Method for manufacturing natural antibacterial warming knitted fabric with kapok bamboo charcoal

A natural antibacterial, knitted fabric technology, applied in knitting, weft knitting, warp knitting, etc., to achieve the effect of superior thermal performance, long-lasting thermal performance, excellent deodorization and antibacterial ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

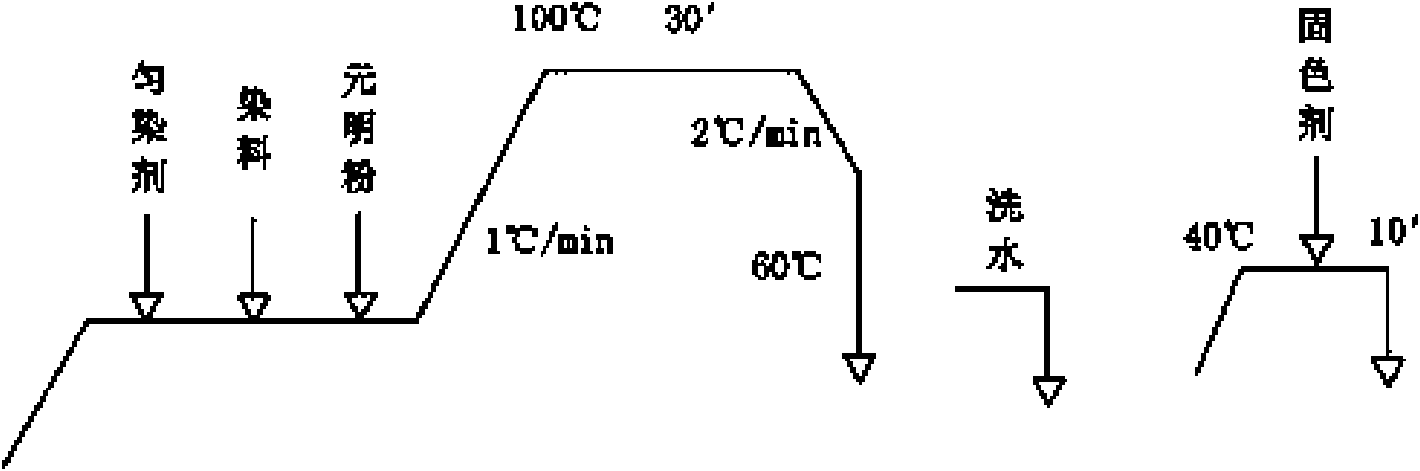

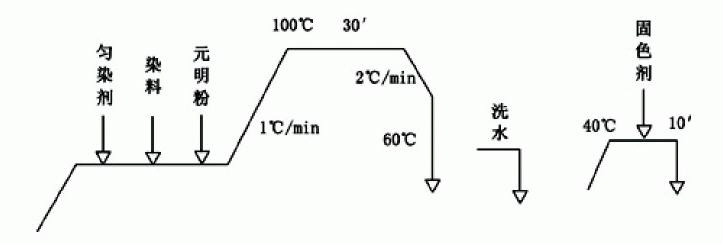

Image

Examples

Embodiment Construction

[0024] The manufacture method of kapok bamboo charcoal natural antibacterial warm knitted fabric, comprising:

[0025] 1. Raw material selection

[0026] Select 40S kapok / cotton (20 / 80) blended yarn and 75D / 72F bamboo charcoal polyester fiber, the ratio of kapok / cotton blended yarn and bamboo charcoal polyester fiber is 44.5%:55.5%.

[0027] Kapok / cotton (20 / 80) blended yarn uses 40S CEIBOR fiber produced by Shanghai Rishu Technology Textile Co., Ltd. CEIBOR fiber is currently the lightest and most hollow green ecological fiber among natural fibers. The bamboo charcoal polyester fiber is 75D / 72F NANOBON carbon fiber produced by Nanliang Group Shanghai Nande Textile Technology Co., Ltd., which is a multi-effect combination with strong adsorption, antibacterial and disinfection, and can emit far infrared rays and release negative ions. The all-natural, healthy and environmentally friendly bamboo charcoal polyester fiber.

[0028] 2. Weaving

[0029] The German Terrot double-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com