Self-anchored hybrid beam cable-stayed suspension cooperative system bridge

A hybrid beam and self-anchored technology, which is applied in the direction of cable-stayed bridges, suspension bridges, bridges, etc., can solve the problems of high engineering cost, huge ground anchors, and difficult construction, so as to achieve multiple construction work areas, reduce risks, and make construction difficult low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

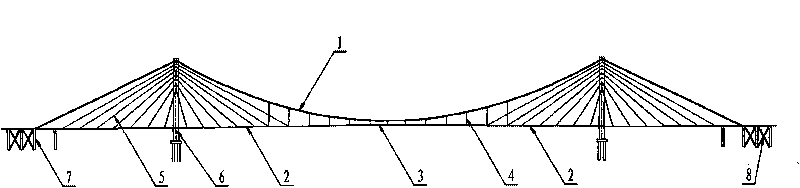

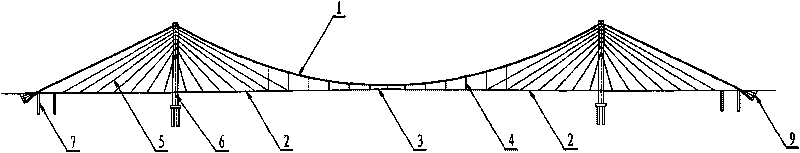

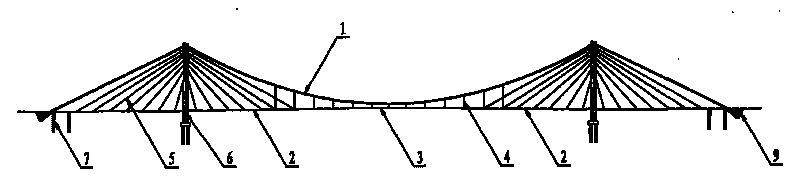

[0025] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

[0026] After the main girder of the cable-stayed bridge is assembled in place, the main cable is suspended, and the main cable is anchored on the anchor block at the end of the concrete beam, and the anchor block is anchored on the temporary anchoring structure through the temporary anchor cable. The middle steel box girder is hoisted. After the main girder is closed, the system conversion is completed to form a permanent self-anchored system, and then the cable force of the whole bridge is adjusted.

[0027] Main girder section: part of the main girder of the cable-stayed bridge adopts concrete box section, and part of the suspension bridge adopts steel box girder section.

[0028] Material properties: C50 concrete is used for part of the main girder and wet joints of the cable-stayed bridge, and C30 concrete is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com