Halogen-free flame-retardant polyether type polyurethane elastomer material

A technology of polyurethane elastomer and polyether polyurethane, which is applied in the field of polymer elastomer materials, can solve the problems of simple start-up process, difficulty in achieving production efficiency and quality, and achieve the effect of soft hand feeling, low hardness and increased stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

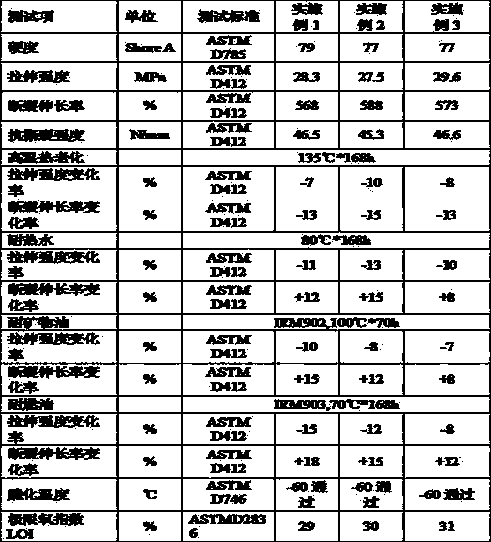

[0026] Examples 1-3: A halogen-free flame-retardant polyether polyurethane elastomer material, which consists of the following components by weight, as shown in Table 1:

[0027] Table 1

[0028] Example 1 Example 2 Example 3 Polyether polyurethane elastomer / part 55 50 50 Ethylene-butyl acrylate copolymer / part 15 20 20 Maleic anhydride / part 2 2 2 Double 25 / set 0.5 0.5 1 Aluminum diethylphosphinate / part 5.1 5.1 5 Piperazine Phosphate / part 19.4 19.4 20 Compton 445 / part 0.2 0.25 0.18 US Dover S-9228 / copy 0.3 0.25 0.35 Polymerized carbodiimide / part 1.5 1.4 1.6 Antioxidant / part 0.5 0.4 0.7

Embodiment 1

[0029] In the polyether polyurethane elastomer of Example 1, the polyether polyol is polyethylene glycol, and the antioxidant is a compound of an amine antioxidant and a high molecular weight phosphite antioxidant, and the compounding weight ratio is 2:3, the amine antioxidant is 4,4'-bis(phenylisopropyl)diphenylamine, and the high molecular weight phosphite antioxidant is bis(2,4-dicumylphenyl)pentaerythritol disulfide Phosphate.

Embodiment 2

[0030] In the polyether polyurethane elastomer of Example 2, the polyether polyol is polytetrahydrofuran ether glycol, and the antioxidant is a compound of an amine antioxidant and a high molecular weight phosphite antioxidant, and the compounding weight ratio is is 2:4,

[0031] The amine antioxidant is 4,4'-di(phenylisopropyl)diphenylamine, and the high molecular weight phosphite antioxidant is bis(2,4-dicumylphenyl)pentaerythritol diphosphite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com