Glass bottle cleaning device

A glass bottle cleaning and glass bottle technology, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of time-consuming cleaning, low efficiency, and increased labor costs, and achieve good softness and hollowness. high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described in detail below in conjunction with specific examples, but the implementation of the present invention is not limited thereto.

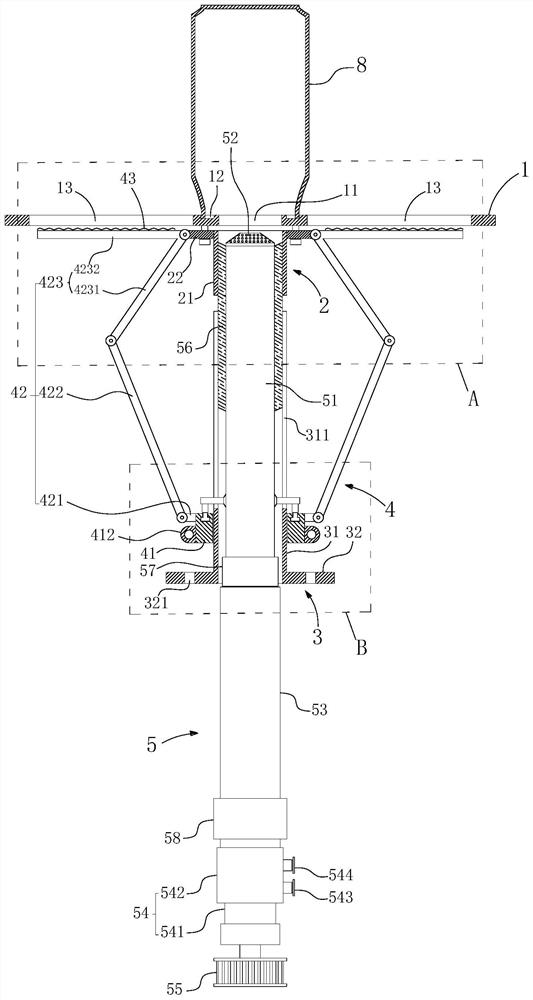

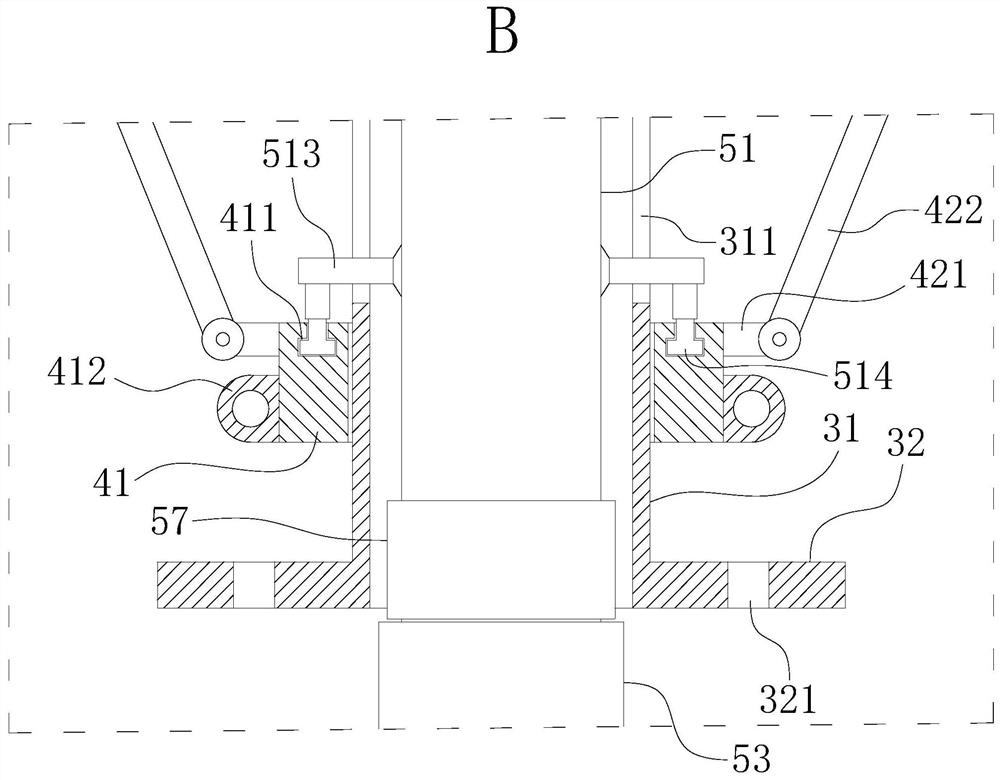

[0058] Such as Figure 1-Figure 12 As shown, the present invention provides a glass bottle cleaning device, which includes a working surface 1 , a first fixing sleeve 2 , a second fixing sleeve 3 , a clamping mechanism 4 and an inner chamber cleaning mechanism 5 .

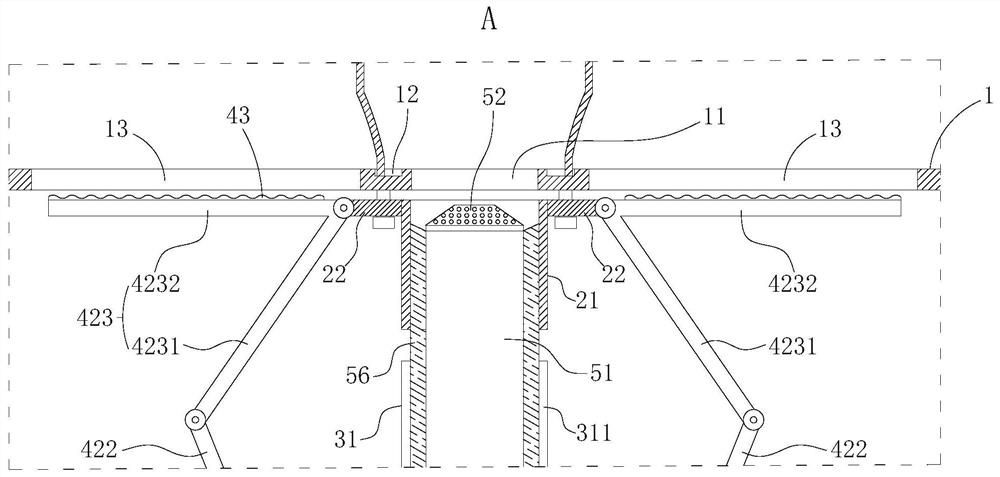

[0059] Such as figure 1 with figure 2 As shown, the worktable 1 is arranged horizontally, and the worktable 1 is provided with a round hole 11 that penetrates longitudinally, and there is an annular groove around the round hole 11 where the mouth of the glass bottle to be cleaned can be placed upside down. 12. The left and right sides of the annular groove 12 are each provided with a strip-shaped slot 13 extending in the left and right directions and penetrating the worktable 1 .

[0060] Such as figure 1 with figure 2 As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com