Design method of extrusion molding mold of phase-compensated cable fluorinated ethylene-propylene protective jacket

A polyperfluoroethylene propylene, phase-stable cable technology, which is used in household appliances, other household appliances, household components, etc., can solve the problems of patents and articles without the design of FEP sheath extrusion molds for phase-stabilized cables, and reduce the number of The cost of human and material resources, the effect of improving stress cracking and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

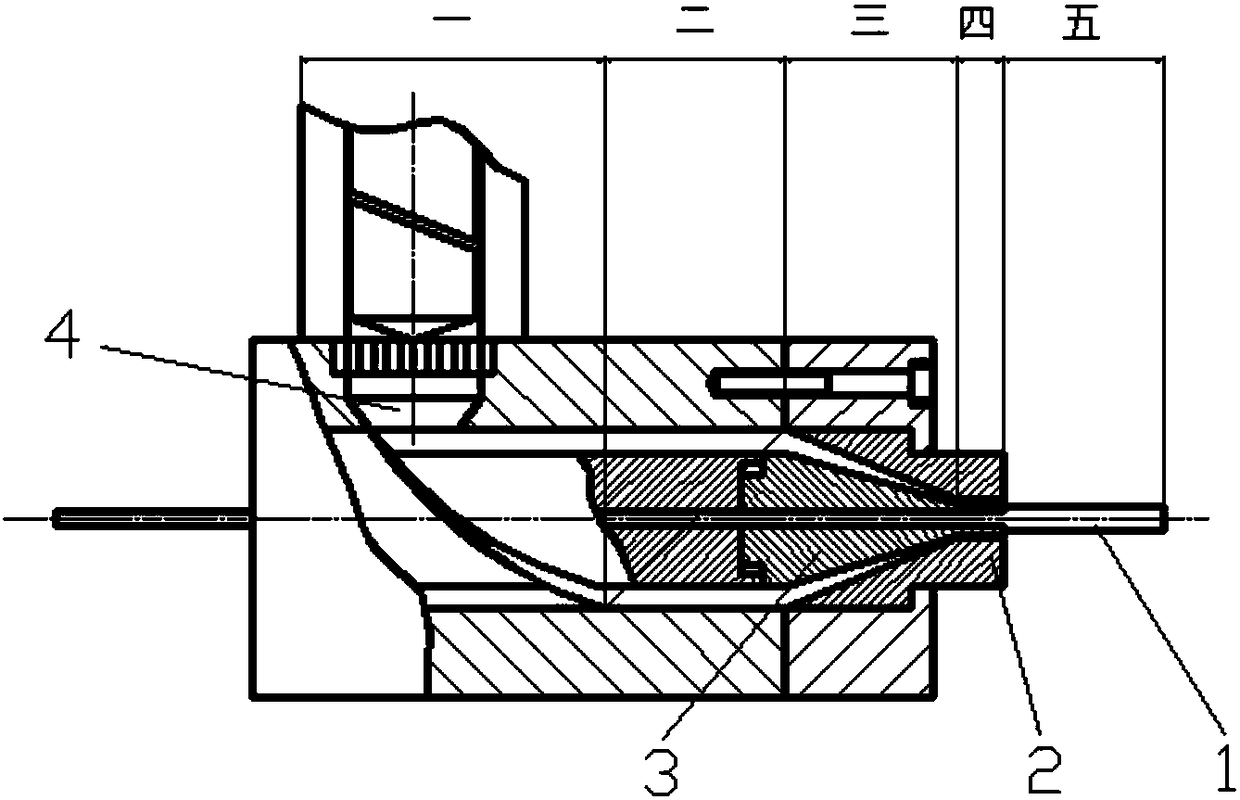

[0027] 1. Finite element simulation design

[0028] ⑴Design of model parameters

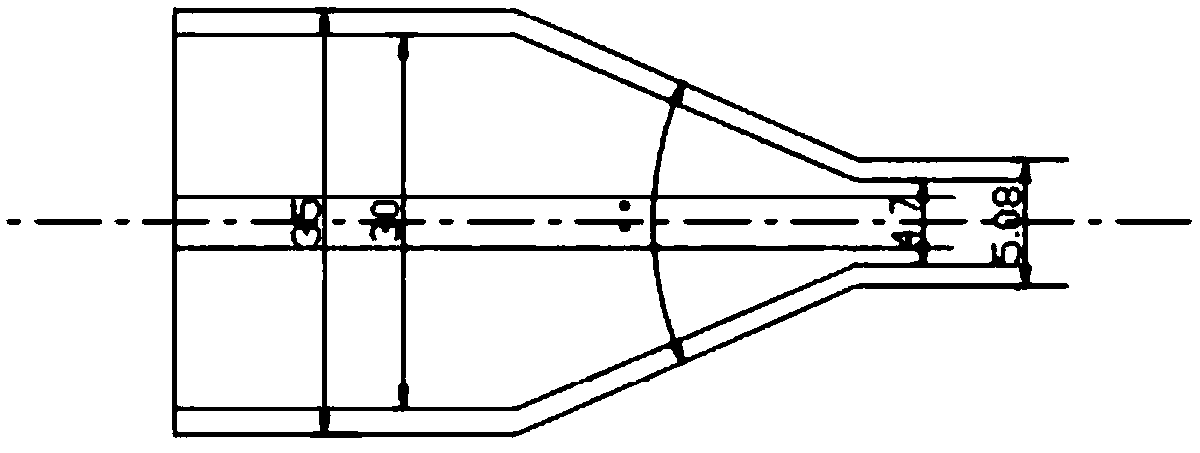

[0029] The circular runner structures with inlet diameters of 30mm and 35mm and outlet diameters of 4.7mm and 5.08mm were established, and the melt flowed in three dimensions. Take its flow channel structure part to form figure 2 The floor plan shown. The size of the compression angle β is 38°, and the corresponding length of the forming section L is 12.3mm.

[0030] ⑵ Grid division

[0031] In the GAMBIT software, draw the runner model of the steady-phase cable extruder, draw the internal grid of the sub-runner model, and output the file as .msh format.

[0032] ⑶ simulation analysis

[0033] Open the flow field analysis software, read the grid file, and input the boundary conditions to calculate and simulate the velocity field and pressure field distribution characteristics of the flow channel.

[0034] Through calculation and analysis, under this condition, the outlet pressure and veloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com