Multifunctional membrane separation device for treating pulping and paper-making waste water and separation method thereof

A pulp and papermaking and membrane separation technology, applied in semipermeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problem of single structure and function, poor function pertinence, and inability to realize serial and parallel connection between components and processes Operation and other issues to improve experimental efficiency and reduce data errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

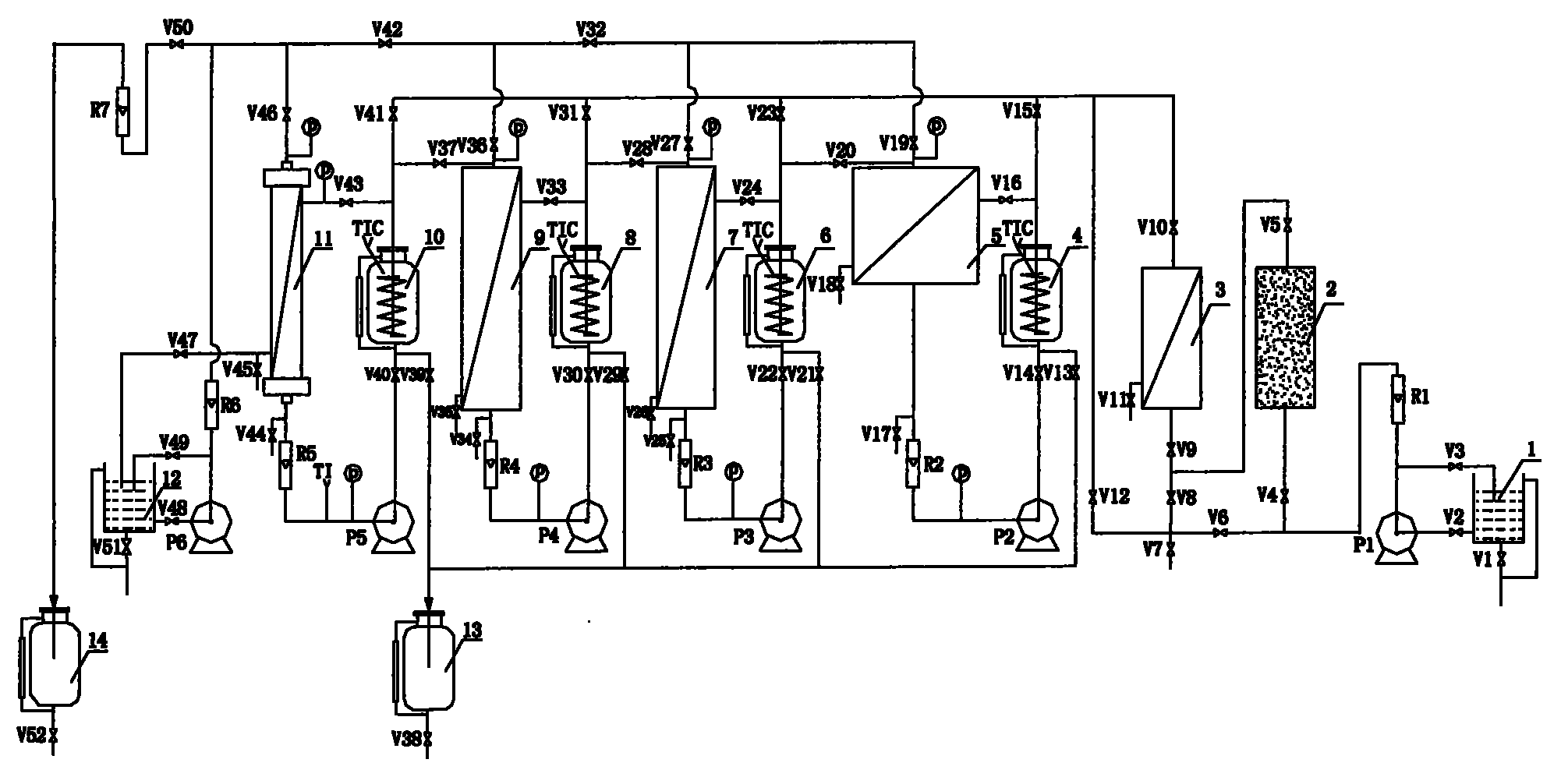

[0026] Using the present invention as figure 1 The multi-functional membrane separation device shown, according to the following steps, the alkaline hydrogen peroxide chemical mechanical pulp (APMP) comprehensive wastewater is sequentially passed through the plate and frame membrane module, the tubular membrane module, the roll membrane module and the hollow fiber membrane module The tandem membrane separation operation:

[0027] 1) The APMP comprehensive wastewater is only pretreated by the coarse filter module 2: inject the APMP comprehensive wastewater to be separated into the liquid inlet tank 1; open the valves V2, V3, V4, V5, V8, and V12, and close the other valves; open the main liquid inlet Pump P1, through adjusting the valve V3 to control the inlet flow to the specified flow; the working time is 5 to 10 minutes.

[0028]2) Plate and frame membrane module 5 (microfiltration), tubular membrane module 7 (ultrafiltration), roll membrane module 9 (nanofiltration) and hol...

Embodiment 2

[0038] Using the present invention as figure 1 The multi-functional membrane separation device shown, according to the following steps, the pulp bleaching comprehensive wastewater is simultaneously separated through parallel membrane modules of plate and frame membrane modules, tubular membrane modules, roll membrane modules and hollow fiber membrane modules:

[0039] 1) The pulp bleaching comprehensive wastewater is only pretreated by the fine filter assembly 3: inject the pulp bleaching comprehensive wastewater to be separated into the liquid inlet tank 1; open the valves V2, V3, V6, V8, V9, V10, close the other valves; open the main The liquid inlet pump P1 controls the liquid inlet flow to the specified flow rate by adjusting the valve V3; the working time is 10 to 15 minutes.

[0040] 2) Parallel operation of plate and frame membrane module 5 (microfiltration), tubular membrane module 7 (ultrafiltration), roll membrane module 9 (nanofiltration) and hollow fiber membrane m...

Embodiment 3

[0050] Using the present invention as figure 1 In the multifunctional membrane separation device shown, the separate membrane separation operation of the plate and frame membrane module is performed on the paint pipeline cleaning wastewater according to the following steps:

[0051] 1) The cleaning wastewater of the paint pipeline is not pretreated: inject the wastewater for cleaning the paint pipeline to be separated into the liquid inlet tank 1; open the valves V2, V3, V6, and V12, and close the other valves; turn on the main liquid inlet pump P1, and adjust the valve V3 controls the liquid flow rate to the specified flow rate; the working time is 1 to 5 minutes.

[0052] 2) The plate and frame membrane module 5 (microfiltration) operates alone: open the valve V15, close the other valves, inject the pretreated wastewater into the storage tank heat exchanger 4 to a specified volume; open the storage tank heat exchanger 4 Temperature sensor switch, adjust the wastewater in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com