Small-sagittal-degree-difference cableway bridge

A technology of vector and main cable, applied in the direction of suspension bridge, bridge, bridge construction, etc., can solve the problems of high cost, difficult to control the sag accuracy of the main cable of the air cable, and long construction period, so as to reduce the uneven stress and improve the The main cable stress and the effect of reducing the difference of the main cable sag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

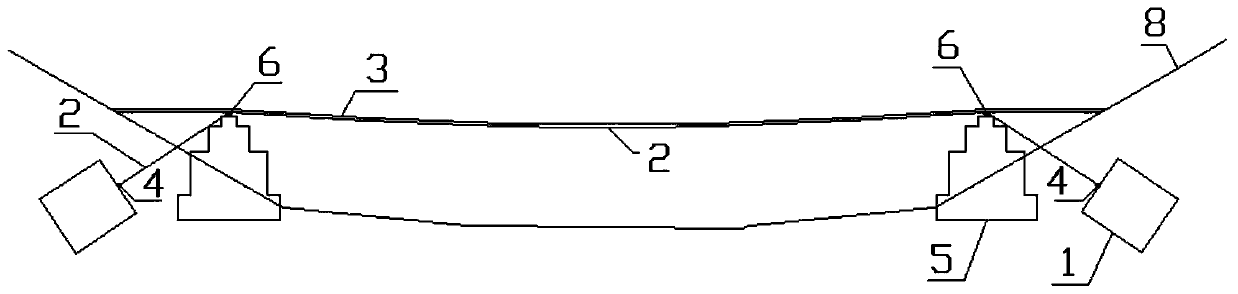

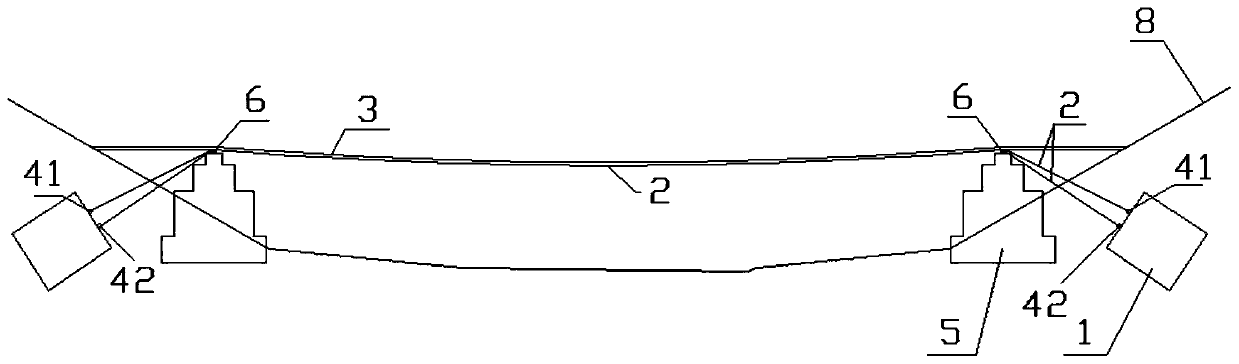

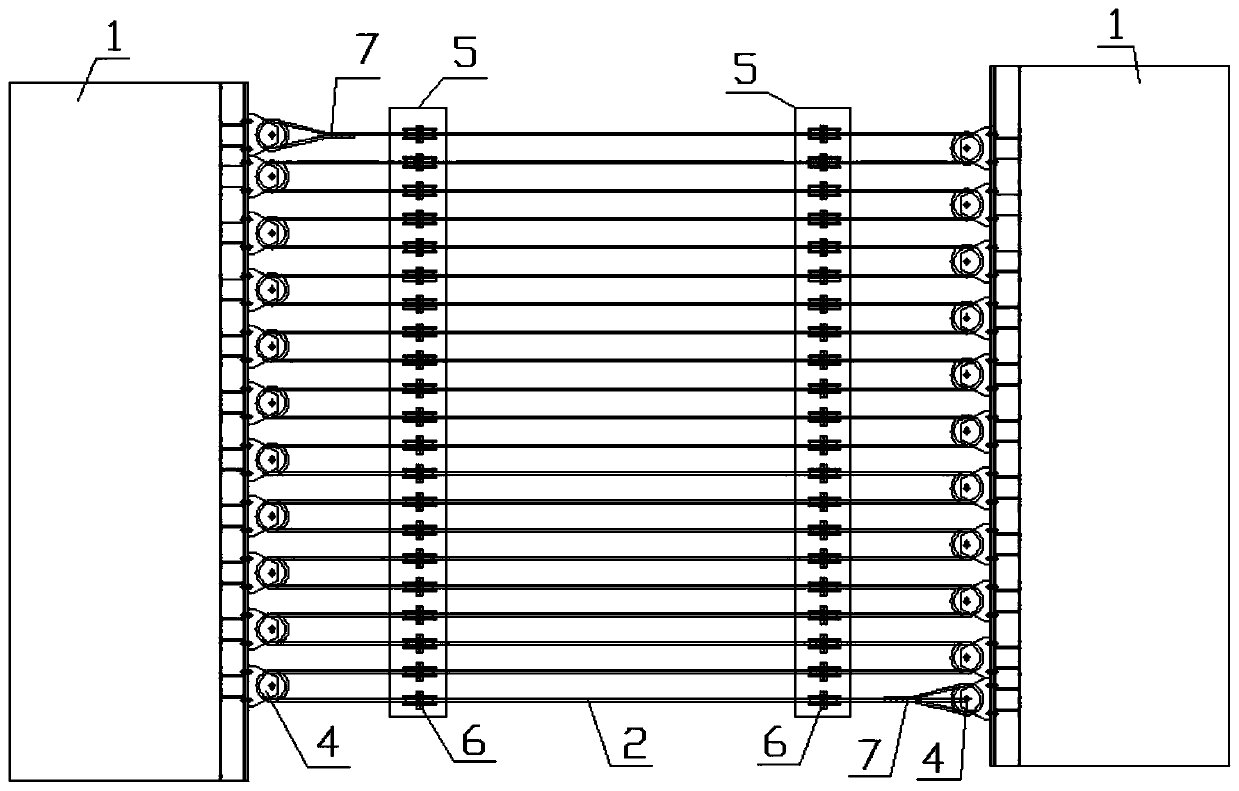

[0028] like figure 1 and image 3 As shown, the present invention includes anchorages 1 arranged on both banks of the river, and bridge abutments 5 are respectively arranged inside the anchorages 1 on both sides of the river, the main cable 2 is laid between the anchorages 1, and the top of the abutment 5 is provided with an abutment 5 corresponding to the main cable 2. Adapted cable saddle 6, the bridge deck 3 is laid on the main cable 2, and the pulley 4 is fixedly installed on the inner side of the anchorage 1. The pulleys 4 are arranged in a row along the width direction of the bridge deck, and the main cable 2 is between the pulleys 4 of the two anchorages 1. Pass through in sequence to form an S-shaped layout structure, and the ends of the main cables 2 are fixed. The main cable 2 can be set as one as a whole, or can be set as several after bein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com