High formwork system and construction method thereof

A construction method and high-support formwork technology, which is applied in the connection of formwork/formwork/work frame, preparation of building components on site, construction, etc., can solve the problem of long time spent and difficult formwork unit formwork unit Alignment and other issues to achieve the effect of increasing stability, reducing the time spent on adjustment, and broadening the market prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

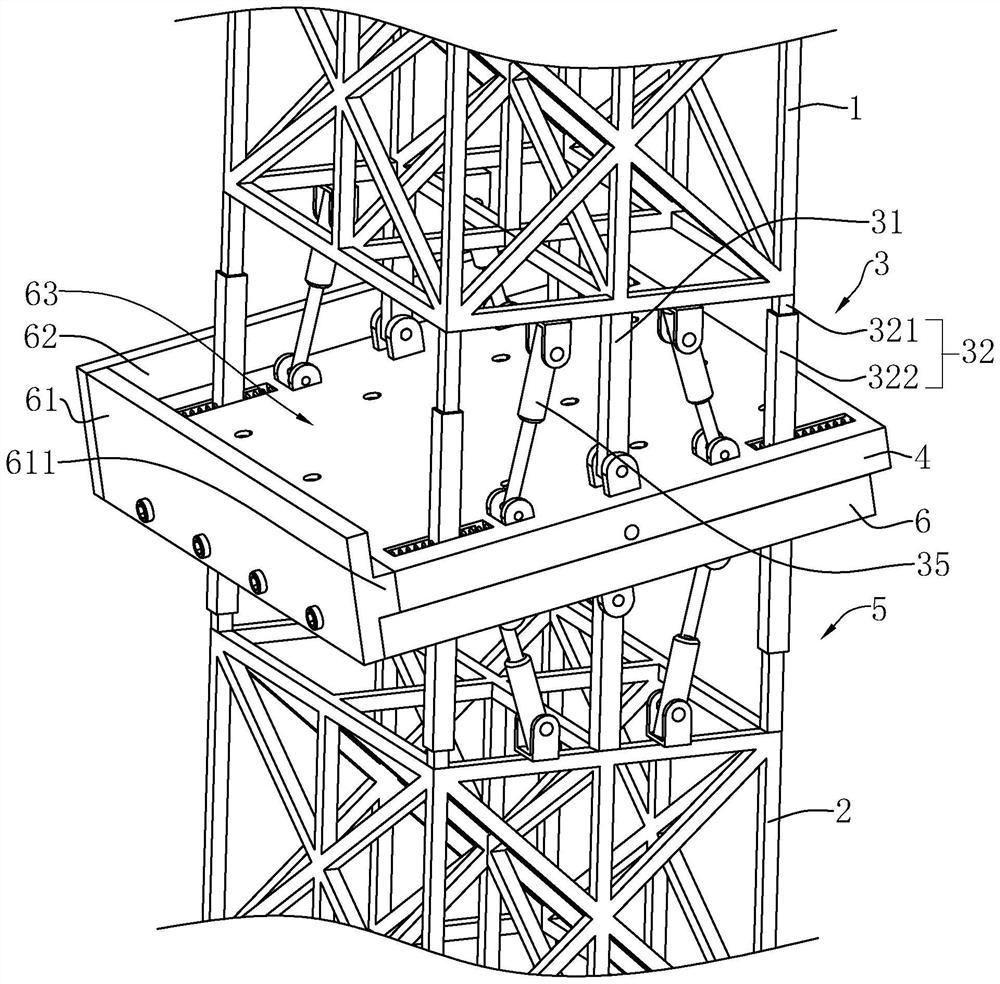

[0040] The following is attached Figure 1-4 The application is described in further detail.

[0041] The embodiment of the application discloses a high-support formwork system and a construction method thereof.

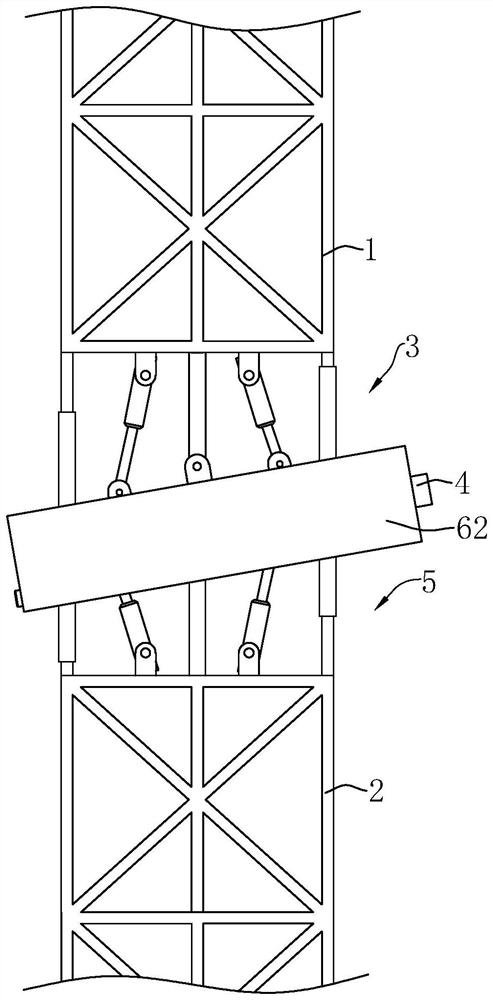

[0042] refer to figure 1 , a high-support formwork system, including a plurality of formwork units arranged vertically in sequence, and any two vertically adjacent formwork units are provided with a connecting mechanism for connecting the two formwork units.

[0043] The formwork unit includes a plurality of longitudinal beams arranged in a rectangular array, cross beams and braces fixed between the longitudinal beams.

[0044] Among the two vertically adjacent formwork units, the upper formwork unit is the upper formwork unit 1 , and the lower formwork unit is the lower formwork unit 2 .

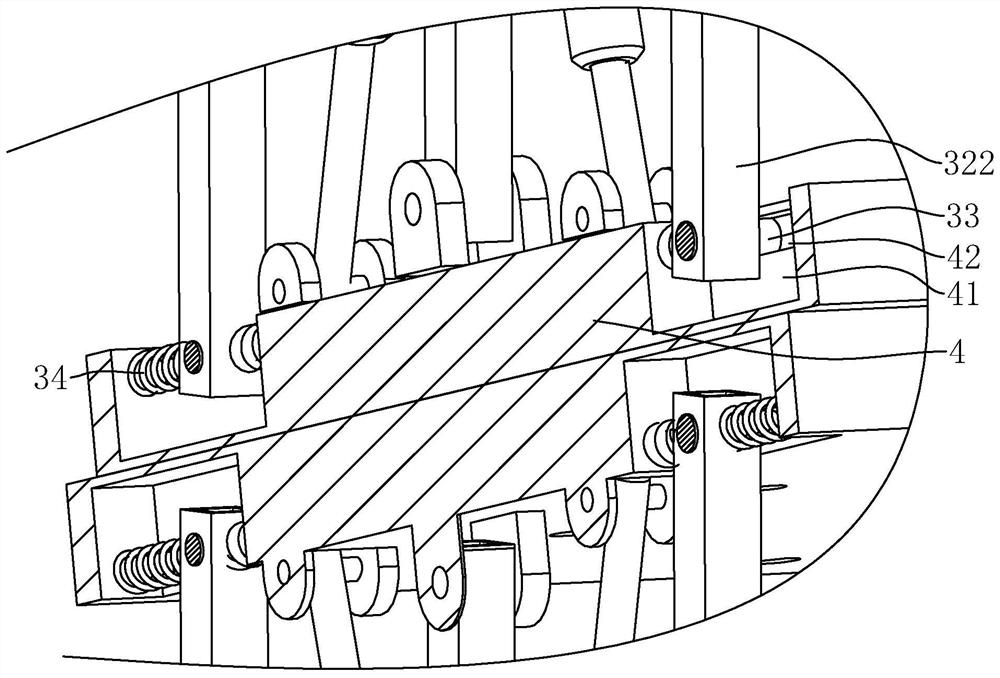

[0045] combine figure 1 and figure 2, the connection mechanism includes an upper connection plate 4 connected to the bottom of the upper formwork unit 1 by an upper connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com