A graphite microcrystalline carbon coating for a metal bipolar plate of a fuel cell and application thereof

A technology of metal bipolar plates and graphite microcrystals, which is applied to fuel cell parts, fuel cells, metal material coating technology, etc., can solve the problems of unknown coating durability, carbon coating performance attenuation, and complex vehicle working conditions and other issues, to achieve excellent electrical conductivity and corrosion resistance, improve stability and durability, and promote the effect of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

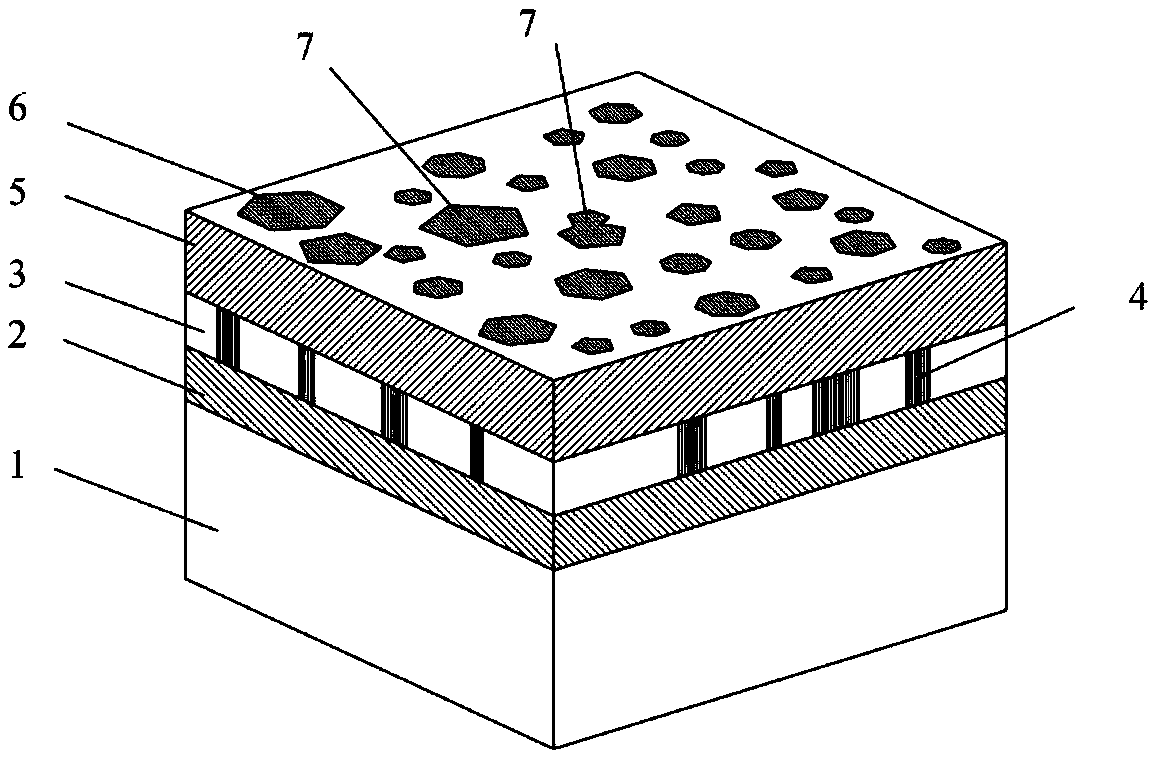

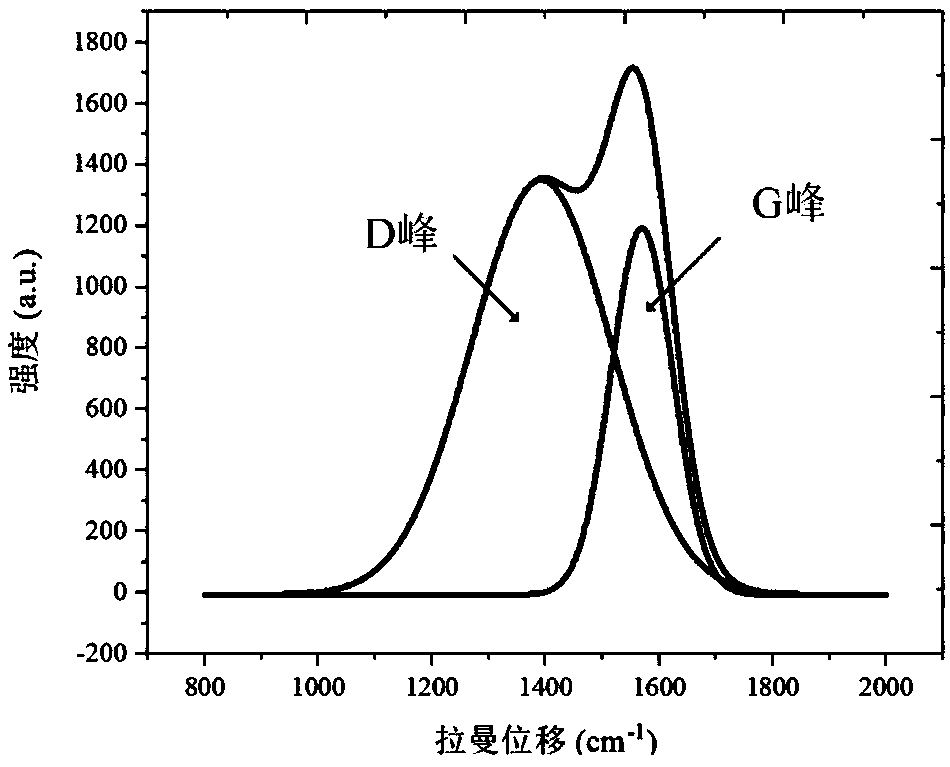

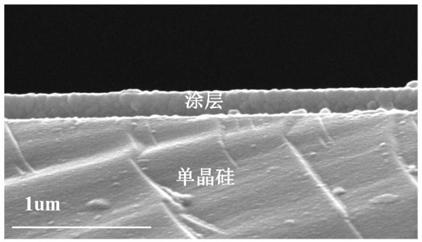

[0044] like figure 1 As shown, the preparation method of highly conductive, corrosion-resistant, and stable carbon coatings for metal bipolar plates includes the following steps:

[0045]1) Use a cleaning agent to clean the oil and impurities on the surface of the metal bipolar plate 1, dry the cleaned metal bipolar plate 1 and put it into the furnace chamber, then control the vacuum degree of the furnace chamber, and turn on the ionizer after the vacuum degree reaches the set value. The source generates plasma to bombard the surface of the metal bipolar plate 1 to remove the metal oxide layer on the surface of the plate 1, improve the surface cleanliness, and then improve the bonding force of the film base;

[0046] 2) Pre-deposit a 100nm corrosion-resistant metal (Cr) primer layer 2 on the surface of the metal bipolar plate 1 treated in the first step to improve the corrosion resistance of the coating and improve the bonding force of the film base;

[0047] 3) On the surfac...

Embodiment 2

[0051] 1) Use a cleaning agent to clean the oil and impurities on the surface of the metal bipolar plate 1, and dry the cleaned metal bipolar plate 1 and put it into the furnace chamber, then control the vacuum degree of the furnace chamber, and start to pass through after the vacuum degree reaches the set value. The heating device heats up the furnace cavity, and after the temperature rises to 400°C, it is kept for a period of time. After the temperature in the cavity is uniform, the ion source is turned on to generate plasma to bombard the surface of the metal bipolar plate to remove metal oxidation on the surface of the metal bipolar plate 1. layer, improve the surface cleanliness, and then improve the binding force of the membrane base;

[0052] 2) Pre-deposit a 50nm corrosion-resistant metal Ti primer layer on the surface of the metal bipolar plate 1 after the first step treatment to improve the corrosion resistance of the coating and improve the bonding force of the film ...

Embodiment 3

[0057] The method for preparing a highly conductive, corrosion-resistant and stable carbon coating for a metal bipolar plate comprises the following steps:

[0058] 1) Use a cleaning agent to clean the oil and impurities on the surface of the metal bipolar plate 1, dry the cleaned metal bipolar plate 1 and put it into the furnace chamber, then control the vacuum degree of the furnace chamber, and turn on the ionizer after the vacuum degree reaches the set value. The source generates plasma to bombard the surface of the metal bipolar plate 1 to remove the metal oxide layer on the surface of the plate 1, improve the surface cleanliness, and then improve the bonding force of the film base;

[0059] 2) Pre-deposit a 50nm corrosion-resistant metal Ti primer layer on the surface of the metal bipolar plate 1 after the first step treatment to improve the corrosion resistance of the coating and improve the bonding force of the film base;

[0060] 3) Deposit the corrosion-resistant meta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com