Nano-catalysis, electrolysis, flocculation and air-floatation device

A technology of electrolytic flocculation and nano-catalysis, which is applied in the fields of flocculation/sedimentation water/sewage treatment, chemical instruments and methods, flotation water/sewage treatment, etc. Low problems, to achieve the effect of accelerating the sedimentation of impurities and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Treatment effect on eutrophic lake water

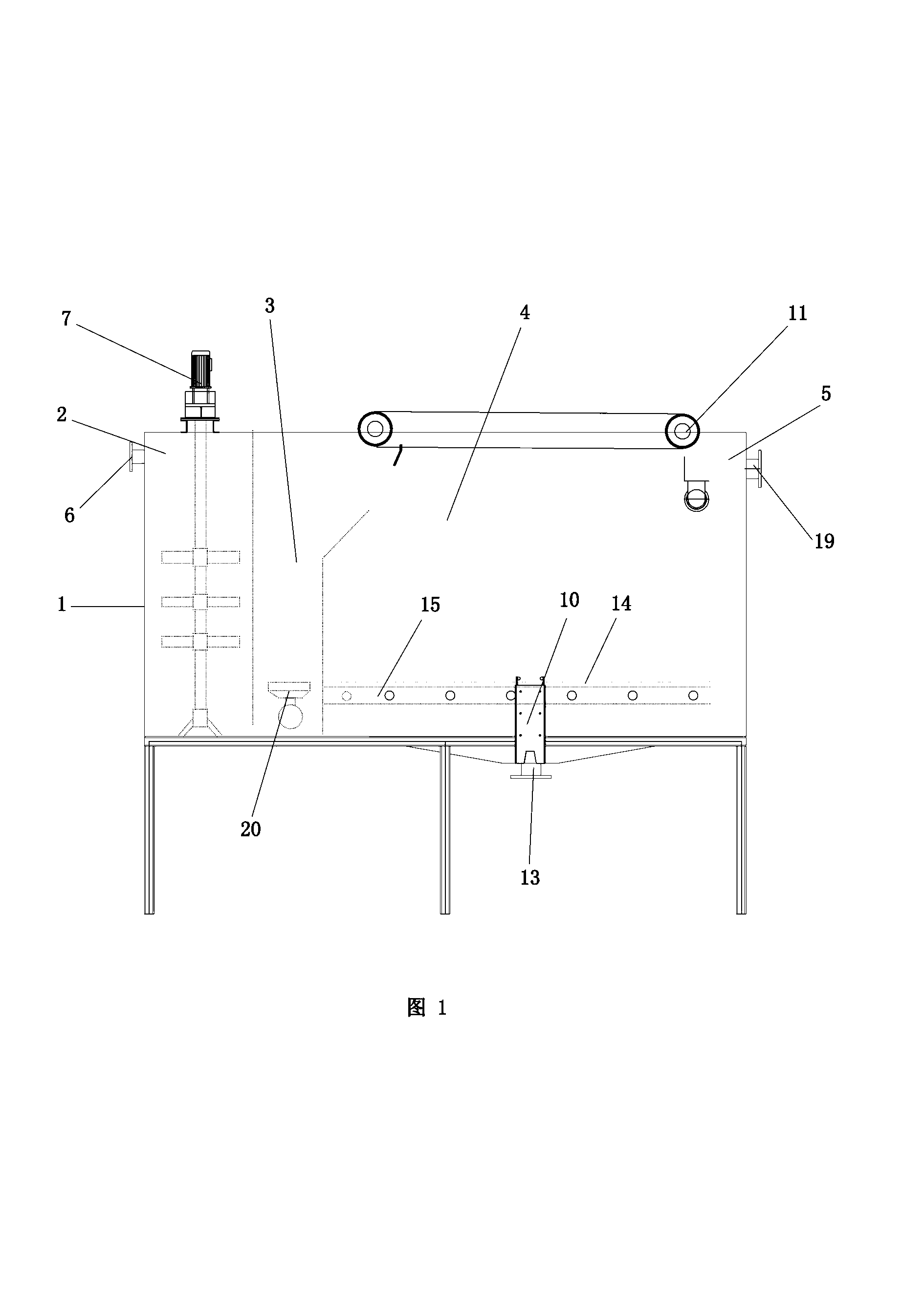

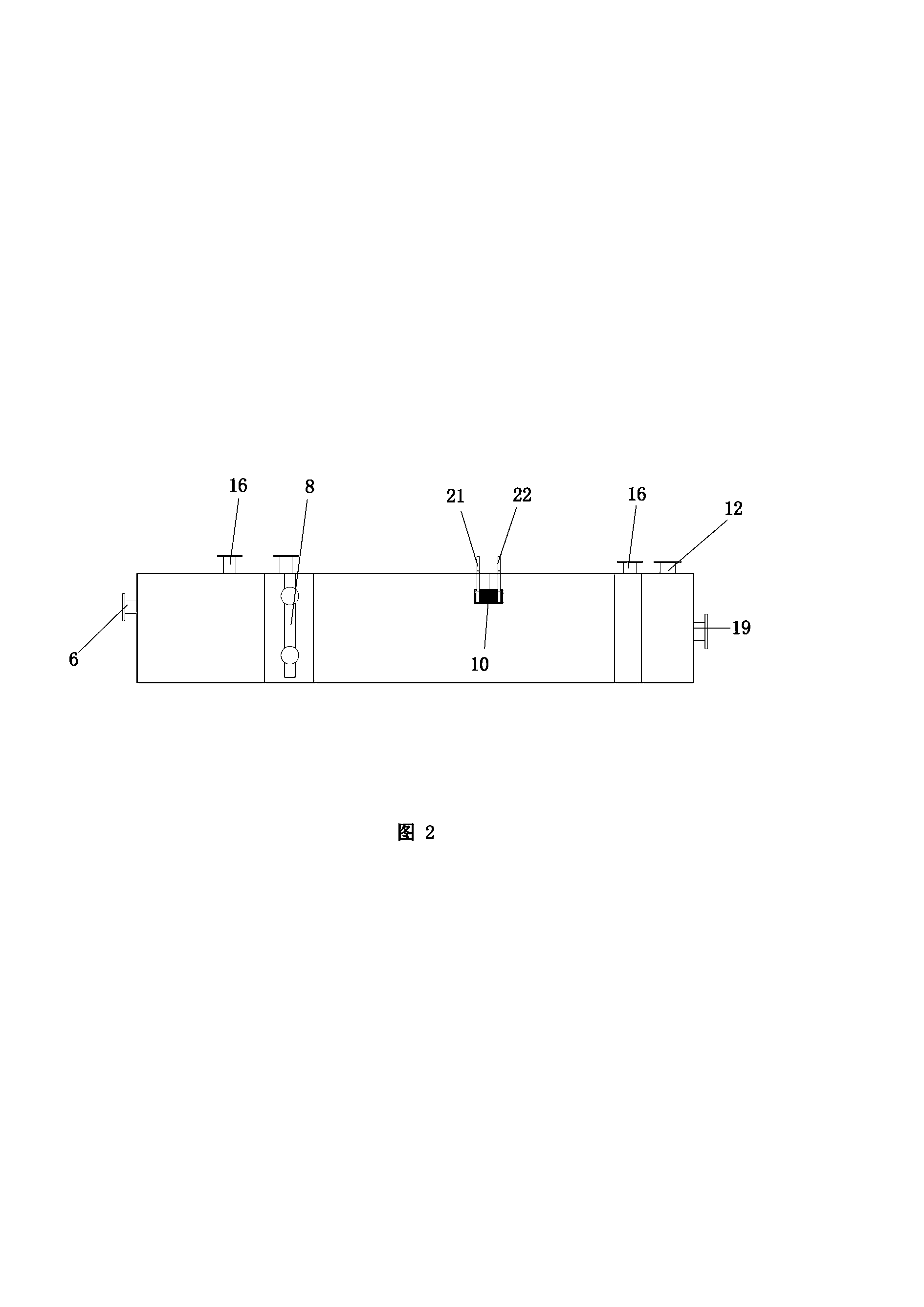

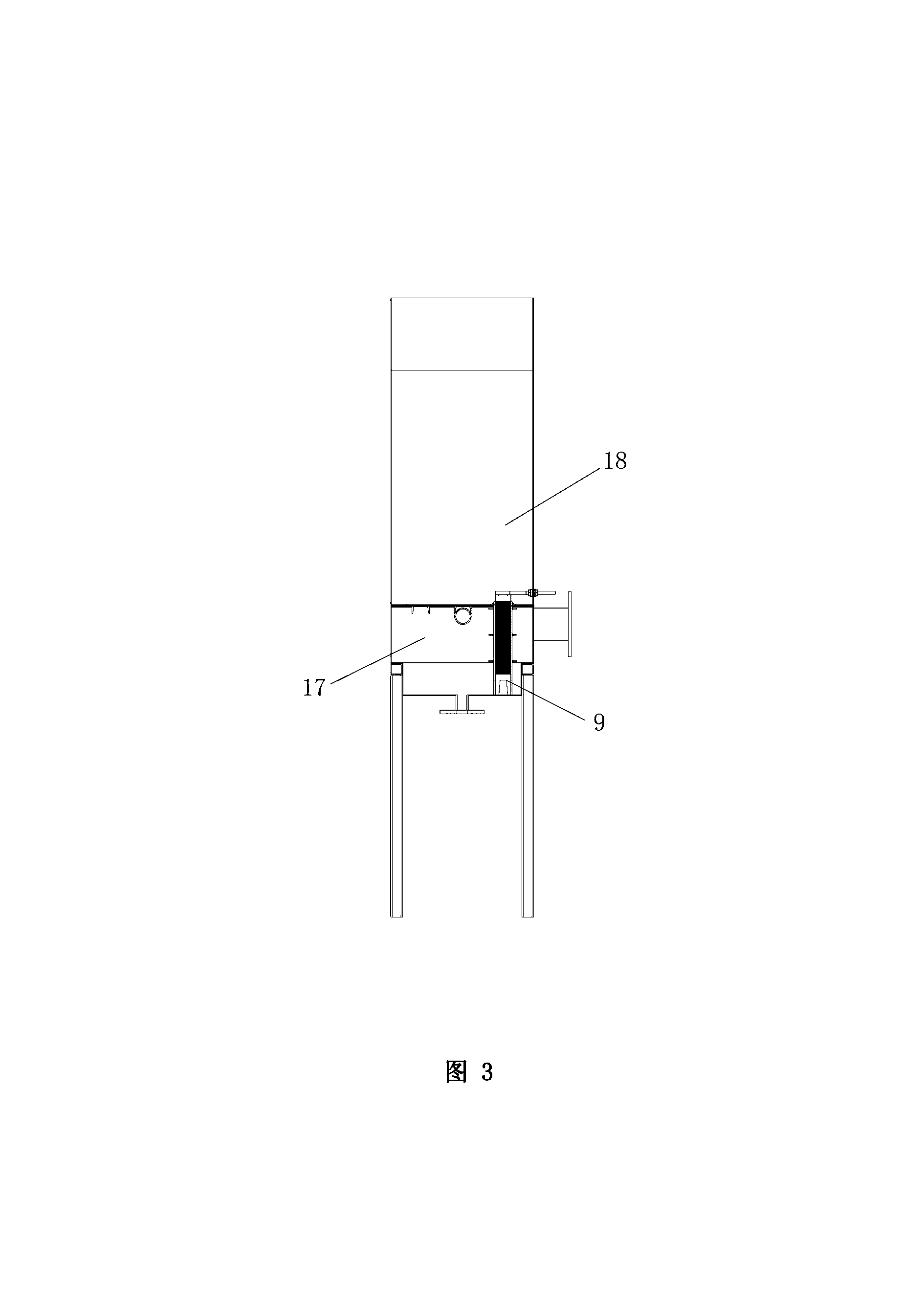

[0057] Pump the lake water into the nano-catalytic electrolysis flocculation air flotation device, and press 20-500g / m in the coagulation sedimentation tank 2 3 Add flocculant PAC, utilize stirrer 7 to stir, accelerate sedimentation; Open the dissolved air releaser 20 in the primary air flotation tank 3 simultaneously, and regulate appropriate gas flow; In the electrolysis air flotation tank 4, the voltage between the two poles of the electrolyzer 9 is 3~8V, the current density is 10~150mA / cm 2 The state of keeping lake water in the primary air flotation tank 3 is 1-2 minutes, and the residence time between the 9 plates of the electrolytic cell is 0.3-1 minute. The effects before and after treatment are shown in Table 1.

[0058] Table 1 Effect of treatment on eutrophic lake water purification

[0059]

Embodiment 2

[0061] Treatment effect on seawater

[0062] Pump seawater into the nano-catalytic electrolysis flocculation air flotation device, and add 2-100g / m2 into the coagulation sedimentation tank 2 3 The flocculant PAC is stirred by the agitator 7 to accelerate the sedimentation; at the same time, the dissolved air releaser 20 in the primary air flotation tank 3 is opened, and an appropriate gas flow is adjusted; the voltage between the two poles of the electrolytic cell 9 in the electrolytic air flotation tank 4 is 3 ~5V, the current density is 10~200mA / cm 2 state, keep the residence time of seawater in the primary air flotation tank 3 for 1 to 2 minutes, and the residence time between the 9 plates of the electrolytic cell is 0.3 to 1 minute. The effects before and after treatment are shown in Table 2.

[0063] Table 2 Treatment effect on seawater purification

[0064]

Embodiment 3

[0066] Treatment effect on printing and dyeing advanced treatment wastewater

[0067] Pump the printing and dyeing advanced treatment wastewater from the secondary sedimentation tank that has undergone biochemical treatment into the nano-catalytic electrolytic flocculation air flotation device, add flocculant PAC into the coagulation sedimentation tank 2, add 800g of PAC per ton of wastewater, and use the agitator 7 to stir to accelerate Settling; at the same time, open the dissolved air releaser 20 in the primary air flotation tank 3, and adjust the appropriate gas flow rate; the voltage between the two electrodes of the electrolytic cell 9 in the electrolytic air flotation tank 4 is 3-5V, and the current density is 10-250mA / cm 2state, keep the residence time of wastewater in the primary air flotation tank 3 for 5 to 10 minutes, and the residence time between the 9 plates of the electrolytic cell is 2 to 5 minutes. The effects before and after treatment are shown in Table 3. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com