Method and device for removing hydrogen sulphide from mixture gas containing low-concentration hydrogen sulphide

A technology of mixing gas and hydrogen sulfide, which is applied in chemical instruments and methods, separation methods, and dispersed particle separation, etc., can solve the problems of small gas processing capacity, difficulty in absorbing liquid regeneration, and low hydrogen sulfide removal rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

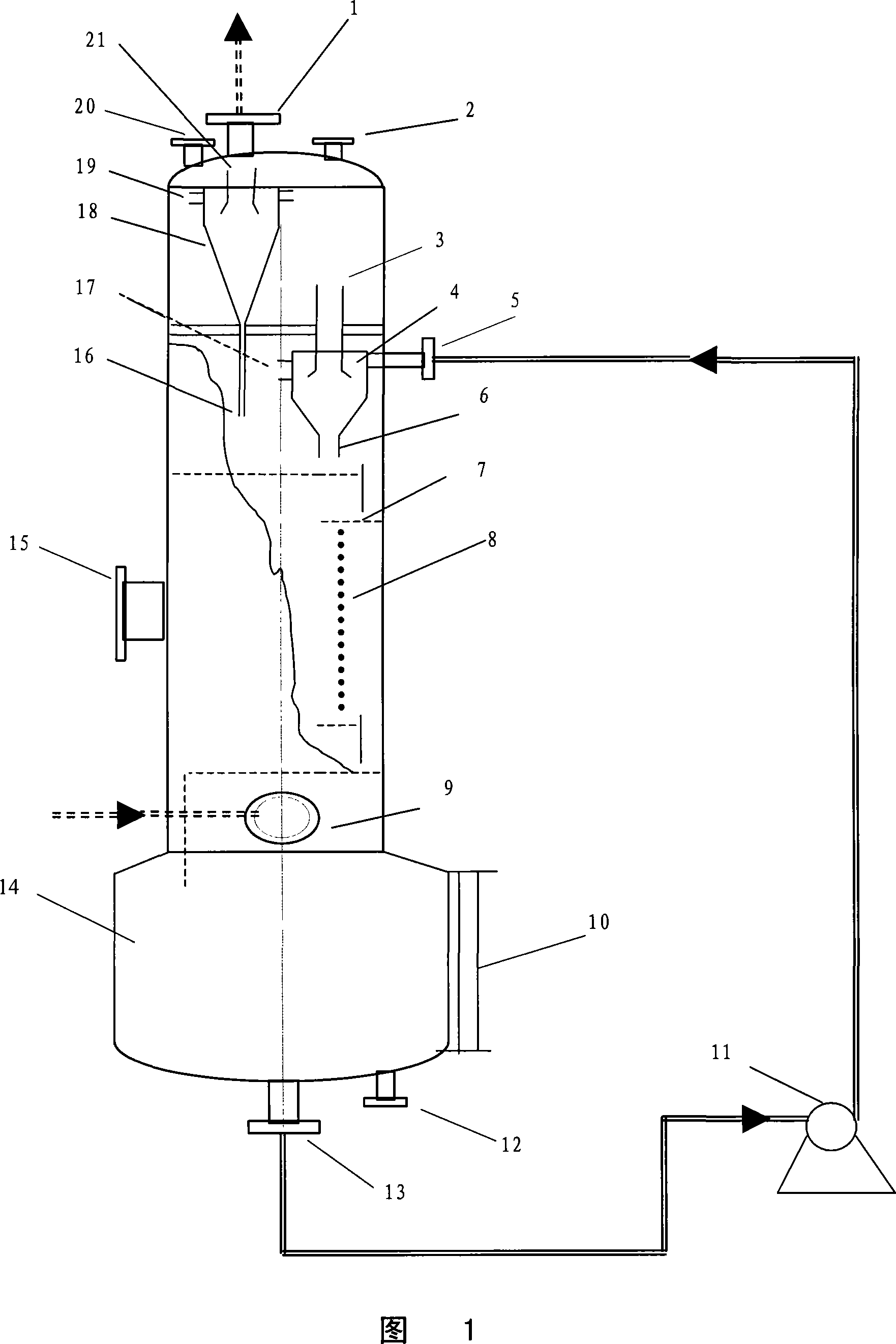

[0049] In a 2.5 million tons / year delayed coking unit cold coke water closed circulation system, according to the method of the present invention, an absorption tower is set to absorb the hydrogen sulfide gas in the mixed gas discharged from the cold coke hot water tank, and then remove the mixed gas The stench in it, its specific operation process and effect are described as follows:

[0050] 1. The nature of the gas mixture

[0051] The exhaust volume of coking hot water tank V=600m 3 / h, the outlet pipe of the coking hot water tank is DN 400mm; the mixed gas is composed of air, water vapor, and a small amount of hydrogen sulfide gas, of which the content of hydrogen sulfide is not more than 100ppm, and the temperature is 80-90°C.

[0052] 2. The nature of the absorption liquid

[0053] The absorption solution used is 30% N-methylethylene glycol amine solution (MDEA), and 10% triethanolamine (TEA) is added as an additive.

[0054] 3. Device (absorption tower)

[0055] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com