Patents

Literature

33results about How to "Reduce uneven stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

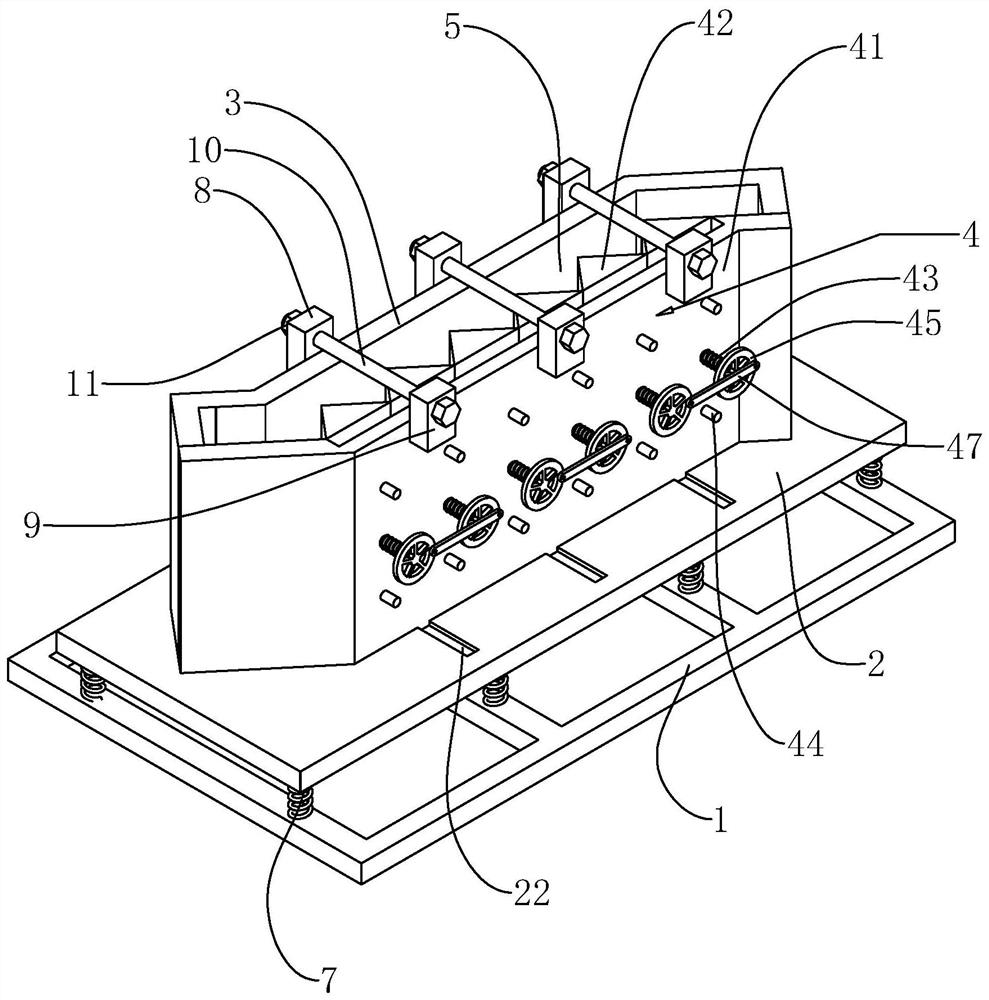

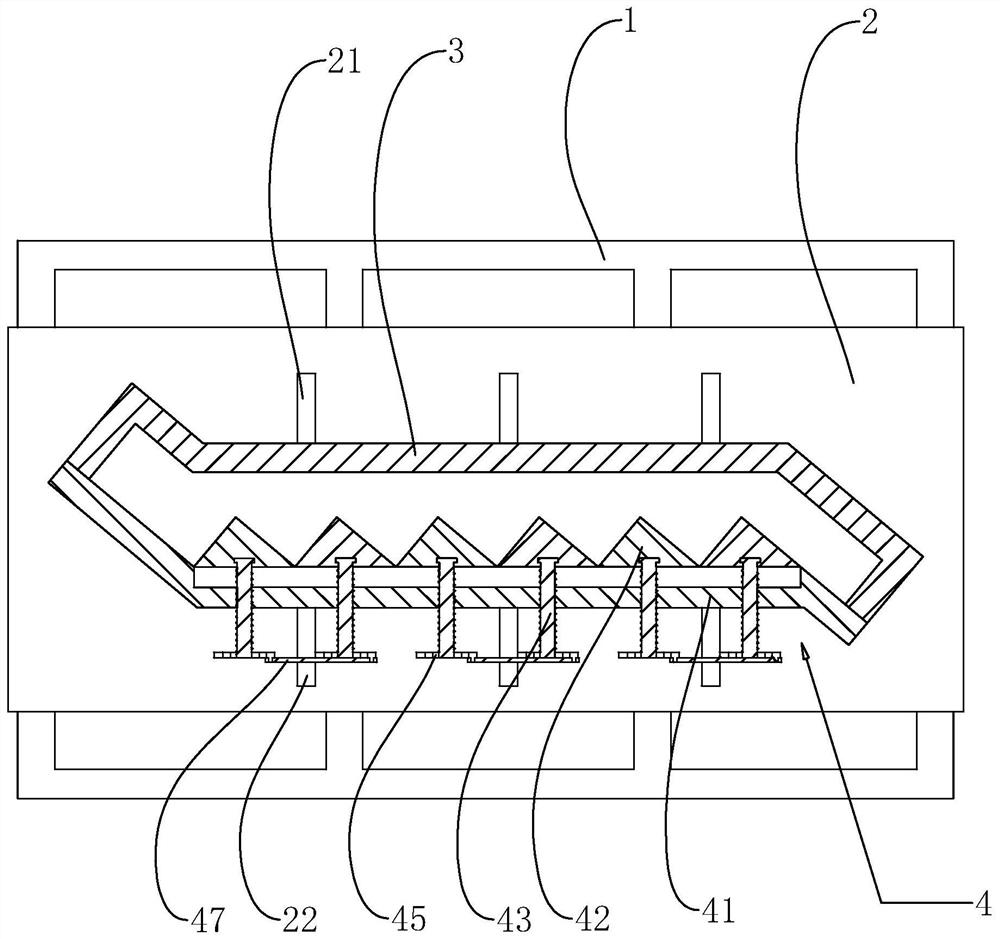

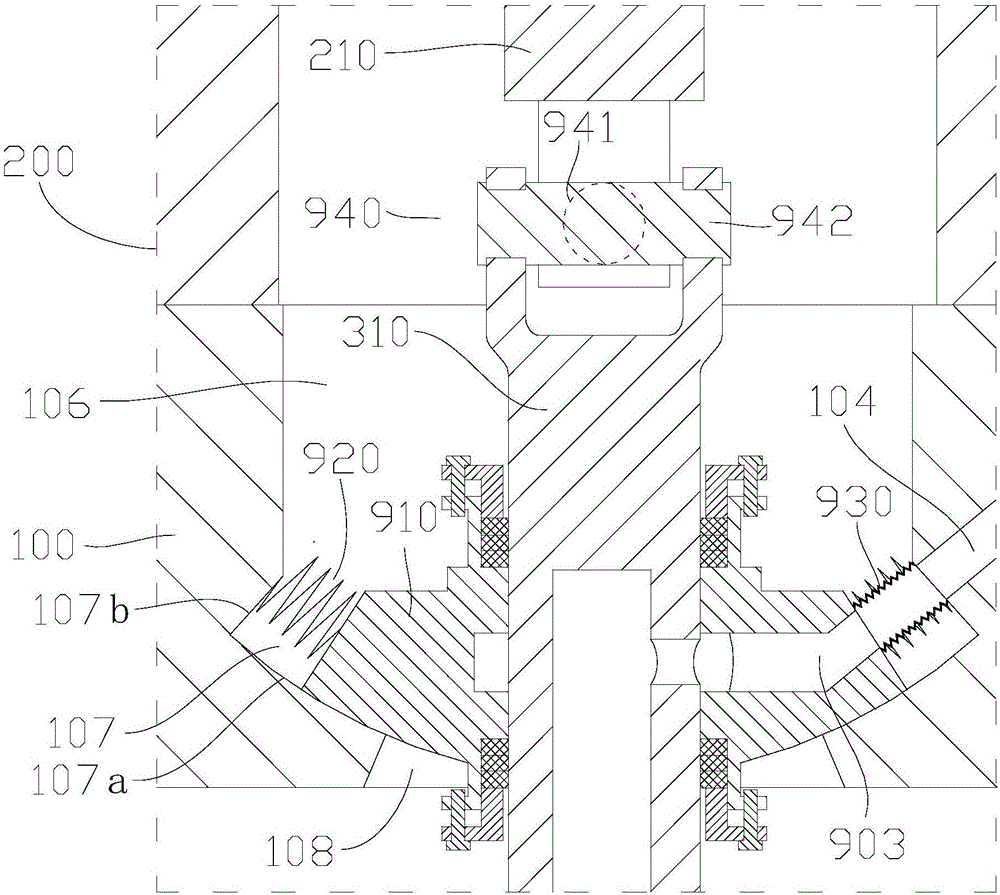

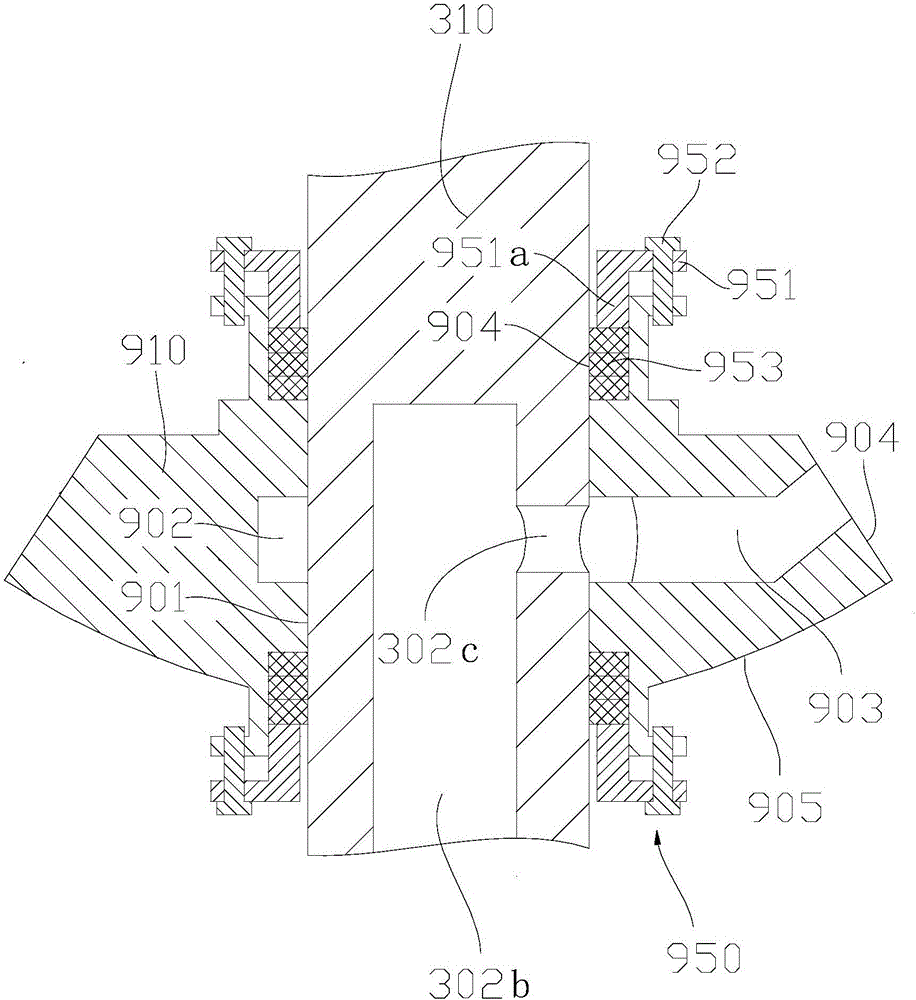

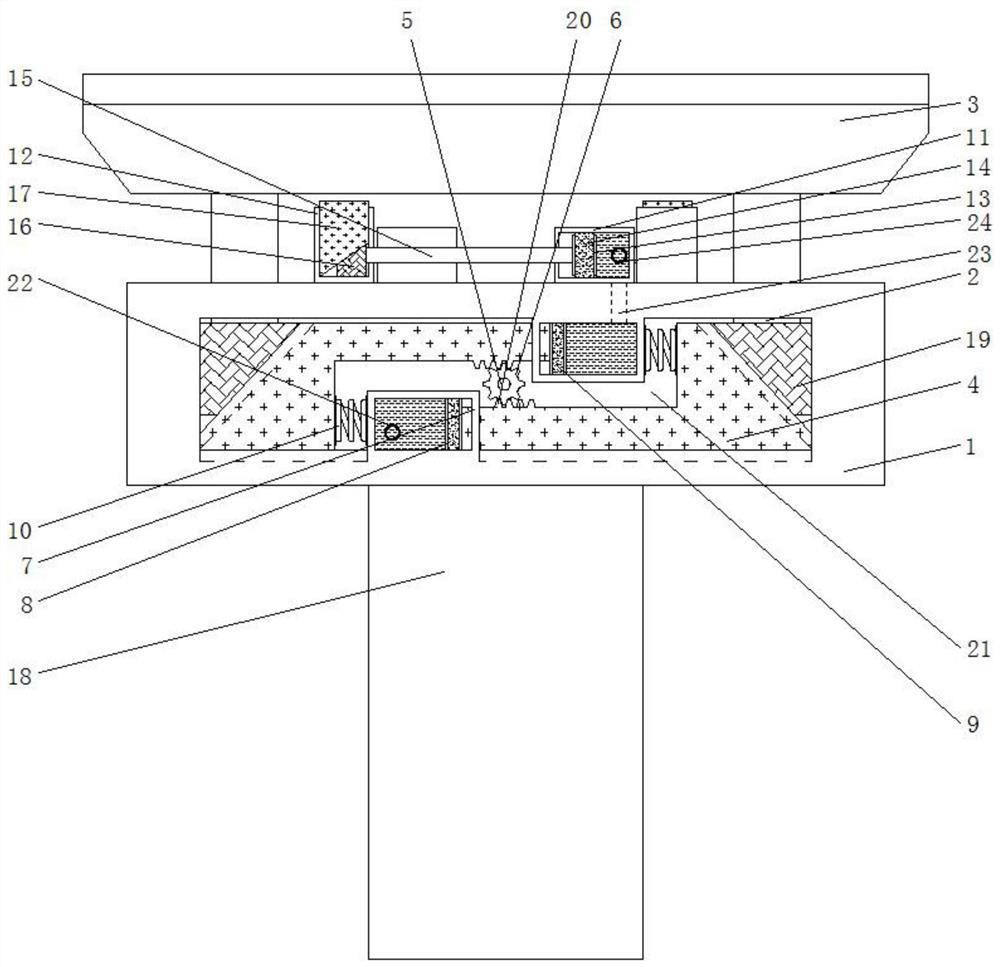

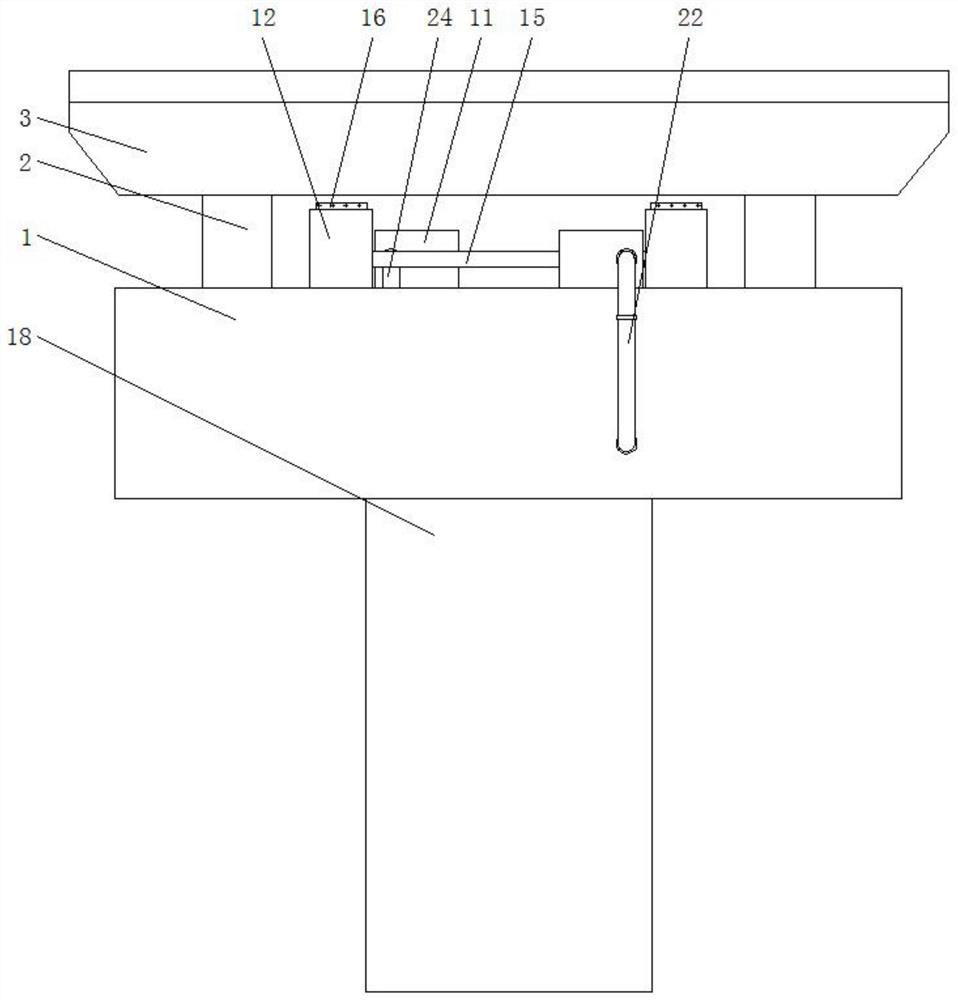

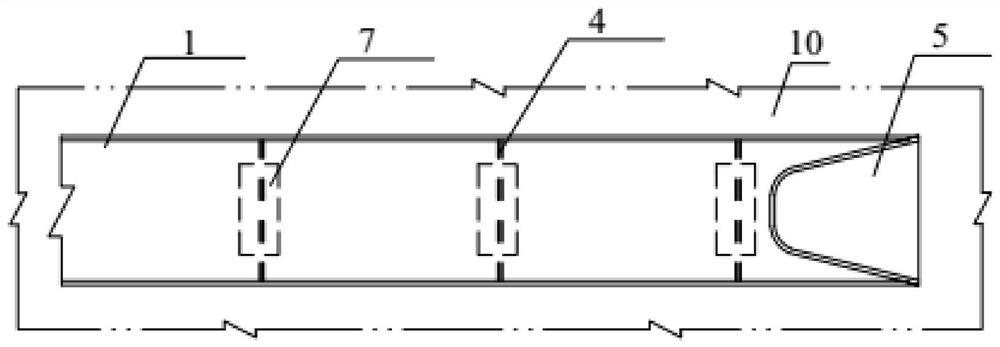

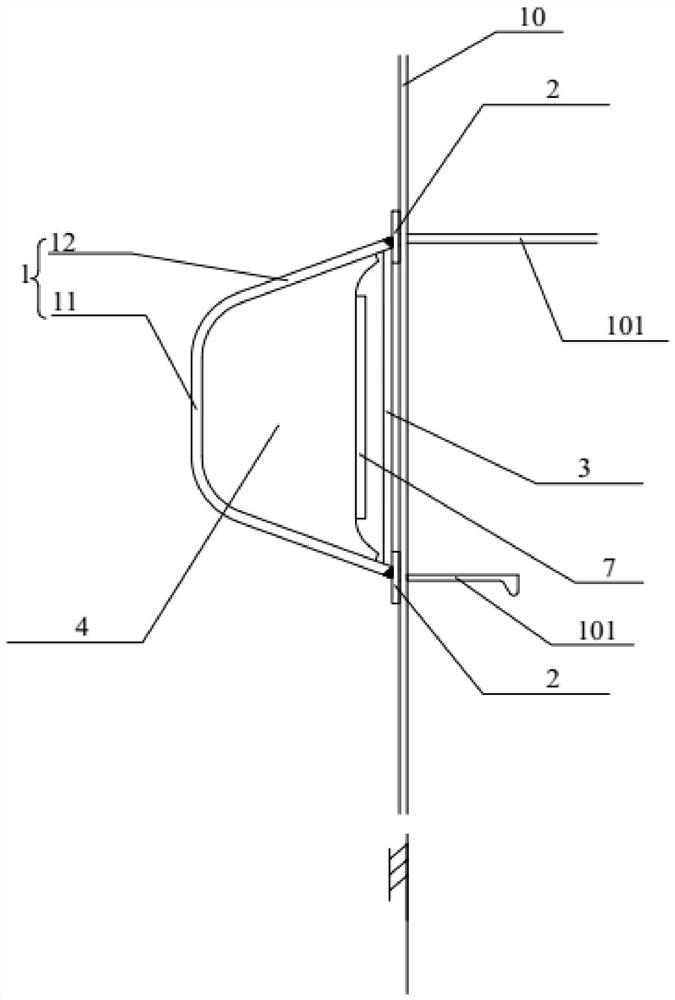

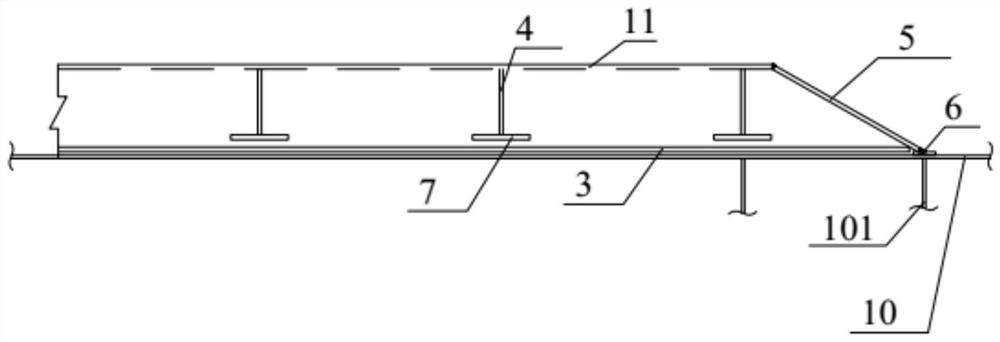

Precast stair mold and precast stair machining process

InactiveCN112192724AImprove qualityReduce uneven stressMouldsMould fastening meansMachining processIndustrial engineering

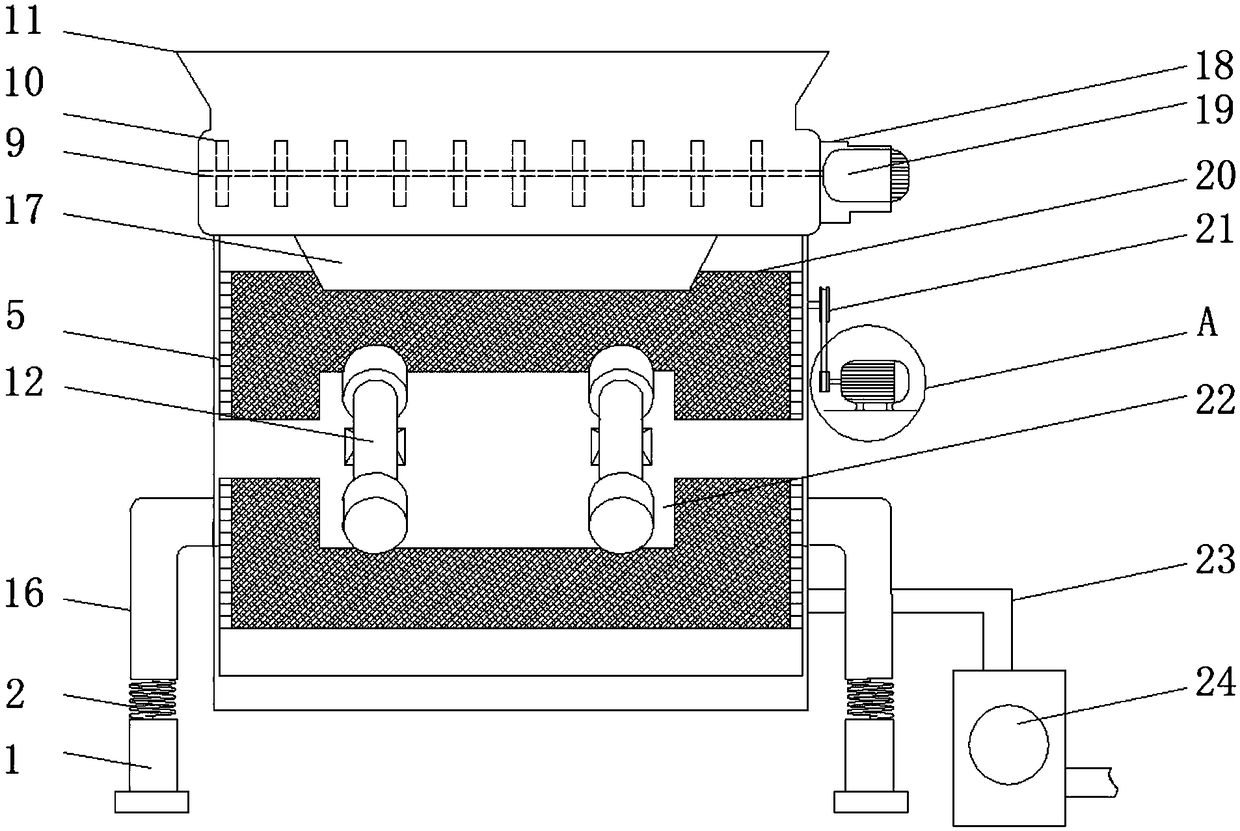

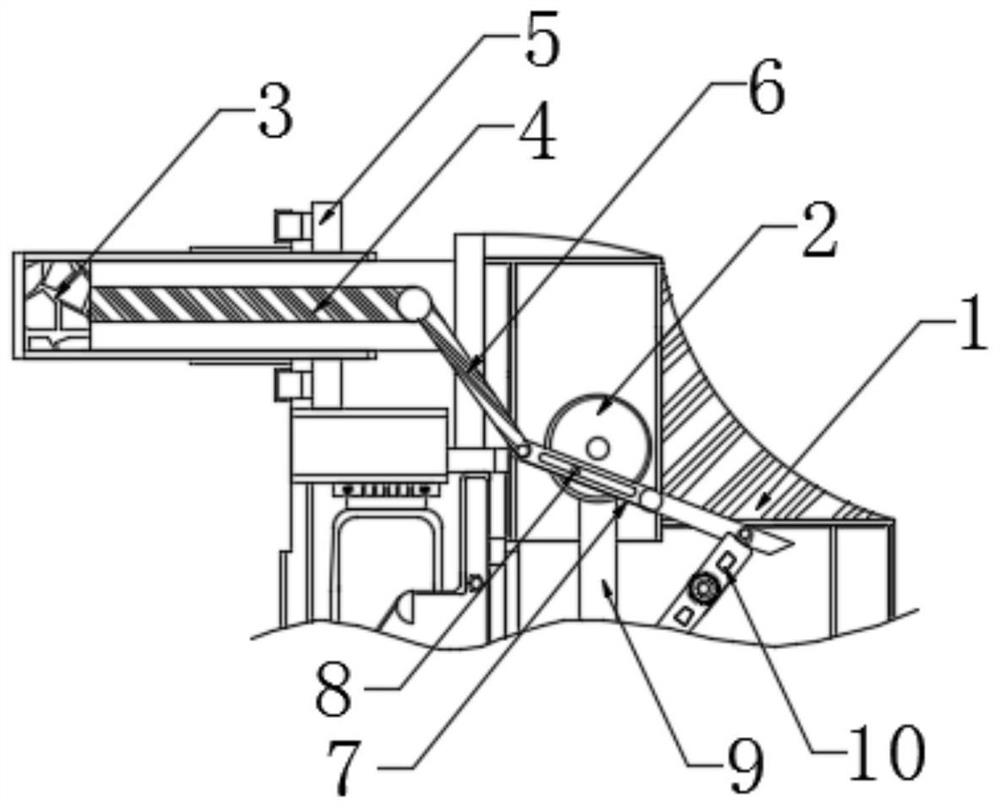

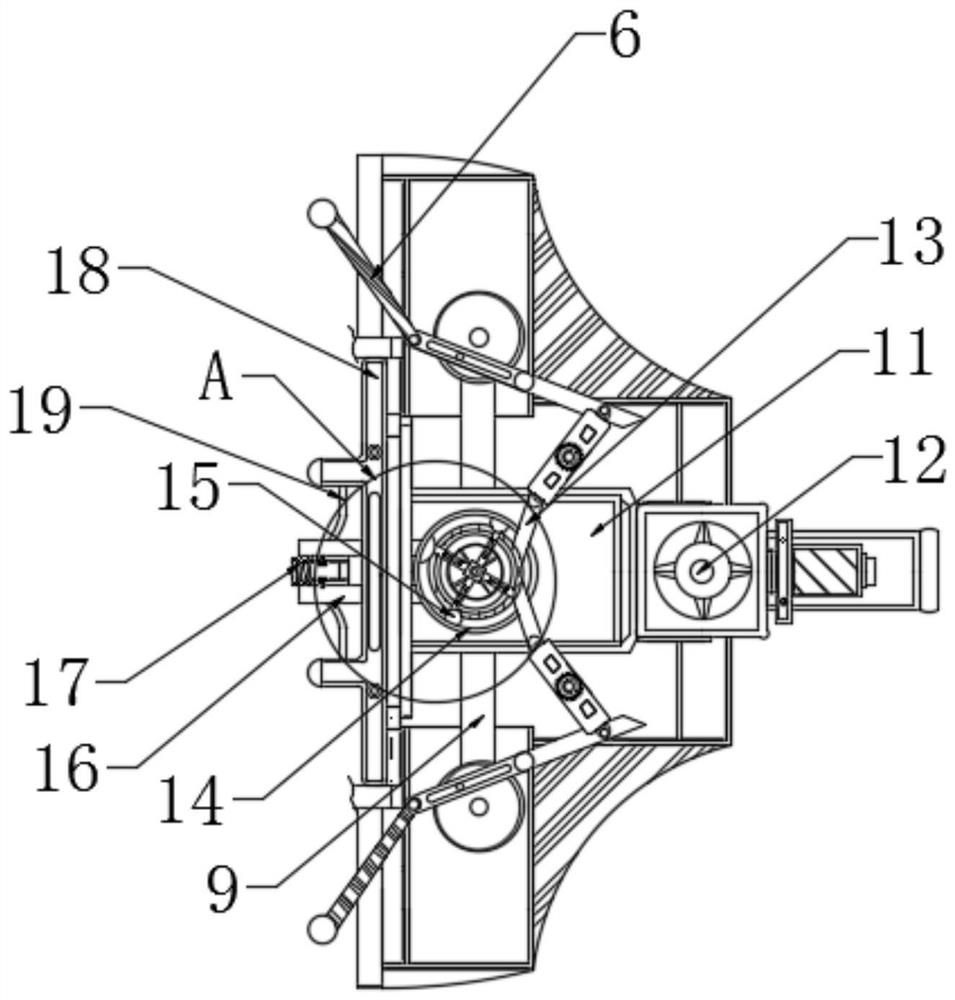

The invention relates to a precast stair mold and a precast stair machining process. The mold comprises a supporting frame, wherein a bottom plate is arranged on the supporting frame, a side mold bodyand a stair mold body are connected to the bottom plate in a sliding mode, the bottom plate, the side mold body and the stair mold body are matched in an abutting mode to jointly form a pouring cavity, the stair mold body comprises a stair support, the stair support is arranged on the bottom plate and slides, a plurality of adjacent shaping plates are connected to the stair support in a sliding mode, the ends, close to the side mold body, of the shaping plates are in a right-angle shape, movable rods are in threaded connection with the stair support, and one end of each movable rod is rotationally connected with the corresponding shaping plate. When the precast stair is demolded, the shaping plates are sequentially separated from the precast stair, step-by-step demolding is realized, thesituation that stress is uneven during demolding is reduced, the precast stair is easily separated from the stair mold in the demolding process, and the effect of improving the quality of the precaststair is achieved.

Owner:WEIHAI YUQUAN NEW BUILDING MATERIAL

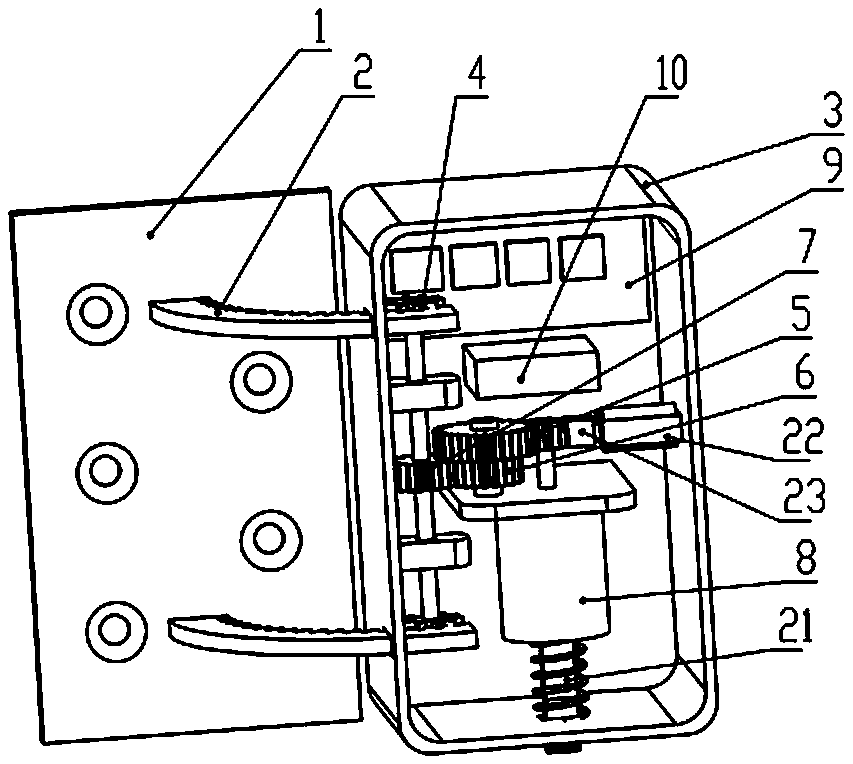

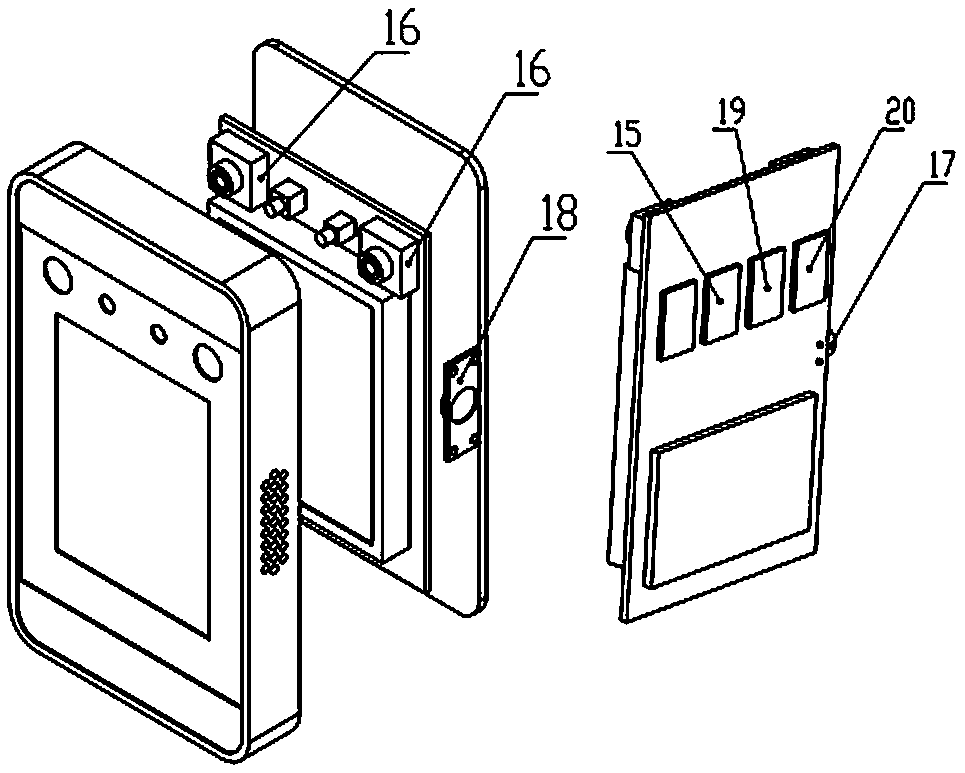

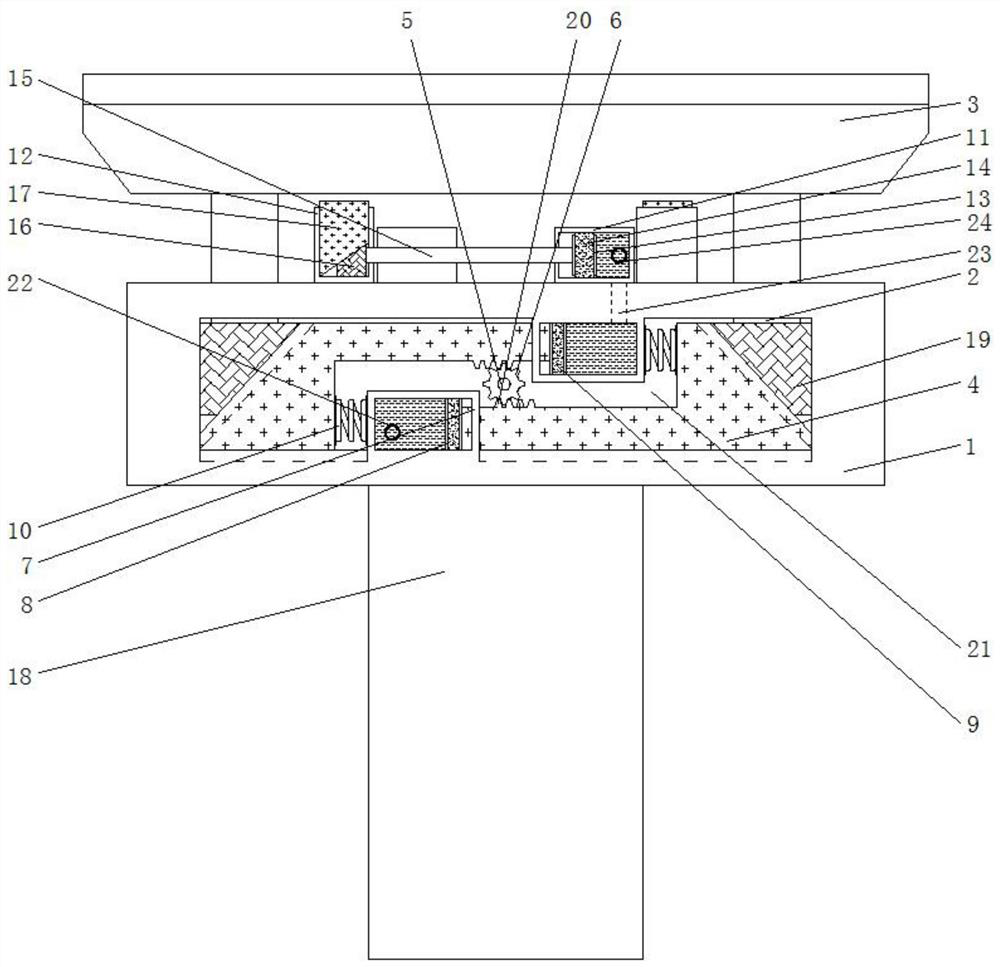

Intelligent novel automatic door and window opening and closing door closer device

PendingCN111441686ARealize IoTEven strengthNon-mechanical controlsPower-operated mechanismWireless transmissionAutomatic control

The invention belongs to the field of smart home, and particularly relates to an intelligent novel automatic door and window opening and closing door closer device. The problems that in the prior art,opening and closing of a door and window cannot be remotely controlled, stress of door and window opening and closing is not uniform, and the service life of the door and window is affected can be solved. According to the scheme, the device comprises a shell body, a door plate mounting plate is rotatably mounted on one side of the shell body, two opening and closing gear rings are fixedly mountedon one side of the door plate mounting plate, two through holes are formed in one side of the shell body, the opening and closing gear rings are movably mounted in the corresponding through holes, according to the device, wireless transmission and remote automatic door and window control can be achieved, differential maintenance manners at different levels can have the internet of things intelligent product characteristics, remote controllability and voice control shrinkage can be achieved, the device can be applied to small family equipment, the control manner is diverse, the device can achieve automatic control, local control and remote control with a mobile terminal, a door and window lock, voices and other manners, the traditional furniture losses can be reduced, and the effect of prolonging the service life is achieved.

Owner:智慧式有限公司

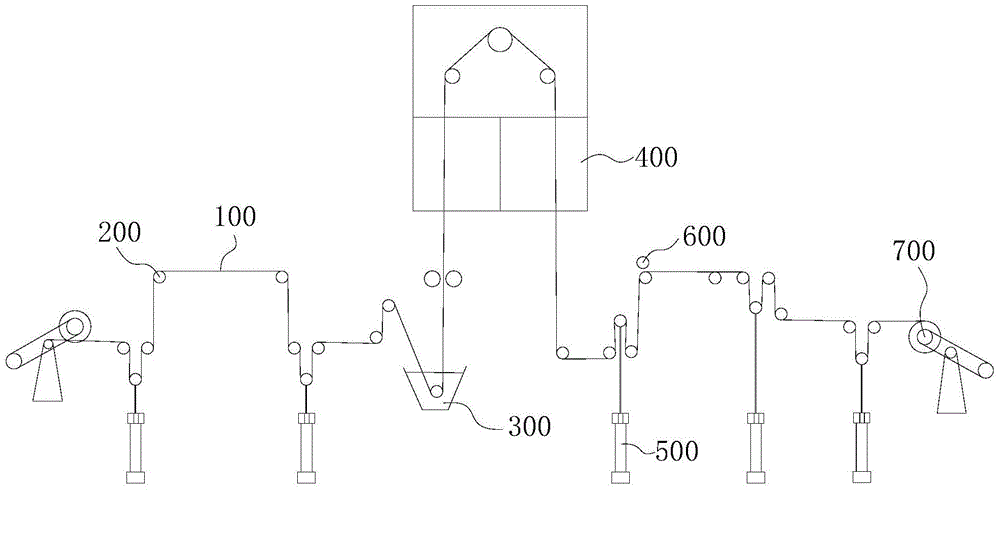

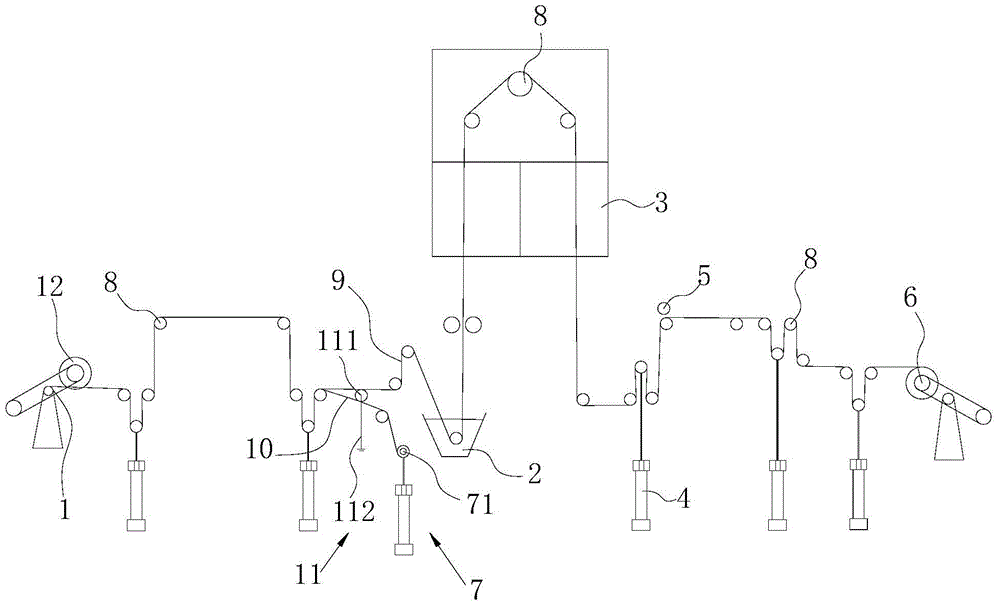

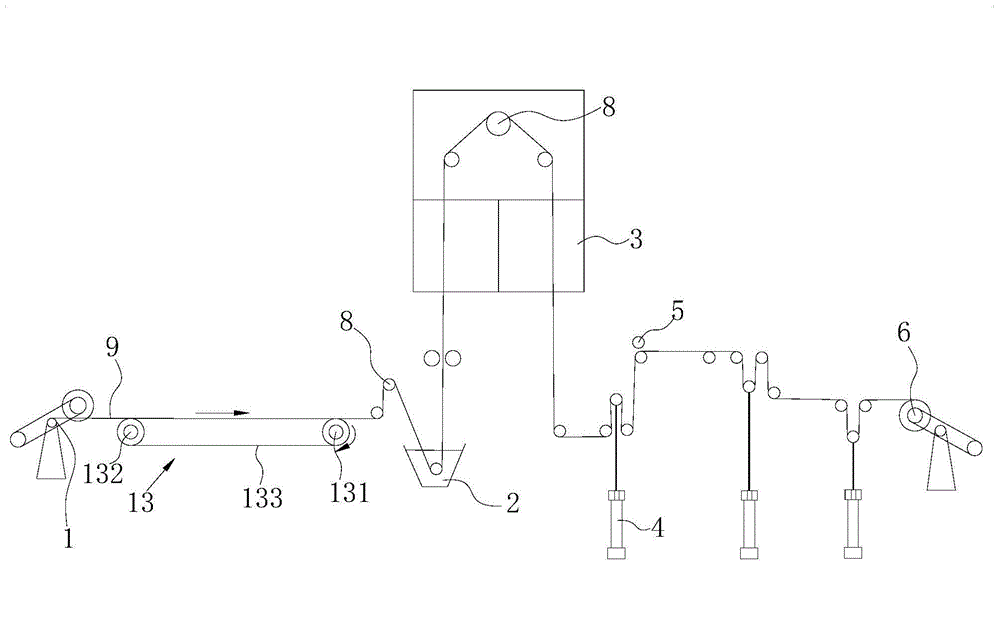

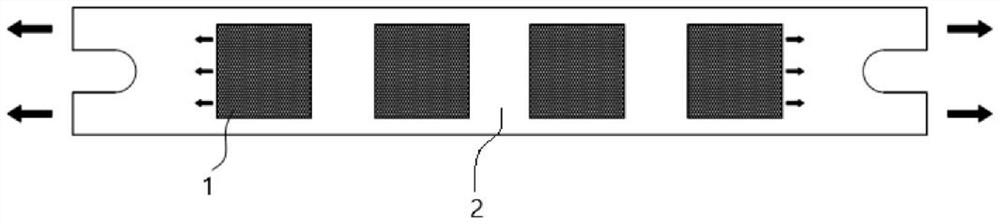

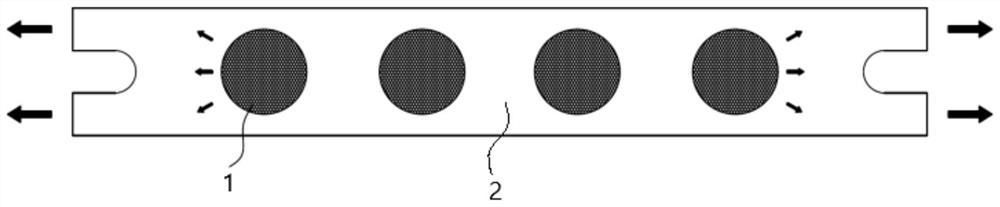

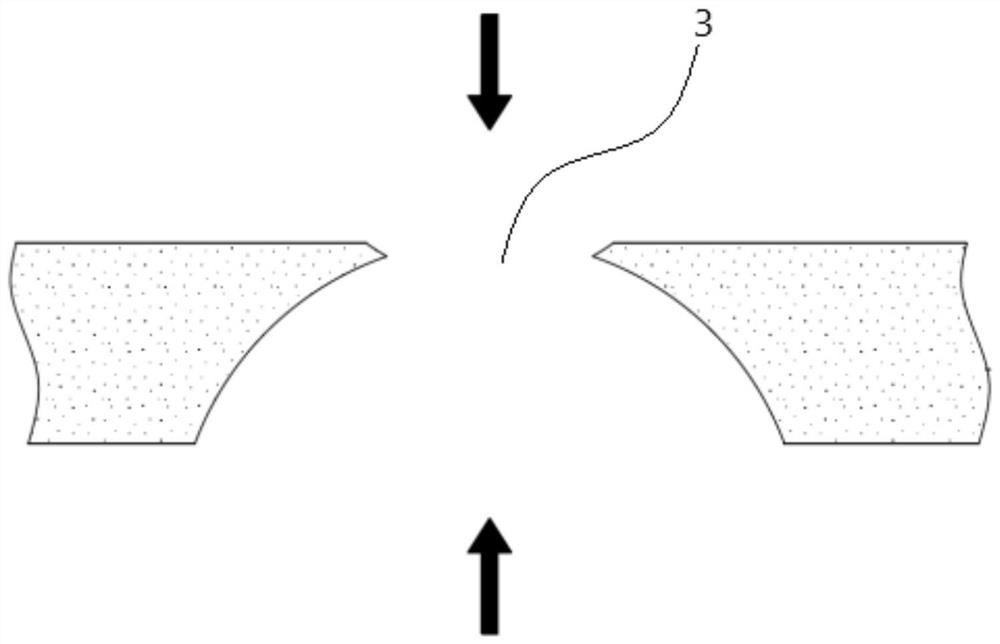

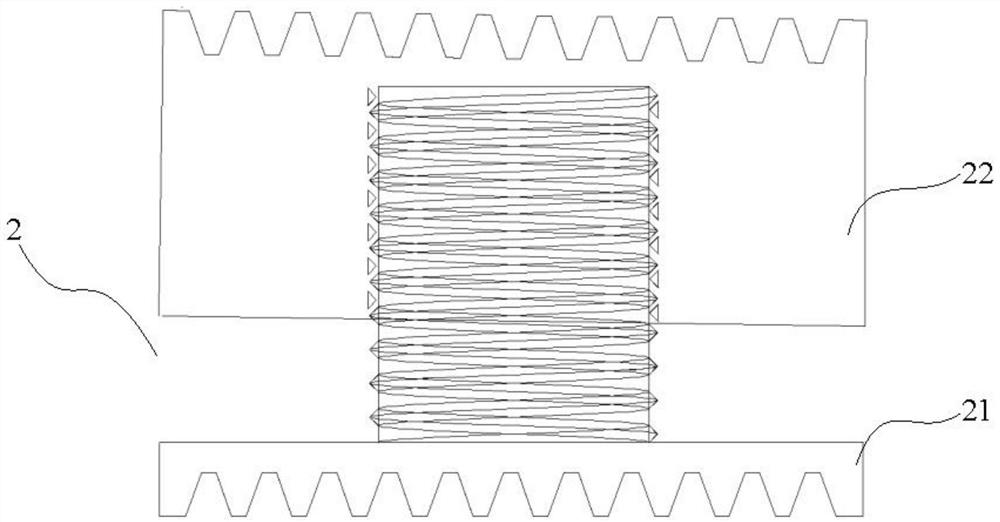

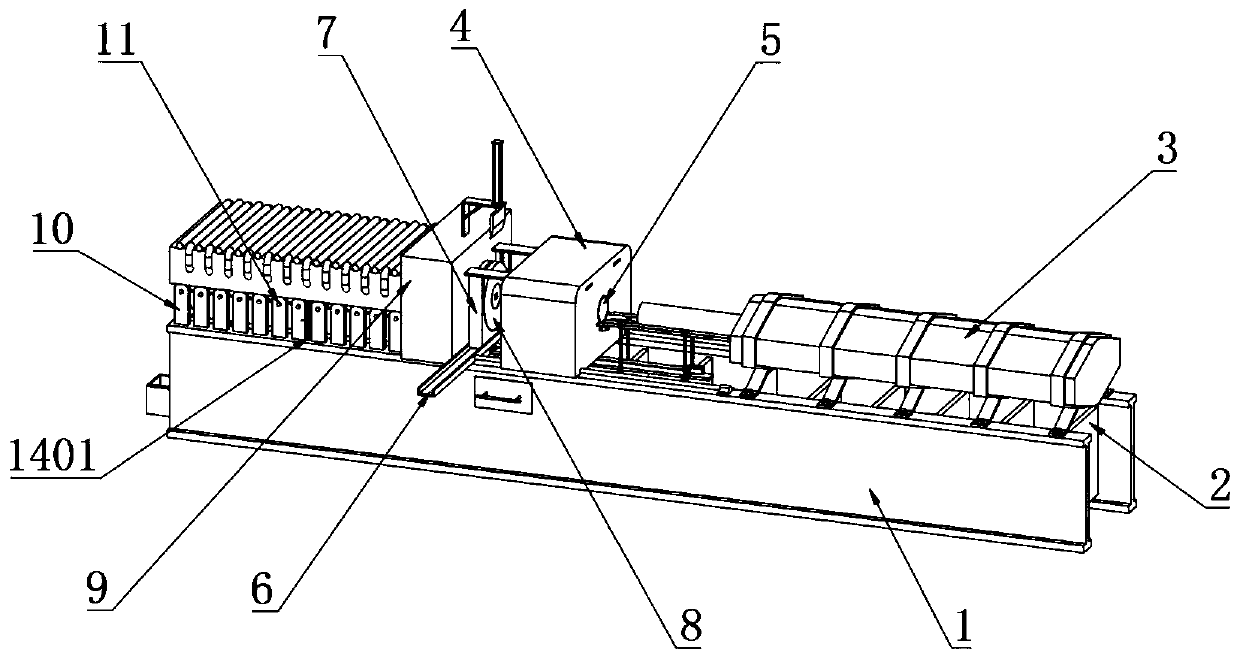

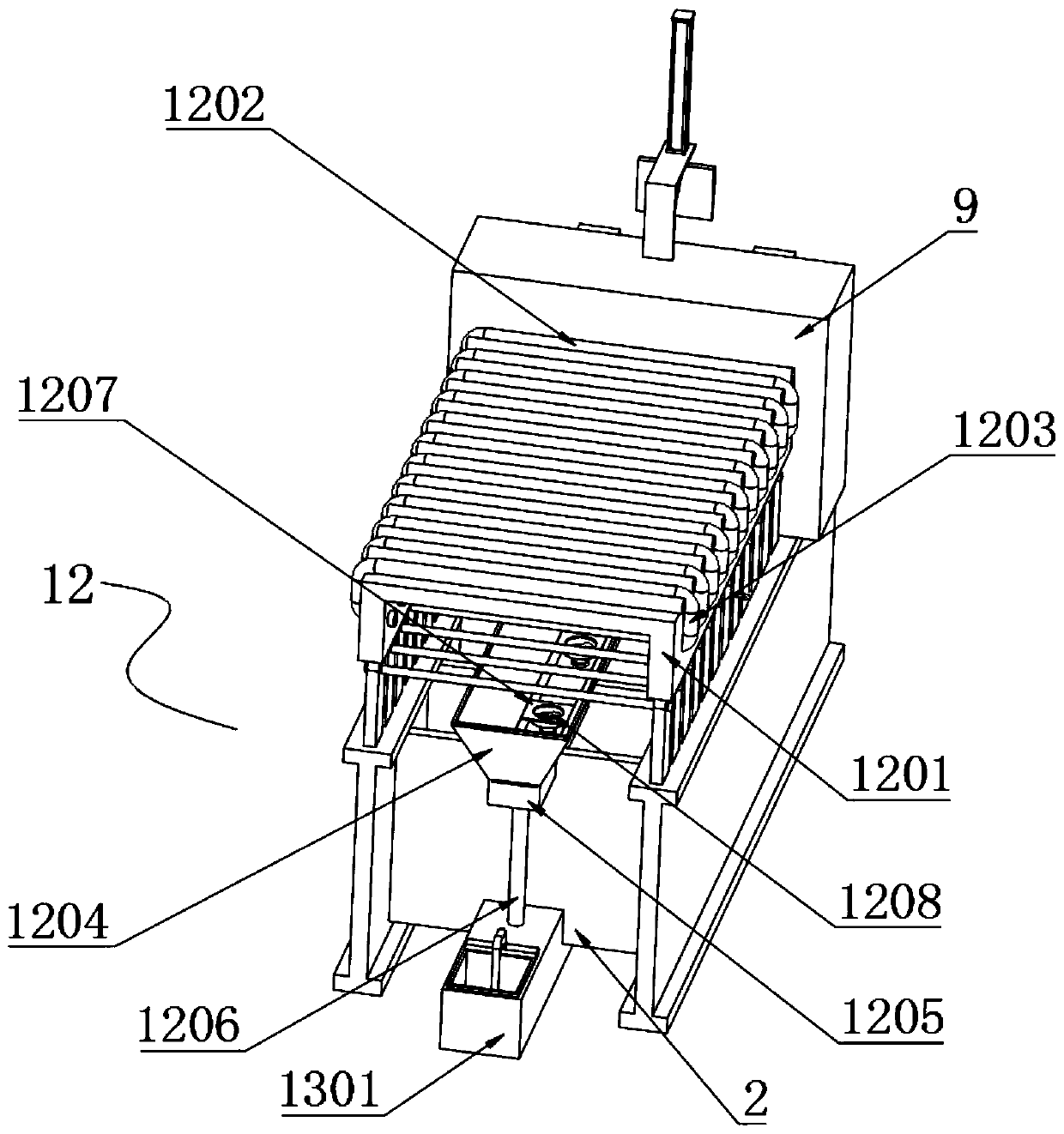

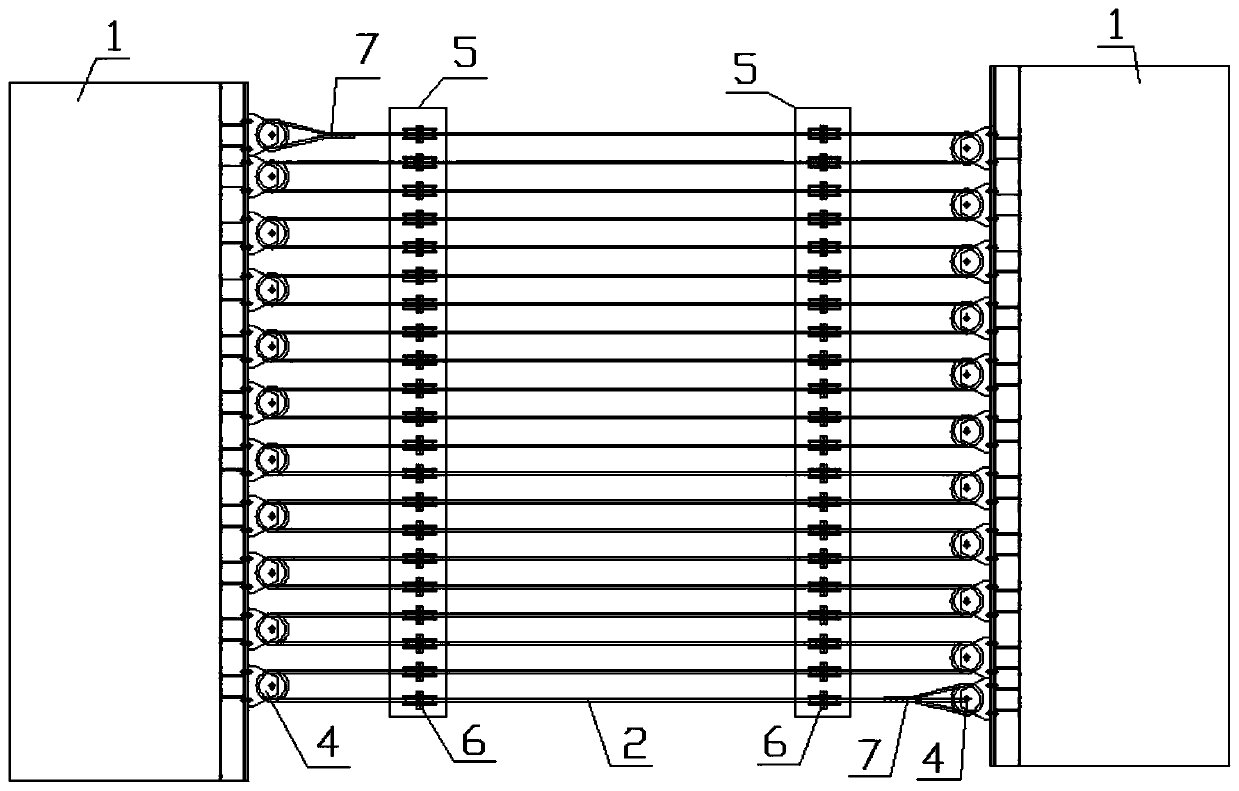

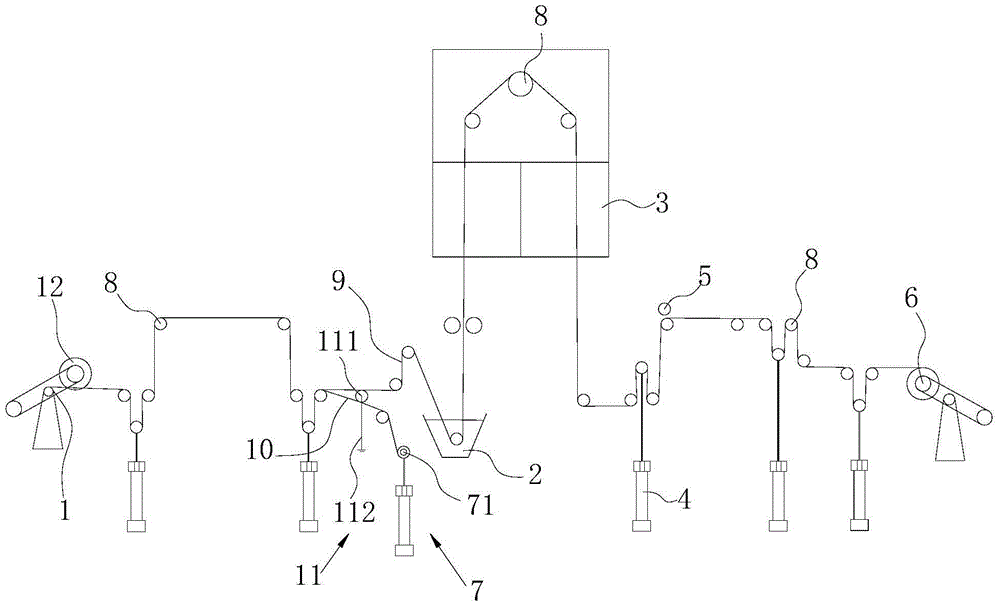

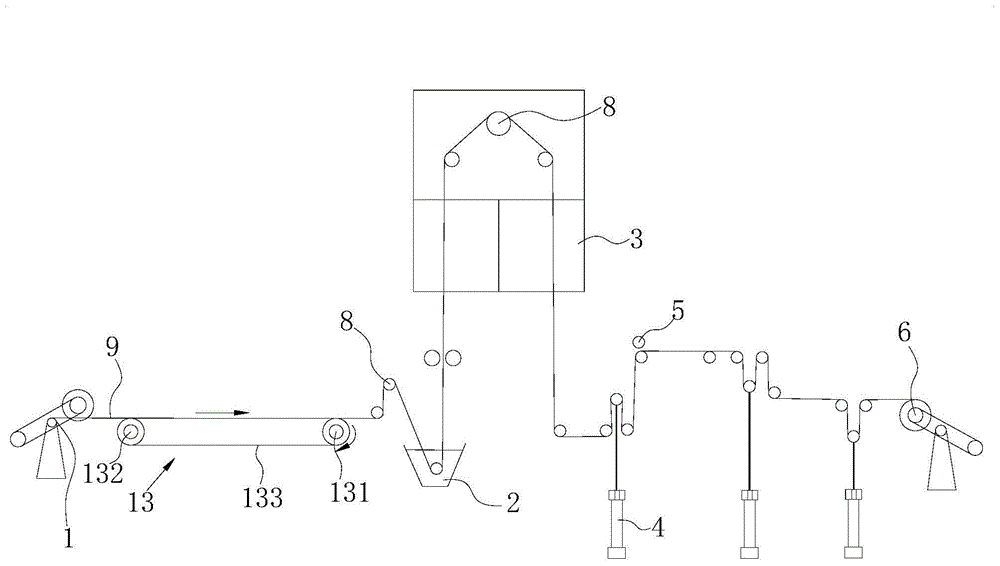

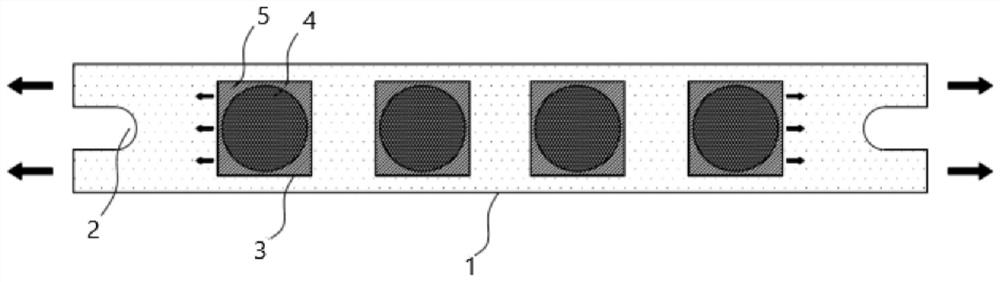

Process and device for producing thin prepreg

The invention discloses a process and a device for producing a thin prepreg. The process comprises the impregnation process; and before the impregnation process, a reinforcing material is arranged on a carrier so that the carrier directly acts on a roll shaft to share the acting force applied by the roll shaft on the reinforcing material. By arranging the reinforcing material on the carrier before the impregnation, the roll shaft can be prevented from being directly contacted with the reinforcing material, the pulling force directly applied from a device to the reinforcing material is effectively reduced, the condition that the reinforcing material is partially stressed unevenly is reduced, the thin reinforcing material is protected particularly, such phenomena as dislocation, shape change and tearing of the thin reinforcing material and the ultrathin prepreg are reduced, and the production efficiency and product percent of pass are improved.

Owner:GUANGDONG SHENGYI SCI TECH

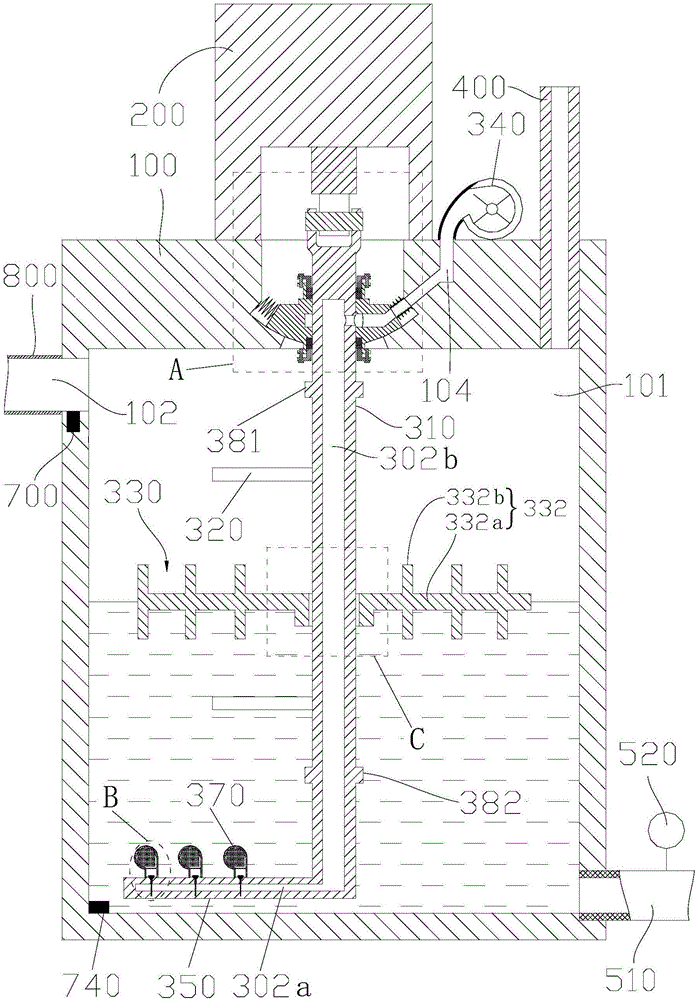

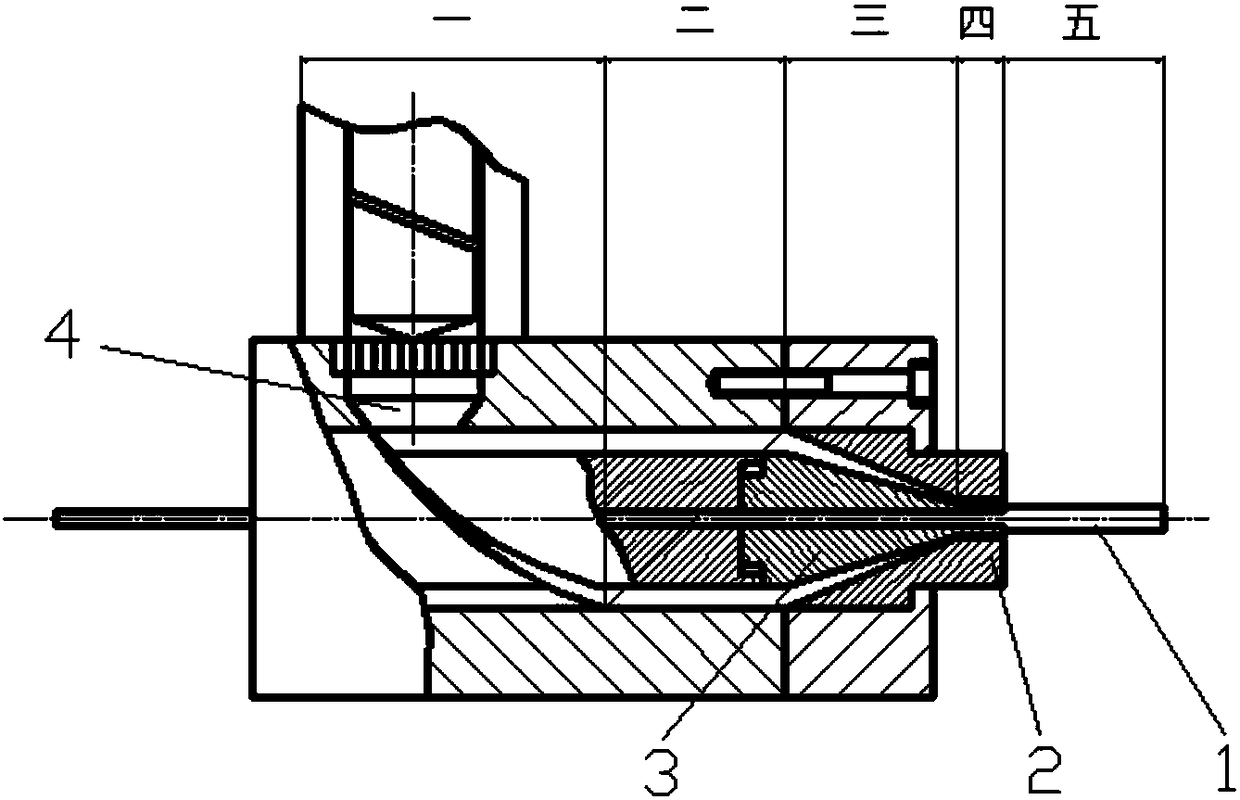

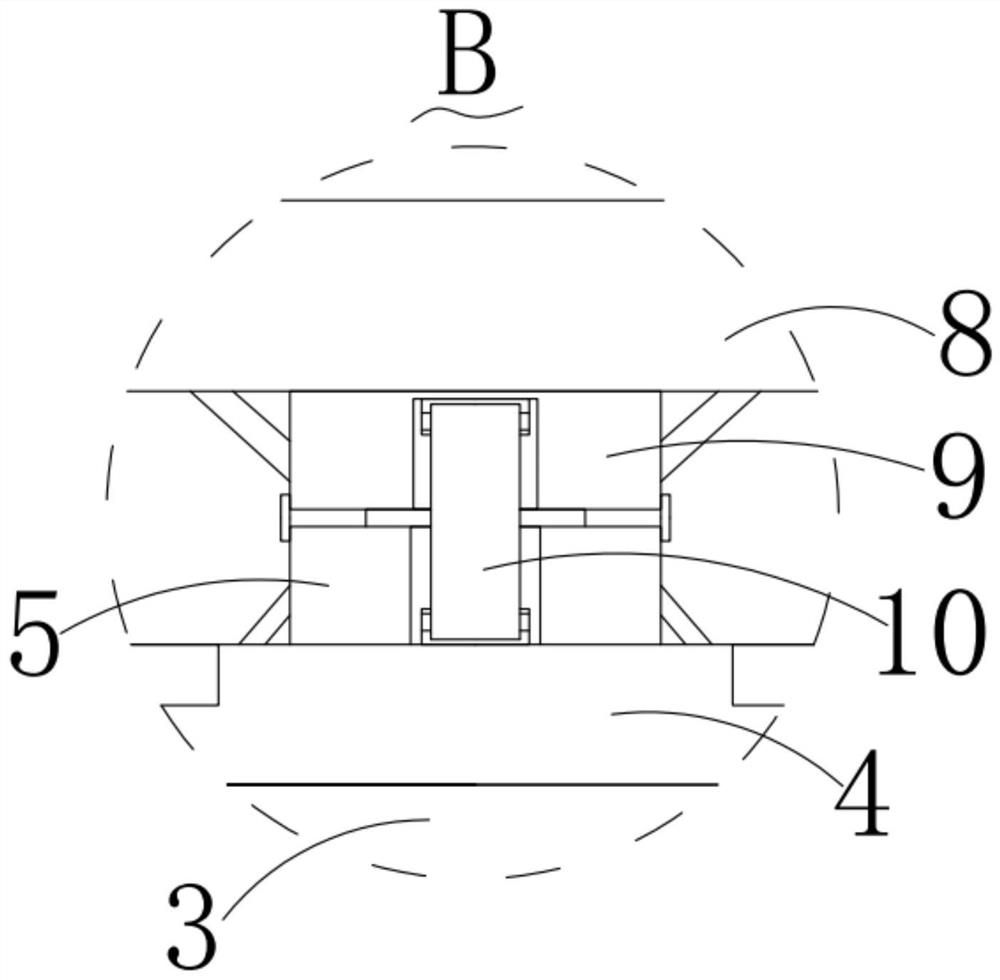

Sewage oxygen charging device

ActiveCN106430539AReduce uneven stressStable dynamic sealTreatment using aerobic processesSustainable biological treatmentSewageEngineering

The invention relates to the technical field of sewage treatment, and discloses a sewage oxygen charging device. The device comprises an aeration tank body, a first rotation rod and a rotation sleeve. The rotation sleeve is provided with a rotation hole. The first rotation rod is placed in the rotation hole. The first rotation rod is connected with the rotation hole in dynamic sealing mode. The inner wall of the rotation hole is annularly provided with a revolving groove. A second gas transmission channel is communicated with the revolving groove. The rotation sleeve is provided with a fourth gas transmission channel which is communicated with the revolving groove. The fourth gas transmission channel is communicated with the side wall of the rotation sleeve. The rotation sleeve is provided with a second slide bearing face which is a partial spherical surface sharing the same center with the first slide bearing surface. The second slide bearing face is loaded on the first slide bearing face. When the first rotation rod makes a small angular swing in any direction relative to an output shaft, the rotation sleeve along with the first rotation rod make a displacement in a deflection cavity, thus effectively relieving the uneven stress between the rotation sleeve and the first rotation rod, and stabilizing the dynamic sealing between the rotation sleeve and the first rotation rod.

Owner:广州森态环保科技有限公司

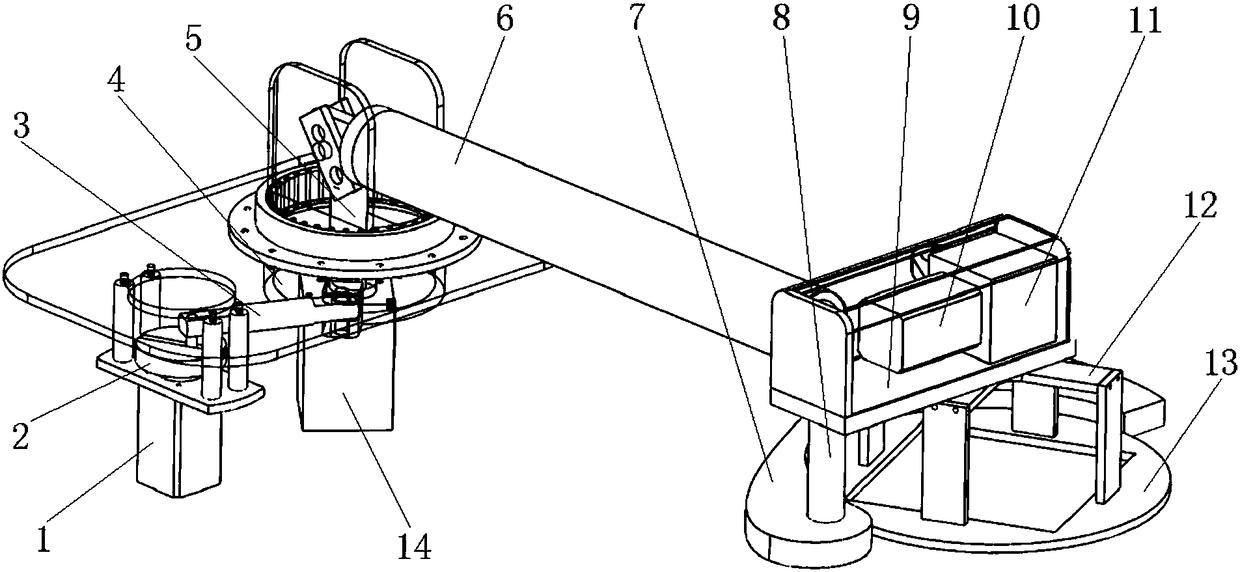

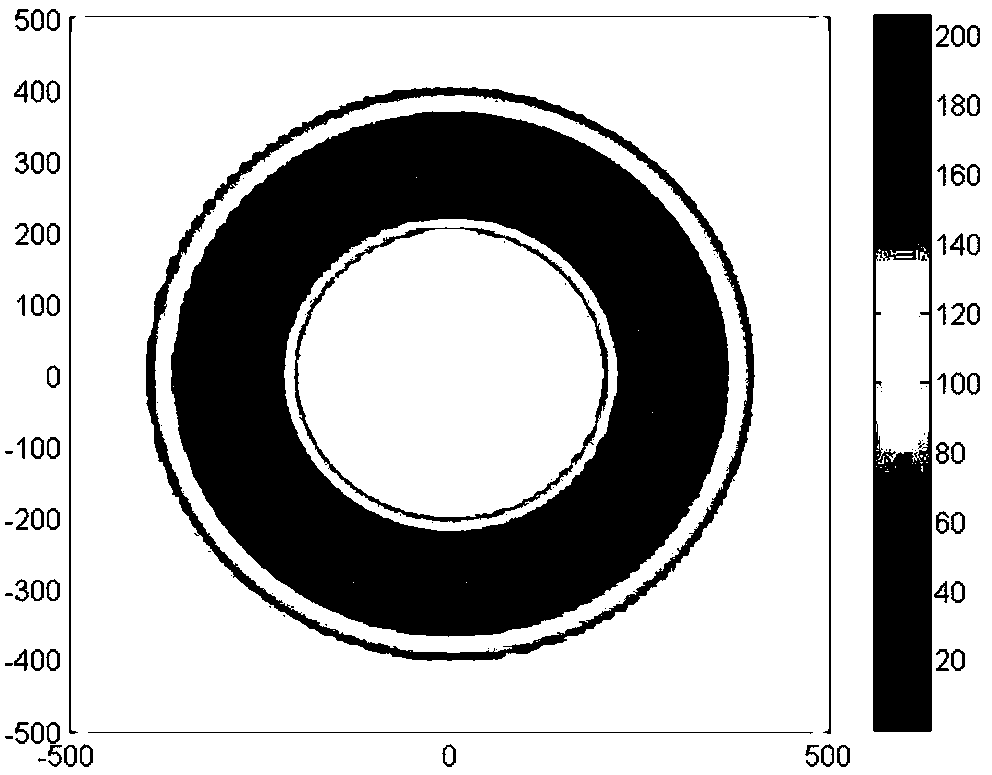

Deflection type plane polishing device with wear compensation

PendingCN108296931AImprove qualityReduce uneven stressGrinding machine componentsOptical surface grinding machinesEngineeringFace shape

The invention discloses a deflection type plane polishing device with wear compensation. The deflection type plane polishing device with wear compensation comprises a holder used for containing an element and an annular polishing drive mechanism; the holder is used for carrying out pressure loading on the polishing disc face, and enables the element to be attached to the polishing disc face, the annular polishing drive mechanism drives the holder to rotate on the polishing disc face so as to enable the element to be subject to annular polishing machining, a deflection mechanism capable of driving the holder to carry out deflection motion along the polishing disc face is arranged, a polishing disc wear compensation block attached to the polishing disc face is arranged on the periphery of the holder. The element is subject to deflection polishing while being subject to annular polishing, annular marks of the element can be effectively restrained, the polishing disc wear compensation block is used for compensating force uneven wear of the polishing disc face in the radial direction, the face form long-term stability of the polishing disc face is kept, the element machining precision and face form consistency are improved, the holder is used for carrying out pressure loading on the polishing disc, uneven stress of the element edge can be reduced, and element side collapsing and corner collapsing can be avoided.

Owner:成都精密光学工程研究中心

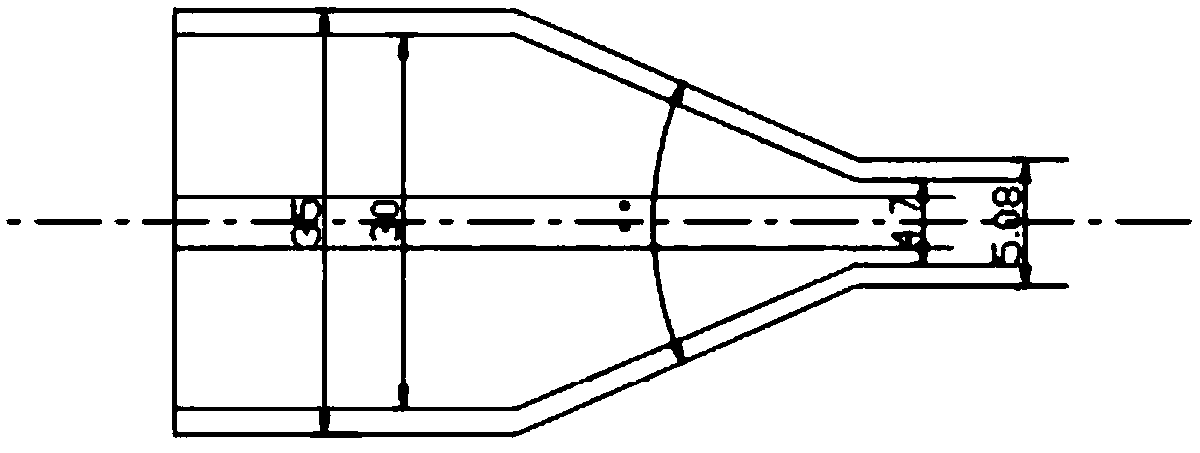

Design method of extrusion molding mold of phase-compensated cable fluorinated ethylene-propylene protective jacket

InactiveCN108284547AImprove performanceReduce the manpower and material cost of processing testDomestic articlesMaterial resourcesFluorinated ethylene propylene

The invention belongs to the technical fields of cable protective jacket extrusion molding, mold design and forming simulation, and particularly relates to a design method of an extrusion molding moldof a phase-compensated cable fluorinated ethylene-propylene protective jacket. The design method comprises the following steps that I, different extrusion molding head runner models are established in grid division software, a grid is divided, and a grid model is acquired; II, the corresponding grid model is imported in finite element simulation analysis software, boundary conditions are input, and outlet pressure and speed distribution of a plastic extruding machine are acquired through calculation; and III, the proper extrusion molding head runner model is selected according to an analog computation result, and specific parameters suitable for the mold are finally acquired. According to the design method, manpower and material resource cost of a processing experiment of the phase-compensated cable fluorinated ethylene-propylene protective jacket is greatly reduced, fastening coating of the protective jacket is achieved, bending phase position stability of a phase-compensated cable is improved, and the stress cracking problem of the cable protective jacket is effectively solved.

Owner:THE 23RD RES INST OF CHINA ELECTRONICS TECH GRP CORP

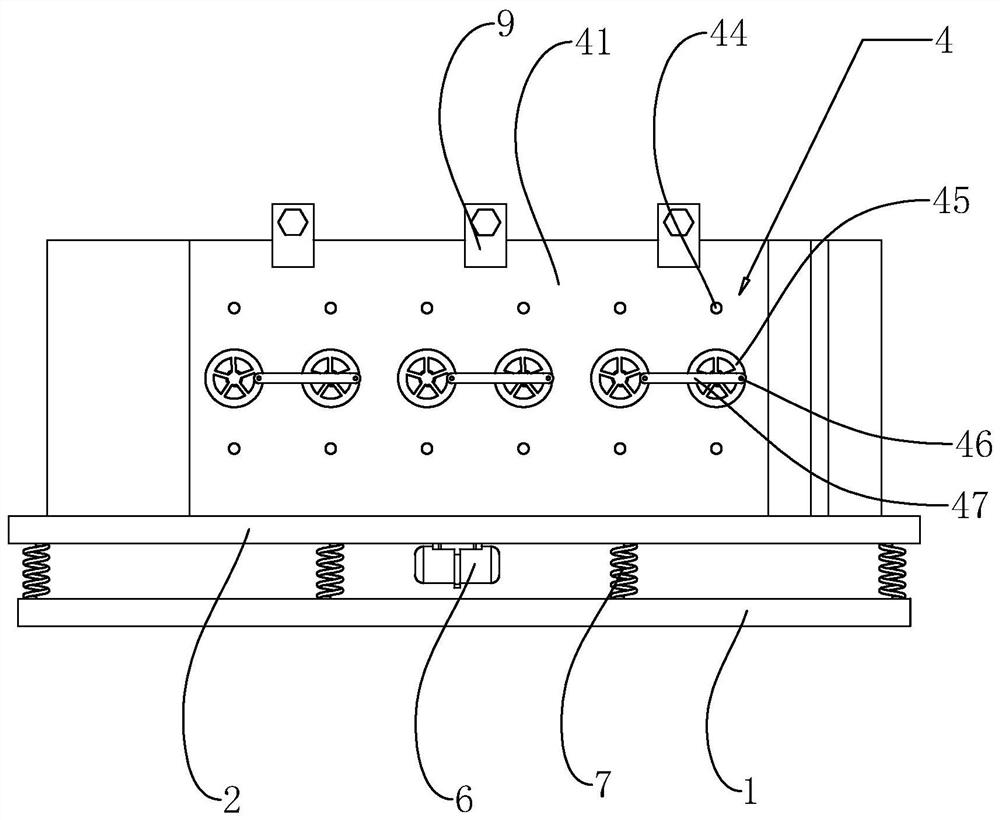

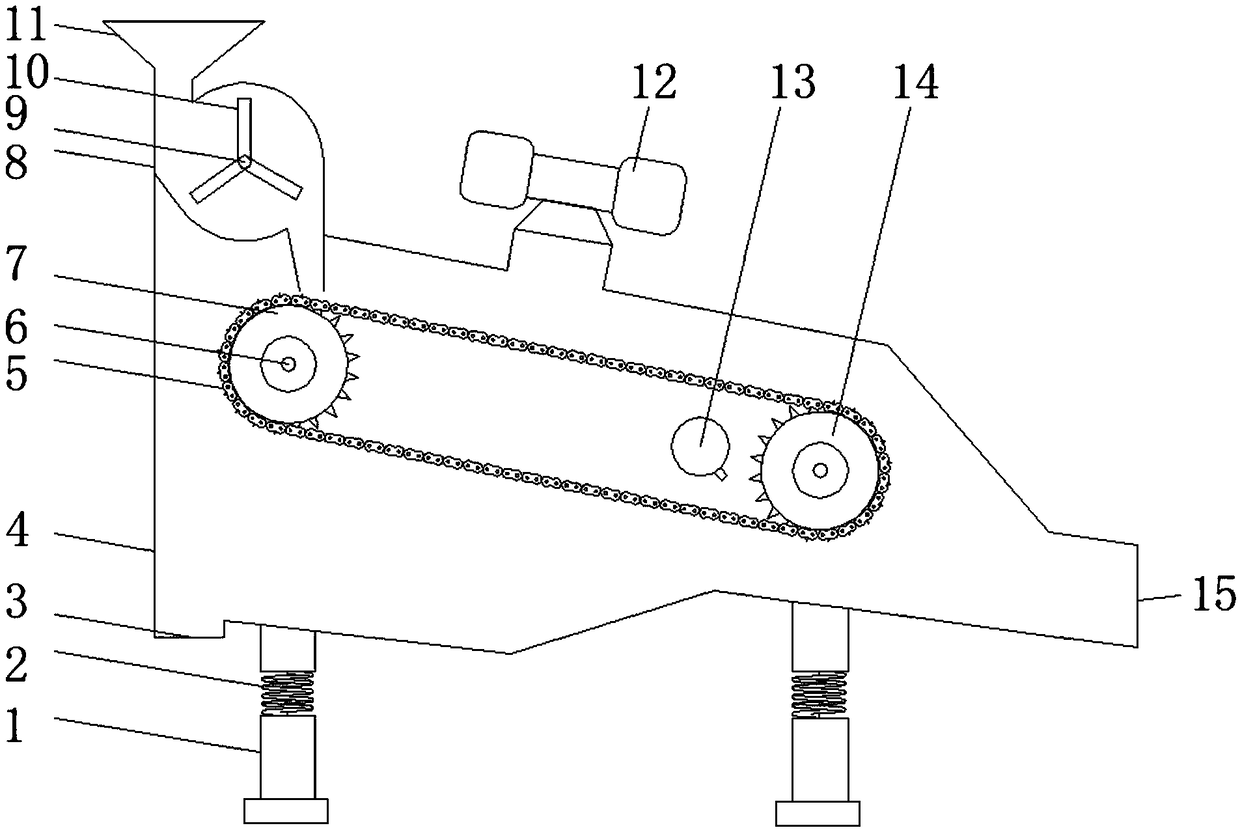

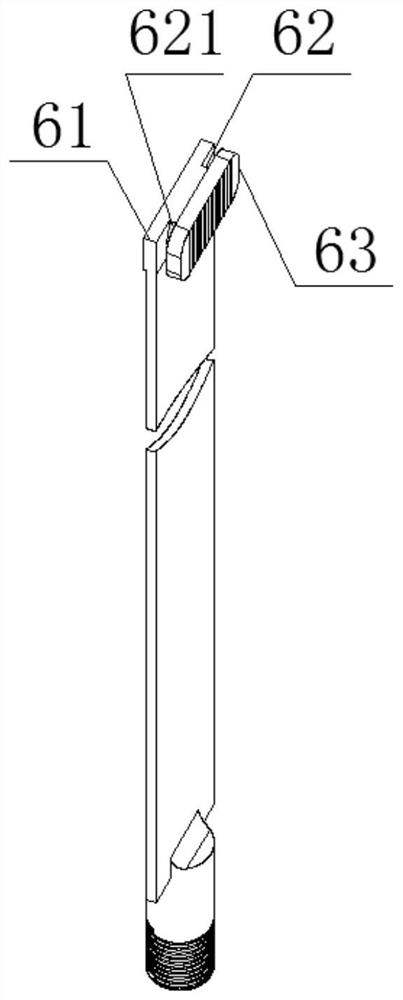

Vibrating filtering device for oil exploitation

InactiveCN108434831APlace stableReduce vibrationMoving filtering element filtersDrive wheelEngineering

The invention discloses a vibrating filtering device for oil exploitation, comprising an outer shell, a sprayer, a first motor, a filter screen, a second driven wheel, a water pump and a second motor;a first rotating shaft is arranged at the rear end inside the outer shell, two ends of the first rotating shaft are provided with first driving wheels, a first rotating shaft is arranged at the frontend inside the outer shell, two ends of the first rotating shaft are provided with first driven wheels, the first driving wheels are connected with the first driven wheels through chains, opposite sides of the two chains are welded with fixed sheets, the upper surfaces of the fixed sheets are welded with screws, the filter screen is fixed on the fixed sheets by screw caps, and one end of the first rotating shaft on the first driving wheel is connected with the second driven wheel. According to the vibrating filtering device provided by the invention, by rotating the filter screen, the function of automatic cleaning of the filter screen can be realized by matching with the sprayer, the frequency of disassembling the filter screen is reduced, and the workload of workers is reduced.

Owner:刘以年

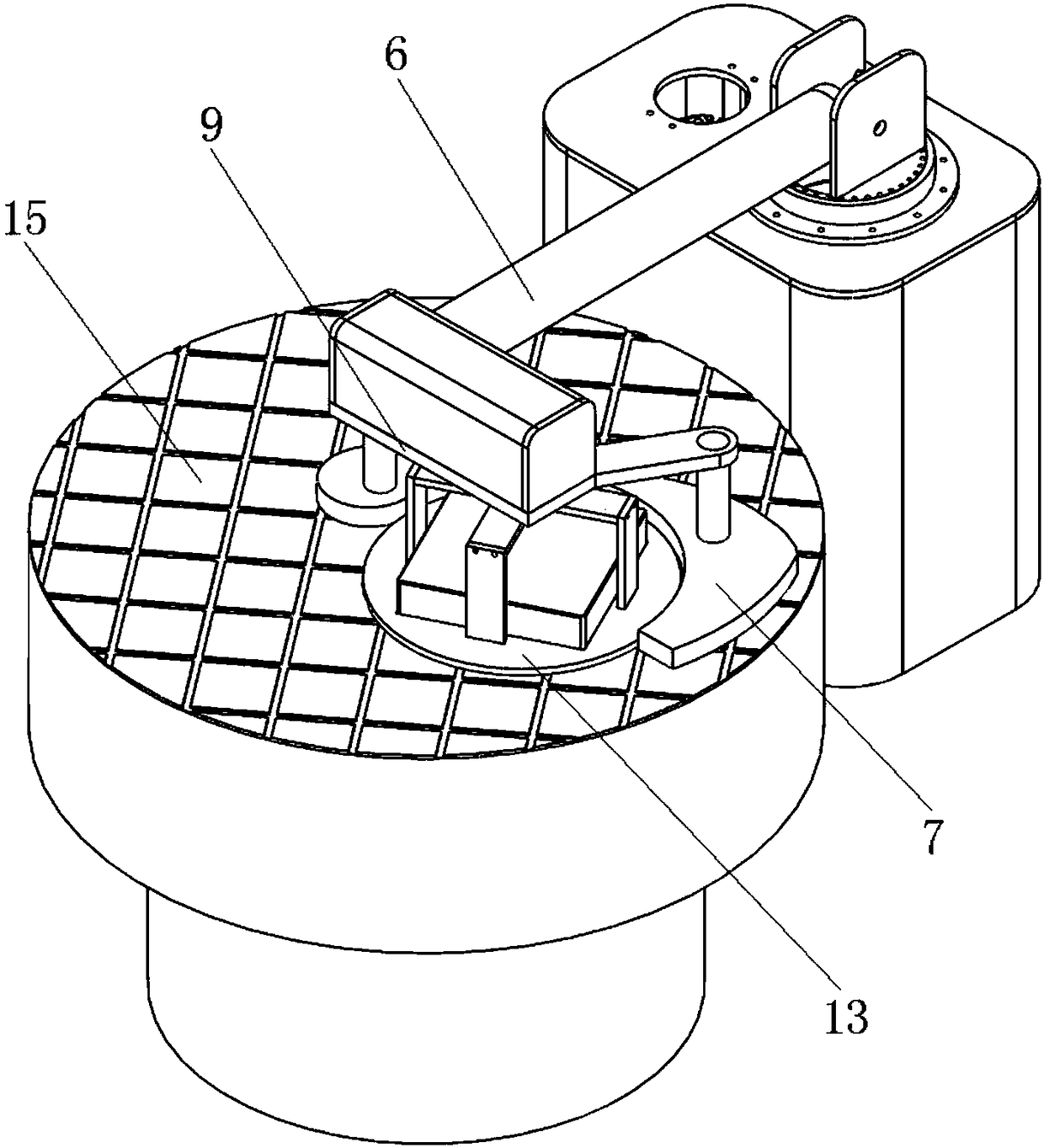

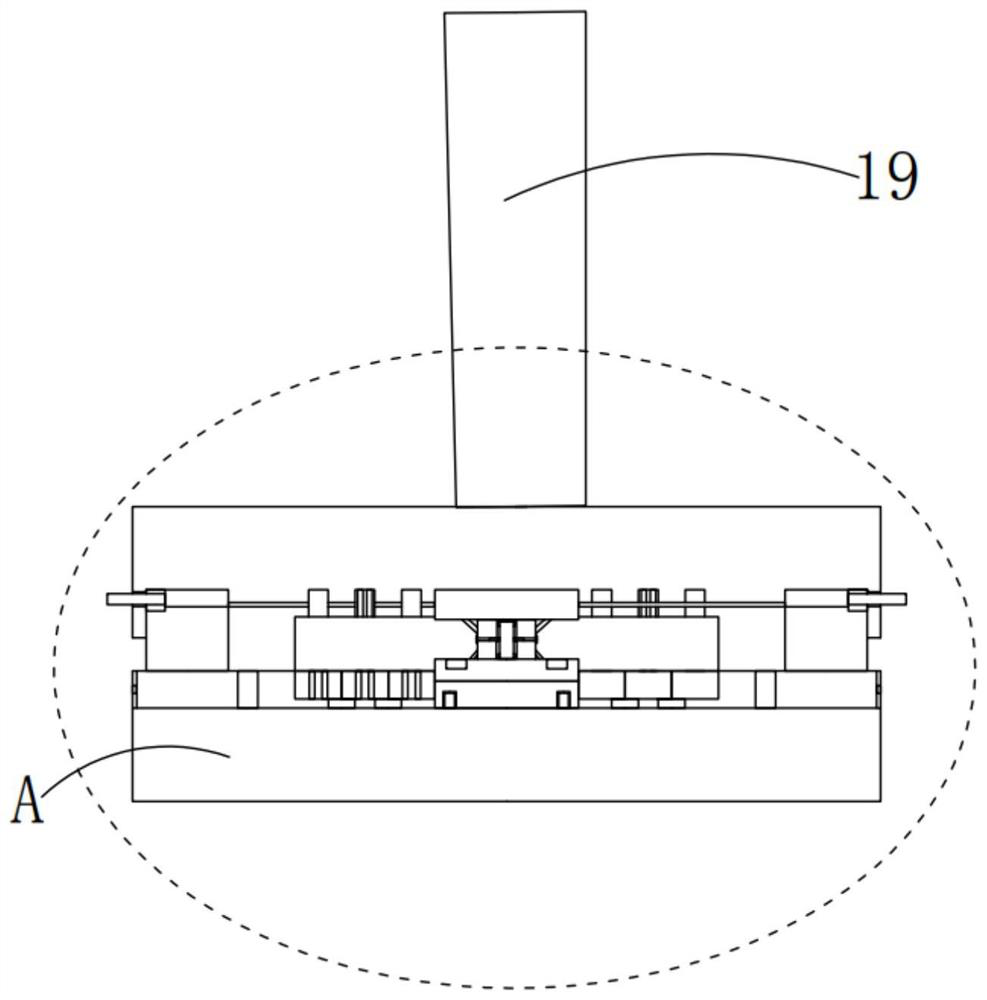

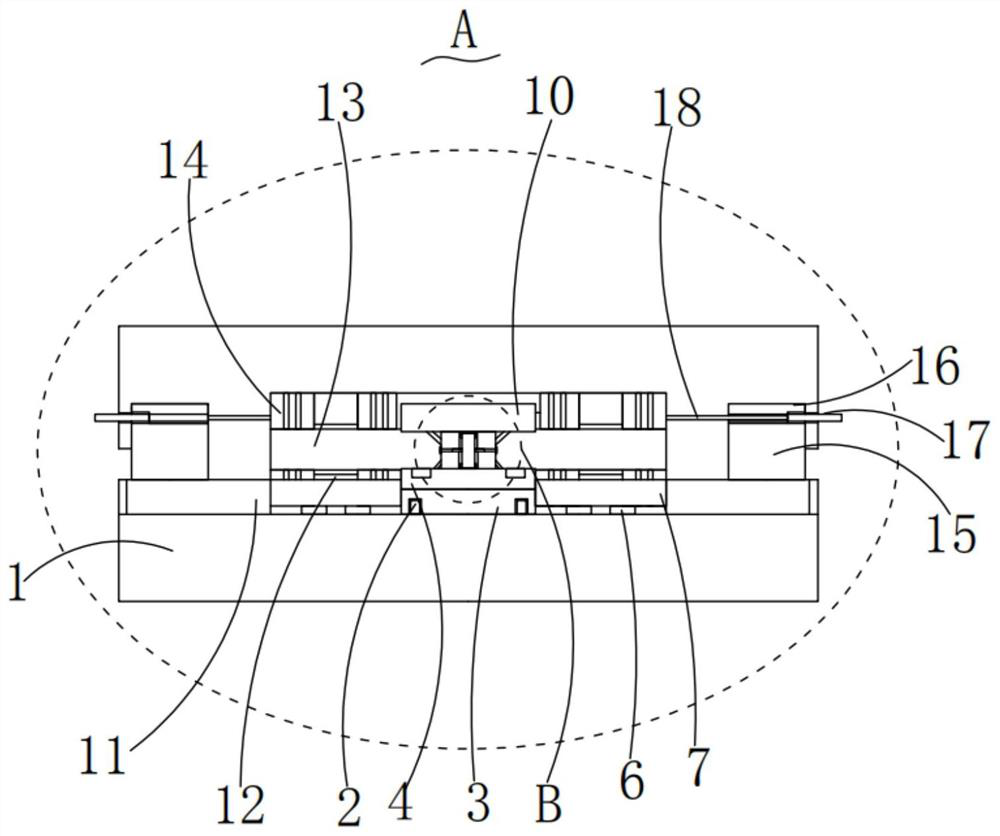

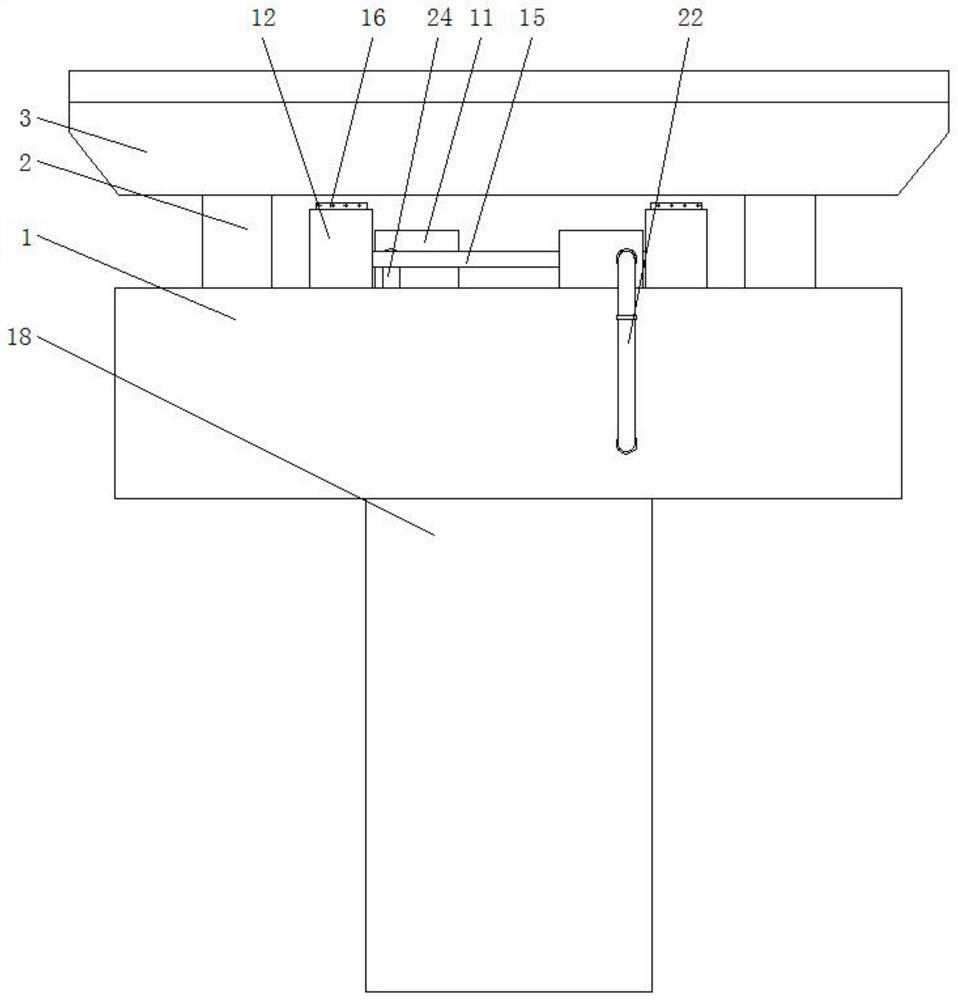

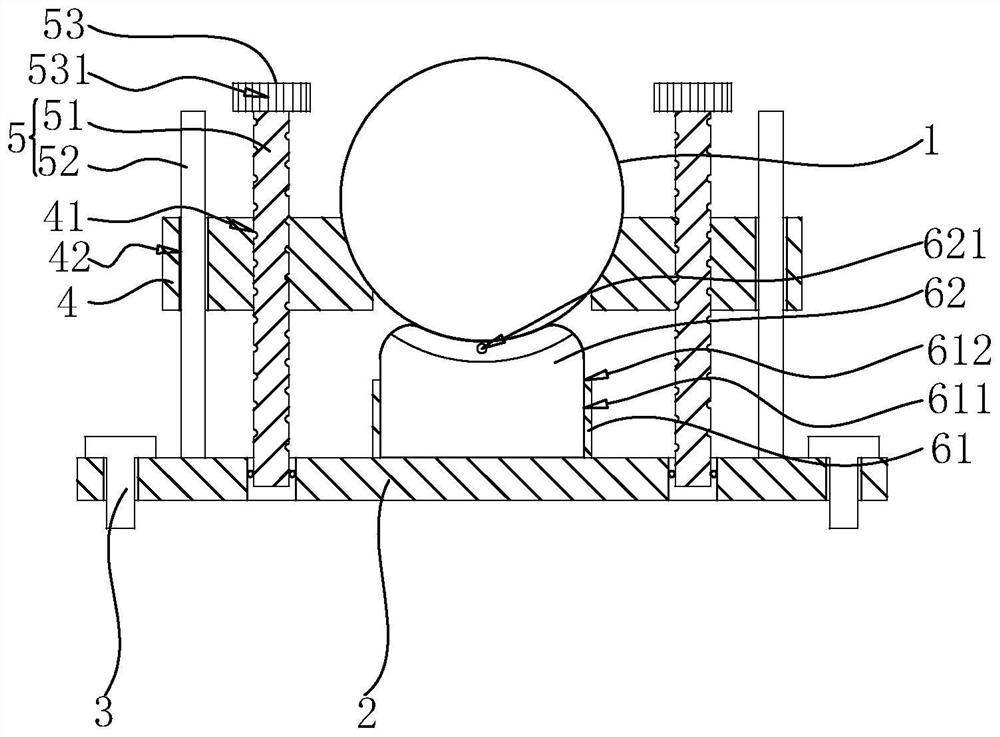

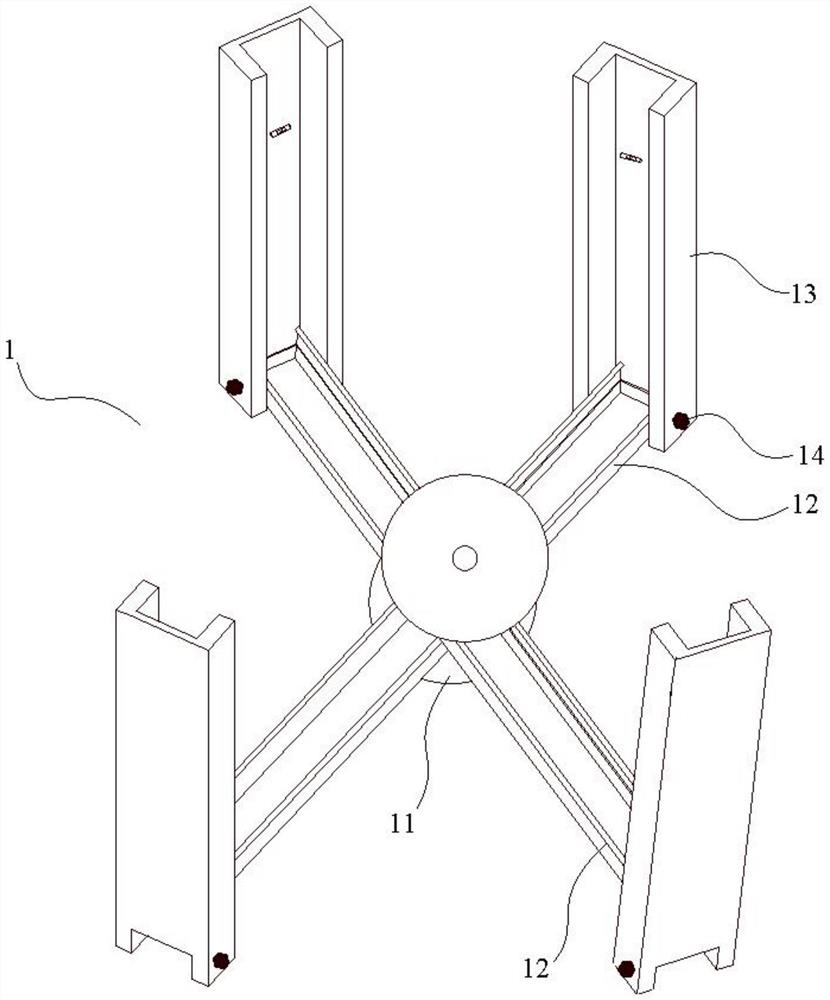

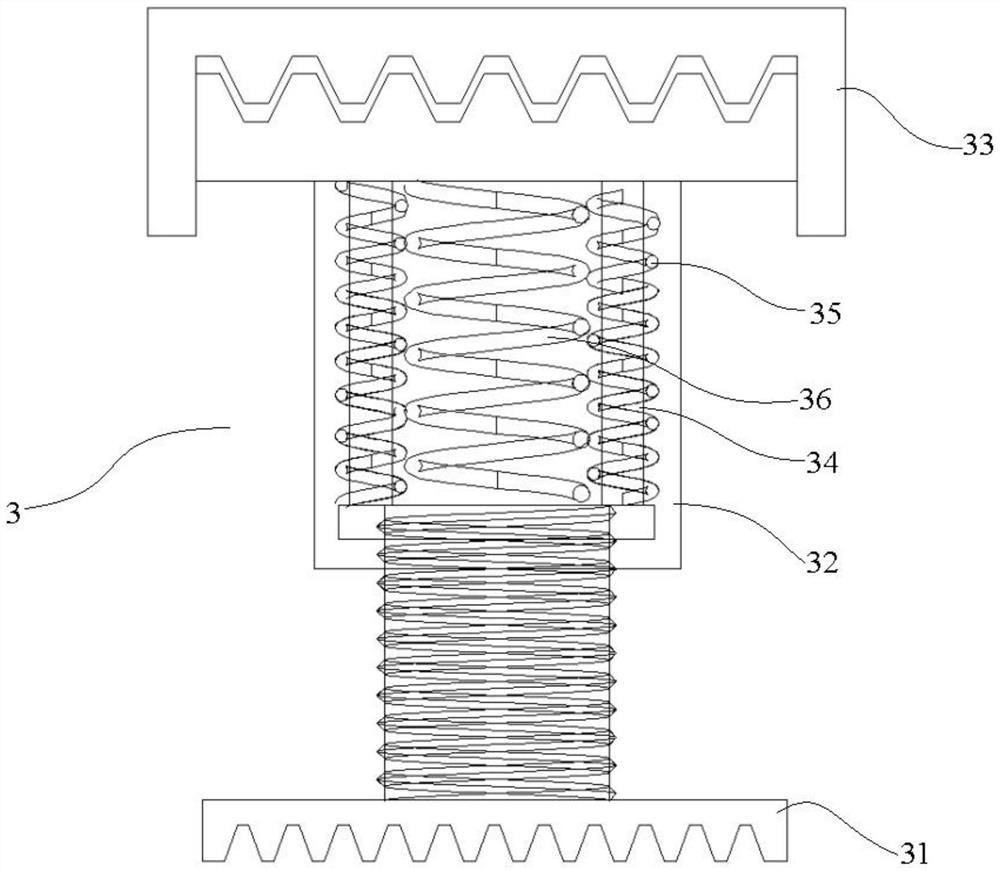

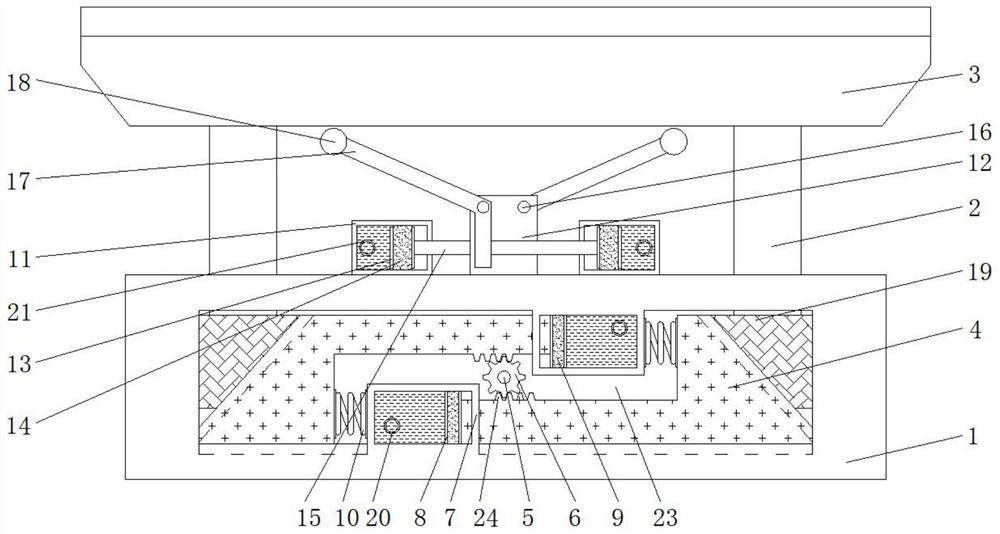

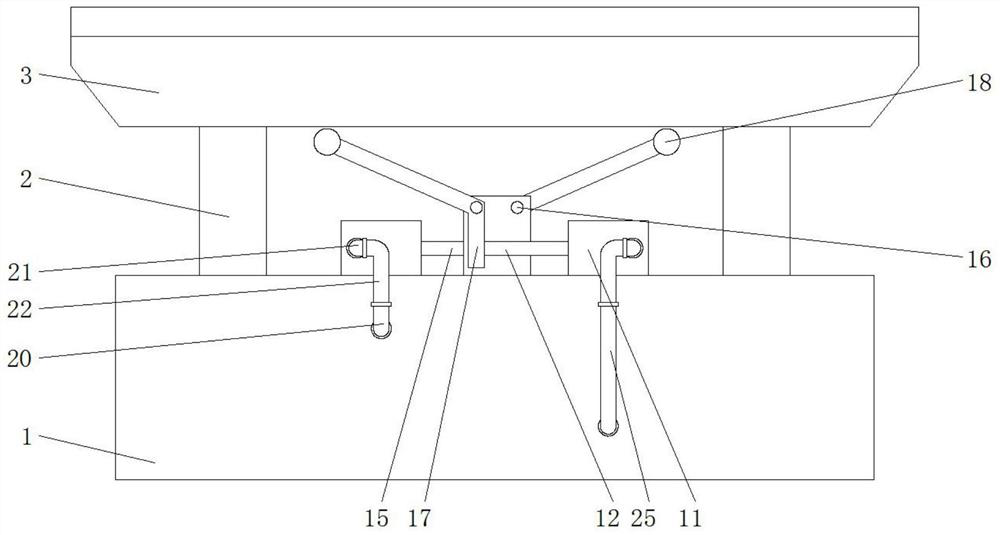

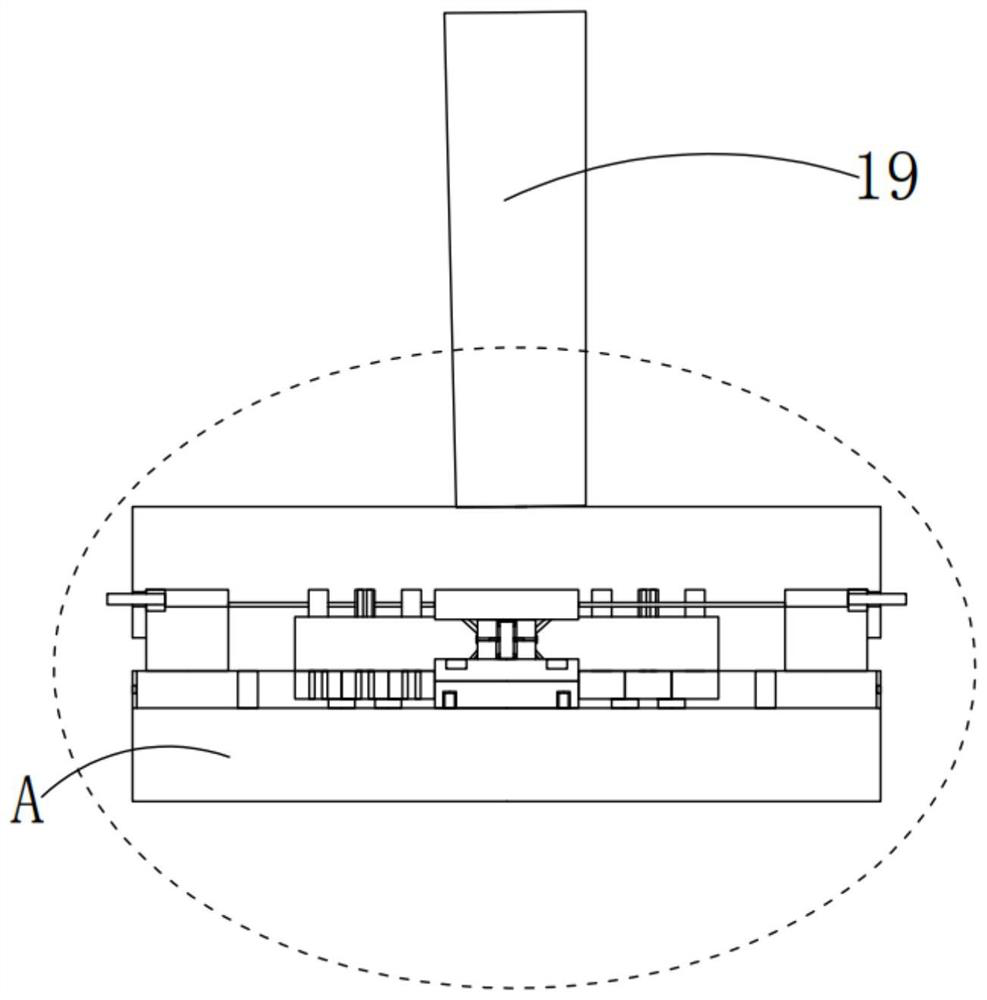

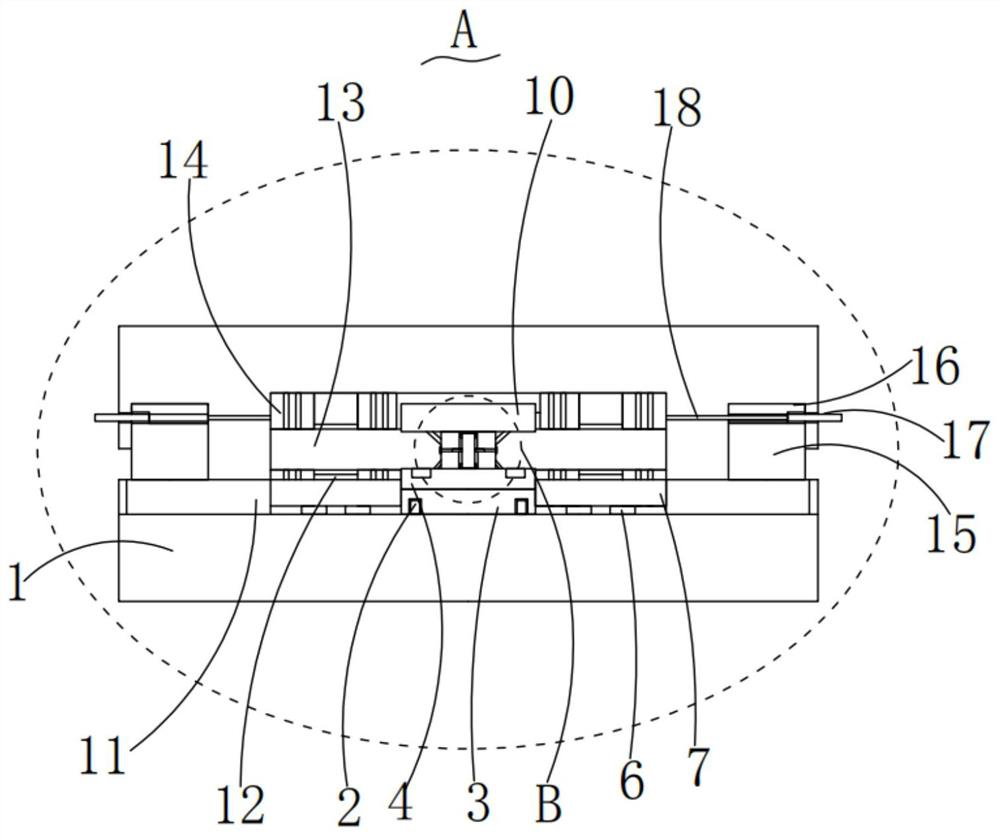

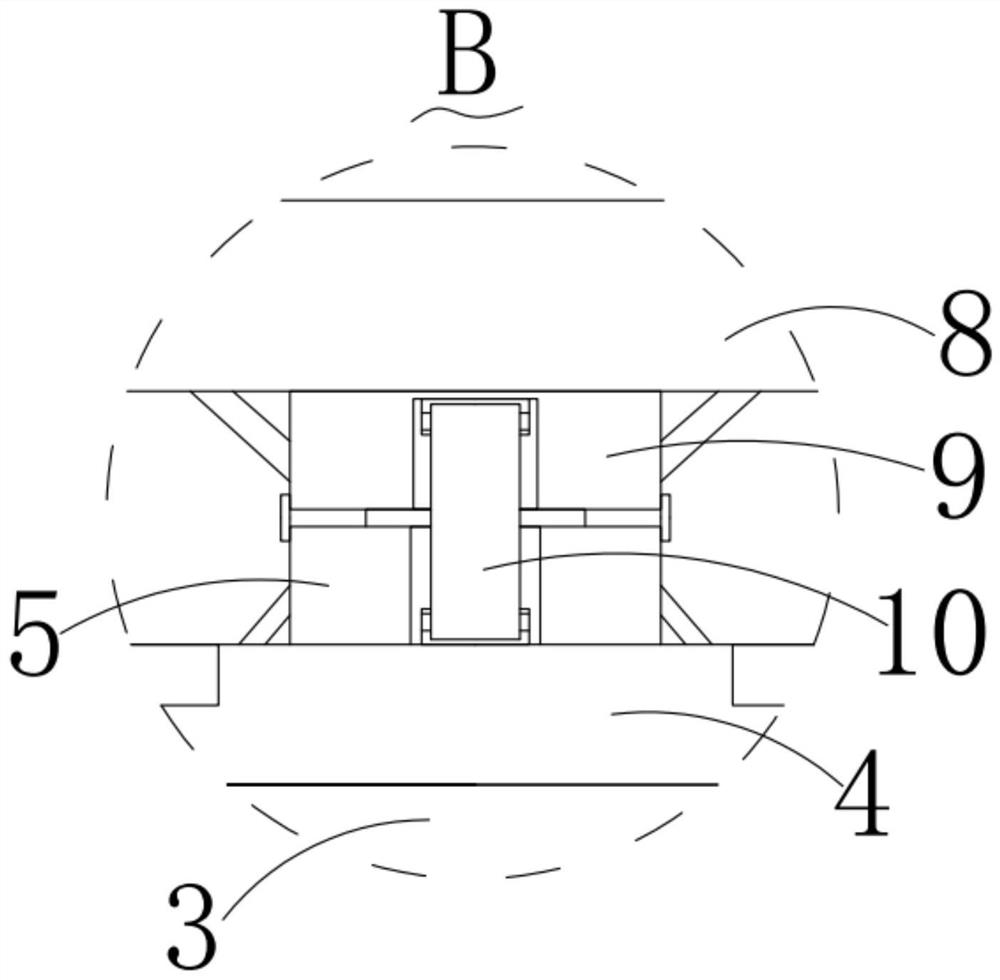

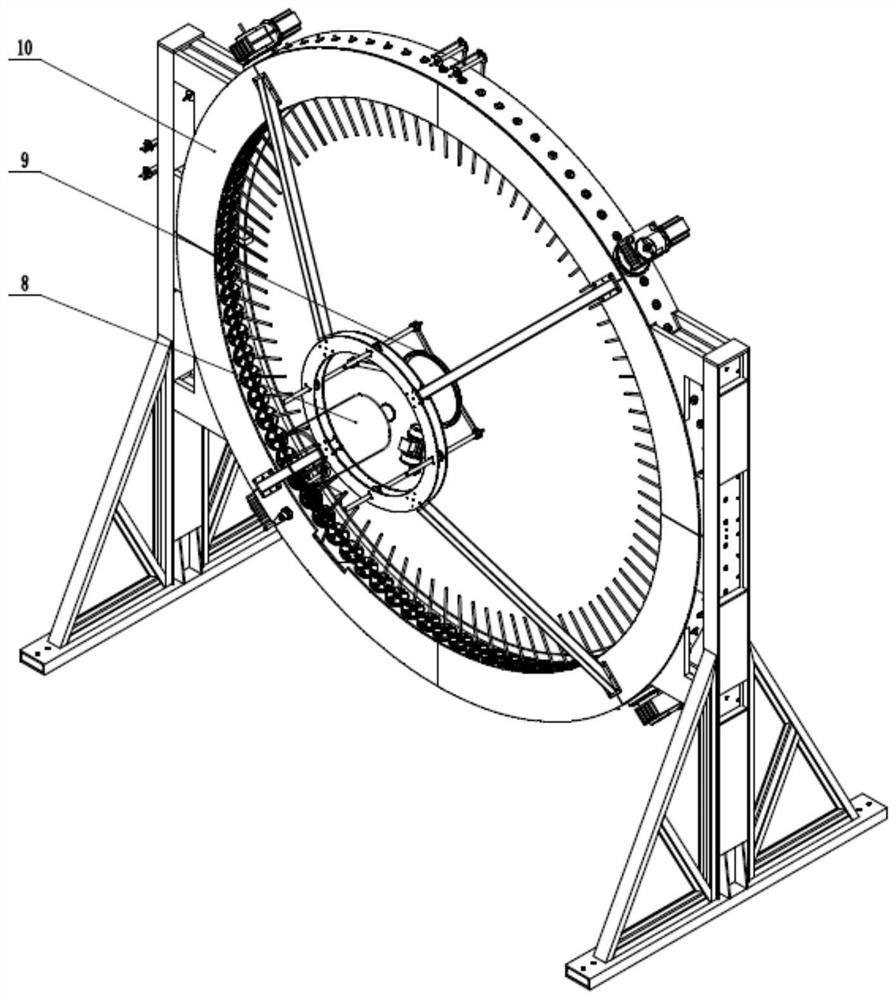

Bridge turning device for traffic construction bridge construction

ActiveCN112796228AEasy to operateReduce uneven stressBridge erection/assemblyPhotovoltaic energy generationArchitectural engineeringRebar

The invention provides a bridge turning device for traffic construction bridge construction. The bridge turning device for traffic construction bridge construction comprises a mounting platform, four positioning steel bars which are fixedly mounted at the top of the mounting platform and are distributed in a rectangular array, a positioning steel framework which is fixedly mounted on the four positioning steel bars, a spherical hinge lower disc which is fixedly mounted at the top of the positioning steel framework, and a lower spherical hinge which is fixedly mounted at the top of the spherical hinge lower disc. The bridge turning device for traffic construction bridge construction has the advantages that operation is easy, the phenomenon of uneven stress is reduced, and the phenomena of blocking and the like are avoided.

Owner:郑州市公路工程公司

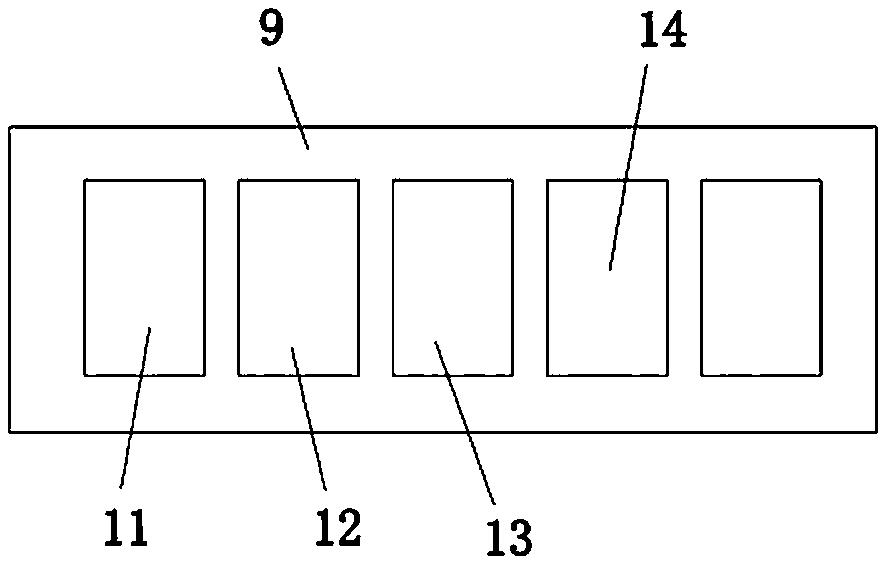

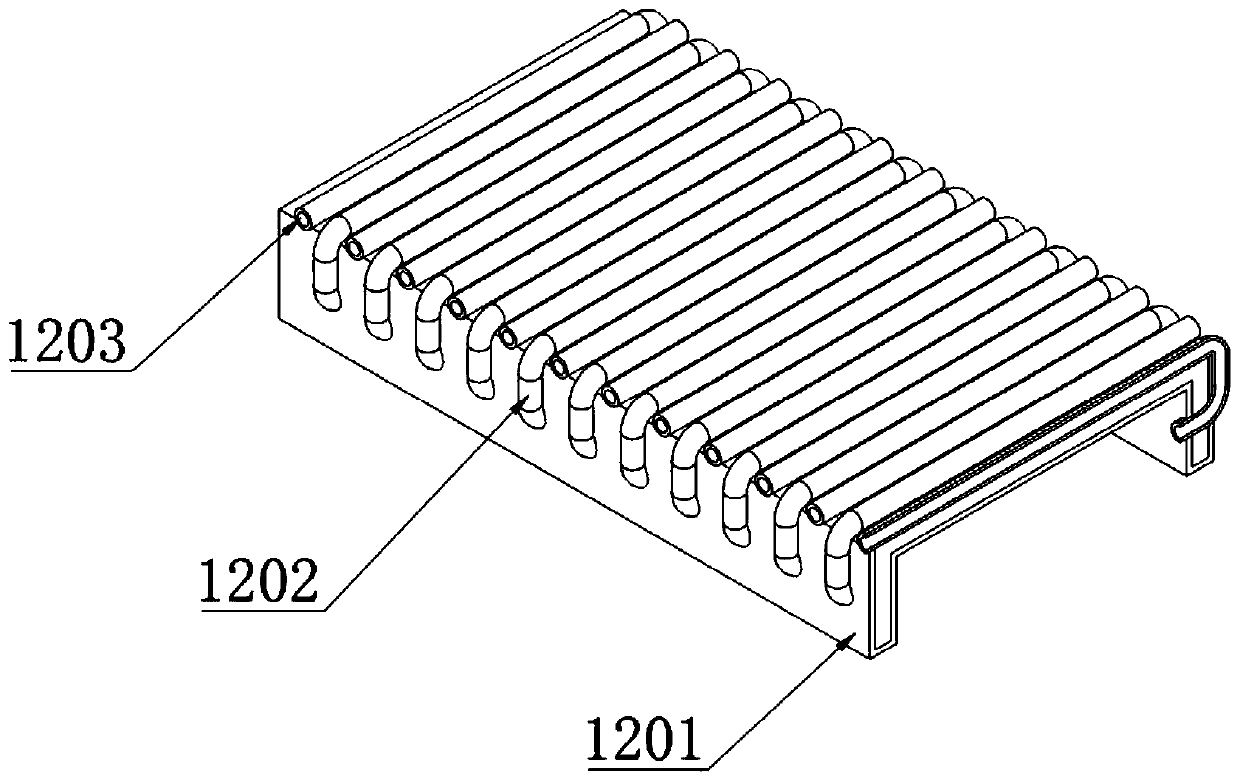

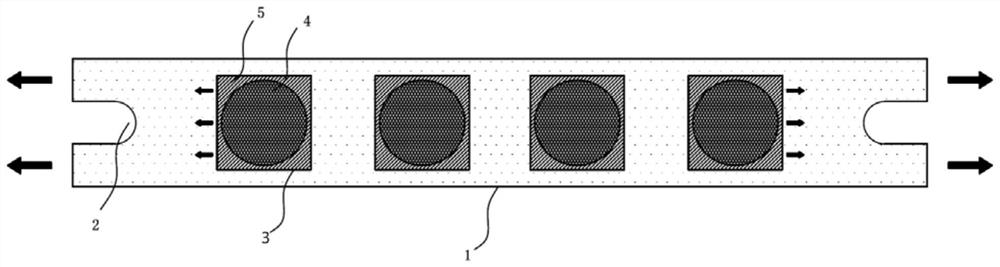

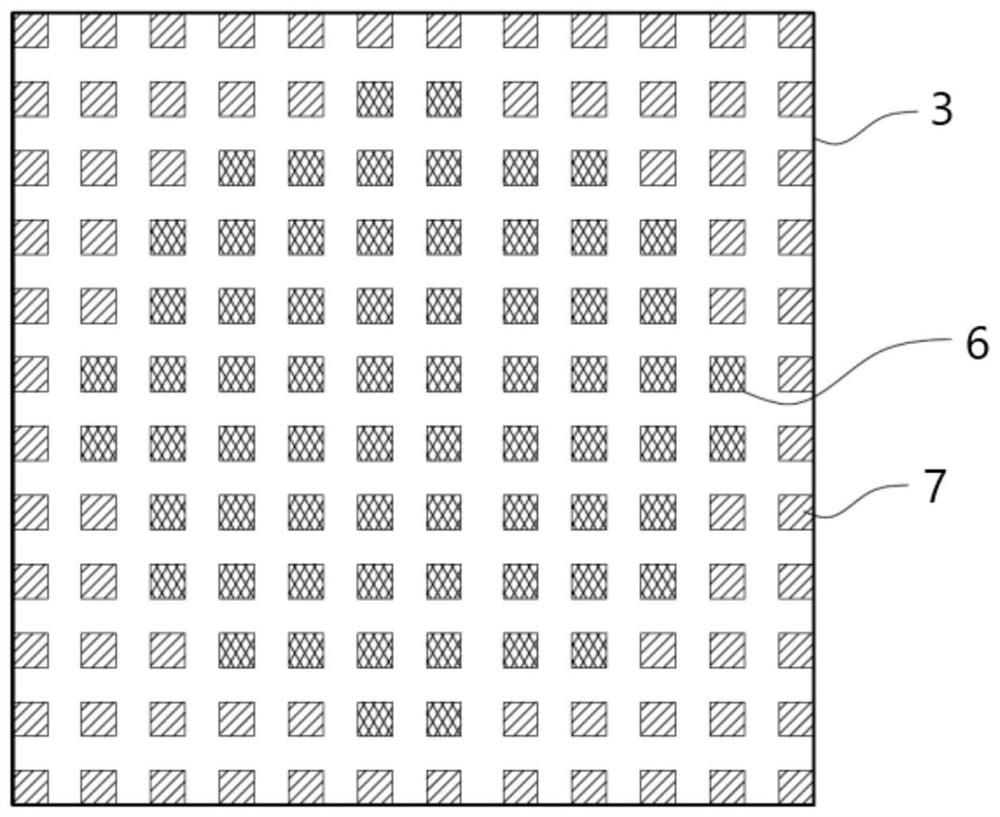

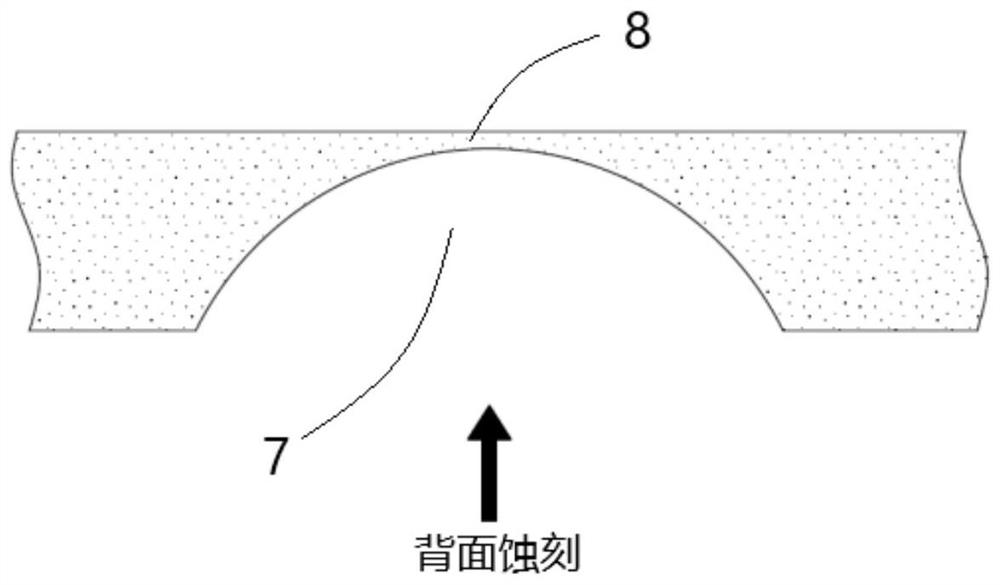

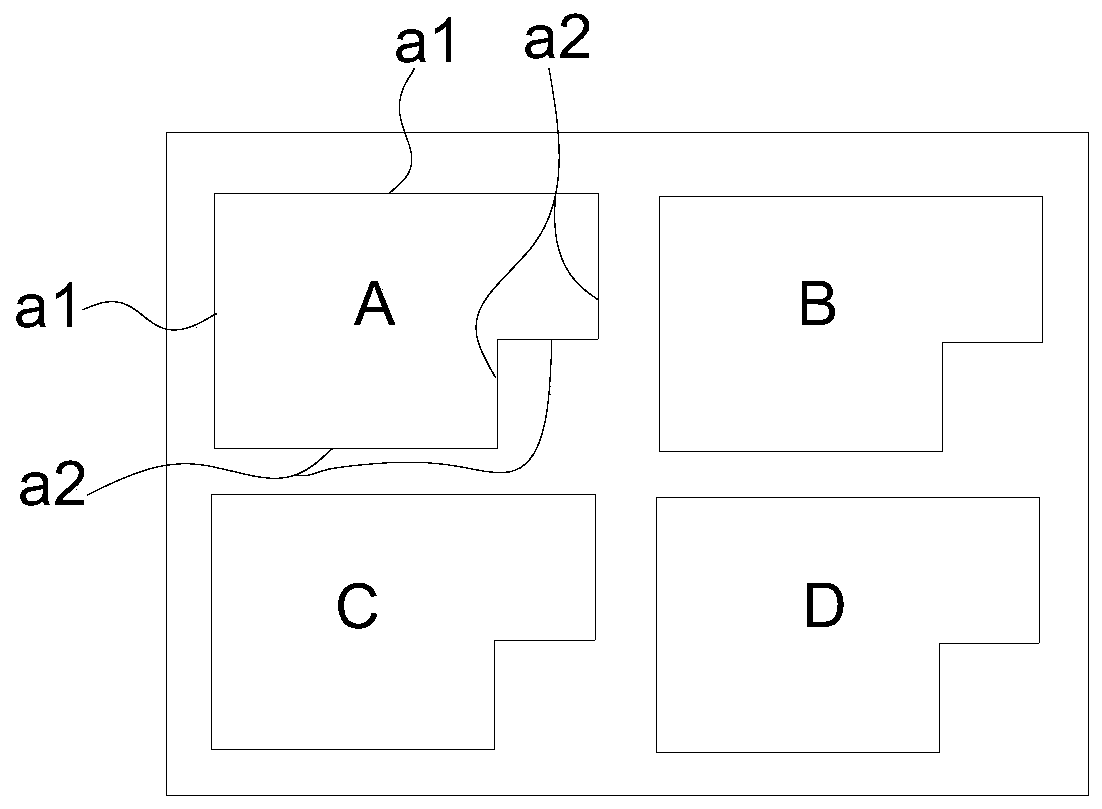

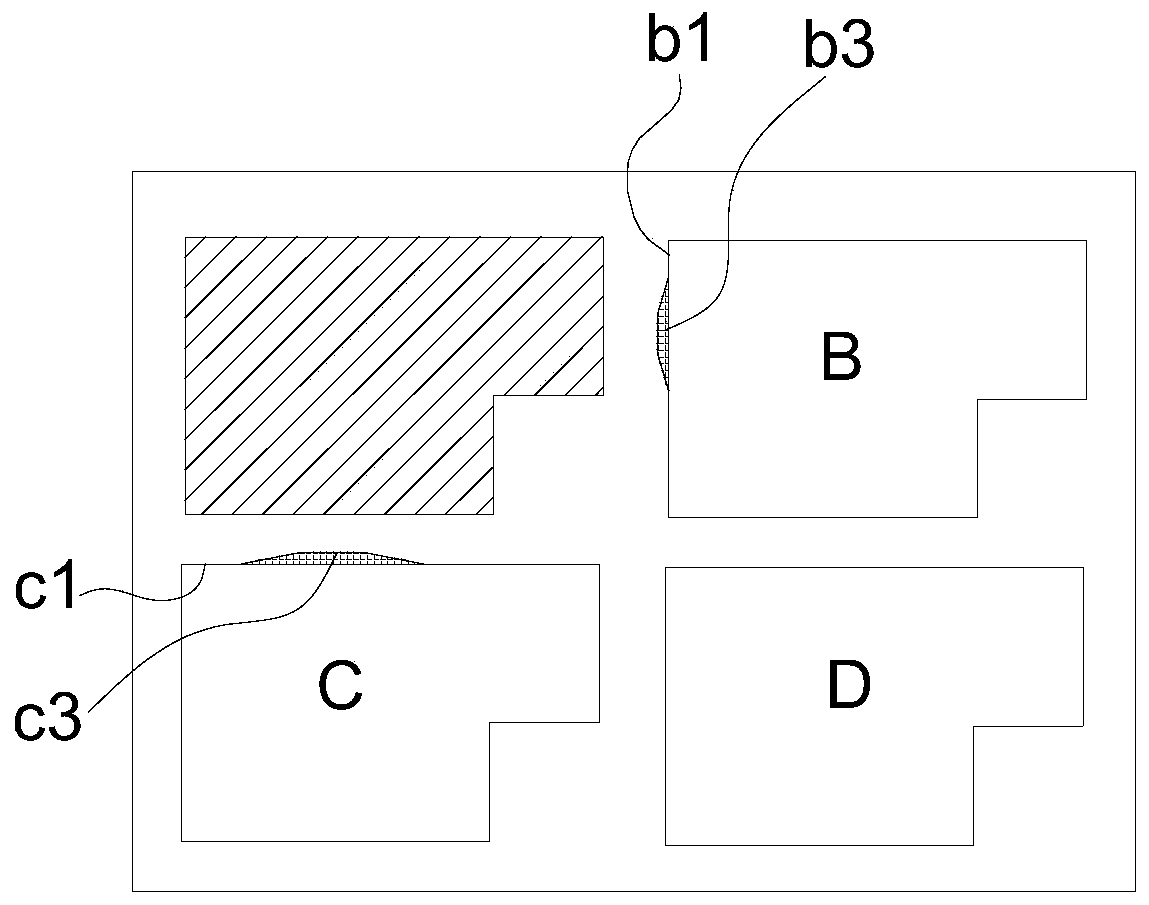

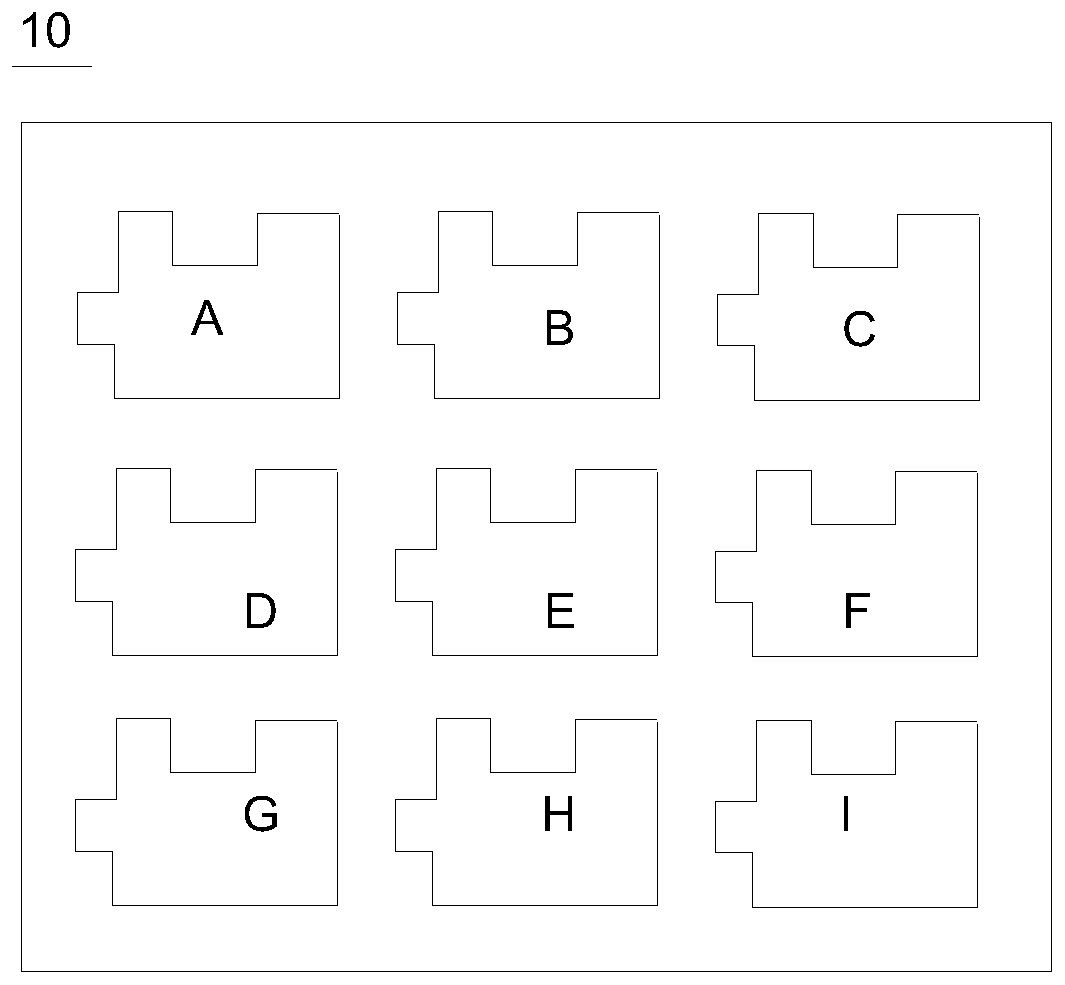

Mask strip structure for special-shaped screen and manufacturing process thereof

PendingCN113862612AReduce uneven stressImprove the netting yieldSolid-state devicesVacuum evaporation coatingEngineeringMechanical engineering

The invention discloses a mask strip structure for a special-shaped screen and a manufacturing process thereof. The mask strip structure comprises a mask strip plate, the mask strip plate is provided with a plurality of groups of effective areas distributed at equal intervals, the effective areas are quartz photomasks, the outer sides of the effective areas are provided with surrounding layers, the surrounding layers are etching areas, the etching areas are arranged in a rectangular shape, buffer areas are arranged between the effective areas and the corresponding etching areas, a plurality of groups of through holes are uniformly distributed in the effective areas, and a plurality of groups of non-through holes are uniformly distributed in the buffer areas. According to the mask strip structure, the net stretching yield of the mask strip plate for the special-shaped screen can be improved, and the net stretching efficiency is improved; and according to the structure of the mask strip plate, the phenomenon of uneven stress of the special-shaped screen is relieved, the problem of wrinkles is solved, the color mixing risk is reduced, and the color mixing phenomenon is improved.

Owner:FUJIAN HUAJIACAI CO LTD

Elevated steel-concrete composite beam

ActiveCN112342899AImprove self-adjusting balance performanceExtended service lifeClimate change adaptationBridge structural detailsConcrete beamsArchitectural engineering

The invention discloses an elevated steel-concrete composite beam which comprises a cross beam and a pier stud, the cross beam is fixedly connected to the top of the pier stud, transmission bases areslidably connected to the two sides of the bottom of the inner wall of the cross beam, sliding bases are slidably connected to the sides, away from each other, of the two transmission bases, and steelbeams are fixedly connected to the tops of the two sliding bases. The tops of the two steel beams penetrate through the cross beam and extend to the position above the cross beam, a concrete plate isfixedly connected between the tops of the two steel beams, rectangular grooves are formed in the bottom of one transmission base and the top of the other transmission base, and the two transmission bases are symmetrically connected to the bottom of the inner wall of the cross beam in a staggered and sliding mode. The two sides of the bottom of the concrete slab are stressed at the same time and do not descend any more, the force is decomposed and converted, the situation that the concrete slab is stressed unevenly is reduced, the stability of the overall structure of the concrete beam is improved, the underpinning is in a straight rod shape, longitudinal and horizontal stress is conducted, and the bending phenomenon is avoided.

Owner:GUIZHOU ROAD & BRIDGE GRP

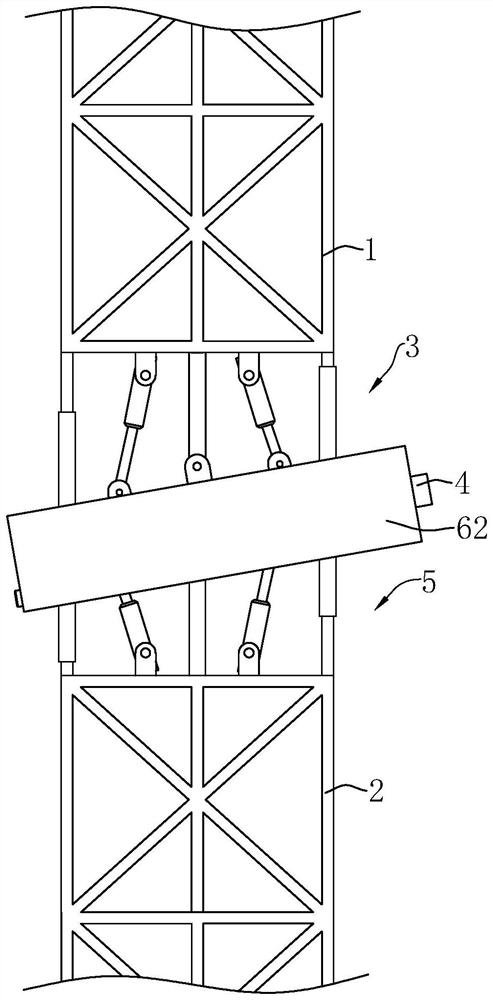

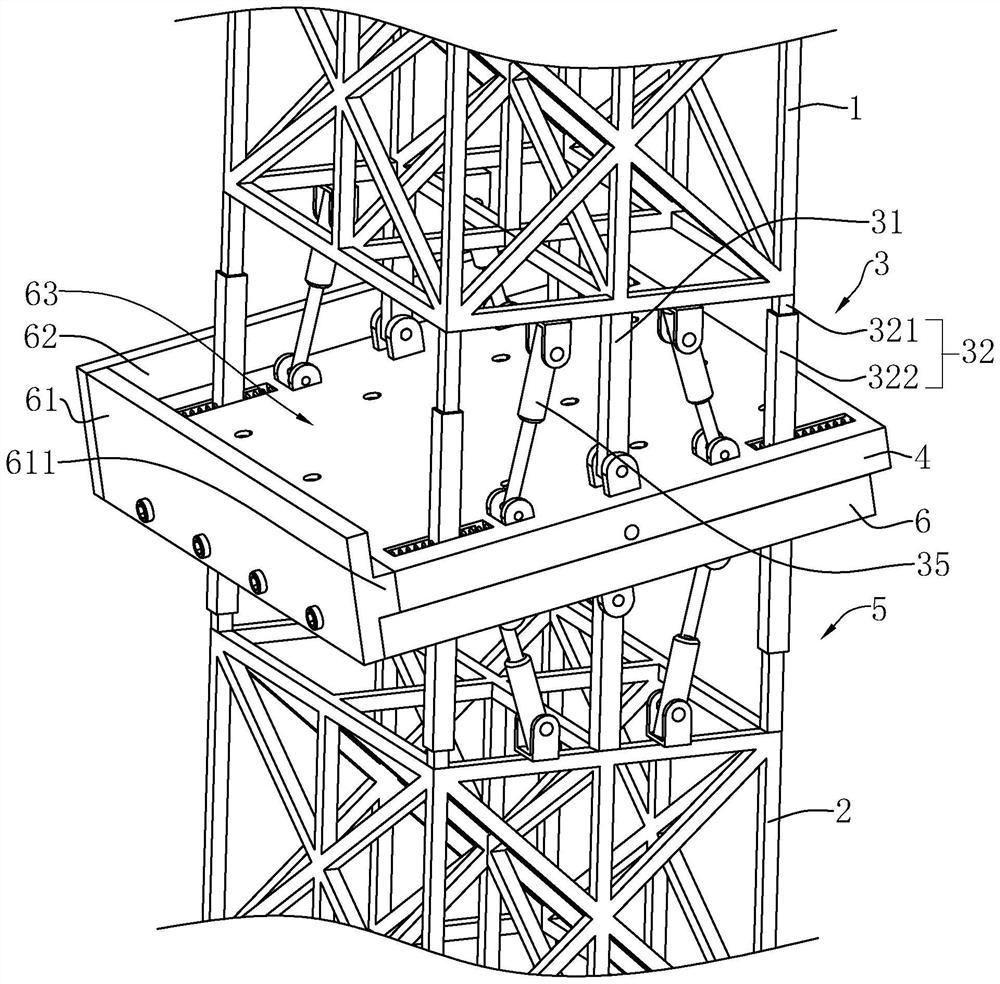

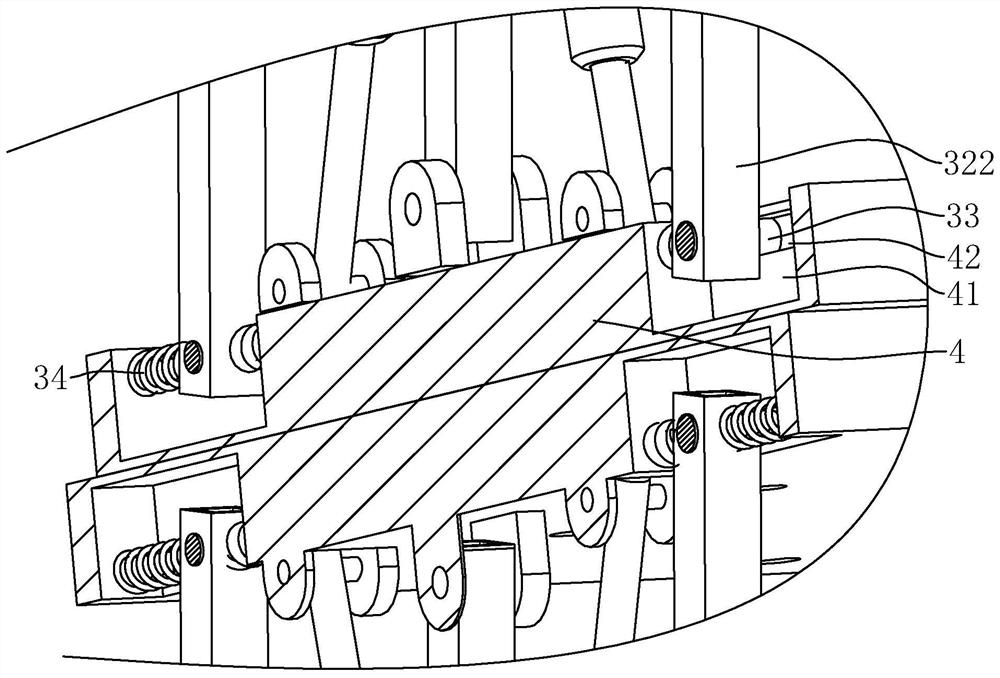

High formwork system and construction method thereof

ActiveCN114109037AShorten the timeShorten the construction periodAuxillary members of forms/shuttering/falseworksBuilding material handlingSupporting systemArchitectural engineering

The invention discloses a high formwork supporting system and a construction method thereof, and relates to the field of formwork supporting system construction, the high formwork supporting system comprises a plurality of formwork units which are sequentially arranged in the vertical direction, in every two vertically adjacent formwork units, the formwork unit located on the upper portion is an upper formwork unit, and the formwork unit located on the lower portion is a lower formwork unit; a connecting mechanism is arranged between every two vertically adjacent formwork units and comprises an upper connecting plate stably connected to the bottom end of the upper formwork unit and an upper connecting plate stably connected to the top end of the lower formwork unit, the lower connecting plate is obliquely arranged, and a sinking groove is formed in the upper surface of the lower connecting plate in the thickness direction of the lower connecting plate. The sinking groove penetrates through the higher end, in the inclination direction, of the lower connecting plate, when the upper connecting plate is embedded into the sinking groove, every two vertically adjacent formwork units are aligned, and a locking assembly used for locking the upper connecting plate and the lower connecting plate is arranged between the upper connecting plate and the lower connecting plate. The device has the effect that the time spent on adjusting the formwork units on site is shortened.

Owner:韶关市鹏成建筑工程有限公司

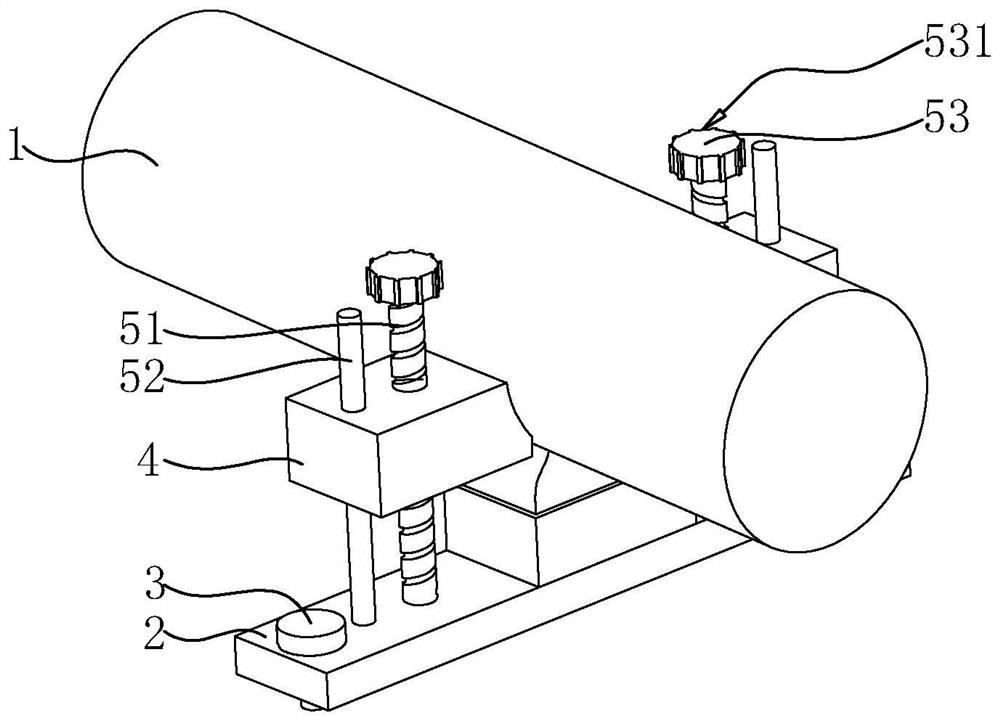

An anti-leakage device for pipelines passing through municipal engineering

ActiveCN113007445BReduce uneven stressReduce breakagePipe supportsPipe elementsEngineeringProcess engineering

This application relates to the technical field of municipal engineering, and in particular to an anti-leakage device for pipelines passing through municipal engineering. A support assembly, the support assembly includes an air bag connected to the support plate, the support plate is located directly below the pipeline, the air bag is located between the pipeline and the support plate, and the air bag is provided with an air hole for the staff to inflate, The air bag is used to bear against the pipeline. The present application has the technical effect of reducing pipeline leakage.

Owner:惠州城际工程咨询有限公司

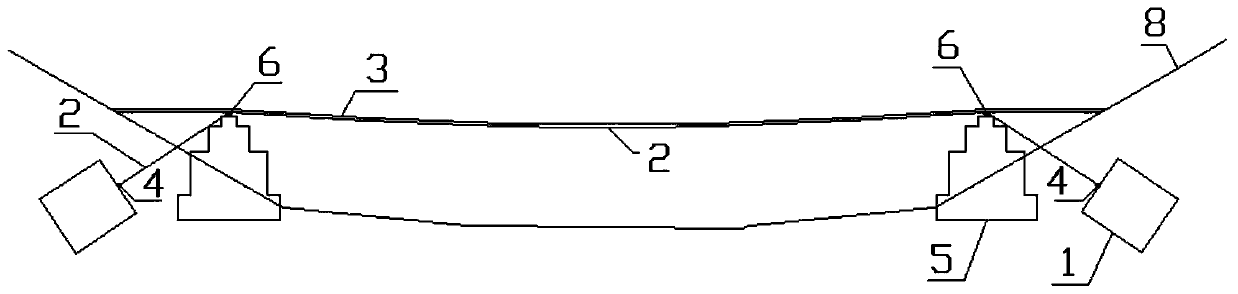

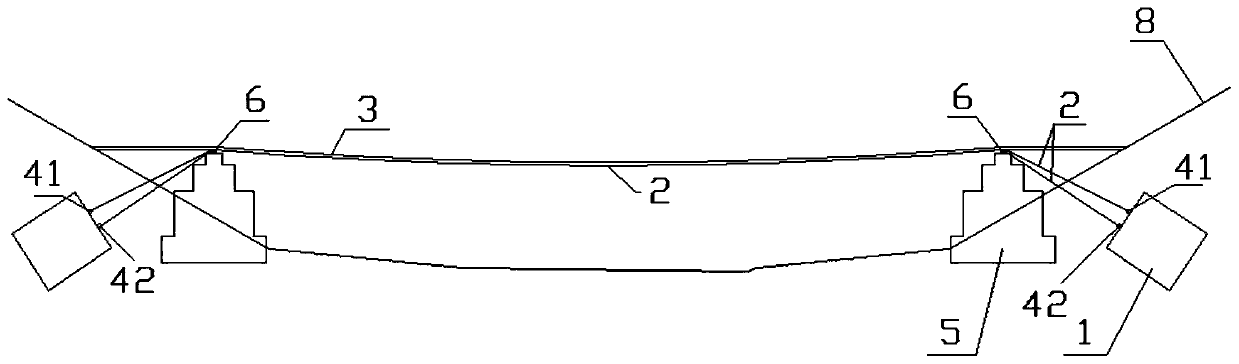

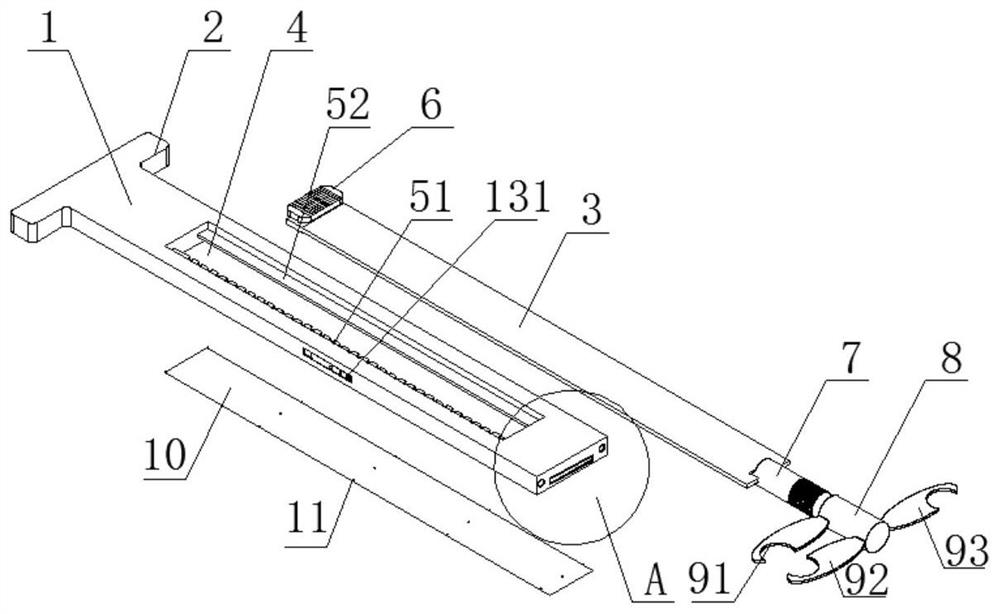

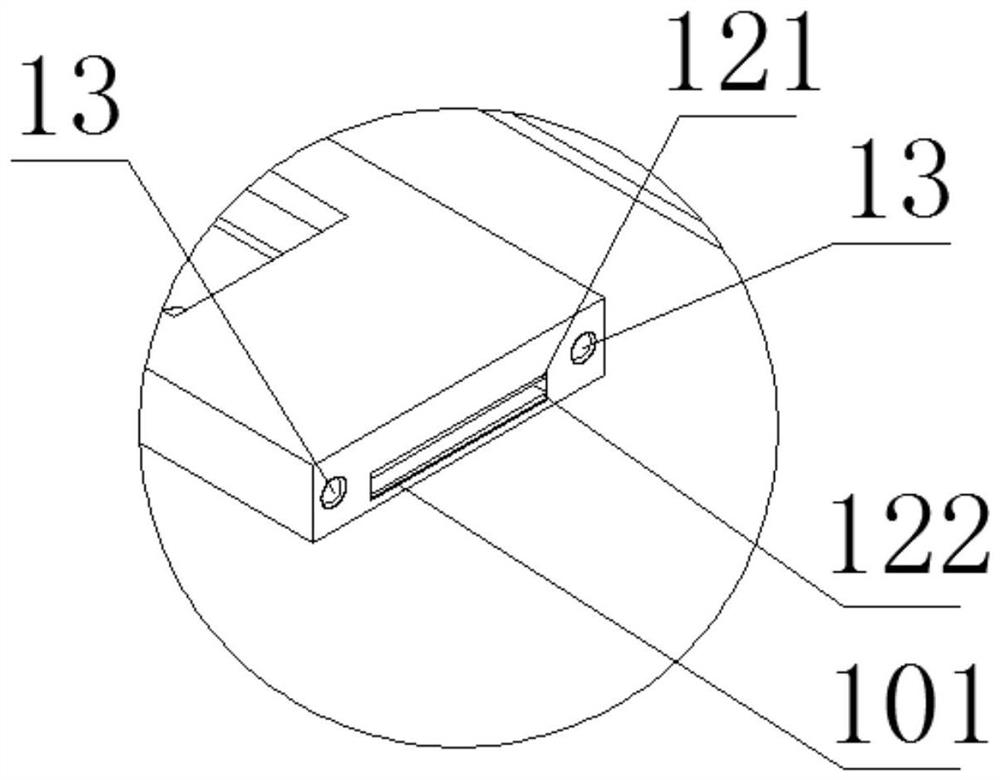

Transportation component and transportation method suitable for wide and large-span prefabricated slabs

PendingCN114248681AReduce uneven stressAvoid breakingLoad securingTransportation itemsArchitectural engineeringEngineering

Owner:CHINA FIRST METALLURGICAL GROUP

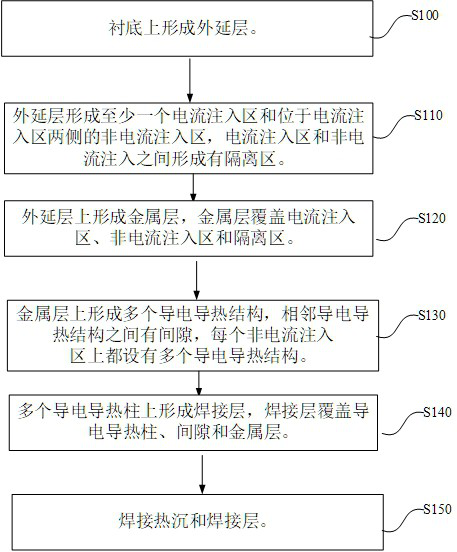

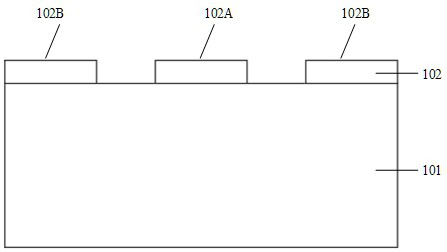

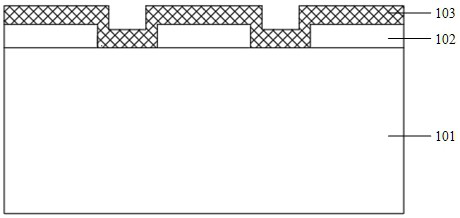

Semiconductor device and heat sink bonding method

ActiveCN113345809AReduce stress build-upReduce uneven stressSemiconductor/solid-state device detailsSolid-state devicesPhysicsHeat sink

The invention provides a semiconductor device and a heat sink bonding method, and relates to the technical field of semiconductors, and the method comprises the steps: forming an epitaxial layer on a substrate, wherein the epitaxial layer forms at least one current injection region and non-current injection regions located on the two sides of the current injection region, and an isolation region is formed between the current injection region and the non-current injection region; forming a metal layer on the epitaxial layer, wherein the metal layer covers the current injection region, the non-current injection region and the isolation region; forming a plurality of electric conduction and heat conduction structures on the metal layer, forming gaps between adjacent electric conduction and heat conduction structures, and arranging a plurality of electric conduction and heat conduction structures on each non-current injection region; forming a welding layer on the plurality of conductive and heat-conducting structures, wherein the welding layer covers the conductive and heat-conducting structures, the gap and the metal layer; and welding the heat sink and the welding layer. The electric conduction and heat conduction structure ensures that the current injection region is not stressed, and welding stress concentration is reduced when the heat sink is welded; the formation of the metal layer and the conductive and heat-conducting structure reduces the welding stress of the heat sink and the semiconductor device, and reduces or avoids local distortion of the semiconductor device caused by welding.

Owner:度亘激光技术(苏州)有限公司

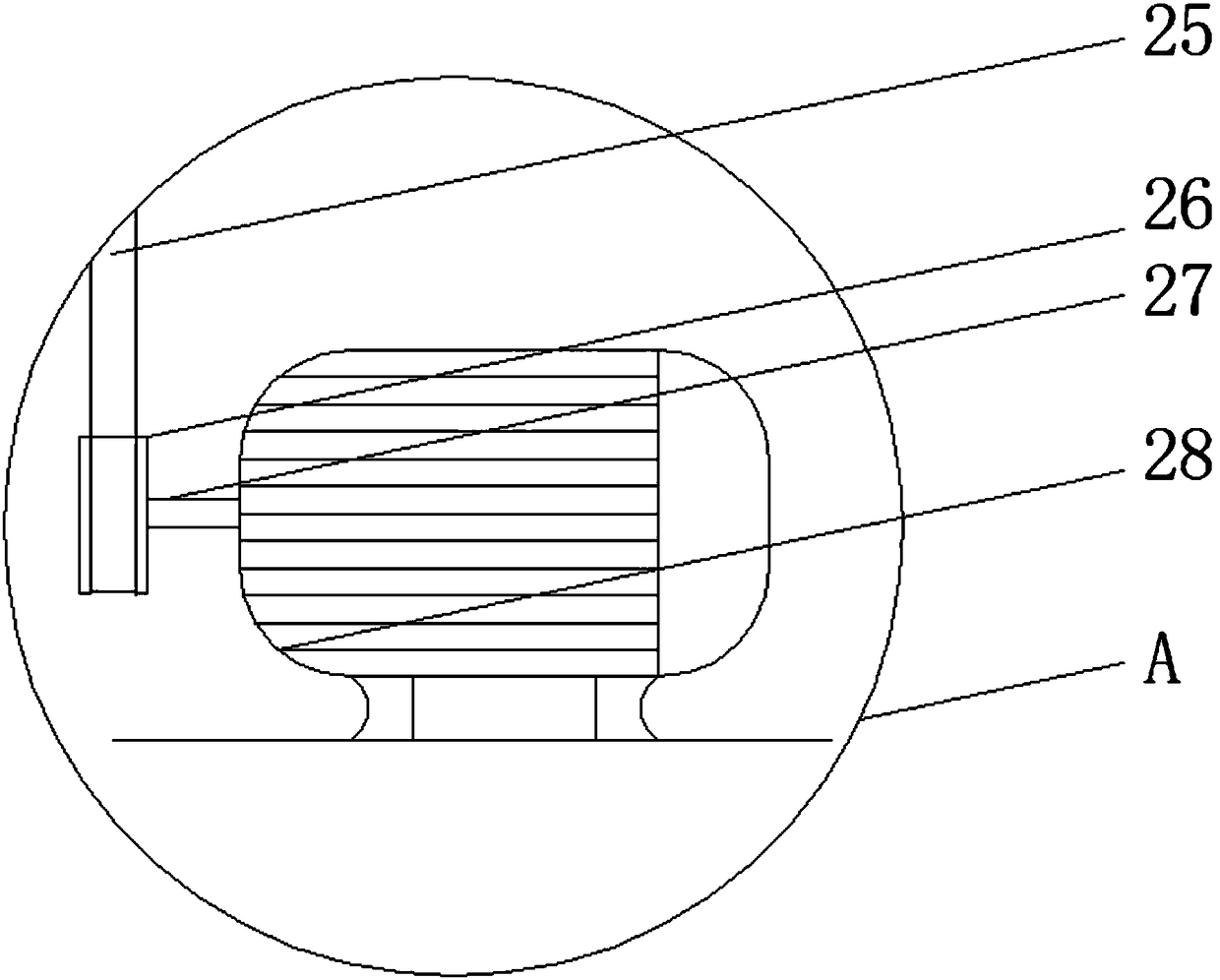

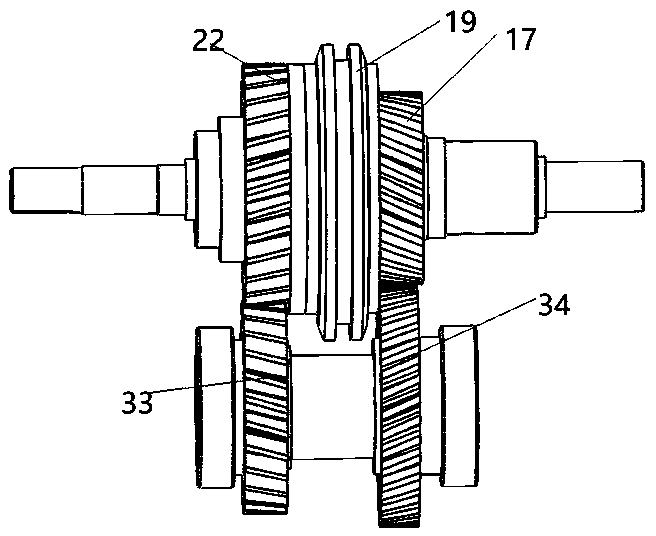

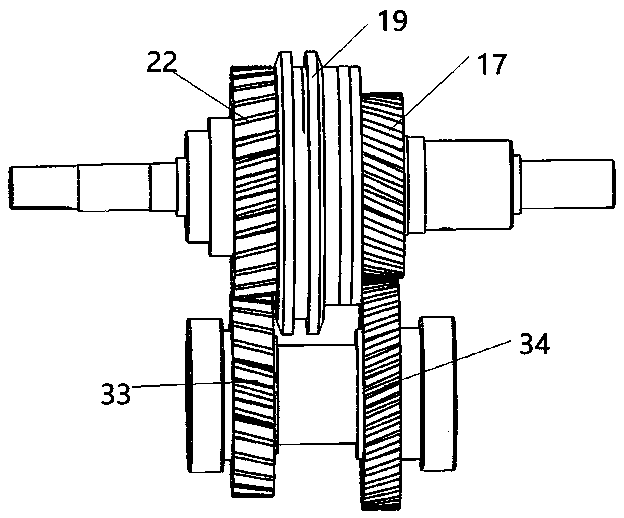

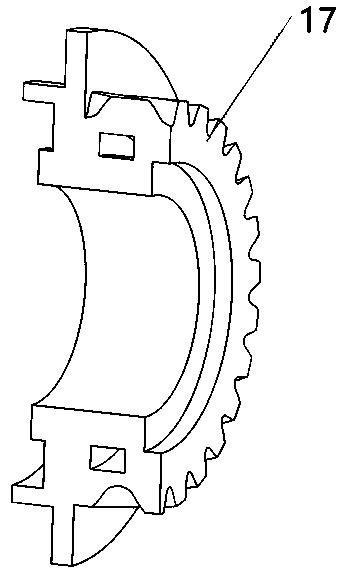

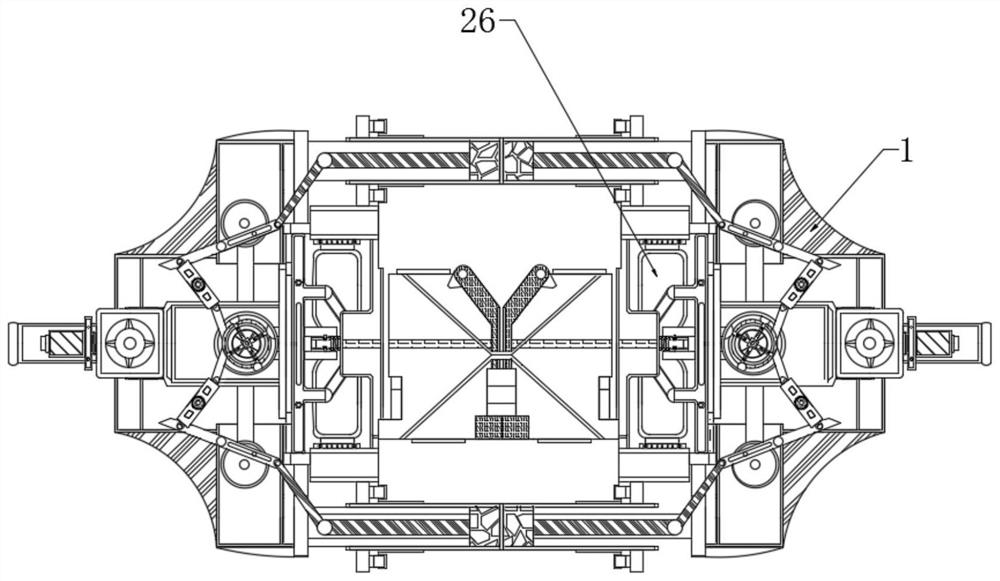

An integrated motor reduction drive system for helicopter empennage

ActiveCN108058824BAchieve high concentrationAchieve balanceToothed gearingsEfficient propulsion technologiesMotor speedReduction drive

Owner:HEFEI UNIV OF TECH

Garment processing auxiliary equipment facilitating automatic cuff edge sealing

InactiveCN114134649AFacilitate automatic edge bandingIncrease productivityWork-feeding meansNeedle severing devicesEngineeringAssistive equipment

The invention relates to the technical field of clothing, and discloses clothing processing auxiliary equipment facilitating automatic edge sealing of cuffs, and a magnetic block is fixedly mounted at the upper end of a pulling strip. According to the garment processing auxiliary equipment facilitating automatic cuff edge sealing, a pulling strip is powered on to move towards the right end, the pulling strip drives a pressing block to gradually move towards the right end, the pulling strip pushes a main shaft piece to move towards the lower end, and matched torque buckles are arranged at the axis positions of the bottom ends of an acting block and a penetrating needle; through cooperative use of an acting block, a penetrating needle, a main shaft piece and a pulling strip, the equipment can conveniently sew the clothing cloth at the proper position of the front end of the collecting box, so that the equipment achieves the automatic sewing effect, deviation is avoided, the situation of uneven stress is reduced, and the working efficiency is improved. Large-amplitude wrinkling and folding caused by uneven stress of the fabric are prevented, the automation degree of bottom edge folding is increased, and the production efficiency of clothes is improved.

Owner:未来空间数字科技(浙江)有限公司

An environmentally friendly high-precision aluminum alloy profile extrusion machine

ActiveCN110711790BEasy to useRapid coolingEdge grinding machinesGas treatmentHydraulic cylinderThermodynamics

The invention discloses an environment-friendly high-precision aluminum alloy profile extruder which comprises a base frame, a hydraulic cylinder, a material liner and a die. An abutting block is welded to the side, corresponding to a slide way, of the top end of the base frame. A cooling mechanism is arranged on one side of the abutting block. A cooling water box is welded to the top of the surface of one side of the abutting block. A second air inlet pipe staggered with a first air inlet pipe is arranged on the surface of the outer side of the cooling water box. An air inlet cover is weldedto the top end of a carrying box. A plurality of exhaust pips are inserted in the bottom end of the carrying box in a penetrating mode. A supporting plate is installed at the position, corresponding to the exhaust pipes, of the top in the carrying box. A draught fan is installed in the middle of the supporting plate. The input end of the draught fan is electrically connected with the output end ofan external power supply. Waste and scraps are carried by a drawer and a filter screen to be recycled, polluting substances generated at a high temperature are absorbed through a filtering mechanism,the harm of the waste, scraps and polluting substances to the environment is effectively avoided, and the environmental protection aim is realized.

Owner:浙江埃尔法流体科技有限公司

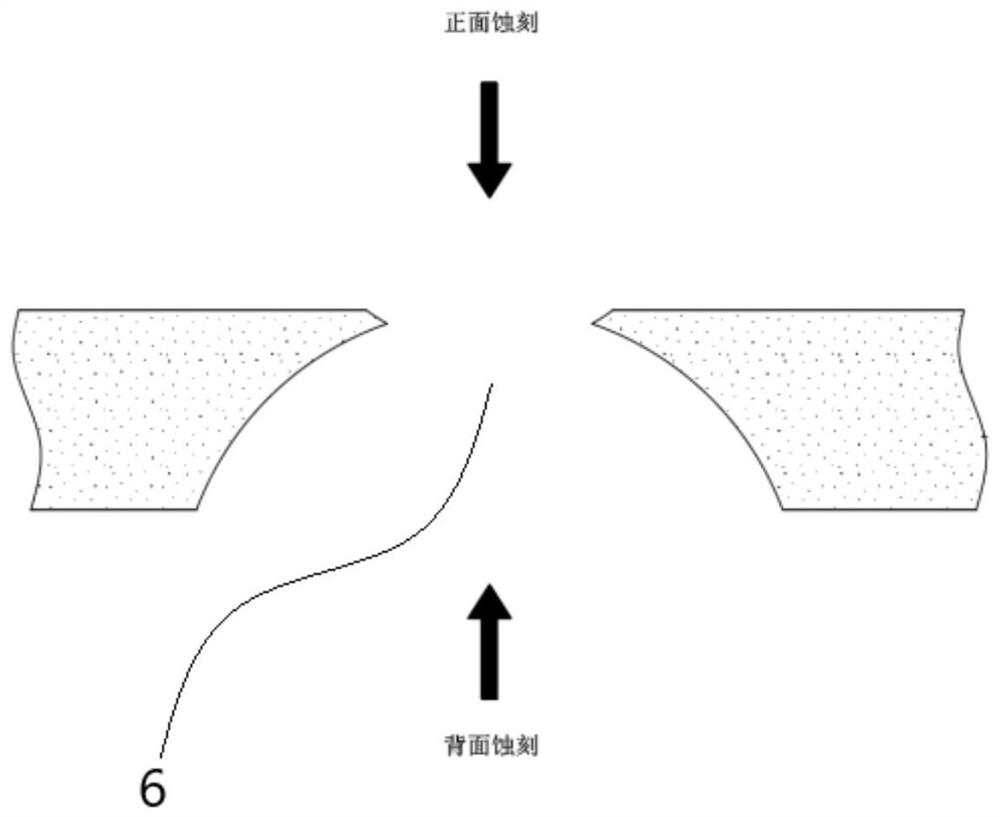

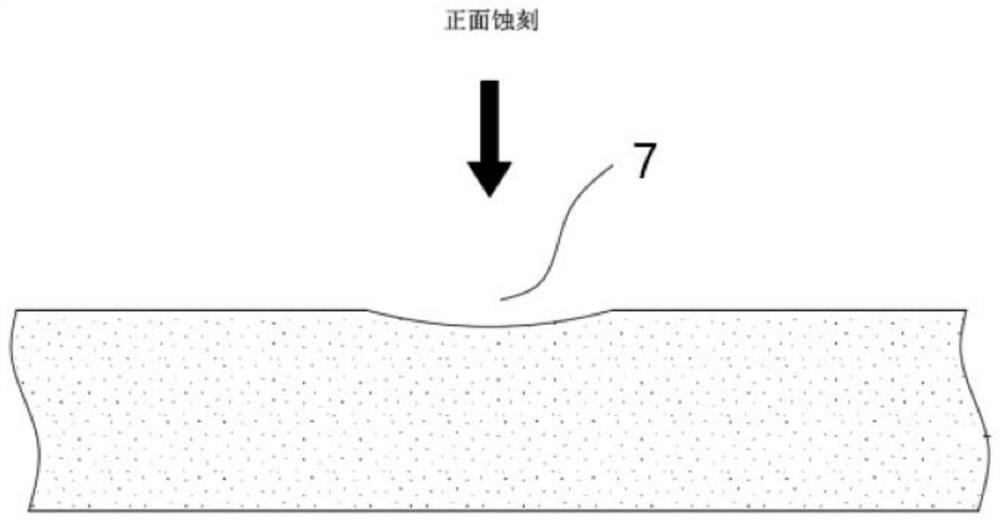

Mask strip structure for special-shaped screen and manufacturing method of mask strip structure

PendingCN114150265AImprove the netting yieldImprove the efficiency of stretching netVacuum evaporation coatingSolid-state devicesColor mixingEtching

The mask strip structure comprises a metal mask strip body, U-shaped grooves with outward openings are formed in the middles of the two ends of the metal mask strip body, and a plurality of sets of etching areas distributed at equal intervals are arranged on the surface of the metal mask strip body. The etching area comprises an effective area which is circularly arranged and a buffer area which is positioned on the outer side of the effective area and is rectangularly arranged. A double-sided etching process is adopted in the effective area, and after double-sided etching is conducted on the metal mask strip body, through holes are formed. A double-face etching and single-face filling technology is adopted in the buffer area, and a groove etched in the front face of the buffer area is filled with a barrier layer of 1-3 microns. According to the metal mask strip, the net stretching yield of the metal mask strip body for the special-shaped screen can be increased, the net stretching efficiency is improved, the phenomenon of uneven stress of the special-shaped screen is relieved through the structure of the metal mask strip body, the wrinkle problem is solved, the color mixing risk is reduced, and the color mixing phenomenon is improved.

Owner:FUJIAN HUAJIACAI CO LTD

Small-sagittal-degree-difference cableway bridge

PendingCN110359356AConsistent vectorReduce the absolute sag differenceSuspension bridgeBridge structural detailsBridge engineeringCable transport

The invention relates to a small-sagittal-degree-difference cableway bridge, and belongs to the field of bridge engineering. According to the cableway bridge, steering pulleys are arranged on an anchorage, two or more adjacent main cables are enabled to be connected with each other, the sagittal degrees of the main cables connected with each other are kept consistent all the time, meanwhile, the absolute deflection difference is reduced by connecting the main cables, the number of the main cables of the whole bridge is reduced by 1 / 2-2 / 3 compared with the number of the main cables of a commoncableway bridge, even the whole bridge is formed by a steel wire rope, so that the absolute sagittal degree difference is reduced, even the deflection is equal, and the stress of the main cable is improved. According to the cableway bridge, the absolute sagittal degree difference of the free main cables can be reduced, a new main cable difference generated in the running period can be automatically coordinated to reduce the absolute sagittal degree difference or eliminate the main cable deflection difference, the deflection difference of the free main cables of the cableway bridge can be effectively improved, the situation of uneven stress between the plurality of main cables can be reduced, and the main cable deflection difference generated in the running process of the cableway bridge can be reduced.

Owner:POWERCHINA CHENGDU ENG

Production process and device of a thin prepreg

The invention discloses a process and a device for producing a thin prepreg. The process comprises the impregnation process; and before the impregnation process, a reinforcing material is arranged on a carrier so that the carrier directly acts on a roll shaft to share the acting force applied by the roll shaft on the reinforcing material. By arranging the reinforcing material on the carrier before the impregnation, the roll shaft can be prevented from being directly contacted with the reinforcing material, the pulling force directly applied from a device to the reinforcing material is effectively reduced, the condition that the reinforcing material is partially stressed unevenly is reduced, the thin reinforcing material is protected particularly, such phenomena as dislocation, shape change and tearing of the thin reinforcing material and the ultrathin prepreg are reduced, and the production efficiency and product percent of pass are improved.

Owner:GUANGDONG SHENGYI SCI TECH

An elevated steel-concrete composite beam

ActiveCN112342899BImprove self-adjusting balance performanceExtended service lifeClimate change adaptationBridge structural detailsConcrete beamsArchitectural engineering

Owner:GUIZHOU ROAD & BRIDGE GRP

Steel-concrete composite beam

ActiveCN112342900AImprove self-adjusting balance performanceAvoid breakageBridge structural detailsGear wheelSupport point

The invention discloses a steel-concrete composite beam which comprises a base, transmission bases are slidably connected to the two sides of the bottom of the inner wall of the base, sliding bases are slidably connected to the sides, away from each other, of the two transmission bases, steel beams are fixedly connected to the tops of the two sliding bases, and the tops of the two steel beams penetrate through the base and extend to the upper portion of the base. By pushing the transmission base on the left side rightwards, teeth in the rectangular groove in the transmission seat also move rightwards along with the transmission seat, so that the gear is driven to rotate, the teeth below the gear are driven to move rightwards, the other transmission seat is driven to move rightwards from the left side of the base, and the supporting point at the bottom of the sliding base on the other side is lowered; the top of the right sliding seat is stressed by the other steel beam and the right side of the concrete plate, so that the right sliding base slides downwards, the two sides of the concrete plate are balanced, the self-adjusting balance performance of the steel-concrete composite beamis improved, the situation that the composite beam is broken due to the fact that one end is stressed to incline is prevented, and the service life of the steel-concrete composite beam is prolonged.

Owner:GUIZHOU ROAD & BRIDGE GRP

Bridge swivel device for traffic construction bridge construction

ActiveCN112796228BEasy to operateReduce uneven stressBridge erection/assemblyPhotovoltaic energy generationArchitectural engineeringSteel frame

The invention provides a bridge swivel device for traffic construction and bridge construction. The bridge swivel device for the construction of the traffic construction bridge includes: an installation platform; four positioning steel bars, and the four positioning steel bars are all fixedly installed on the top of the installation platform; the four positioning steel bars are distributed in a rectangular array; Steel frame, the positioning steel frame is fixedly installed on the four positioning steel bars; the lower plate of the spherical hinge is fixedly installed on the top of the positioning steel frame; the lower ball hinge, the lower ball hinge It is fixedly installed on the top of the lower plate of the ball hinge. The bridge swivel device for traffic construction and bridge construction provided by the present invention has the advantages of simple operation, less uneven stress, and avoiding jamming and the like.

Owner:郑州市公路工程公司

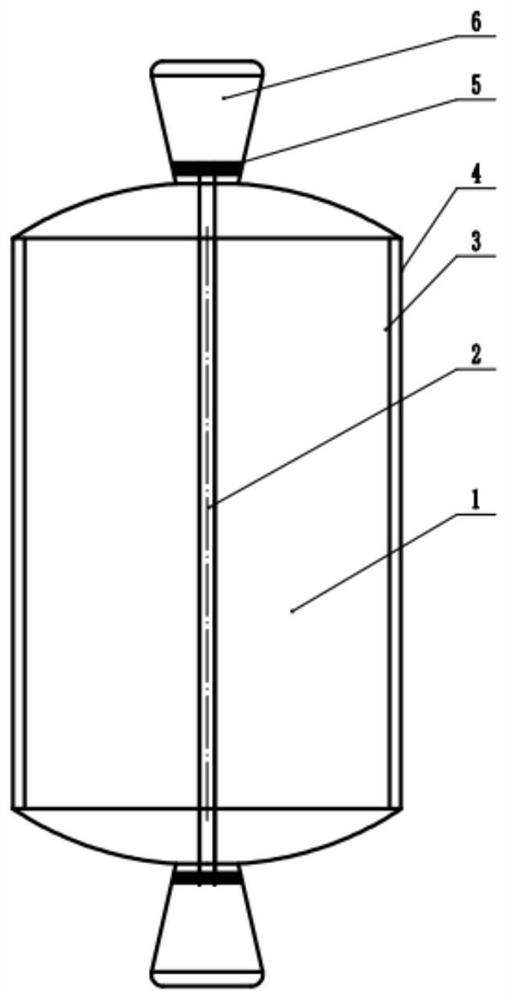

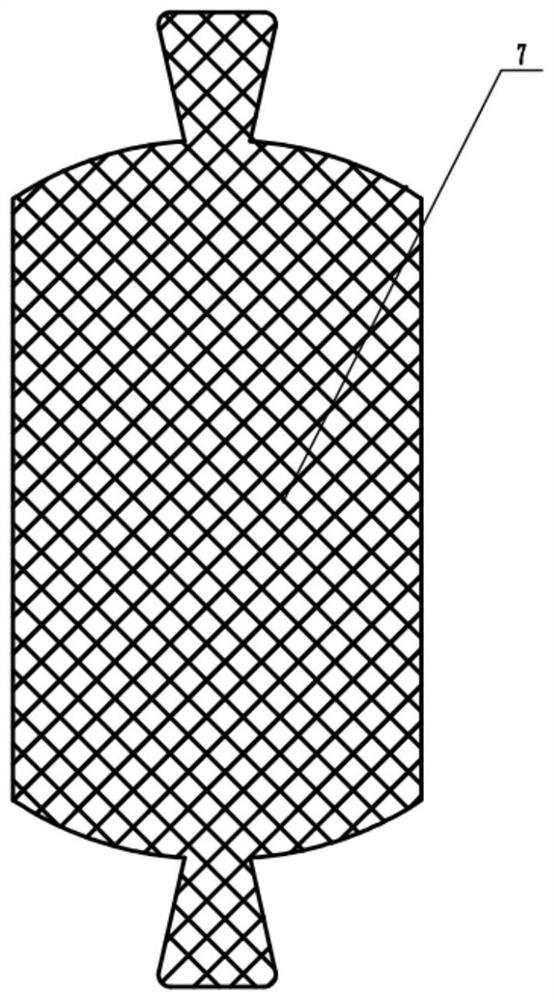

Carbon fiber composite material hydrogen storage tank preformed body weaving forming method

PendingCN114737299AImprove weaving effectReduce uneven stressVessel mounting detailsVessel manufacturingCarbon fiber compositeManufacturing engineering

The invention discloses a carbon fiber composite hydrogen storage tank preformed body weaving forming method. The method comprises the following steps that size design is carried out according to a hydrogen storage tank preformed body, inner layer forward fiber weaving is carried out on the surface of a hydrogen storage tank core mold, then fiber winding is carried out, and reverse fiber weaving is carried out on an outer layer. The weaving process is started from the head of the hydrogen storage tank, weaving is conducted to the tail of the hydrogen storage tank for a stroke, the tail is fixed through an adhesive tape or a ribbon, then weaving is conducted again, fiber winding is conducted after the preset thickness of the inner layer is achieved, and finally reverse weaving is conducted on the wound outer layer. The hydrogen storage tank is preformed in a forward weaving-winding-reverse weaving mode, the phenomenon that fibers of a hydrogen storage tank preformed body are uneven in longitudinal and transverse stress due to single weaving or winding can be avoided, the wrapping performance of the hydrogen storage tank preformed body is improved, meanwhile, raw materials can be saved, and the weaving cost can be reduced.

Owner:云路复合材料(上海)有限公司

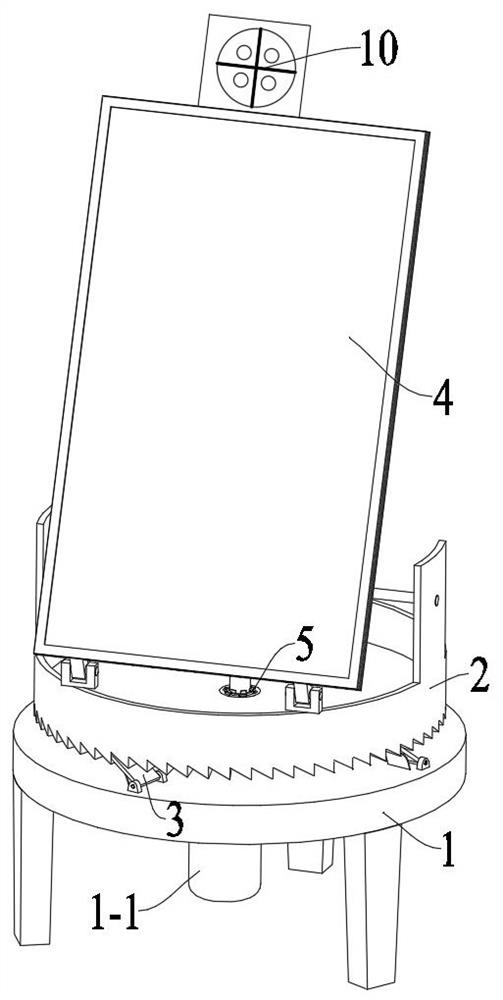

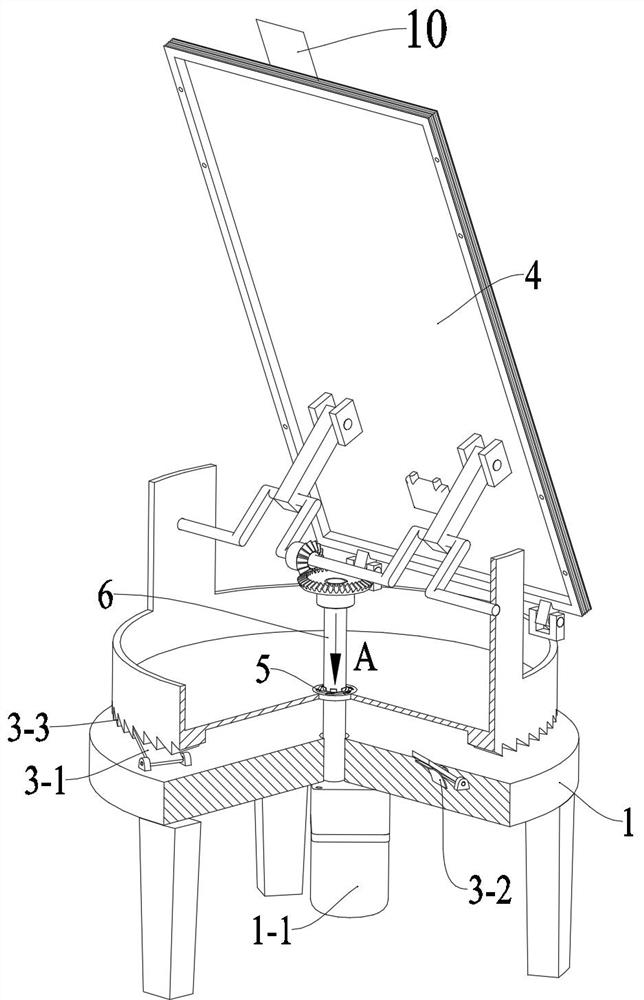

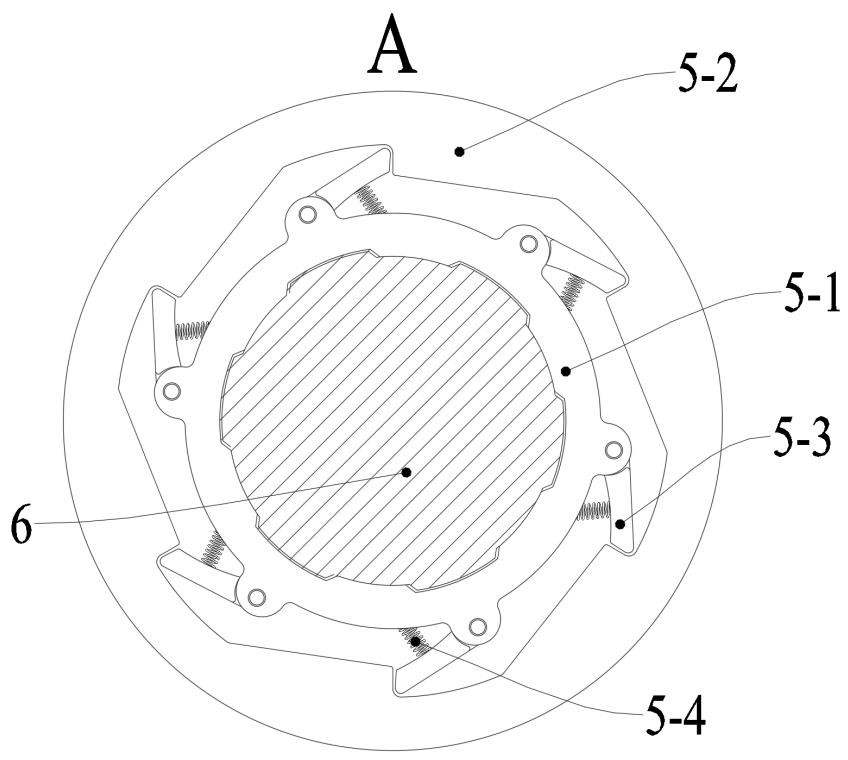

A single-motor two-degree-of-freedom light-following solar heat collector and its heat collection method

ActiveCN112556207BIncrease the total heatSimple structureSolar heating energySolar heat collector controllersElectric machineDrive motor

The invention discloses a single-motor two-degree-of-freedom light-following solar heat collector and a heat collecting method thereof. The solar power generation device includes a base, a revolving disk, a central rotating shaft, a pitch transmission assembly and a solar heat collecting plate. The epicyclic disc is installed on the base, and forms a unidirectional rotating pair with the base. The central rotating shaft and the epicyclic disc form a revolving pair that rotates in one direction. The rotation direction of the epicyclic disk relative to the base is opposite to the rotation direction of the epicyclic disk relative to the central shaft. The central shaft is driven to rotate by a drive motor. One side edge of the solar heat collecting plate is hinged with the turntable. The solar thermal collector plate is connected with the central rotating shaft through a pitch transmission assembly. The pitching transmission assembly converts the one-way rotation of the central shaft relative to the epicyclic disk into the reciprocating and flipping motion of the solar heat collecting plate. The invention realizes the adjustment of the azimuth angle and the elevation angle of the solar heat collecting plate by using the forward rotation and the reverse rotation of the driving motor respectively, so that the solar heat collecting plate always faces the sun.

Owner:HANGZHOU VOCATIONAL & TECHN COLLEGE

Mask strip structure of special-shaped screen and preparation method of mask strip structure

PendingCN114182204AReduce uneven stressGuaranteed odd shapeVacuum evaporation coatingSolid-state devicesStructural engineeringMechanical engineering

Owner:FUJIAN HUAJIACAI CO LTD

An easy-to-operate foreign matter cleaning device for distribution network lines

ActiveCN109616947BEasy to cleanAvoid destructionCleaning processes and apparatusApparatus for overhead lines/cablesForeign matterInsulation layer

Owner:广西电网有限责任公司桂林阳朔供电局

A method for forming a unit panel with at least one single-segment panel edge

ActiveCN108112172BGuaranteed dimensional accuracyReduce uneven stressInsulating layers/substrates workingEngineeringLine segment

Owner:JIANGMEN SUNTAK CIRCUIT TECH

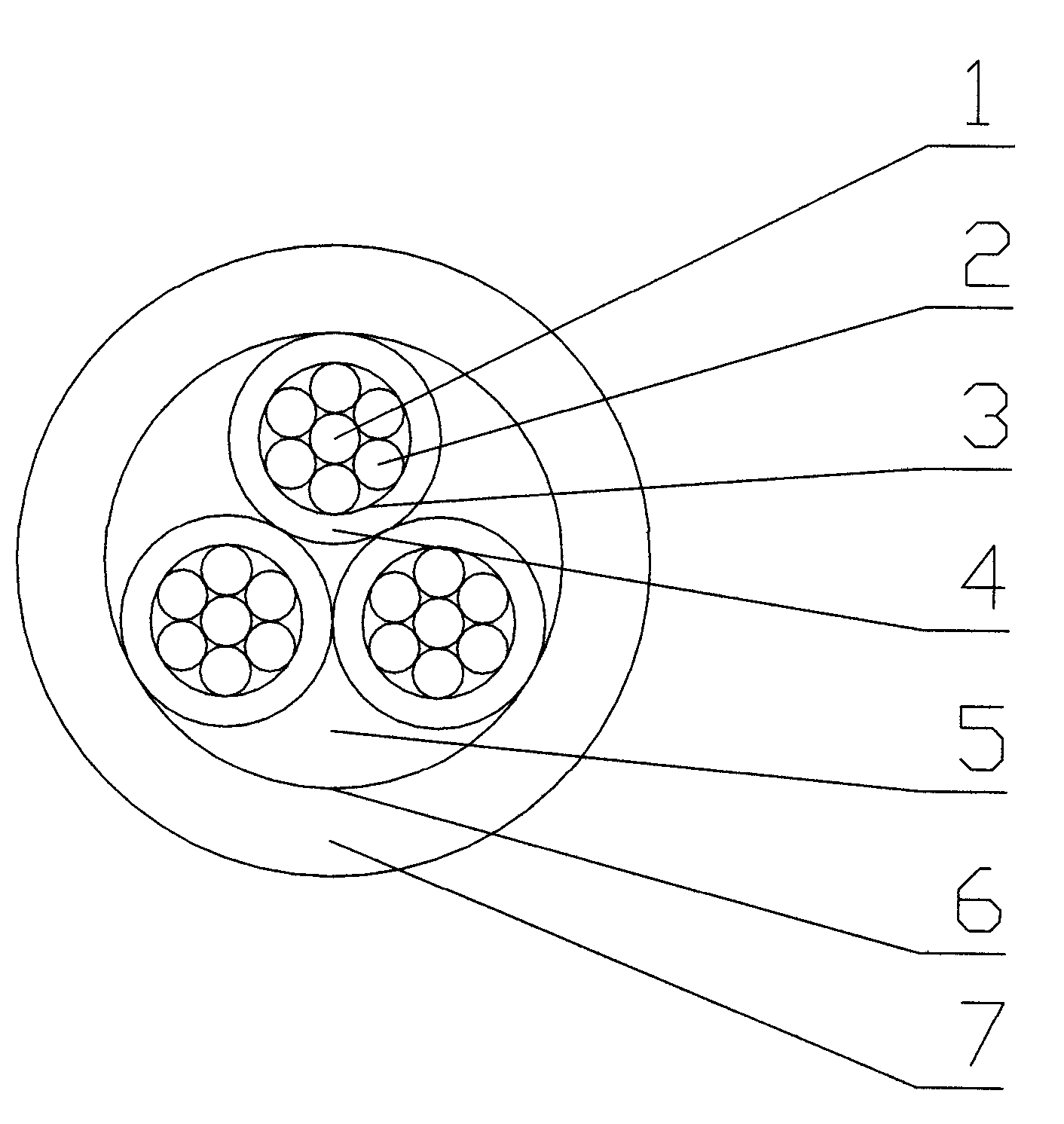

Special cable for buggy ladle

InactiveCN102751007BUnique and stable structureGood workmanshipNon-insulated conductorsInsulated cablesFiberElectrical conductor

The invention discloses a special cable for a buggy ladle. The special cable for the buggy ladle structurally comprises an outer protective casing and a conductor core in the protective casing, wherein the conductor core consists of a tensile resistant strengthening inner core in the middle and a copper bundle wire core at the periphery of the inner core, and the inner core and the copper bundle wire core are stranded together. The tensile resistant strengthening inner core is an inner core made of a carbon fiber material or a galvanized stranded steel core. The special cable for the buggy ladle adopts the tensile resistant strengthening inner core, a four-layer high-temperature protective structure, a tensile resistant material, a high-temperature resistant material and a tear-friction resistant material. Due to a unique structure, reasonable materials and a scientific process, the tensile resistance, temperature resistance level and tear-friction resistance of the cable are greatly enhanced, the safety and stability of the operation of the cable are improved, the service life of the cable is prolonged, the working efficiency and the product quality are effectively improved, and energy resources are saved.

Owner:LIAONING SULI WIRE & CABLE

Fender device with buffering material and ship

ActiveCN113548159APlay a buffer roleGuaranteed cushioning effectVessel cleaningClimate change adaptationFenderMarine engineering

The invention relates to the technical field of ships and discloses a fender device with a buffering material and a ship. The fender device with the buffering material comprises the fender material, a first connecting plate and a buffering sealing plate, wherein the fender material comprises a fender plate and two side plates, the two side plates are connected to two ends, in the width direction, of the fender plate in an angle mode respectively, and the two side plates extend towards the same side of the fender plate; the first connecting plates are parallel to the fender plate, ends, away from the fender plate, of the side plates are connected to the first connecting plates correspondingly, the buffering sealing plate is arranged between the two side plates and located on the sides, facing the fender plate, of the first connecting plates, and two sides of the buffering sealing plate are connected to the two side plates correspondingly, so a containing space is formed between the buffering sealing plate and the fender material; and the accommodating space is filled with an elastic medium. The protection effect of the fender device on the broadside outer plate is guaranteed, the service life of the broadside outer plate and the service life of the fender device with the buffering material are guaranteed, and maintenance cost is reduced.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com