuum intermediate frequency induction furnace smelting

[0034] First add pure iron into the induction furnace, and the induction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com