Patents

Literature

34results about How to "Meet the softness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-static, anti-corrosion, waterproof and stretching-resistant insulated cable

InactiveCN104318986AReasonable structural designImprove anti-static abilityInsulated cablesInsulated conductorsGraphiteStatics

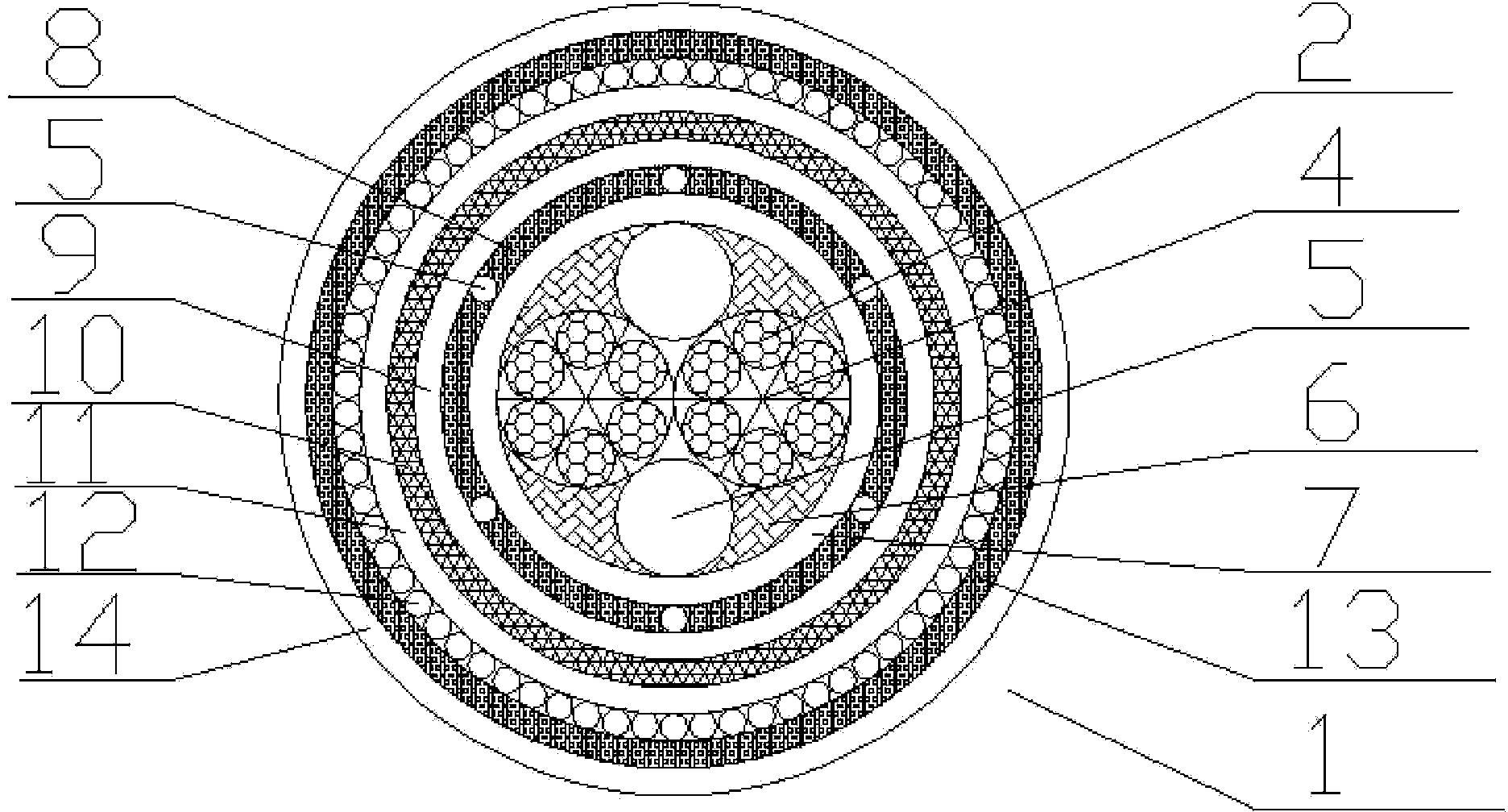

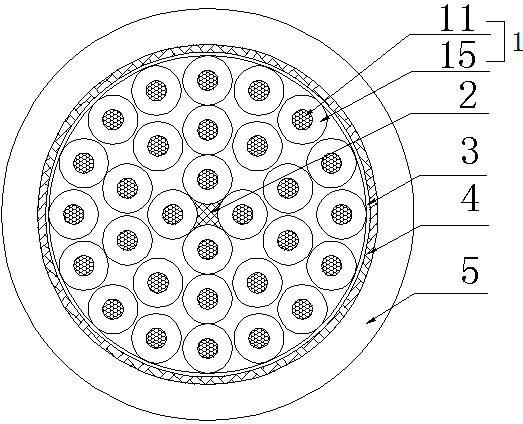

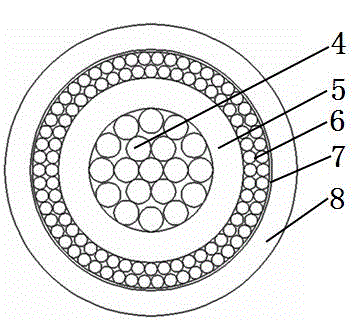

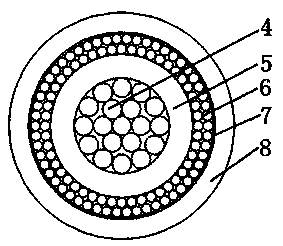

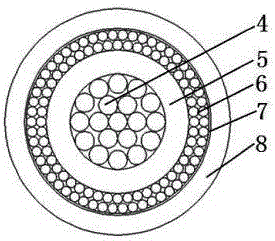

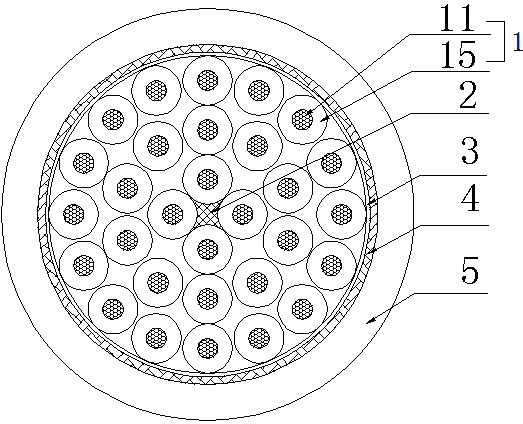

The invention discloses an anti-static, anti-corrosion, waterproof and stretching-resistant insulated cable. The anti-static, anti-corrosion, waterproof and stretching-resistant insulated cable comprises a cable body. The cable body comprises cable cores, a cable core protective layer, an insulating layer, a shielding layer and an outer jacket. The cross section of the cable core protective layer is of a circular structure, and the multiple evenly-arranged cable cores are arranged in the cable core protective layer and separated through PVC plastic connecting rods; a plurality of current guide cores are arranged outside the cable core protective layer and are tangent with the cable core protective layer; the insulating layer is arranged outside the cable core protective layer; waterproof fillers are arranged in a gap between the insulating layer and the cable core protective layer; the shielding layer is tightly extruded on the insulating layer and internally provided with the multiple evenly-arranged current guide cores; a breakdown resistant layer, a steel core protective layer and a waterproof layer are sequentially extruded on the shielding layer from inside to outside; an armor layer is extruded outside the waterproof layer, the outer jacket is arranged outside the armor layer, and a graphite layer is arranged between the armor layer and the outer jacket. The anti-static, anti-corrosion, waterproof and stretching-resistant insulated cable has the advantages of being reasonable in structural design, high in anti-static capacity, good in anti-corrosion performance and the like.

Owner:珠海长盛电缆有限公司

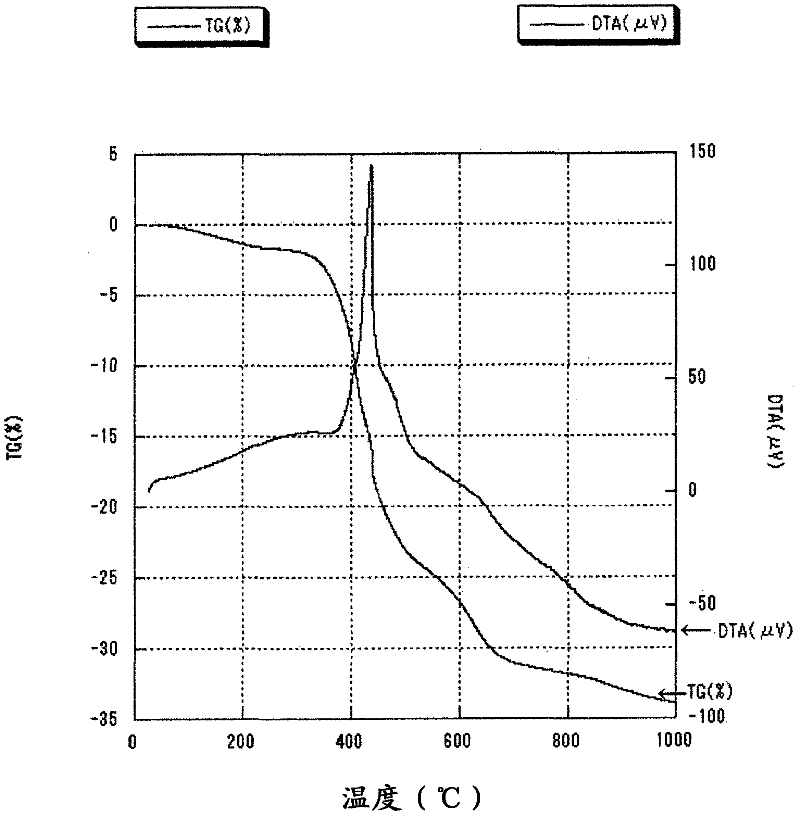

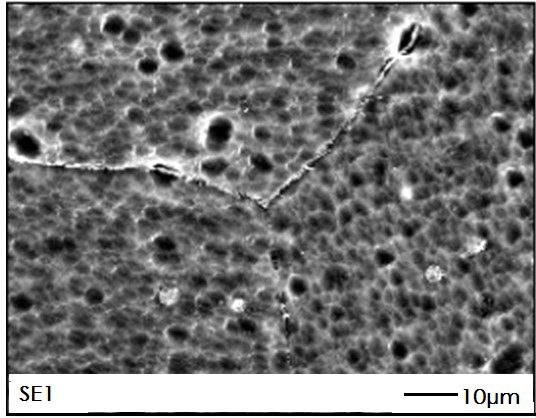

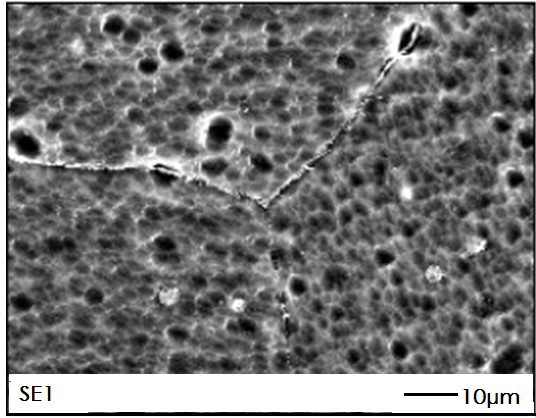

Moisture-proof film for electronic devices

InactiveCN102448884AGood weather resistanceSatisfy the gas barrier propertyMaterial nanotechnologySilicon compoundsWater vaporPolyamide

Disclosed is a moisture-proof film for electronic devices, in which modified clay crystals are oriented and densely laminated, and the mechanical strength thereof is at a satisfactory level for use as a self-supporting film. The moisture-proof film comprises a modified clay and an additive, has a water vapor barrier property, and a water vapor permeability of less than 0.2 g / m2 / day (at 40 DEG C and a relative humidity of 90%), wherein the modified clay is produced by a silylation reaction of a clay, the additive is a polyamide or a polyimide, and lithium ions make up at least 90 mol% of exchangeable ions in the modified clay. The moisture-proof film is a novel material that fulfils all of the requirement of weather resistance, gas barrier performance, water vapor barrier performance, flexibility, heat resistance, electrical insulation performance, and water resistance.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Blended yarn

The present invention is one kind of blended yarn of bamboo fiber and chemical fiber, and solves the problem of insufficiency of natural textile material. Fabric of the blended yarn has the features of bacteriostasis, fast moisture absorption, coolness and soft hand feeling, and the ultimate fabric has stiffness and draping and can meet the requirement as costume material.

Owner:上海日舒棉纺织厂

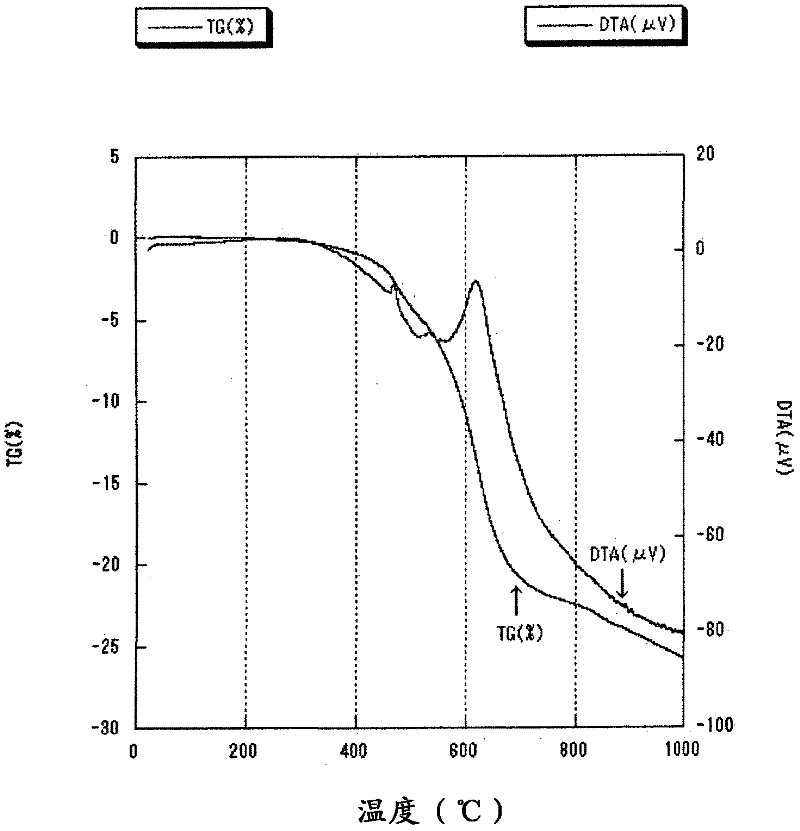

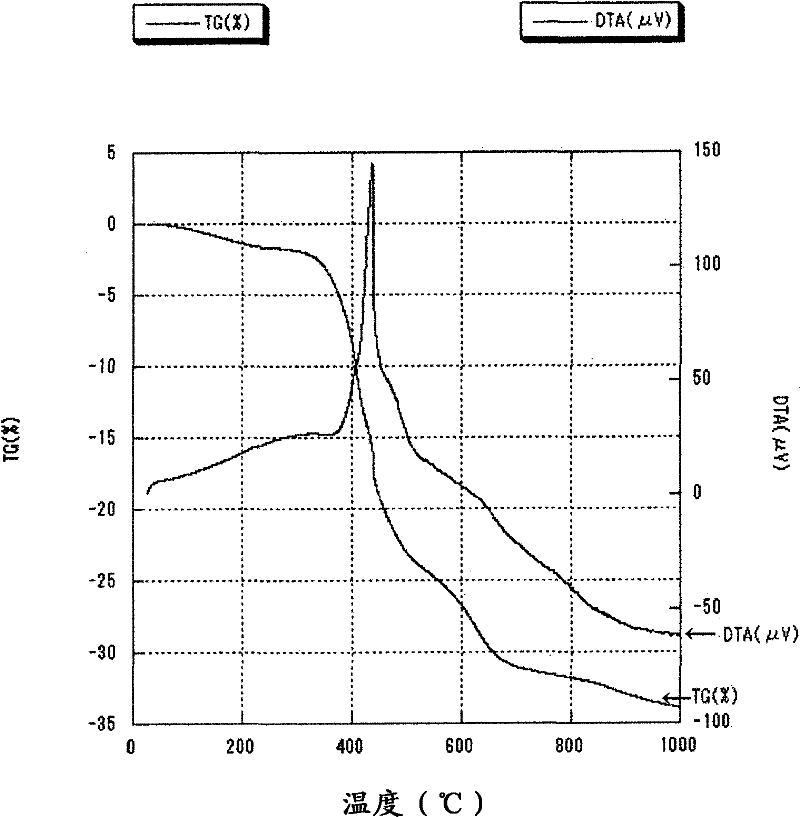

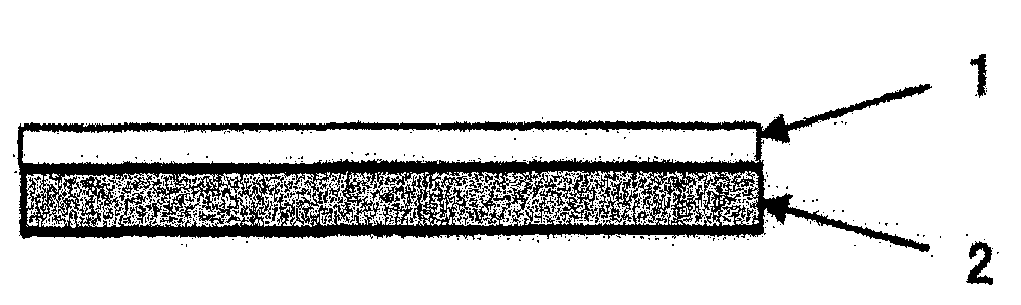

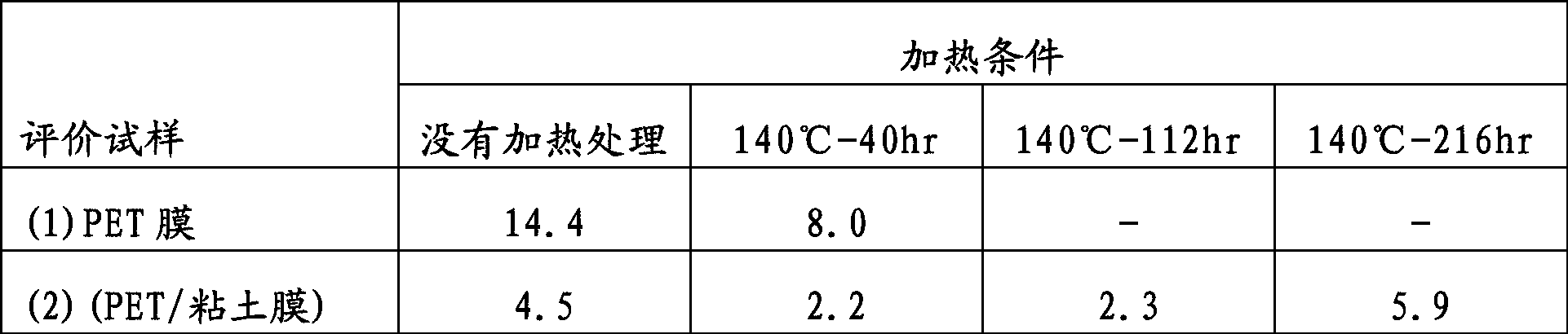

Water vapor barrier film and method for producing same

ActiveCN102939199AGood weather resistanceSatisfy the gas barrier propertyLayered productsPretreated surfacesLithiumWater vapor

Disclosed are: a film for a solar cell back sheet, which has excellent water vapor barrier properties, water resistance and gas barrier properties, while having adequate flexibility, adequate mechanical strength and excellent thermal stability; and a method for producing the film for a solar cell back sheet. Specifically disclosed is a water vapor barrier film which is obtained by coating a PET base with a clay film. The water vapor barrier film is characterized in that: the clay film is configured of clay and an additive; the weight ratio of the clay relative to the total solid is 60-90% by weight in the clay film; the production procedure thereof comprises a water resistance-imparting heat treatment that is carried out at 100-200 DEG C after coating and drying steps; the water vapor barrier film has a water vapor transmission rate of less than 3 g / m2 / day; the additive of the modified clay is a polyimide; and 90% by mole or more of the exchangeable ions are lithium ions. Also specifically disclosed is a method for producing the water vapor barrier film. The film has water vapor barrier properties and is useful as a back sheet for a solar cell or the like.

Owner:NAT INST OF ADVANCED IND SCI & TECH

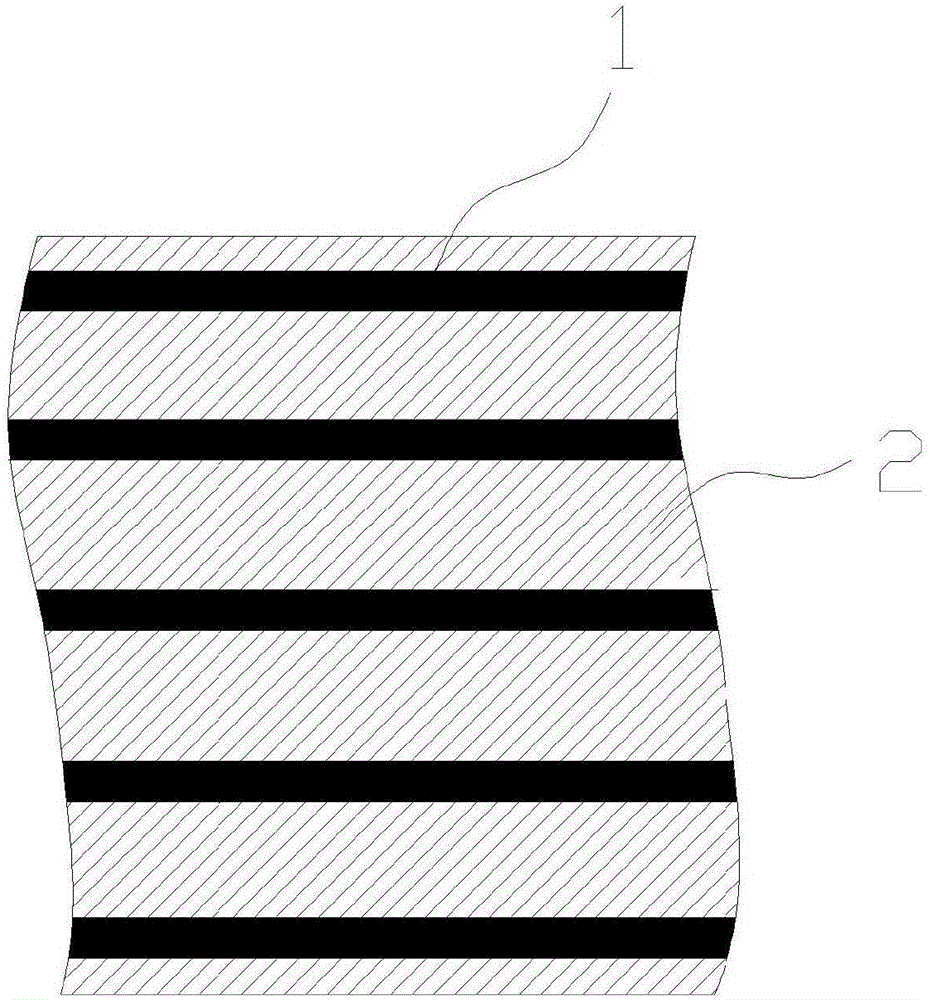

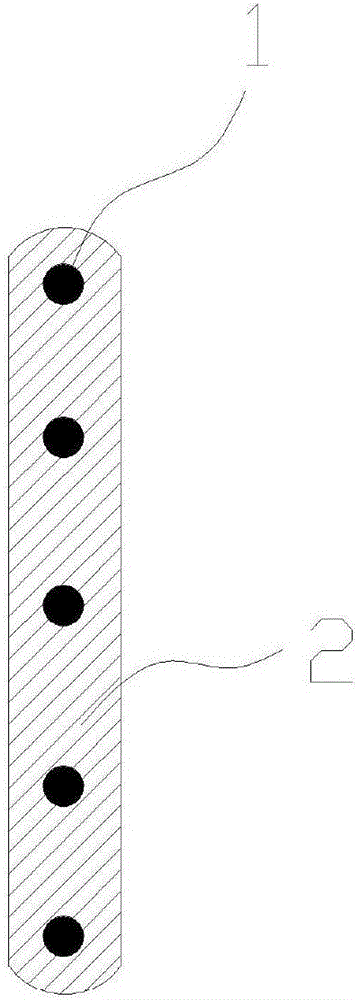

Balance compensation cable for high-speed elevator

InactiveCN105802060AGood load carryingLoad largeFlexible cablesFlexible conductorsFiberCarbon fibers

The invention provides a balance compensation cable for a high-speed elevator.The balance compensation cable comprises a compensation cable body, and the compensation cable body comprises at least one evenly distributed core and an outer wrapping layer wrapping the cores.The compensation cable body is flat, the cores are steel wire bundles or carbon fiber, and the outer wrapping layer comprises polyoxyethylene resin, plasticizer, stabilizer, a lubricating agent, a flame-retardant agent, accelerant, an adhesive, an anti-aging agent, a reinforcing agent and inorganic filler.The cores and the outer wrapping layer are poured together into a solid integrated element.The wide balance compensation cable for the elevator lowers operation noise, increases specific gravity of unit length, and has the advantage of being large in bearing load.The outer wrapping layer meets the requirements for softness, environment stress cracking resistance and heat resistance, elasticity is good, bending radius is small, and safety performance of the elevator is improved.

Owner:JIANGSU XINGHUA RUBBER BELT

Aluminum alloy conductor flexible cable and preparation method thereof

ActiveCN112259284AHigh strengthAnti-agingClimate change adaptationConductive materialCompressive creepElectro conductivity

The invention discloses an aluminum alloy conductor flexible cable and a preparation method thereof, and belongs to the field of flexible cables. The aluminum alloy conductor flexible cable comprisesone or more cabling sheath layers, a cabling and belting layer and conductor insulating wire cores from outside to inside in sequence, wherein the number of the conductor insulating wire cores is oneor more, cabling fillers are filled between the conductor insulating wire cores, and each conductor insulating wire core sequentially comprises a tensile strand, an aluminum alloy conductor and a wirecore insulating layer from inside to outside. The aluminum alloy conductor flexible cable not only has high conductivity, but further has excellent tensile strength and compressive creep resistance,the possibility of replacing copper with aluminum in the flexible cable is realized, the use cost of the flexible cable is reduced, and the wear resistance and the service life of the cable are improved due to light weight and excellent characteristics.

Owner:TBEA DEYANG CABLE CO LTD

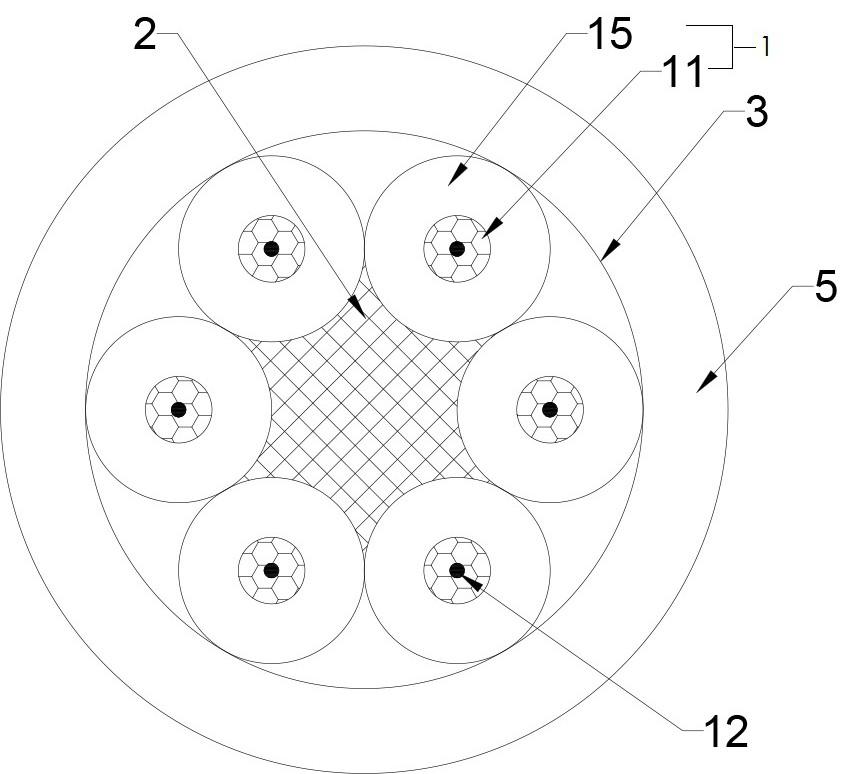

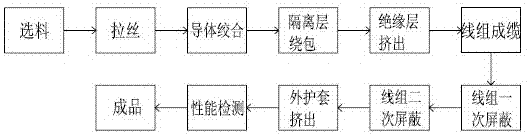

Method for manufacturing enhanced flat cable for wagon dumper

ActiveCN102347111AImprove the extrusion effectGood flexibilityInsulating conductors/cablesElectrical conductorElectric cables

The invention discloses a method for manufacturing an enhanced flat cable for a wagon dumper, and the method is characterized by comprising the following steps: material selection, wire drawing, conductor twisting, winding and wrapping of an isolating layer, extrusion of the insulating layer, cabling of wiring harness, primary shield of wiring harness, secondary shield of wiring harness, extrusion of an outer sheath, performance detection and finished products. In the method, the conductor center of the cable is provided with a steel wire rope stiffener so as to improve the longitudinal stretching resistance of the cable; and a wire braid is used as a metal shielding layer, the primary shielding braid density is not less than 80%, and the secondary shielding braid density is not less than85%, thus not only improving shielding factors of a cable core but also providing effective physical and mechanical protective actions for the cable. The cable manufactured by the method has the advantages of good flexibleness, salt mist resistance, greasy dirt resistance and inflaming retarding property, no cracking and no deformation for long term use, and no core breaking at the movable operating mode speed of 1.2m / s.

Owner:SICHUAN MINGXING CABLE

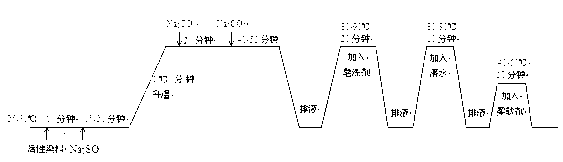

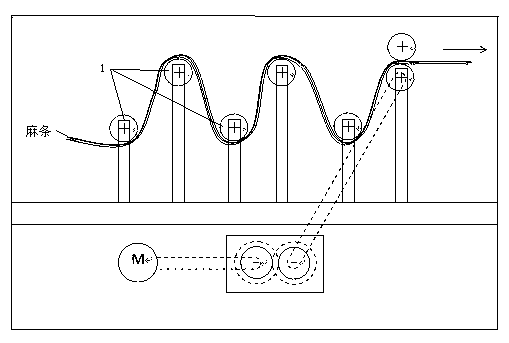

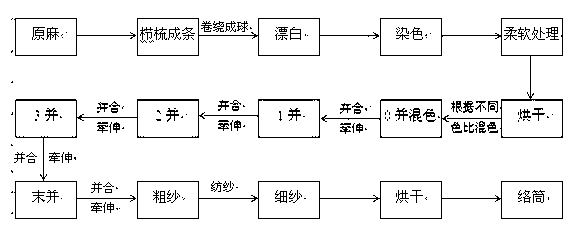

Production method of bastose wet spinning yarn

ActiveCN103215713APromote degradationSolve the problem that the production cannot be openedFabric breaking/softeningSucessive textile treatmentsYarnPulp and paper industry

The invention relates to a production method of a bastose wet spinning yarn. The production method of the bastose wet spinning yarn comprises the steps of heckling, degumming, scouring and bleaching, dyeing, drying and softening, then color mixture is carried out on two kinds or more than two kinds of ramie strips of different colors according to different color ratios, the ramie strips are mixed and drafted after 4-6 drawing working procedures, roving and wet spinning thinning working procedures are carried out on the ramie strips, and finally the ramie strips are dried, spooled and packaged to form a finished product. The production method of the bastose wet spinning yarn is characterized in that the heckling working procedure comprises a process of strip manufacturing and a process of ball formation, the process of strip manufacturing means that short fibers are removed and then long bastose fibers are manufactured into the ramie strips; and the process of ball formation means that the continuous ramie strips are wound layer by layer from inside to outside to form a hollow cylindrical bastose ball. The produced bastose wet spinning yarn is uniform in dyeing, bright in color, rich in level, and good in color fastness.

Owner:ZHEJIANG JINYUAN FLAX

Towel fabric for outdoor occasions

ActiveCN101929023ARetain the characteristics of pure cottonMeet the softnessWoven fabricsYarnNano zinc oxideCotton fibre

The invention relates to a towel fabric for outdoor occasions, which adopts a towel structure with loop piles on single surface. The looped warp yarn is uvioresistant blended yarn; the body warp yarn is purified cotton yarn; the weft yarn is uvioresistant blended yarn or purified cotton yarn; the warp density is 114-120 / 10cm, and the weft density is 180-200 / 10cm; the coefficient of single yarn twist is 350-370; the yarn twist for stranding is 25-30 / 10cm; the uvioresistant yarn is blended by uvioresistant synthetic fiber and cotton fiber; and an ultraviolet isolation factor, which is nano titanium dioxide and / or nano zinc oxide, is added to the raw material of the uvioresistant synthetic fiber prior to the polymerization of the polymer monomers or prior to the melt spinning of the polymer. The fabric of the invention has the advantages of favorable softness, comfortableness, water absorptivity and uvioresistant capability, effectively prevents ultraviolet light from hurting human bodies, and is especially suitable for manufacturing towels, bath towels, shawls and the like for outdoor occasions.

Owner:BEIJING GUANGHUA TEXTILE GRP +1

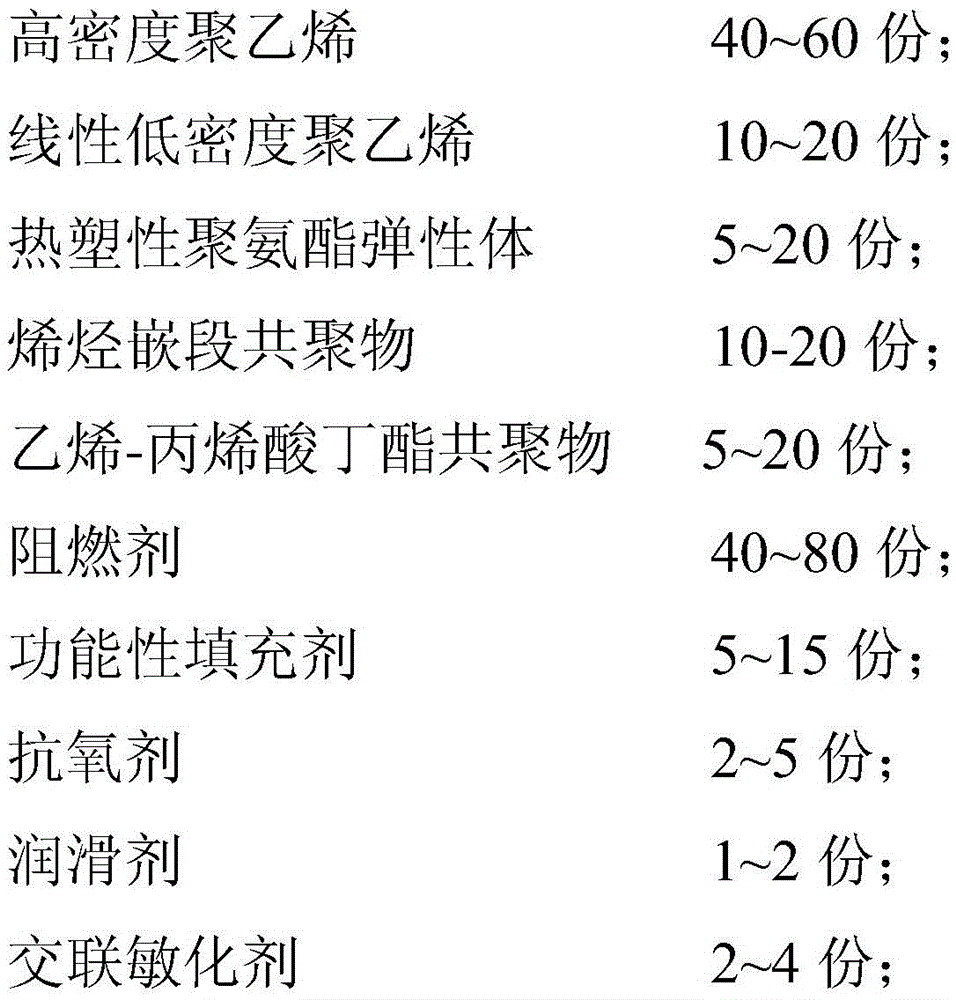

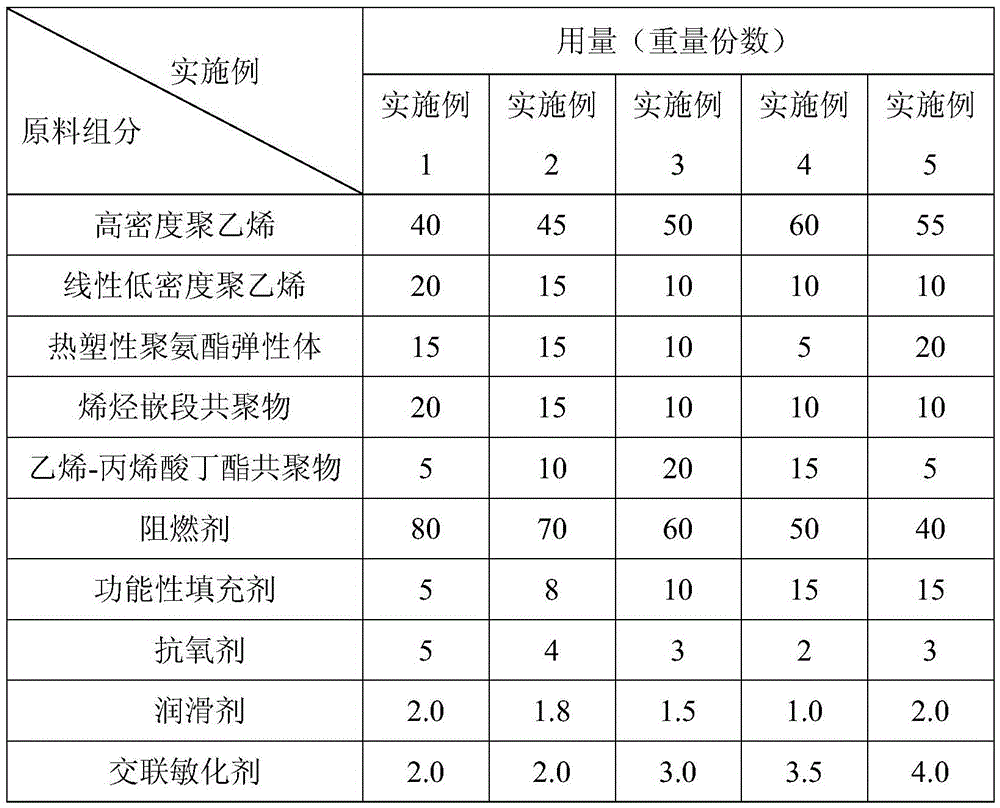

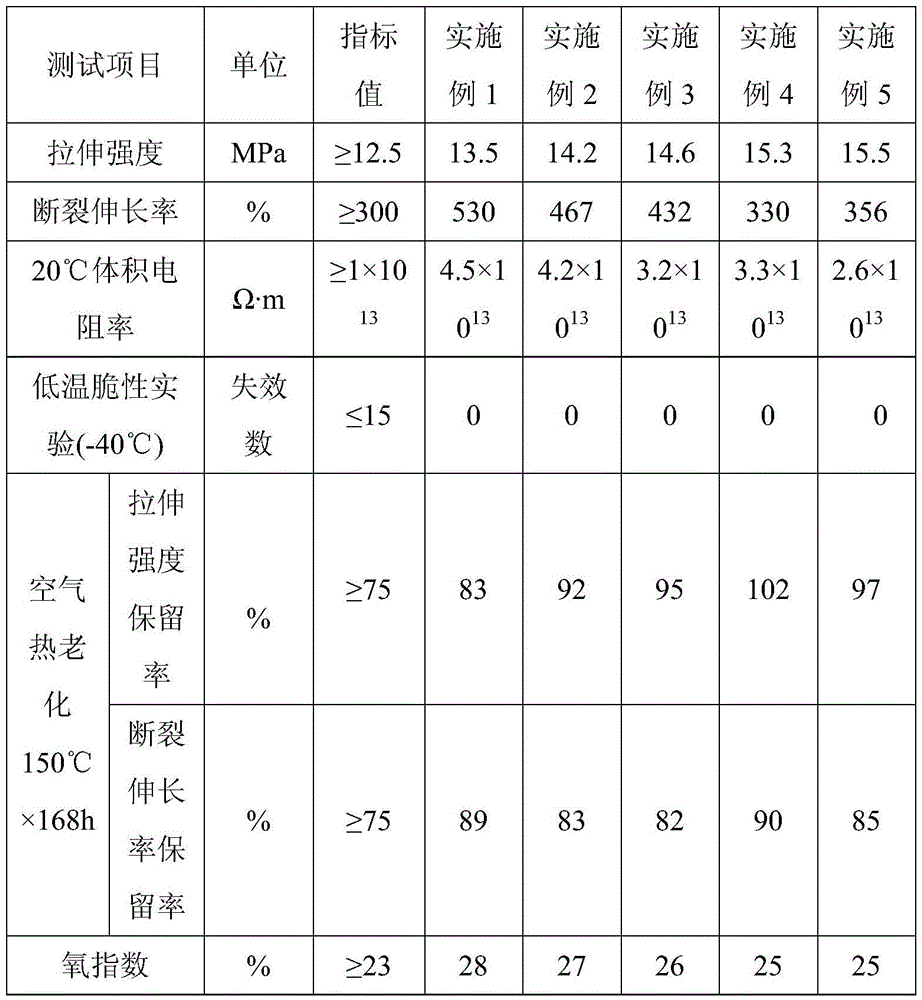

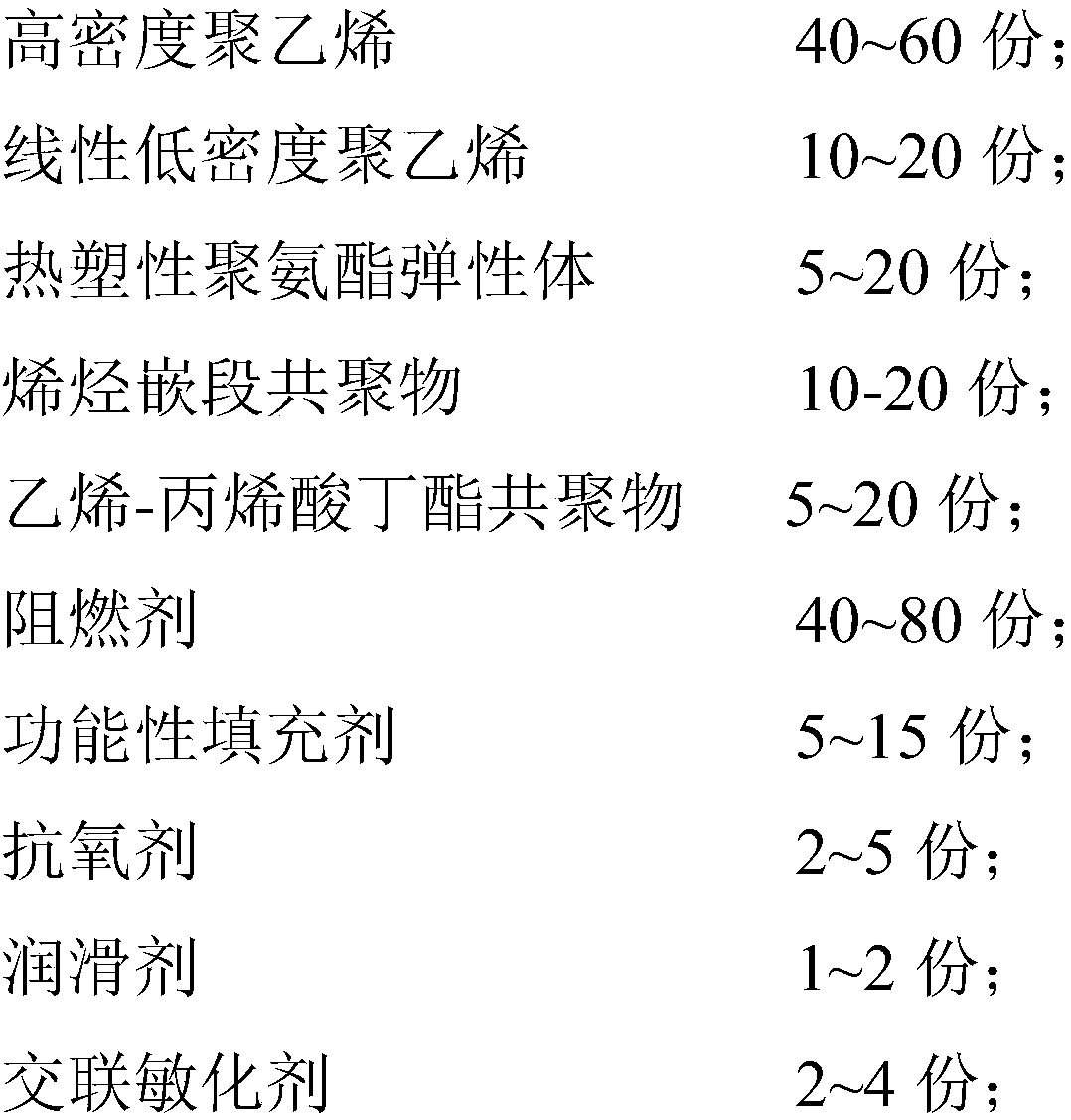

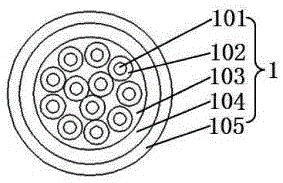

High-temperature-irradiation-resistant halogen-free flame-retardant automobile wire material and preparation method thereof

ActiveCN105602071AImprove flame retardant performanceLow costPlastic/resin/waxes insulatorsAntioxidantResin matrix

The invention discloses a high-temperature-irradiation-resistant halogen-free flame-retardant automobile wire material and a preparation method thereof. The high-temperature-irradiation-resistant halogen-free flame-retardant automobile wire material adopts high-density polyethylene, linear low-density ethylene, a thermoplastic polyurethane elastomer, an olefin block copolymer and an ethylene-butyl acrylate copolymer with different melt indexes as resin matrixes; a halogen-free flame retardant composed of an intumescent flame retardant, magnesium hydroxide and zinc borate is added into the resin matrixes, and a functional filler, an antioxidant, a lubricant and a crosslinking sensitizer are combined; and thus, the obtained automobile wire material can satisfy the required softness and wear resistance and also ensure the thermal overload property of the product. Besides, the wire material has the advantages of favorable flame retardancy, low smoke and no halogen, and conforms to the requirements for environmental protection. The preparation method of the product has the advantages of simple technique and low cost, and is easy to operate and suitable for popularization and application.

Owner:JIANGSU DEWEI ADVANCED MATERIALS

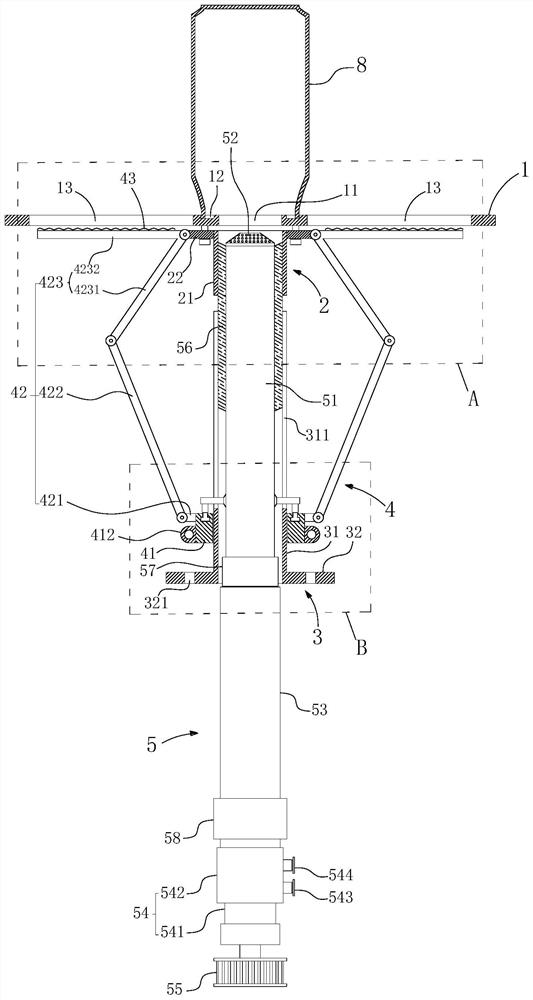

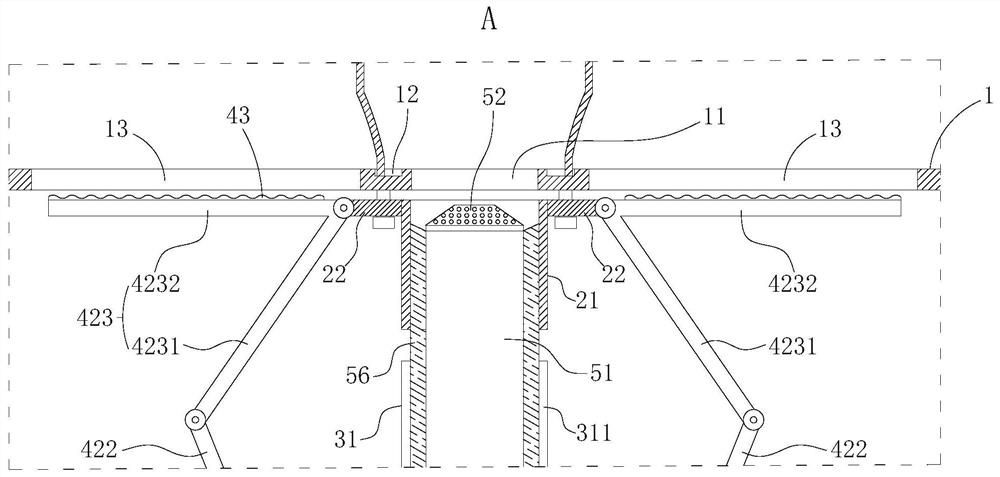

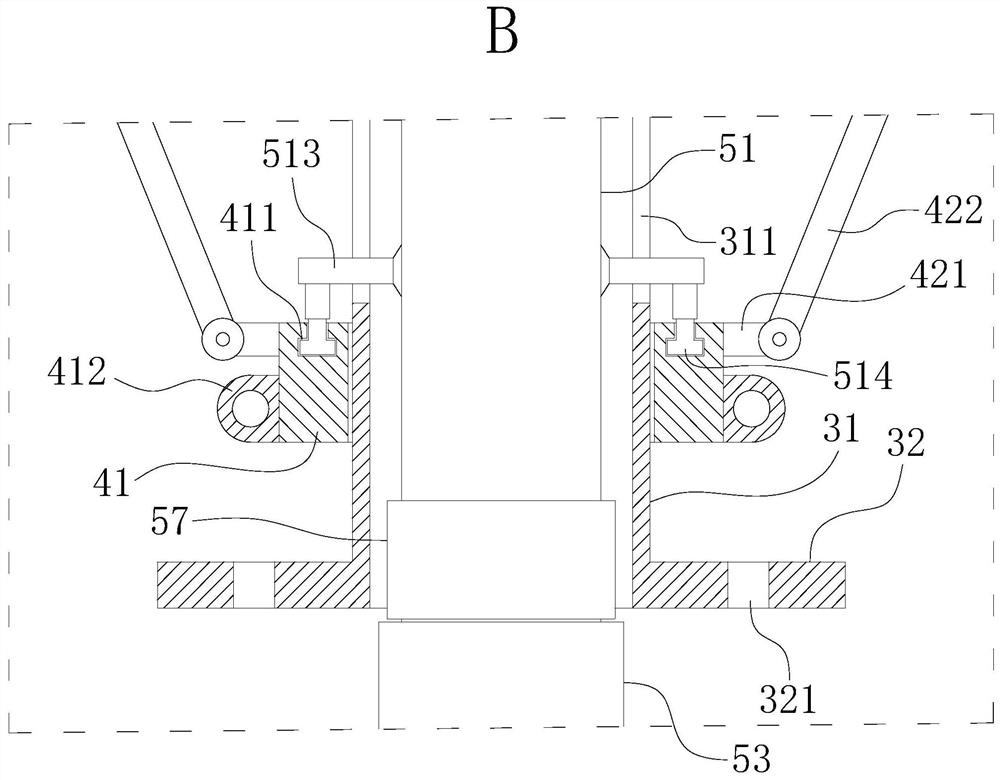

Glass bottle cleaning device

ActiveCN112122280AGood flexibilityHigh hollownessHollow article cleaningStructural engineeringBottle

The invention discloses a glass bottle cleaning device. The glass bottle cleaning device comprises a working table, a first fixing sleeve, a second fixing sleeve, a clamping mechanism, and an inner cavity cleaning mechanism. The first fixing sleeve is fixed below the working table; the second fixing sleeve is arranged below the first fixing sleeve at an interval; the clamping mechanism comprises asliding sleeve, two sets of connecting rod mechanisms and two clamping plates; the sliding sleeve can slide along the second fixing sleeve; the two sets of connecting rod mechanisms are located on two sides of the sliding sleeve respectively and can perform corresponding actions along with movement of the sliding sleeve; the two clamping plates are respectively arranged on the two sets of connecting rod mechanisms and can be driven by the connecting rod mechanisms so as to clamp a glass bottle above the working table; the inner cavity cleaning mechanism comprises a cleaning pipe, an umbrella-shaped nozzle, a telescopic pipe, a gas-liquid transmission sliding ring and a belt wheel; the cleaning pipe can be driven by the sliding sleeve so as to extend into the glass bottle; bristles are arranged on the outer wall of the cleaning pipe; the umbrella-shaped nozzle is installed at the top of the cleaning pipe; and the telescopic pipe, the gas-liquid transmission sliding ring and the belt wheel are sequentially installed below the cleaning pipe. The glass bottle cleaning device provided by the invention can replace an existing manual glass bottle inner cavity cleaning mode, and help enterprises to improve cleaning efficiency and save cost.

Owner:SHANDONG JINGYAO GLASS GRP

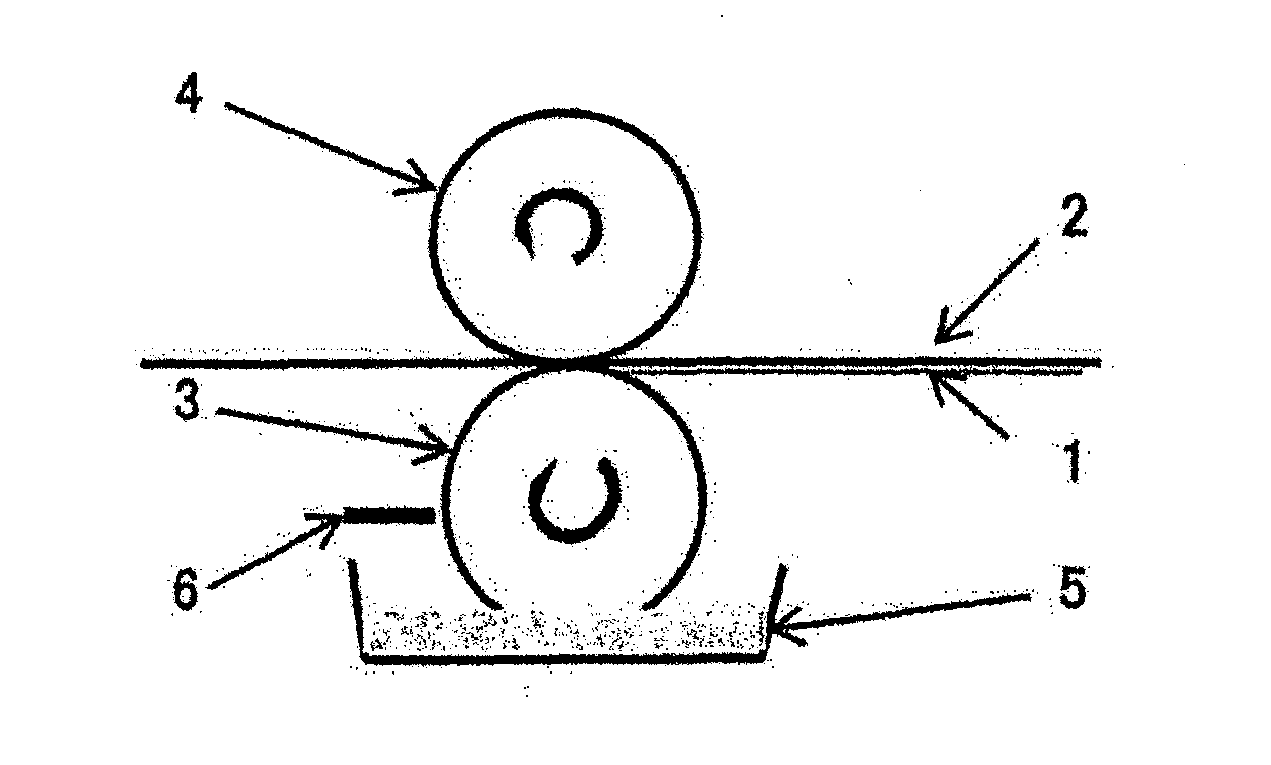

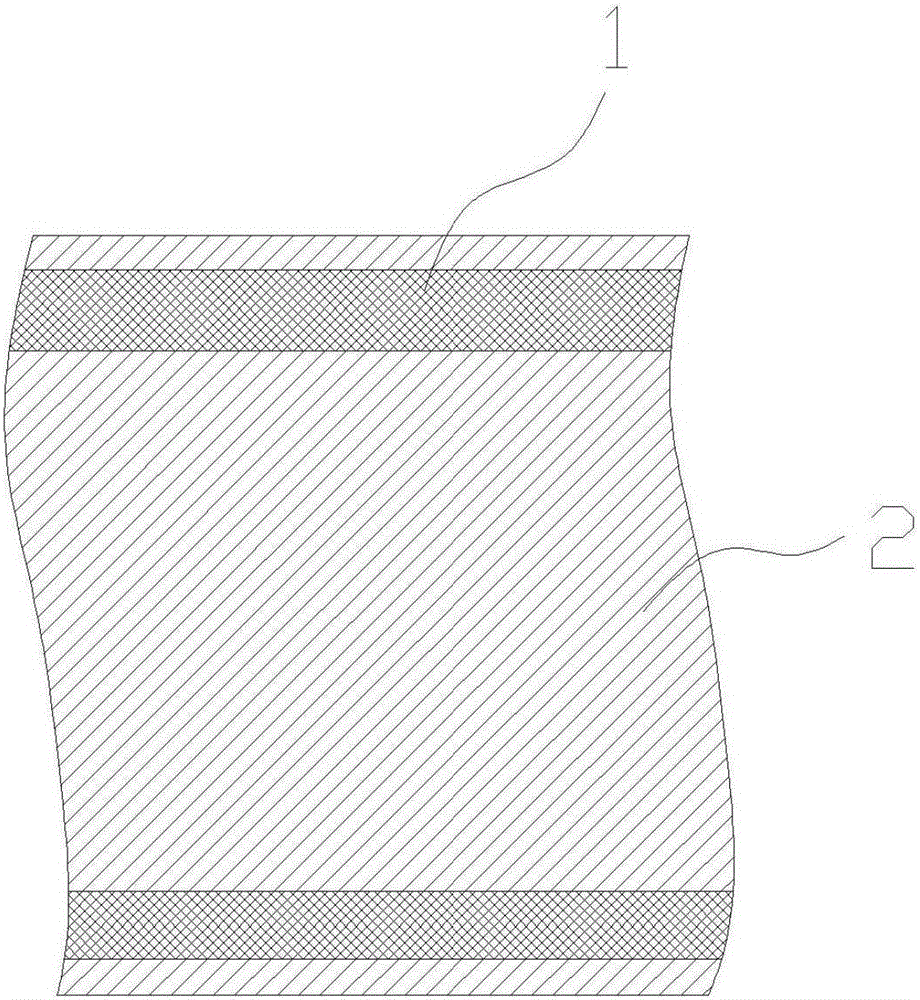

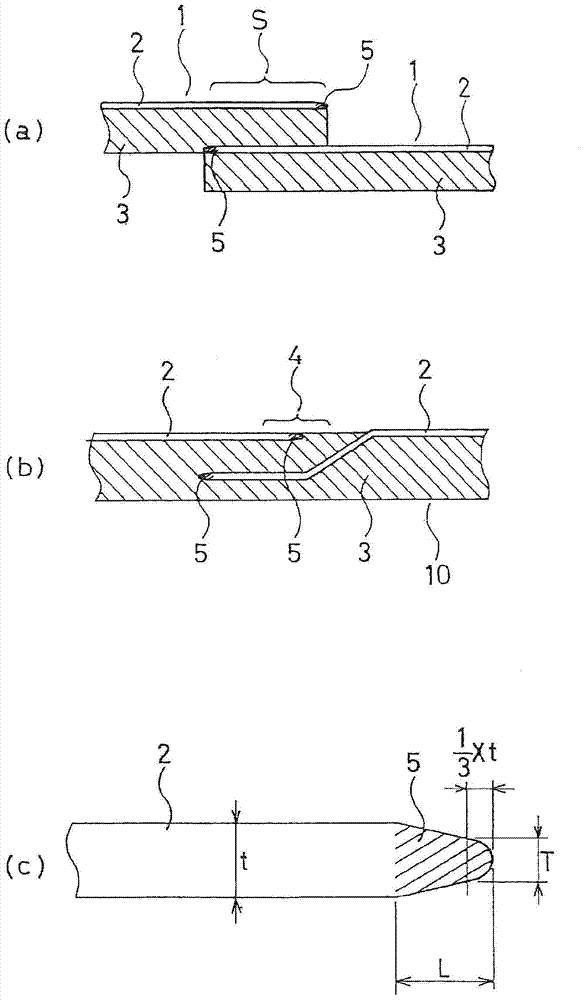

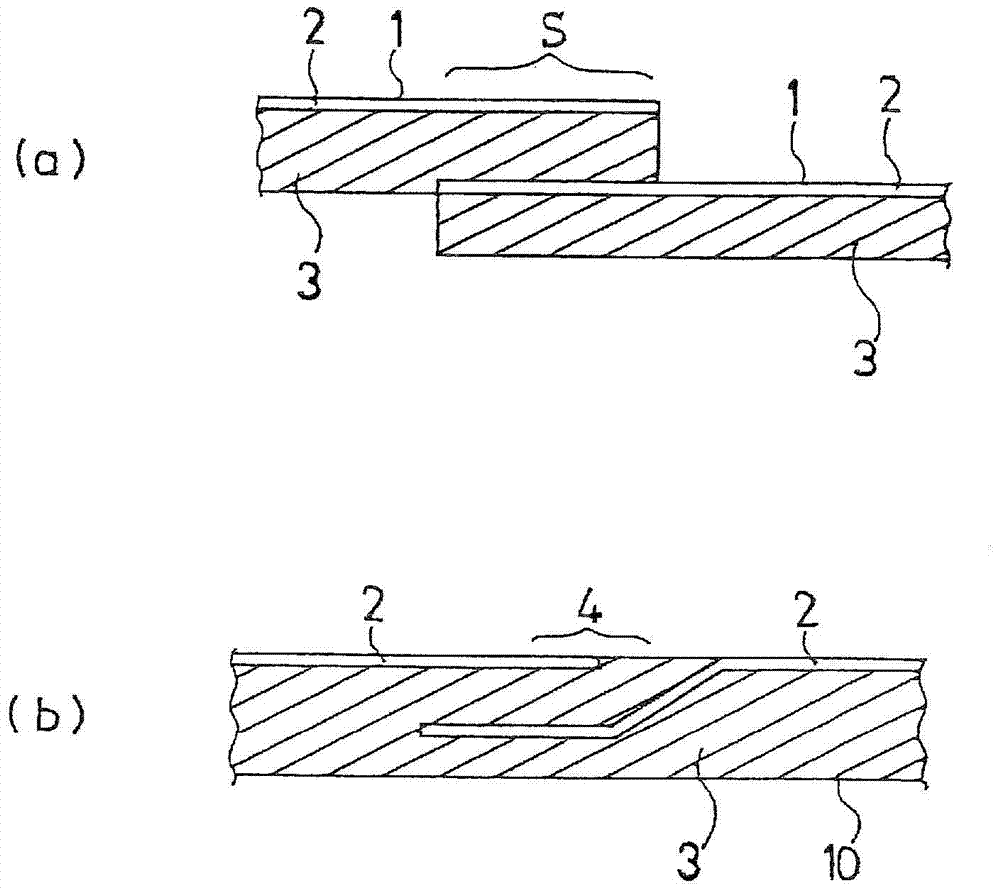

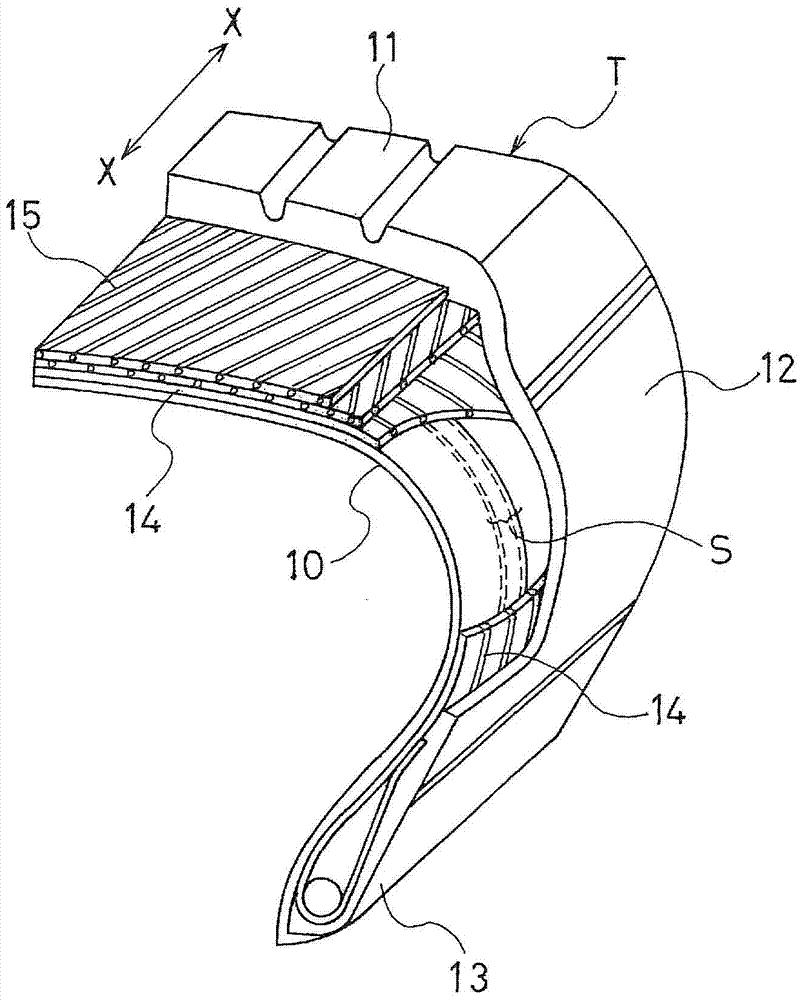

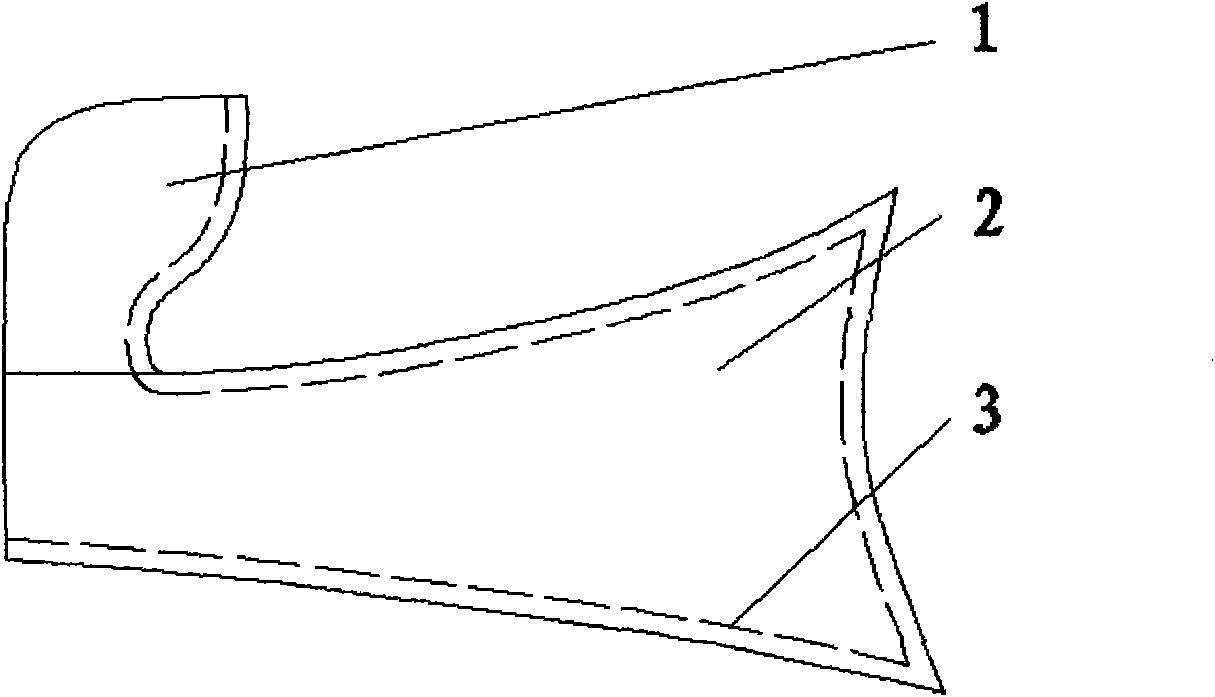

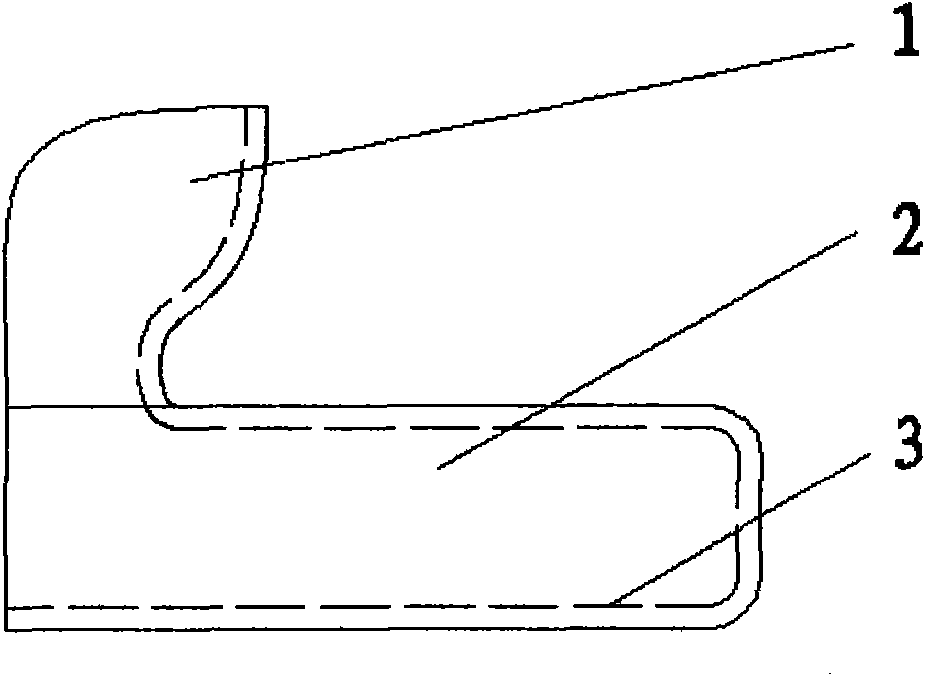

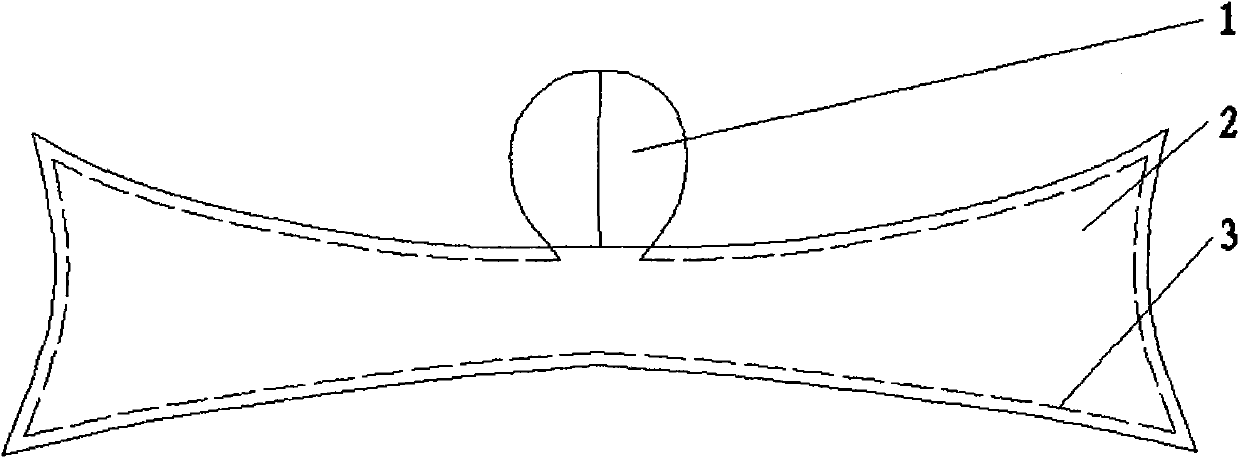

Pneumatic tire manufacturing method

InactiveCN103717382AGood use of characteristicsTake advantage of the characteristicsTyresElastomerVulcanization

The present invention provides a method for manufacturing a pneumatic tire having an inner liner layer or reinforced sheet layer formed from a laminated sheet (1) by lap-splicing the ends thereof. In the laminated sheet (1), a sheet (2) obtained from a thermoplastic resin or a thermoplastic resin composition of a thermoplastic resin blended with an elastomer is laminated with a rubber (3). With the method, cracking and peeling near the spliced region of the laminated sheet do not occur after beginning travel on the manufactured pneumatic tire. The pneumatic tire manufacturing method according to the present invention, the method having a process of lap-splicing the ends of a laminated sheet (1) in which a sheet (2) obtained from a thermoplastic resin or a thermoplastic resin composition of a thermoplastic resin blended with an elastomer is laminated with a rubber (3) that undergoes vulcanizing adhesion to said thermoplastic resin or thermoplastic resin composition, sharpens the ends of the sheet (2) by heat-treatment at a stage after the cutting of lengths of the sheet (2), which is obtained from the thermoplastic resin or thermoplastic resin composition and is to be subjected to the lap-splicing process, and before the tire vulcanization process.

Owner:THE YOKOHAMA RUBBER CO LTD

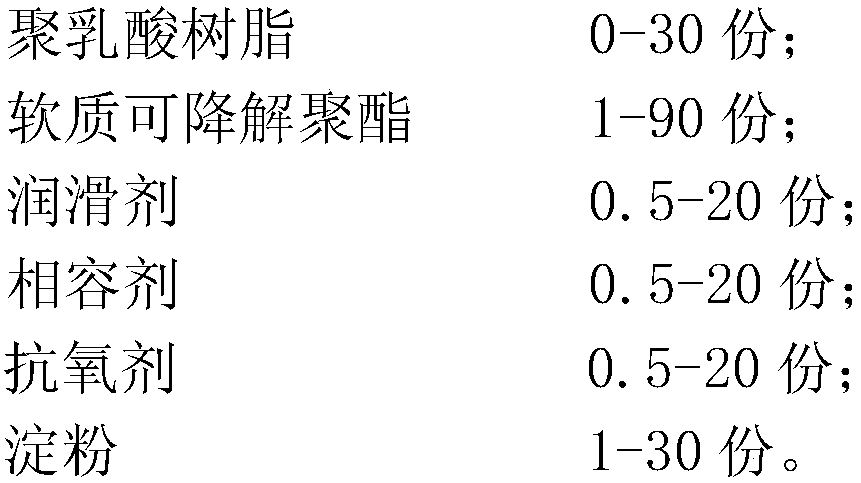

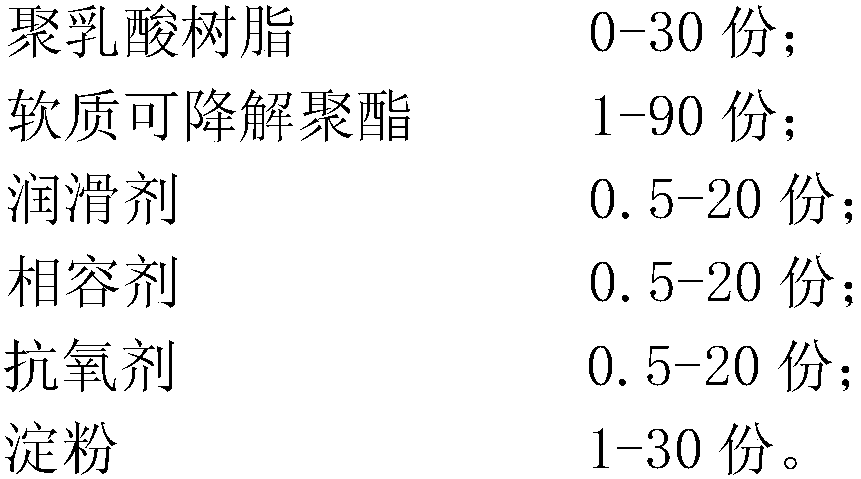

Biodegradable starch membrane material and membrane thereof

The invention relates to the technical field of high molecular materials and specifically relates to a biodegradable starch membrane material and a membrane thereof. The biodegradable starch membranematerial is prepared from polylactic resin, a soft degradable material, a starch and a related additive. The biodegradable starch membrane is membrane generated by processing the biodegradable starchmembrane material. According to the biodegradable starch membrane material and the membrane thereof disclosed by the invention, the strength, the softness and the appearance of the membrane prepared from the material all can meet requirements, the membrane material also can replace traditional membrane materials, white garbage pollution is further reduced, market requirements can be met, and the membrane material can be widely applied to varieties of package bags of stationery bags, food bags, gift bags, clothes bags, garbage bags and the like.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

Inflaming retarding lining cloth

The invention discloses inflaming retarding lining cloth which comprises 30% to 60% of flame-retardant acrylic materials, 20% to 50% of bamboo fiber, 5% to 10% of tencel and 8% to 25% of flame-retardant mucilage glue, wherein the sum of the percentage of all the components is 100%. The raw material components are processed through mix spinning, dying and weaving, and the lining cloth is obtained, wherein weaving comprises the after finishing step, the after finishing step is that soaking treatment is conducted through softening agent acid solutions, the soaking temperature ranges from 40 DEG C to 50 DEG C, the soaking time ranges from 40 min to 60 min, the drying temperature ranges from 125 DEG C to 150 DEG C, and the drying time ranges from 30 min to 40 min. The inflaming retarding lining cloth is soft in hand feeling, capable of meeting the requirements of the lining cloth for flexibility and comfort at the same time and excellent in inflaming retarding effect, has good gas permeability, and is softer than real silk, more excellent in moisture absorption compared with cotton, light and thin and easy to wash and dry.

Owner:ZHEJIANG ADIENT WANFANG TEXTILE TECH CO LTD

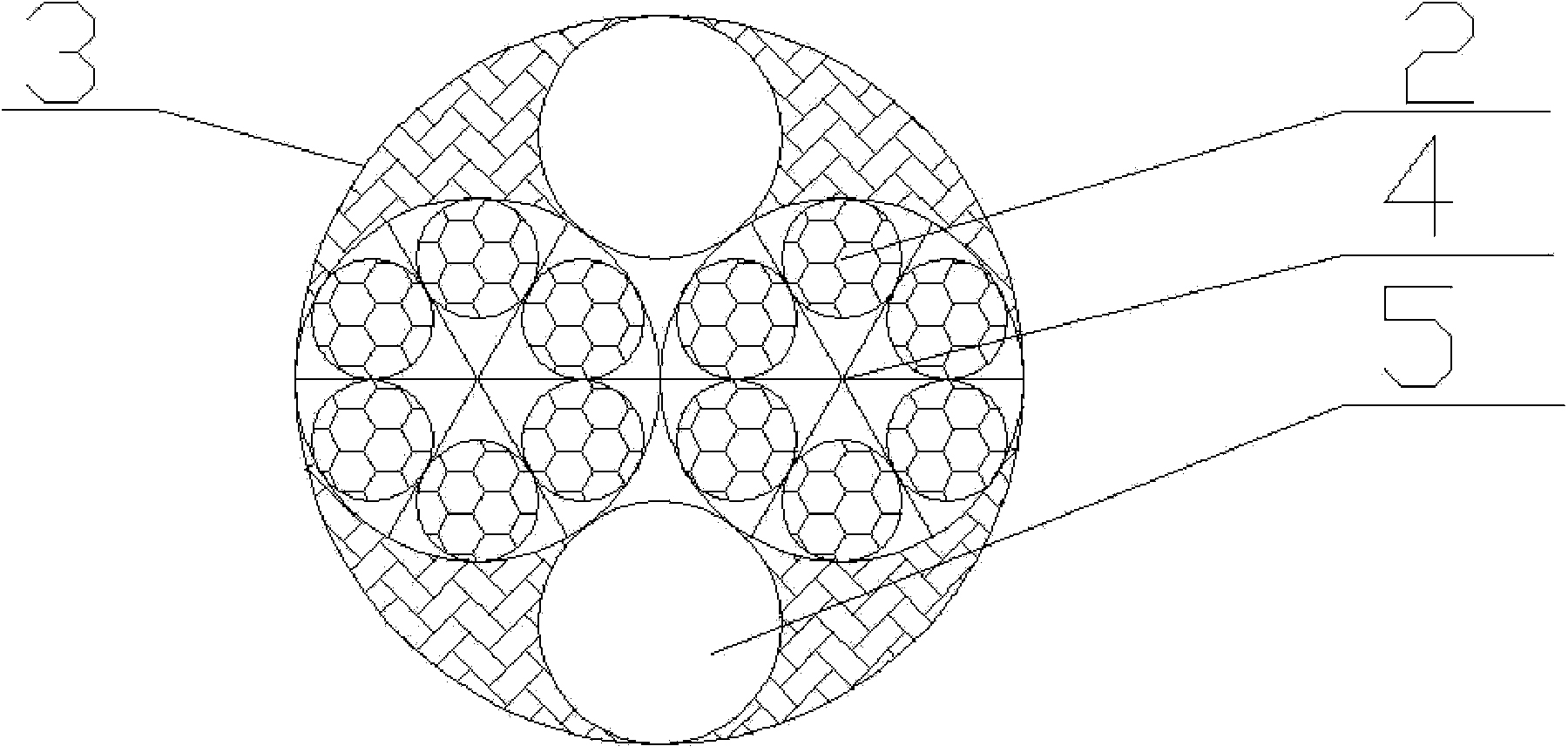

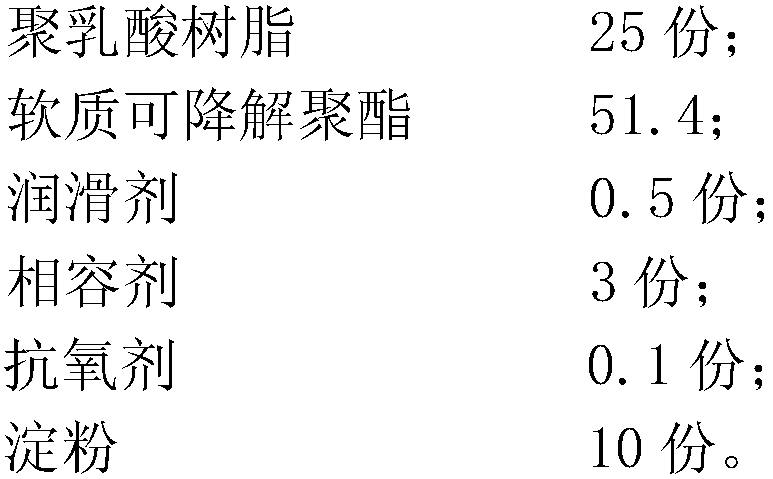

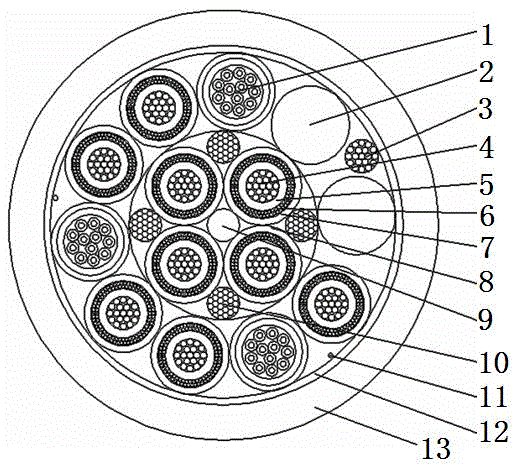

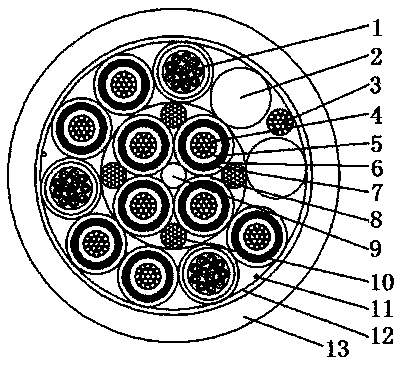

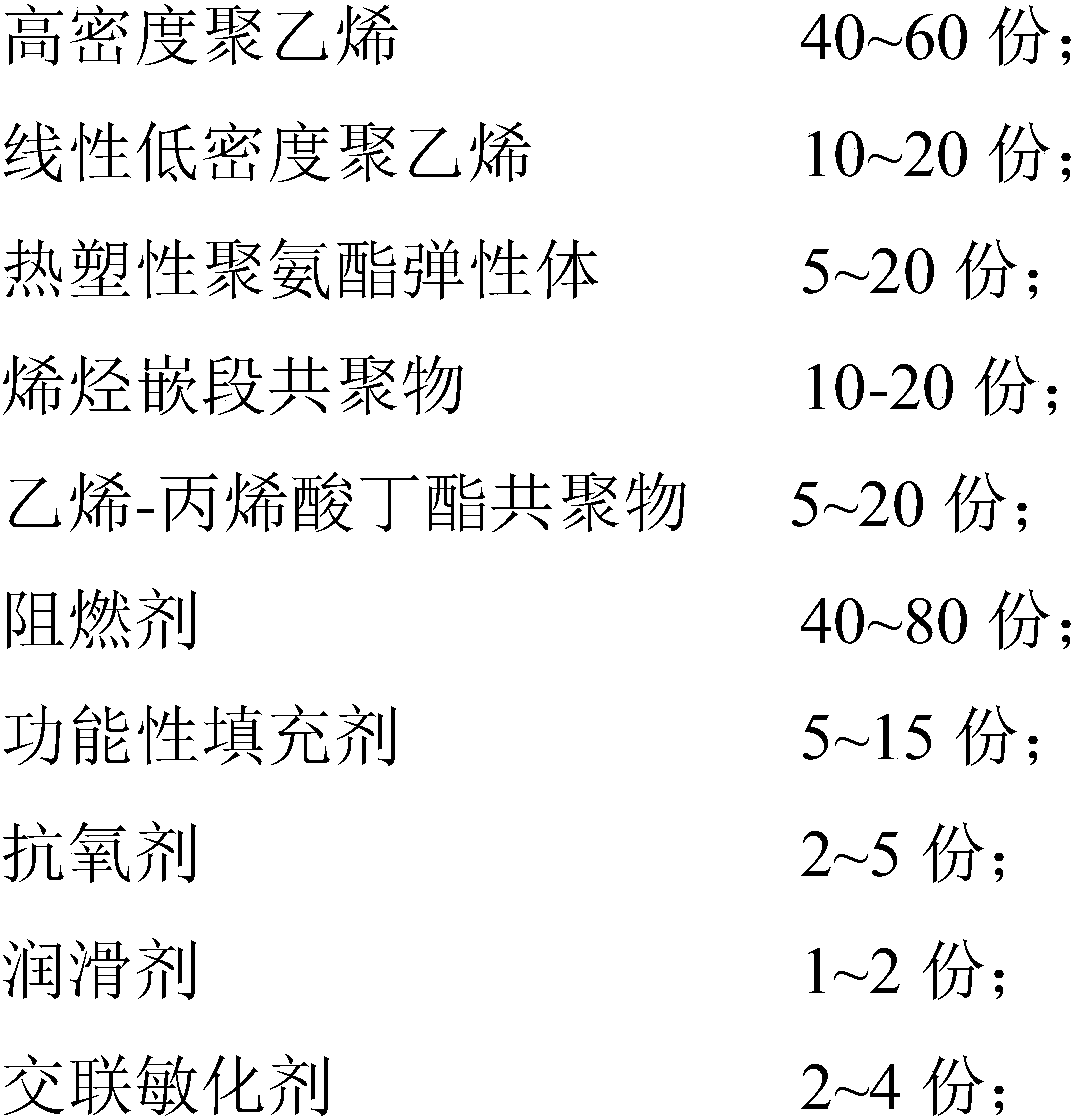

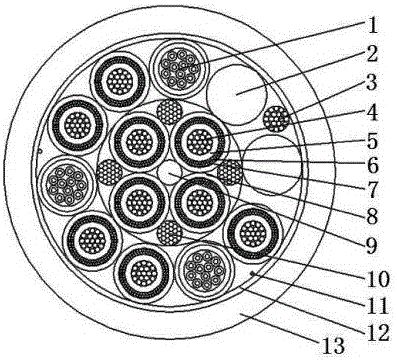

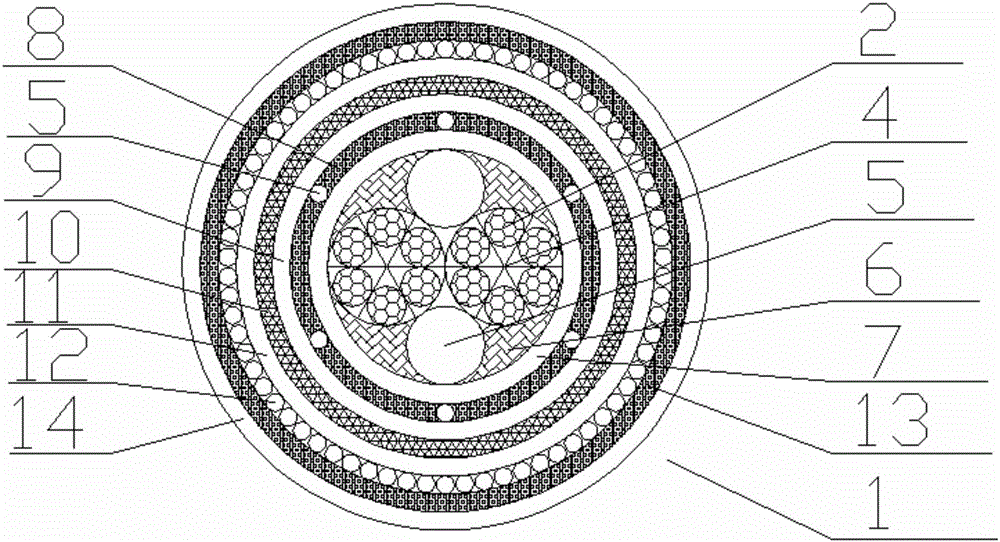

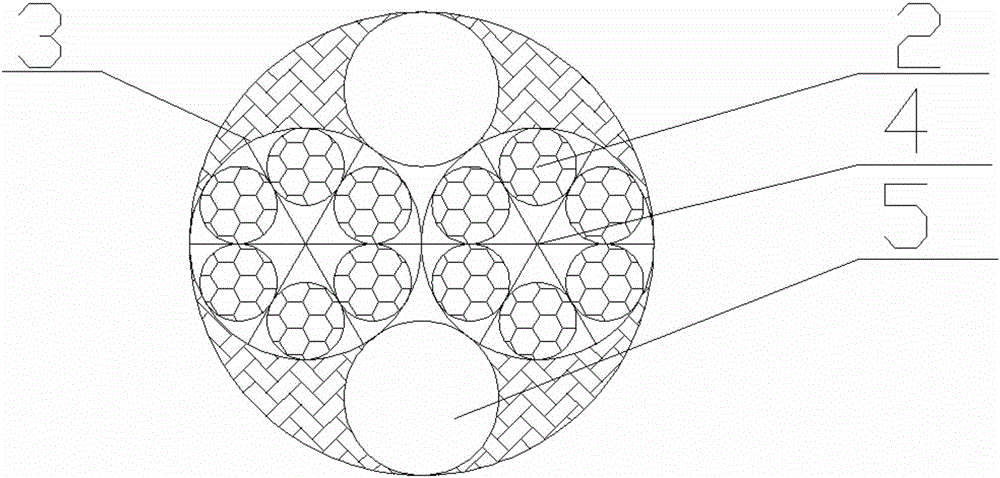

Photoelectric composite cable comprising coaxial electrical units and manufacturing method thereof

ActiveCN104464951AImprove flexibilityGuaranteed tensile strength requirementsCable conductor constructionFlexible cablesMechanical engineeringElectrical and Electronics engineering

The invention belongs to the technical field of cables and particularly relates to a photoelectric composite cable comprising coaxial electrical units. The photoelectric composite cable is composed of a cable core, a shielding layer and an outer sheath, wherein the shielding layer is wrapped outside the cable core, and the outer sheath is wrapped outside the shielding layer in an extrusion molding mode. The cable core is composed of a cable core inner layer and a cable core outer layer located outside the cable core inner layer. The photoelectric composite cable is characterized in that the cable core inner layer is composed of a reinforcer, the inner-layer coaxial electrical units and filling ropes, wherein the reinforcer is located at the center of the cable core inner layer, the inner-layer coaxial electrical units are distributed along the outer edge of the reinforcer, and the filling ropes are located at outer gaps between the adjacent inner-layer coaxial electrical units; the cable core outer layer is composed of the outer-layer coaxial electrical units, a plurality of optical cable units, a plurality of solid filling strips, a ground lead and tearing ropes. The invention further discloses a manufacturing method of the photoelectric composite cable. The photoelectric composite cable has the main advantages of being wider in purpose, better in shielding performance, more excellent in mechanical performance, smaller in diameter, lower in cost and easier to construct, and the manufacturing method is simple.

Owner:JIANGSU ZHONGLI GRP CO LTD

Hot-coated fast-setting cake jam and preparation method thereof

InactiveCN110179082AAdjust the tasteSmooth tasteSugar food ingredientsBaked articles handlingCarrageenanPotassium

The invention provides hot-coated fast-setting cake jam. The jam is prepared from carrageenan, konjac gum, gellan gum, pectin, white sugar, trehalose, glucose powder, sorbitol, glycerin, malt syrup, calcium lactate, potassium chloride, edible salt, hydroxypropyl distarch phosphate, concentrated juice, potassium sorbate, essence for food, citric acid, malic acid and water. The invention further provides a preparation method; the hot-coated fast-setting cake jam is prepared by mixing a prepared emulsifying colloid system and viscous mixed liquor under the condition of the temperature being 85 DEG C to 90 DEG C, and adding a mixture C solution, the essence for food and a premix D. The preparation method provided by the invention is simple; the prepared hot-coated quick-setting cake jam is directly coated on the surface of cake under the condition of the temperature being 85 DEG C; the setting time is short; the setting is fast and nutrition is locked; the appearance is crystal clear aftersetting, the taste is sweet and sour, and the melting performance in the mouth is good.

Owner:LUOHE LIANTAI FOOD

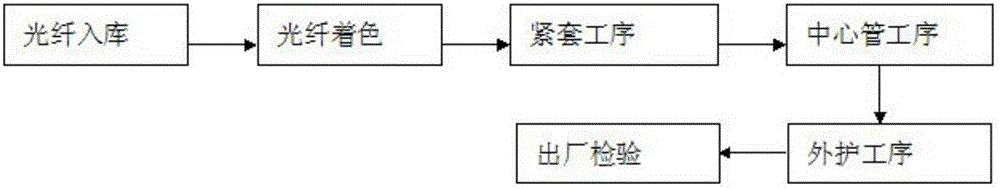

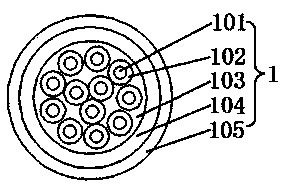

Manufacturing method of central tube FTTH enhanced type leading-in optical cable and optical cable

InactiveCN105204131ASimple structureReduce weightFibre mechanical structuresPolytetramethylene terephthalateEngineering

The invention relates to a manufacturing method of a central tube FTTH enhanced type leading-in optical cable. The manufacturing method comprises the following steps: the procedure of putting optical fibers into a warehouse, the procedure of coloring optical fibers, the procedure of tightly fastening, the central tube procedure, the procedure of external protection and the procedure of warehouse-out detection, wherein in the central tube procedure, a tightly packed optical fiber fixing device is adopted to reduce the possibility of movement of tightly packed optical fibers in the production process to prevent the situation that the tightly packed optical fibers are in contact with a certain point of the inner wall of a dry-type loose tube for a long time to cause adhesion and further guarantee the water resistance of the dry-type loose tube; in the central tube procedure, the excess length of optical fibers is controlled by adopting one or more of the following manners: adjusting the take-up and pay-off tension of tightly packed optical fibers, adjusting the water temperature difference between water tanks, adjusting distance between water tanks, and adopting polybutylene terephthalate as a central tube material, so as to guarantee the high-and-low temperature performance of an optical cable. The optical cable manufactured by adopting the manufacturing method is simple in structure, low in weight, and convenient and rapid in construction, so that the construction cycle and construction cost are greatly reduced, and a brand new solution is provided for the development of optical communication.

Owner:JIANGSU HENGTONG PHOTOELECTRIC

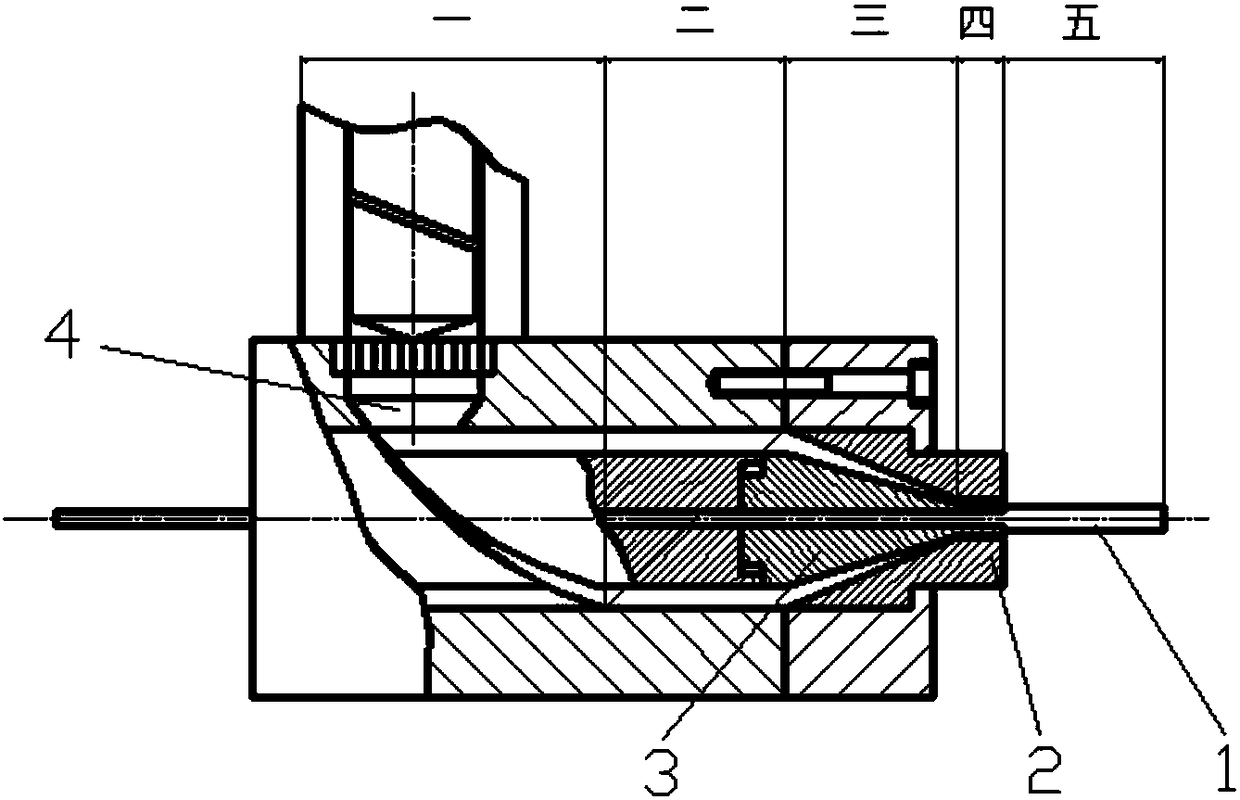

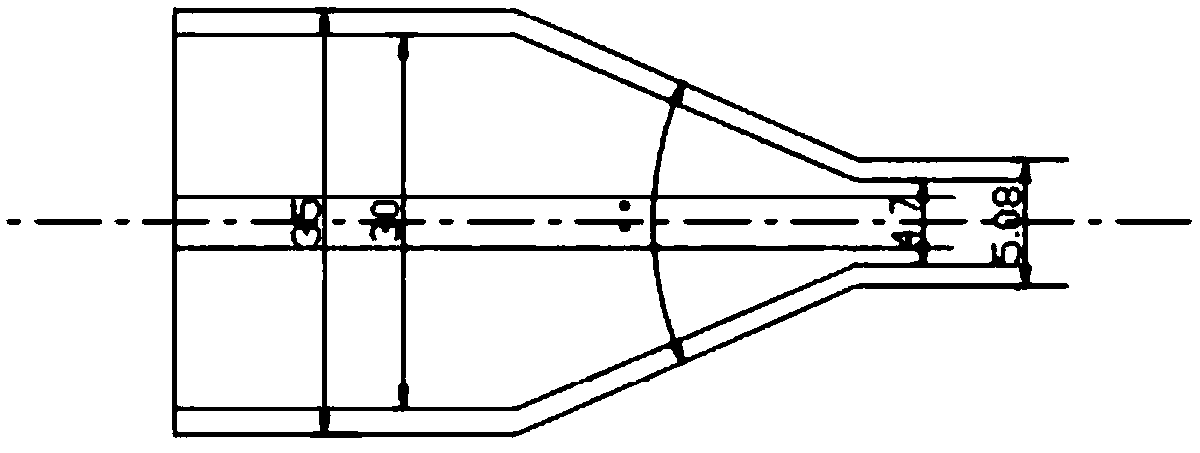

Design method of extrusion molding mold of phase-compensated cable fluorinated ethylene-propylene protective jacket

InactiveCN108284547AImprove performanceReduce the manpower and material cost of processing testDomestic articlesMaterial resourcesFluorinated ethylene propylene

The invention belongs to the technical fields of cable protective jacket extrusion molding, mold design and forming simulation, and particularly relates to a design method of an extrusion molding moldof a phase-compensated cable fluorinated ethylene-propylene protective jacket. The design method comprises the following steps that I, different extrusion molding head runner models are established in grid division software, a grid is divided, and a grid model is acquired; II, the corresponding grid model is imported in finite element simulation analysis software, boundary conditions are input, and outlet pressure and speed distribution of a plastic extruding machine are acquired through calculation; and III, the proper extrusion molding head runner model is selected according to an analog computation result, and specific parameters suitable for the mold are finally acquired. According to the design method, manpower and material resource cost of a processing experiment of the phase-compensated cable fluorinated ethylene-propylene protective jacket is greatly reduced, fastening coating of the protective jacket is achieved, bending phase position stability of a phase-compensated cable is improved, and the stress cracking problem of the cable protective jacket is effectively solved.

Owner:THE 23RD RES INST OF CHINA ELECTRONICS TECH GRP CORP

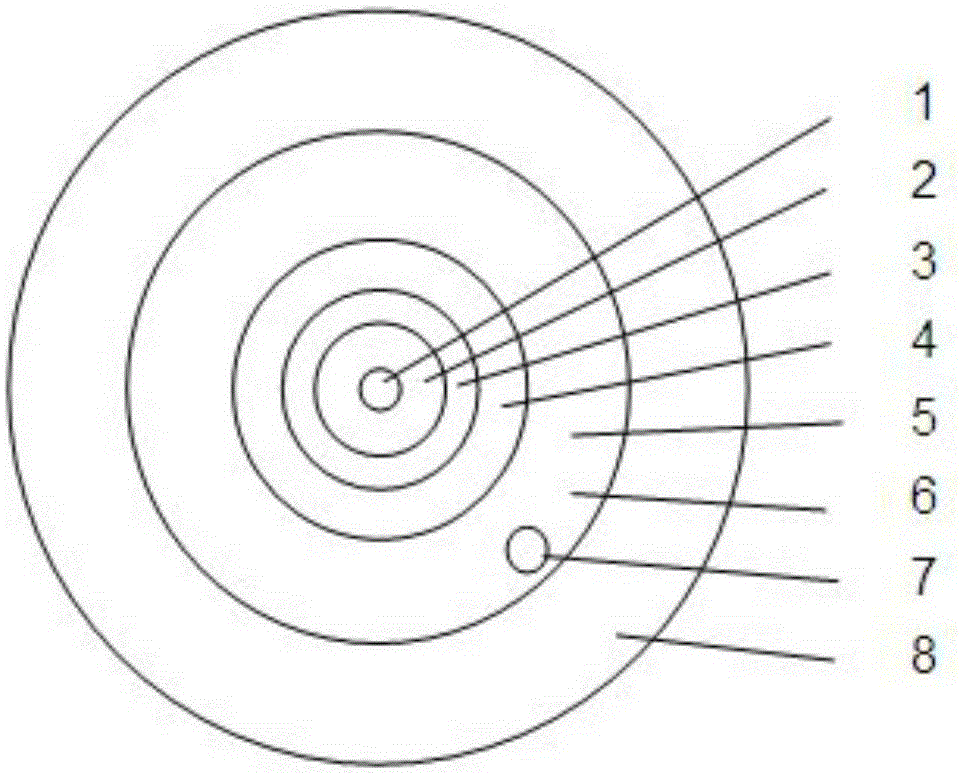

Opto-electric hybrid cable comprising coaxial electric units

InactiveCN105590671AImprove flexibilityGuaranteed tensile strength requirementsCable conductor constructionFlexible cablesElectricityEngineering

The present invention belongs to the technical field of cables and particularly relates to an opto-electric hybrid cable comprising coaxial electric units. The cable is formed by a cable core, a shielding layer which coats the cable core, and an outer sheath which is extruded outside the shielding layer. The cable core is formed by a cable core inner layer and a cable outer layer outside the cable core inner layer and is characterized in that the cable core inner layer is formed by a reinforcing member in the center, multiple inner layer coaxial electric units distributed along the outer edge of the reinforcing member, and filling ropes in the external gaps between the adjacent inner layer coaxial electric units, and the cable core outer layer is formed by multiple outer layer coaxial electric units, multiple optical cable units, multiple solid filling strips, a ground wire and a rip cord. The invention also discloses a manufacturing method of the opto-electric hybrid cable. The cable and the method have the advantages of wide application, good shielding performance, good mechanical performance, a smaller diameter, lower cost, easy construction, and the simple manufacturing method.

Owner:王笑梅

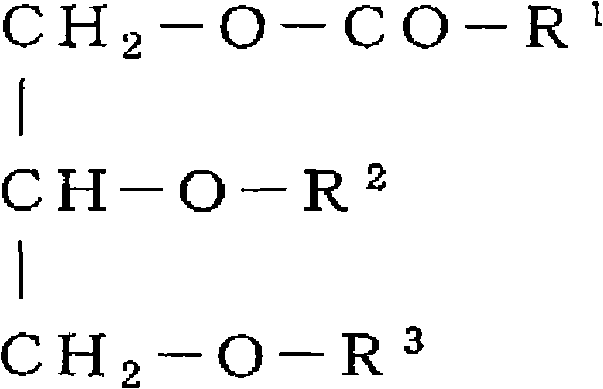

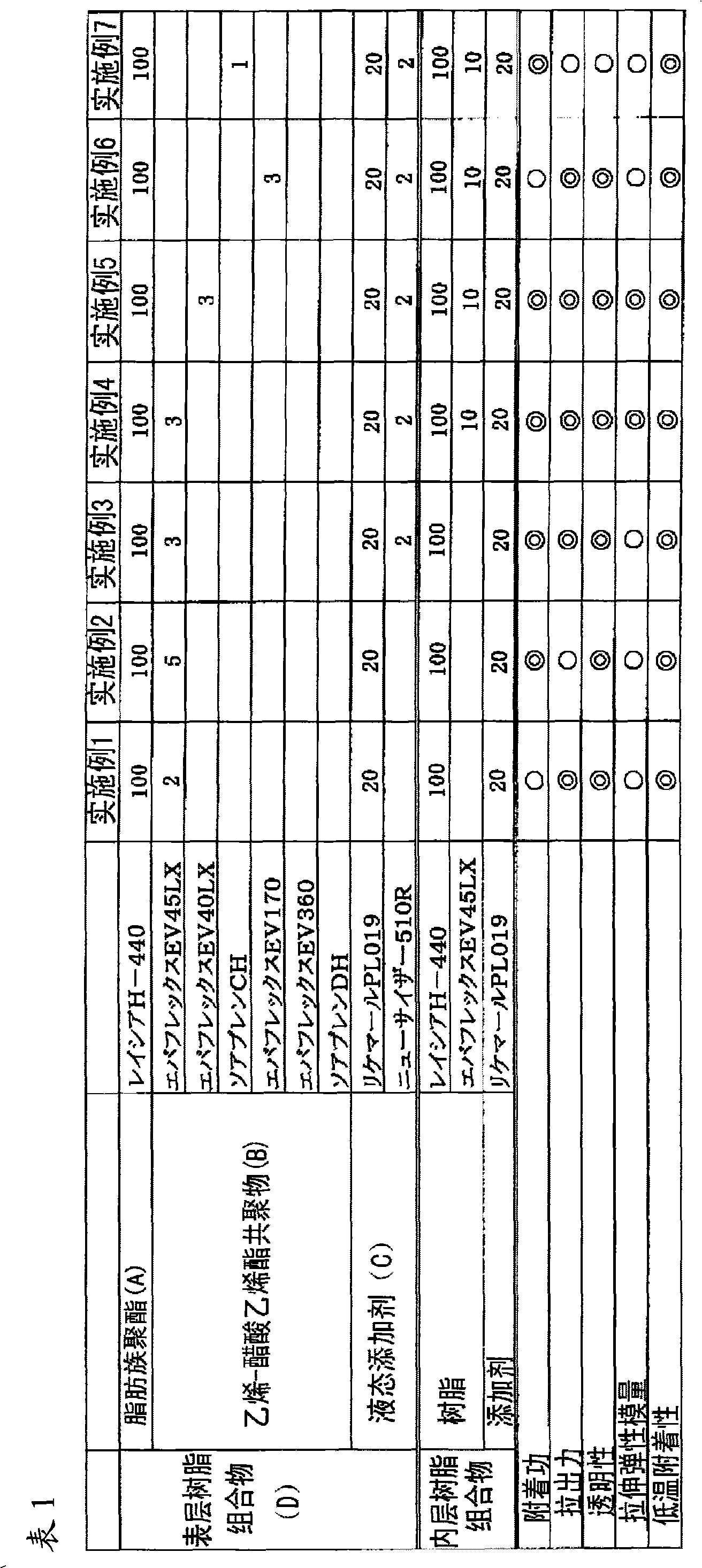

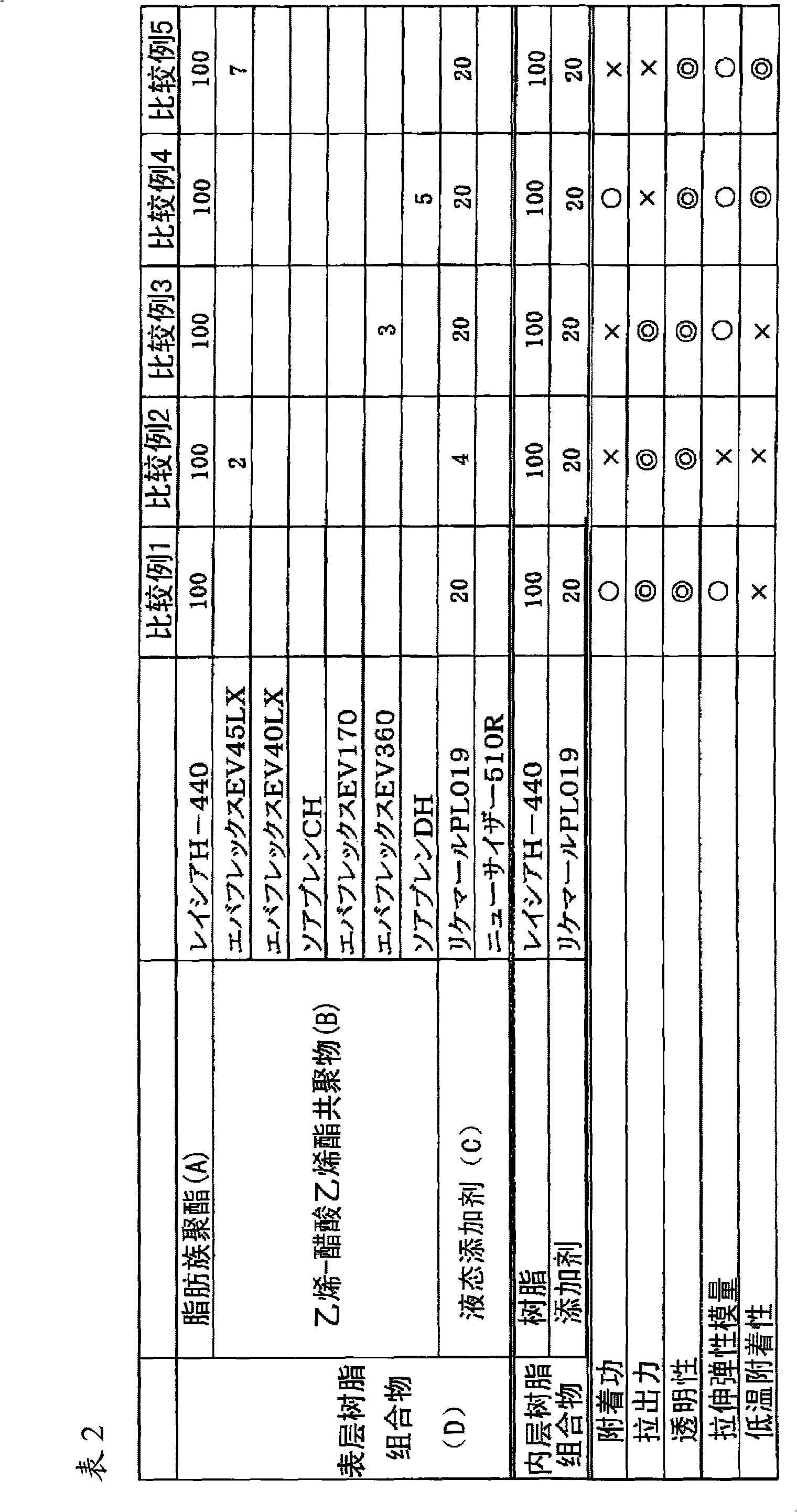

Adhesive wrap film

InactiveCN101516622AMeet the softnessMeet transparencySynthetic resin layered productsDomestic containersSurface layerAdhesive

The present invention relates to a wrapping film comprising, as at least one surface layer, a resin composition (D) layer comprising 0.5 to 5 parts by weight of an ethylene-vinyl acetate copolymer having a vinyl acetate content of 30 to 60% by weight (B) and 5 to 40 parts by weight of a liquid additive (C) based on 100 parts by weight of an aliphatic polyester resin (A).

Owner:ASAHI KASEI HOME PRODS CORP

High-temperature radiation-resistant halogen-free flame-retardant automotive wire material and preparation method thereof

ActiveCN105602071BImprove flame retardant performanceLow costPlastic/resin/waxes insulatorsAntioxidantResin matrix

The invention discloses a high-temperature-irradiation-resistant halogen-free flame-retardant automobile wire material and a preparation method thereof. The high-temperature-irradiation-resistant halogen-free flame-retardant automobile wire material adopts high-density polyethylene, linear low-density ethylene, a thermoplastic polyurethane elastomer, an olefin block copolymer and an ethylene-butyl acrylate copolymer with different melt indexes as resin matrixes; a halogen-free flame retardant composed of an intumescent flame retardant, magnesium hydroxide and zinc borate is added into the resin matrixes, and a functional filler, an antioxidant, a lubricant and a crosslinking sensitizer are combined; and thus, the obtained automobile wire material can satisfy the required softness and wear resistance and also ensure the thermal overload property of the product. Besides, the wire material has the advantages of favorable flame retardancy, low smoke and no halogen, and conforms to the requirements for environmental protection. The preparation method of the product has the advantages of simple technique and low cost, and is easy to operate and suitable for popularization and application.

Owner:JIANGSU DEWEI ADVANCED MATERIALS

Photoelectric cable with coaxial electric units

InactiveCN105719771AImprove flexibilityGuaranteed tensile strength requirementsCommunication cablesInsulated cablesElectricityEngineering

The invention belongs to the technical field of cables, and particularly relates to a photoelectric cable with coaxial electric units. The photoelectric cable comprises a cable core, a shielding layer for coating the cable core and an outer sheath arranged on the exterior of the shielding layer in an extruding and coating manner, wherein the cable layer comprises a cable core inner layer and a cable core outer layer positioned outside the cable core inner layer; the photoelectric cable is characterized in that the cable core inner layer comprises a reinforced layer positioned in the center, multiple inner layer coaxial electric units distributed along the outer edge of the reinforced part and filling ropes positioned in outer gaps of the adjacent inner layer coaxial electric units; and the cable core outer layer comprises multiple outer layer coaxial electric units, multiple optical cable units, multiple solid filling strips, a ground wire and tearing ropes. The invention discloses a manufacturing method for the photoelectric hybrid cable. The photoelectric cable has the main following beneficial effects of wider application, better shielding performance, better mechanical performance, smaller diameter, lower cost, easier construction and simple manufacturing method.

Owner:王笑梅

Cap-carried shawl with anti-ultraviolet function

The invention relates to a cap-carried shawl with an anti-ultraviolet function, which comprises an elongated shawl part, wherein the shawl part is connected with a cap part which can be worn on the head. Towel weave provided with one-sided terry is used as fabric; worsted warp is anti-ultraviolet blended yarn; ground warp is pure cotton yarn; weft yarn is anti-ultraviolet blended yarn or pure cotton yarn; the anti-ultraviolet blended yarn is formed by blending anti-ultraviolet synthetic fiber and cotton fiber; ultraviolet isolation factors are added into the raw material of the anti-ultraviolet synthetic fiber; the warp density is 114-120 pieces / 10cm; the weft density is 180-200 pieces / 10cm; the twist coefficient of single yarn is 350-370; and the yarn twist in the stranding process is 25-30 twists / 10cm. The cap-carried shawl provided by the invention has multiple purposes, can be used conveniently, has good flexibility, comfort, water absorbability and anti-ultraviolet capacity, can effectively prevent the human body from being injured by ultraviolet rays, and is especially suitable for being used outdoors.

Owner:BEIJING GUANGHUA TEXTILE GRP +1

Production process for flame-retardant soft lining cloth for garment

InactiveCN106012302ASoft touchMeet the softnessCarbon fibresHeat resistant fibresTime rangeMoisture absorption

The invention discloses a production process for a flame-retardant soft lining cloth for a garment. By weight, 20-70 parts of flame-retardant acrylic, 10-60 parts of bamboo charcoal fibers, 1-15 parts of tencel and 3-35 parts of flame-retardant viscose are weighed, then the flame-retardant acrylic, the bamboo charcoal fibers and the tencel are subjected to stretching, tatting and calender bonding, and therefore semi-finished lining cloth is obtained; the semi-finished lining cloth is soaked in a softener acid solution, wherein the soaking temperature ranges from 35 DEG C to 55 DEG C, the soaking time ranges from 30 min to 70 min, after being dried, the semi-finished lining cloth is placed on a coating machine to be coated, side cutting and length metering are conducted, then winding is conducted, and the lining cloth is obtained. The manufactured lining cloth for the garment is soft in hand feeling, the softness, the comfort and the excellent flame-retardant effect required by the lining cloth can be met at the same time, good breathability is achieved, and good moisture absorption is achieved; the lining cloth is light, thin, easy to wash and dry, simple in manufacturing process, cheap and fine, and cost is greatly reduced.

Owner:南通江淮衬布有限公司

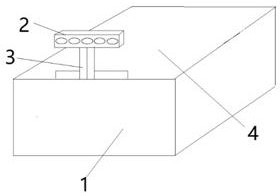

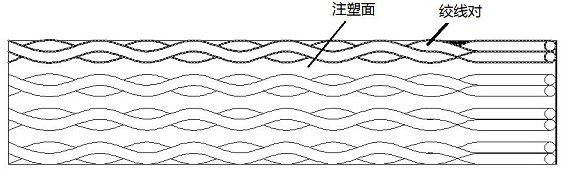

Ultra-flexible LVDS cable production process

PendingCN113327705AMeet the softnessAvoid easy disassemblyFlat/ribbon cablesManufacturing extensible conductors/cablesHigh densityEngineering

The invention provides an ultra-flexible LVDS cable production process. The advancing direction of the cable body is adjusted through the cable passing holes of a multi-hole positioning hole mold, a special casting mold is not needed for injection molding of the three twisted-pair cables and the single cable into a cable row, only the twisted-pair cables and the single cable need to be subjected to injection molding at the bottom of the cable body, the bonding and fixing effects can be achieved, and waste of a coating material is avoided; and the injection molding particles are made of transparent high-density PE, so that the flexibility of the wire row is met, and the cable not easy to disintegrate at the same time.

Owner:乐庭电线工业(常州)有限公司 +1

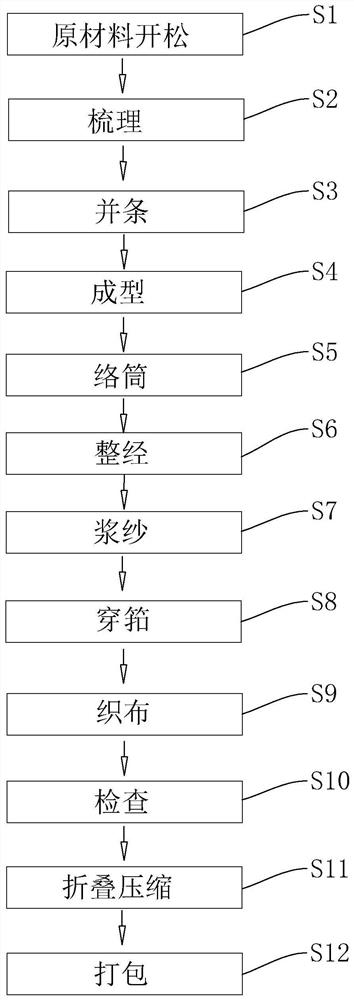

High-elastic gray fabric production process

InactiveCN114541009AIncrease elasticityNo breakDrying solid materials with heatTextile disintegration and recoveryYarnFiber

The invention relates to a high-elastic gray fabric production technology, and relates to the field of gray fabric production technologies, the gray fabric production technology comprises the following steps: S1, raw material opening and impurity removal; S2, carding: raw materials are made into fiber strips through a carding machine and a combing machine; s3, drawing: improving the internal structure of the fiber rod through a drawing frame; s4, forming: further drafting and twisting the fiber strips through a coarse sand machine and a spinning frame to form yarns; s5, spooling is conducted, specifically, the tubular yarn is wound into tubular yarn with the large diameter through an automatic spooling machine; s6, warping: winding a plurality of cylindrical yarns on a winding roller; s7, sizing, wherein the yarn on the winding roller is subjected to sizing treatment through a sizing machine; s8, denting is carried out; s9, weaving; s10, checking, wherein the quality of the gray fabric is detected; s11, folding and compressing; and S12, packaging. The method has the advantages that the elasticity, toughness and strength of the grey cloth are improved, the grey cloth can rebound conveniently after deformation, local damage is not prone to occurring, and the service life of the grey cloth is prolonged.

Owner:石家庄维宝莱纺织有限公司

A kind of aluminum alloy conductor flexible cable and preparation method thereof

ActiveCN112259284BHigh strengthAnti-agingClimate change adaptationConductive materialStructural engineeringElectro conductivity

The invention discloses a flexible cable with an aluminum alloy conductor and a preparation method thereof, belonging to the field of flexible cables. The flexible cable includes one or more layers of cable sheath layers, cable wrapping layers and conductor insulation in sequence from outside to inside. Wire core, the conductor insulated core is one or more strands, each conductor insulated core is filled with a cable filler, and the conductor insulated core includes tensile strands, aluminum alloy conductors and Core insulation. The flexible cable of the present invention not only has high electrical conductivity, but also has excellent tensile strength and compressive creep resistance, realizes the possibility of replacing copper with aluminum in flexible cables, reduces the cost of using flexible cables, and improves the performance of the cable due to its lightweight and excellent characteristics. Abrasion resistance and service life.

Owner:TBEA DEYANG CABLE CO LTD

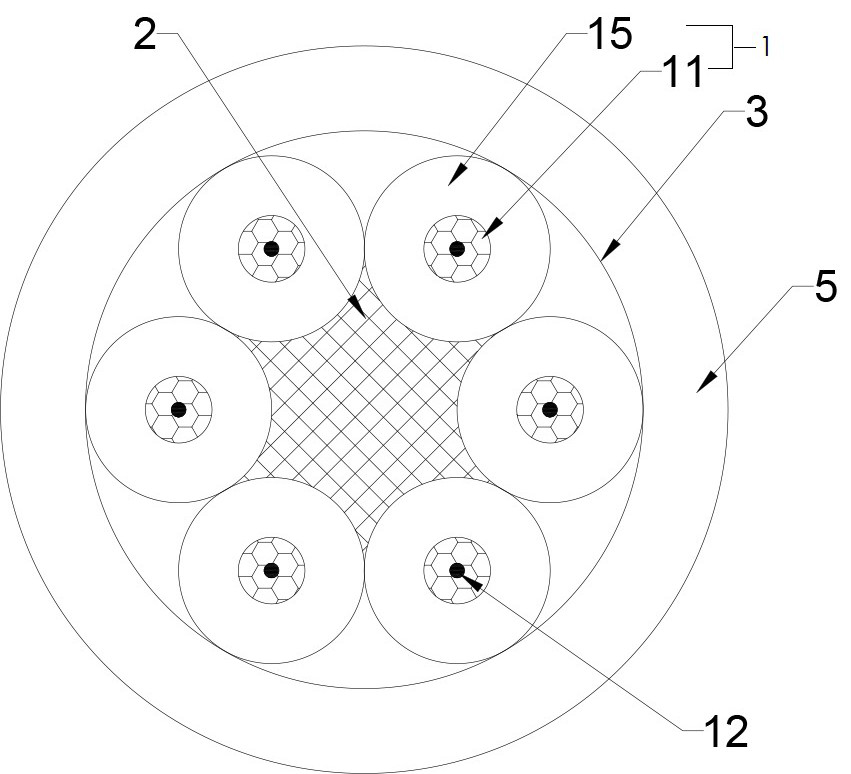

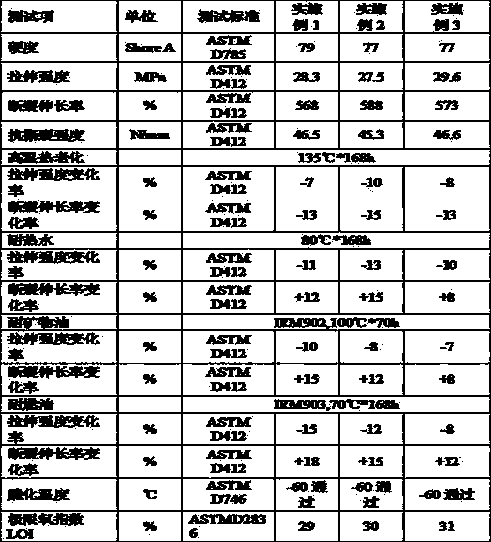

Halogen-free flame-retardant polyether type polyurethane elastomer material

The invention discloses a halogen-free flame-retardant polyether type polyurethane elastomer material which is composed of the following components in parts by weight: 48-58 parts of polyether type polyurethane elastomer, 12-22 parts of ethylene-butyl acrylate copolymer, 1.5-2.5 parts of maleic anhydride, 0.4-1.2 parts of 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane, 4.5-5.1 parts of aluminum diethylphosphinate, 19-22 parts of piperazine phosphate, 0.1-0.3 part of Compton 445, 0.2-0.4 part of American Dover S-9228, 1.2-1.8 parts of polymerization type carbodiimide, and 0.3-0.8 part of antioxidant. The polyether type polyol in the polyether type polyurethane elastomer is one of polyethylene glycol or polytetrahydrofuran ether glycol. According to the halogen-free flame-retardant polyether type polyurethane elastomer material disclosed by the invention, the compatibility is improved, the stability of a chemical structure is improved, the tear resistance is also obviously improved, and meanwhile, thermal aging, hot-water resistance, oil resistance, flame retardancy and lower hardness are also achieved.

Owner:中广核高新核材科技(苏州)有限公司

An anti-static, corrosion-resistant, water-resistant and stretch-resistant insulated cable

InactiveCN104318986BHigh mechanical strengthImprove electrical performanceInsulated cablesInsulated conductorsGraphiteWater block

The invention discloses an anti-static, anti-corrosion, waterproof and stretching-resistant insulated cable. The anti-static, anti-corrosion, waterproof and stretching-resistant insulated cable comprises a cable body. The cable body comprises cable cores, a cable core protective layer, an insulating layer, a shielding layer and an outer jacket. The cross section of the cable core protective layer is of a circular structure, and the multiple evenly-arranged cable cores are arranged in the cable core protective layer and separated through PVC plastic connecting rods; a plurality of current guide cores are arranged outside the cable core protective layer and are tangent with the cable core protective layer; the insulating layer is arranged outside the cable core protective layer; waterproof fillers are arranged in a gap between the insulating layer and the cable core protective layer; the shielding layer is tightly extruded on the insulating layer and internally provided with the multiple evenly-arranged current guide cores; a breakdown resistant layer, a steel core protective layer and a waterproof layer are sequentially extruded on the shielding layer from inside to outside; an armor layer is extruded outside the waterproof layer, the outer jacket is arranged outside the armor layer, and a graphite layer is arranged between the armor layer and the outer jacket. The anti-static, anti-corrosion, waterproof and stretching-resistant insulated cable has the advantages of being reasonable in structural design, high in anti-static capacity, good in anti-corrosion performance and the like.

Owner:珠海长盛电缆有限公司

Photoelectric hybrid cable including coaxial electric unit and manufacturing method thereof

ActiveCN104464951BImprove flexibilityGuaranteed tensile strength requirementsCable conductor constructionFlexible cablesElectricityEngineering

The invention belongs to the technical field of cables and particularly relates to a photoelectric composite cable comprising coaxial electrical units. The photoelectric composite cable is composed of a cable core, a shielding layer and an outer sheath, wherein the shielding layer is wrapped outside the cable core, and the outer sheath is wrapped outside the shielding layer in an extrusion molding mode. The cable core is composed of a cable core inner layer and a cable core outer layer located outside the cable core inner layer. The photoelectric composite cable is characterized in that the cable core inner layer is composed of a reinforcer, the inner-layer coaxial electrical units and filling ropes, wherein the reinforcer is located at the center of the cable core inner layer, the inner-layer coaxial electrical units are distributed along the outer edge of the reinforcer, and the filling ropes are located at outer gaps between the adjacent inner-layer coaxial electrical units; the cable core outer layer is composed of the outer-layer coaxial electrical units, a plurality of optical cable units, a plurality of solid filling strips, a ground lead and tearing ropes. The invention further discloses a manufacturing method of the photoelectric composite cable. The photoelectric composite cable has the main advantages of being wider in purpose, better in shielding performance, more excellent in mechanical performance, smaller in diameter, lower in cost and easier to construct, and the manufacturing method is simple.

Owner:JIANGSU ZHONGLI GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com