Fender device with buffering material and ship

A technology of cushioning materials and fenders, which is applied in the field of ships, can solve problems such as deformation of side shells, short service life, and increased maintenance costs, and achieve the effects of reducing deformation, ensuring service life, and ensuring protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

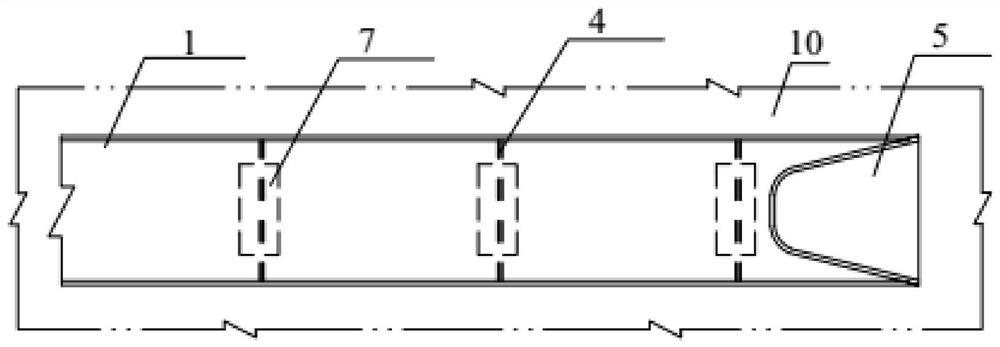

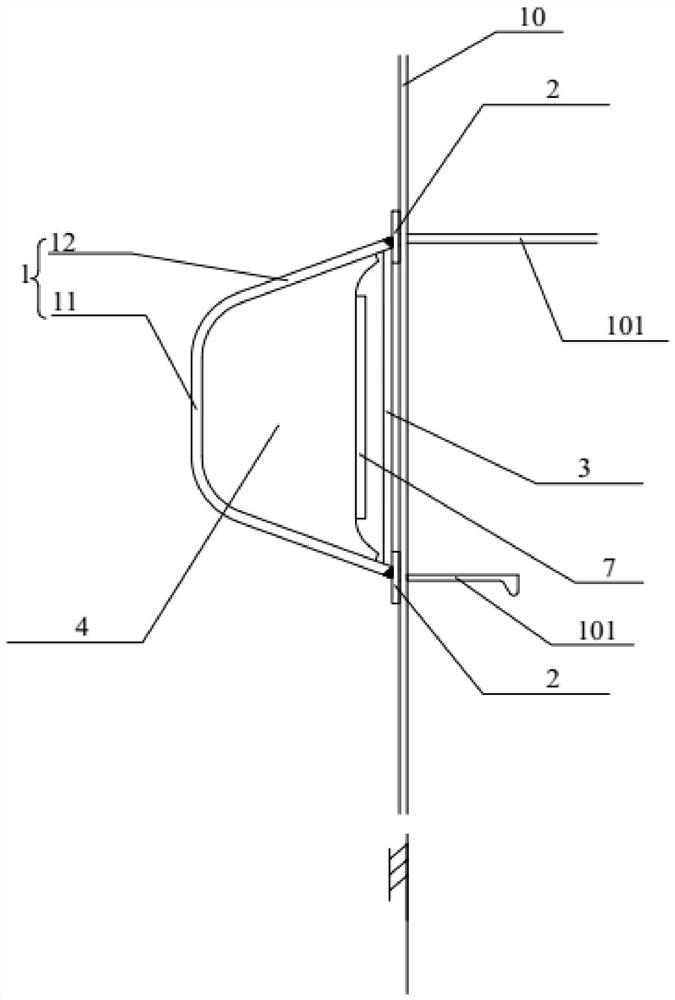

[0036] This embodiment provides a fender with a buffer material, such as Figure 1-Figure 3 shown. Specifically, the fender device with cushioning material includes: a fender 1 , a first connecting plate 2 and a buffer sealing plate 3 . The fender 1 includes a fender 11 and two side plates 12, the two side plates 12 are respectively connected to the two ends of the fender 11 along the width direction at an angle, and the two side plates 12 are all facing the same side of the fender 11. Side extension; the first connecting plate 2 is parallel to the fender 11, the ends of the side plates 12 away from the fender 11 are respectively connected to a first connecting plate 2, and the buffer sealing plate 3 is placed between the two side plates 12 and located The first connecting plate 2 faces the side of the fender 11, and the two sides of the buffer sealing plate 3 are respectively connected to the two side plates 12, so that a storage space is formed between the buffer sealing pl...

Embodiment 2

[0057] This embodiment provides a fender device and a ship with buffer materials, and compared with Embodiment 1, the structure provided by this embodiment is basically the same as Embodiment 1, only the structure of the buffer seal 3 is different. The embodiment does not repeat the same structure as that of the first embodiment.

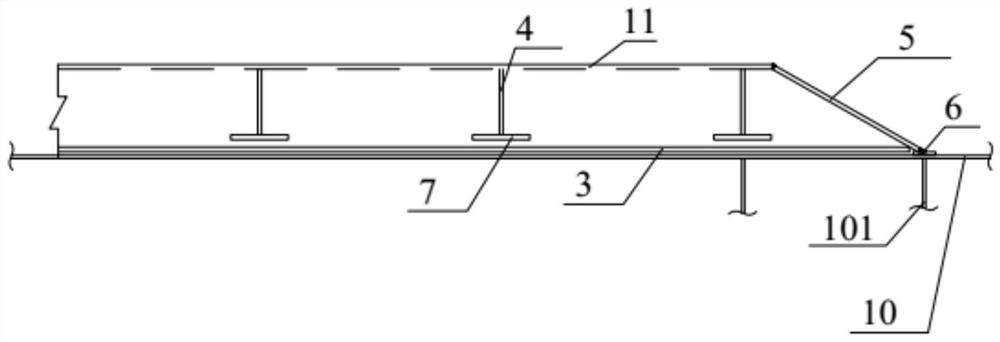

[0058] Such as Figure 4 and Figure 5 As shown, preferably, multiple reinforcing plates 4 and buffer sealing plates 3 are provided along the length direction of the fender 1, the reinforcing plates 4 and the buffer sealing plates 3 are arranged alternately, and the two ends of the buffer sealing plates 3 are respectively connected to the corresponding Two adjacent reinforcing plates 4, so that the buffer sealing plate 3, the fender 1 and the two adjacent reinforcing plates 4 form an accommodation space, the reinforcing plate 4 itself can improve the structural strength of the fender device, and then the buffer The two ends of the sealing plate 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com