High-temperature radiation-resistant halogen-free flame-retardant automotive wire material and preparation method thereof

A technology for automotive wires and high temperature resistance, applied in the direction of plastic/resin/wax insulators, organic insulators, electrical components, etc., can solve a large number of smoke and irritating gases, environmental damage and other problems, to ensure thermal overload performance, flame retardant Excellent performance and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

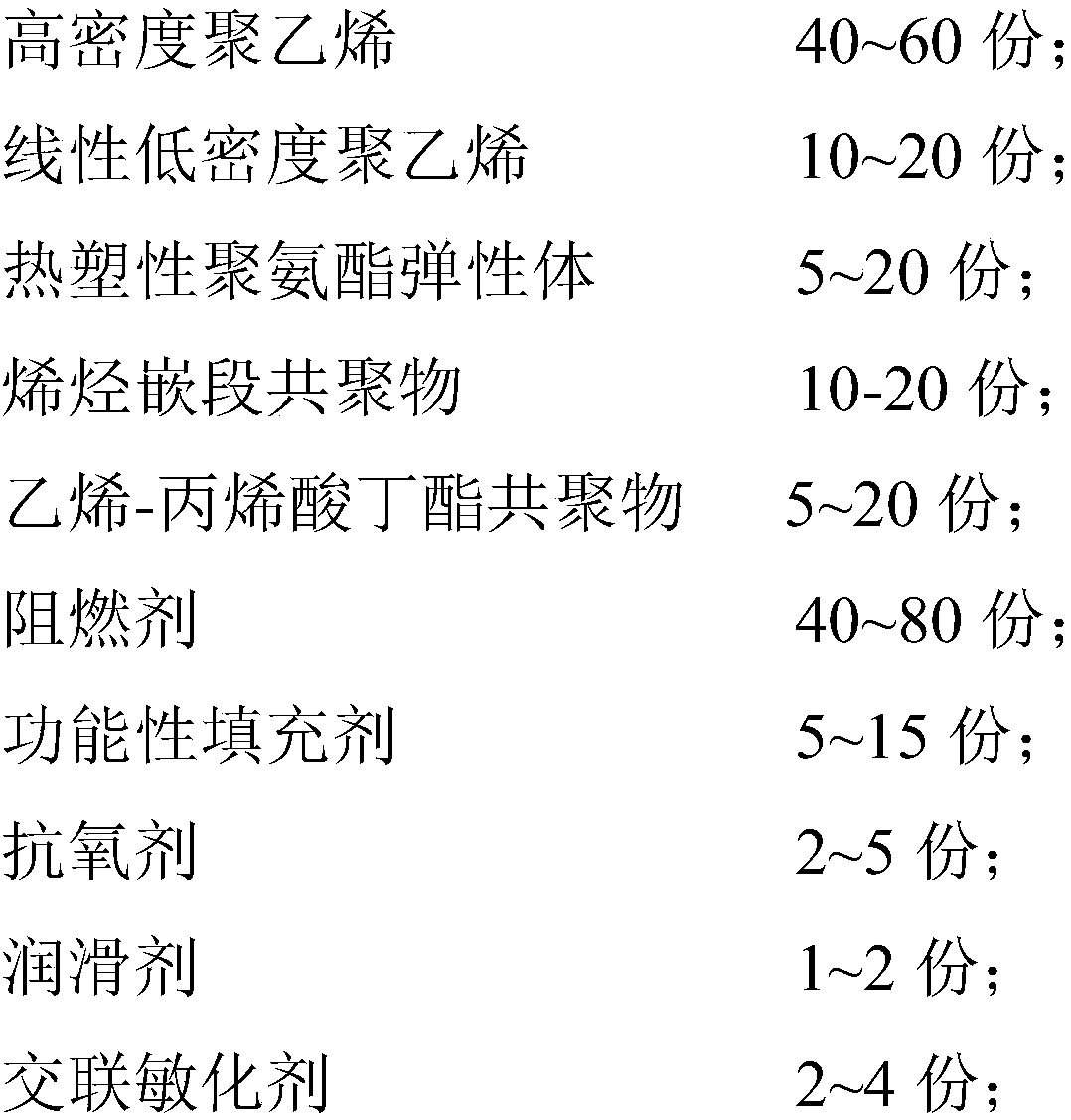

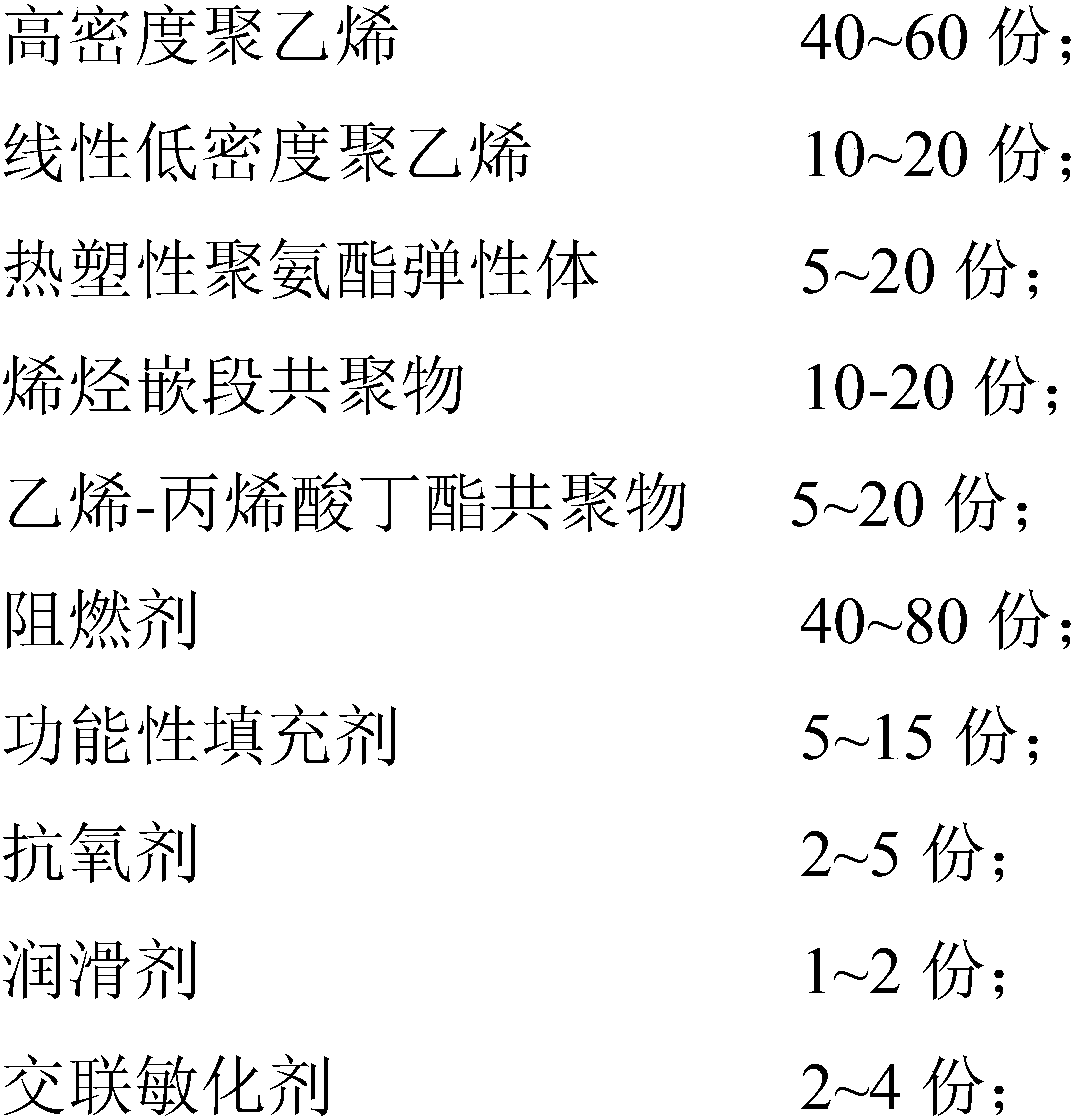

[0031] This example provides a high-temperature radiation-resistant halogen-free flame-retardant automotive wire material A, whose raw material formula is shown in Table 1, wherein:

[0032] The melt index of high-density polyethylene is 0.3g / min; the melt index of linear low-density polyethylene is 20g / min; the Shore A hardness of thermoplastic polyurethane elastomer is 90; the melt index of olefin block copolymer is 5.0g / min min; the melt index of ethylene-butyl acrylate copolymer is 5g / min; the flame retardant is formed by mixing intumescent flame retardant, magnesium hydroxide and zinc borate in a weight ratio of 1:1.4:0.8; functional filler modification Nano kaolin, and this modified nano kaolin particle size is 200nm; Antioxidant is 1.0:1.5:1.0:1.5 according to weight ratio by antioxidant 300, antioxidant 1024, antioxidant 1035 and antioxidant DLTP; The agent is formed by mixing grafted wax and oxidized polyethylene wax, and the grafted wax accounts for 80% by weight of ...

specific Embodiment 2

[0038] This example provides a high-temperature radiation-resistant halogen-free flame-retardant automotive wire material B, whose raw material formula is shown in Table 1, wherein:

[0039] The melt index of high-density polyethylene is 0.5g / min; the melt index of linear low-density polyethylene is 15g / min; the Shore A hardness of thermoplastic polyurethane elastomer is 88; the melt index of olefin block copolymer is 3.5g / min min; the melt index of ethylene-butyl acrylate copolymer is 5g / min; the flame retardant is formed by mixing intumescent flame retardant, magnesium hydroxide and zinc borate in a weight ratio of 1:0.8:0.5; the functional filler is nano Silica and modified nano-kaolin are mixed at a weight ratio of 1:2, and the nano-silica particle size is 200nm, and the modified nano-kaolin particle size is 500nm; the antioxidant is composed of antioxidant 300 and antioxidant 1024 , antioxidant 1035 and antioxidant 1010 are 1.0:1.0:1.2:1.2 according to the weight ratio; T...

specific Embodiment 3

[0041] This example provides a high-temperature radiation-resistant halogen-free flame-retardant automotive wire material C, whose raw material formula is shown in Table 1, wherein:

[0042]The melt index of high-density polyethylene is 0.7g / min; the melt index of linear low-density polyethylene is 18g / min; the Shore A hardness of thermoplastic polyurethane elastomer is 85; the melt index of olefin block copolymer is 2.5g / min min; the melt index of ethylene-butyl acrylate copolymer is 8g / min; the flame retardant is formed by mixing intumescent flame retardant, magnesium hydroxide and zinc borate in a weight ratio of 1:0.4:0.3; the functional filler is nano Silicon dioxide, and the particle size of nano silicon dioxide is 100nm; Antioxidant is 0.8:1.2 according to weight ratio by antioxidant 300, antioxidant 1024, antioxidant 1035, antioxidant DLTP and antioxidant 1010: 0.8:1.5:1.5; the lubricant is formed by mixing grafted wax and silicone masterbatch, and the grafted wax acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com