A method for forming a unit panel with at least one single-segment panel edge

A molding method and unit board technology, which is applied in the processing of electrical components, insulating substrates/layers, printed circuits, etc., can solve problems such as size deviation and affecting the quality of finished products, and achieve the effect of reducing concave-convex positions and ensuring dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

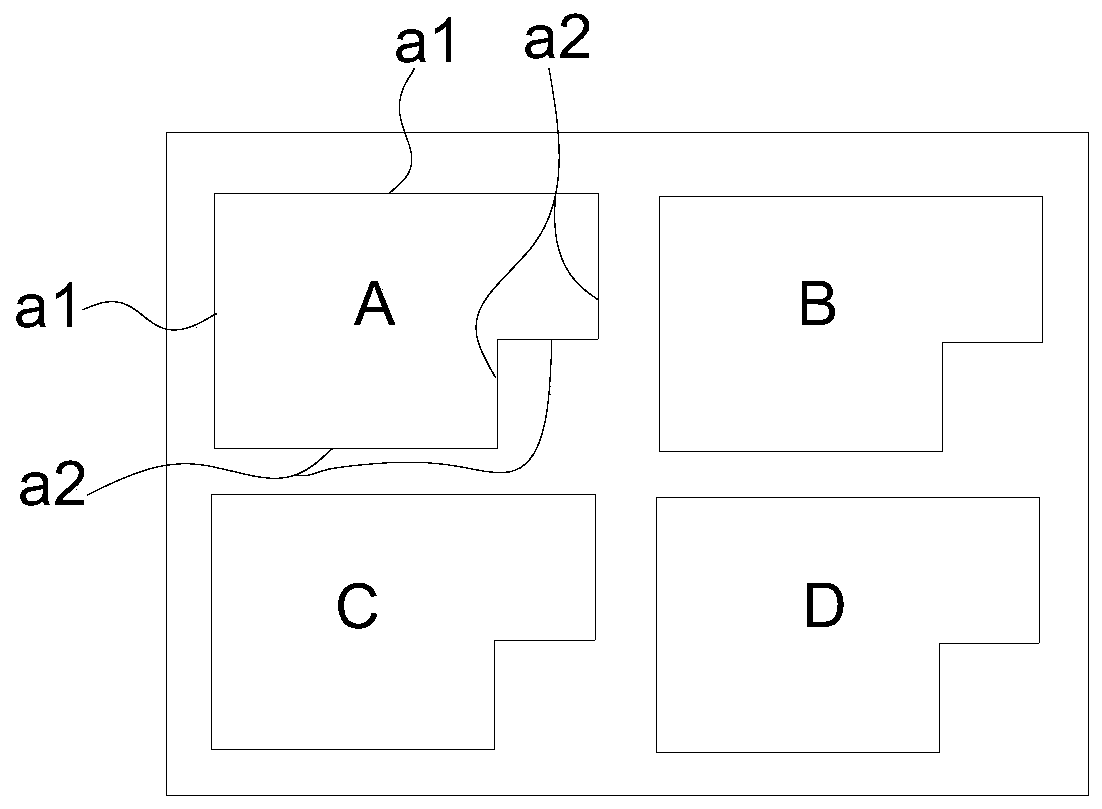

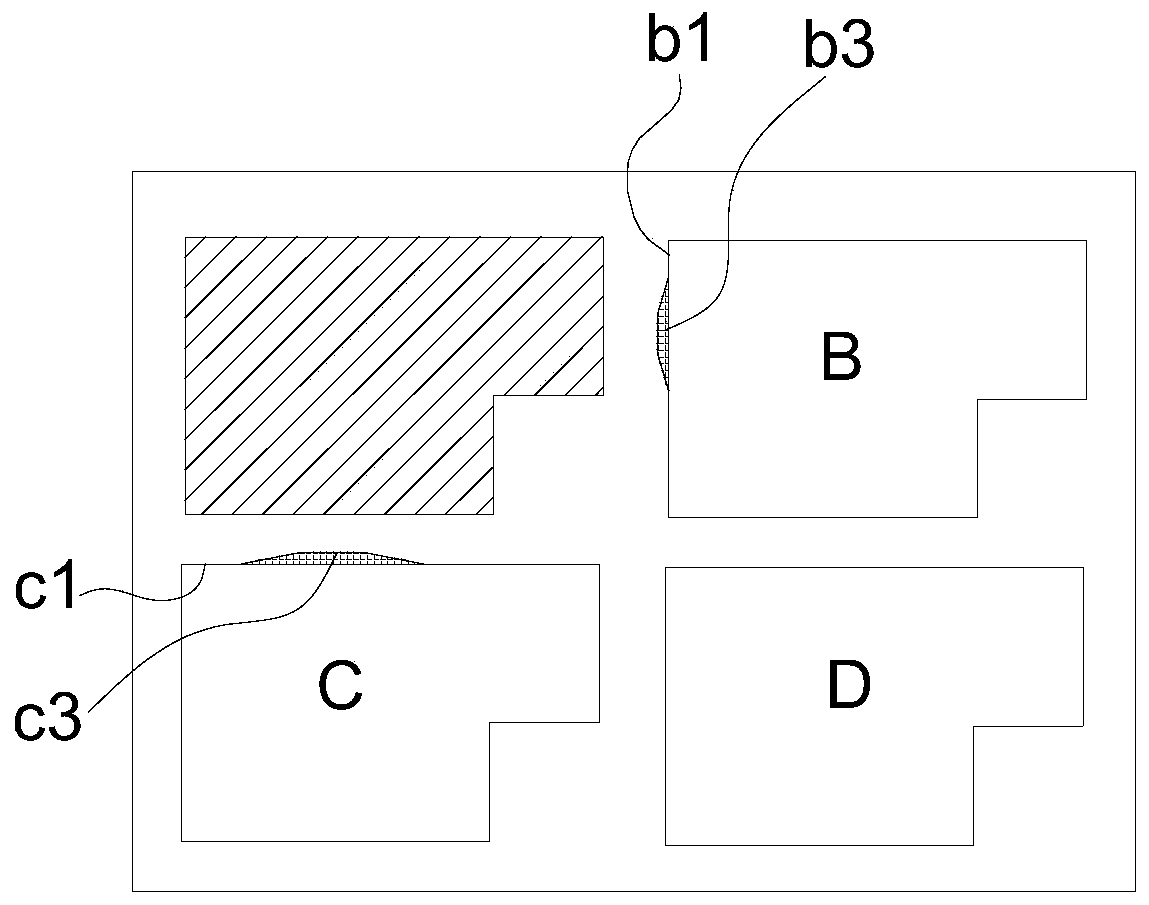

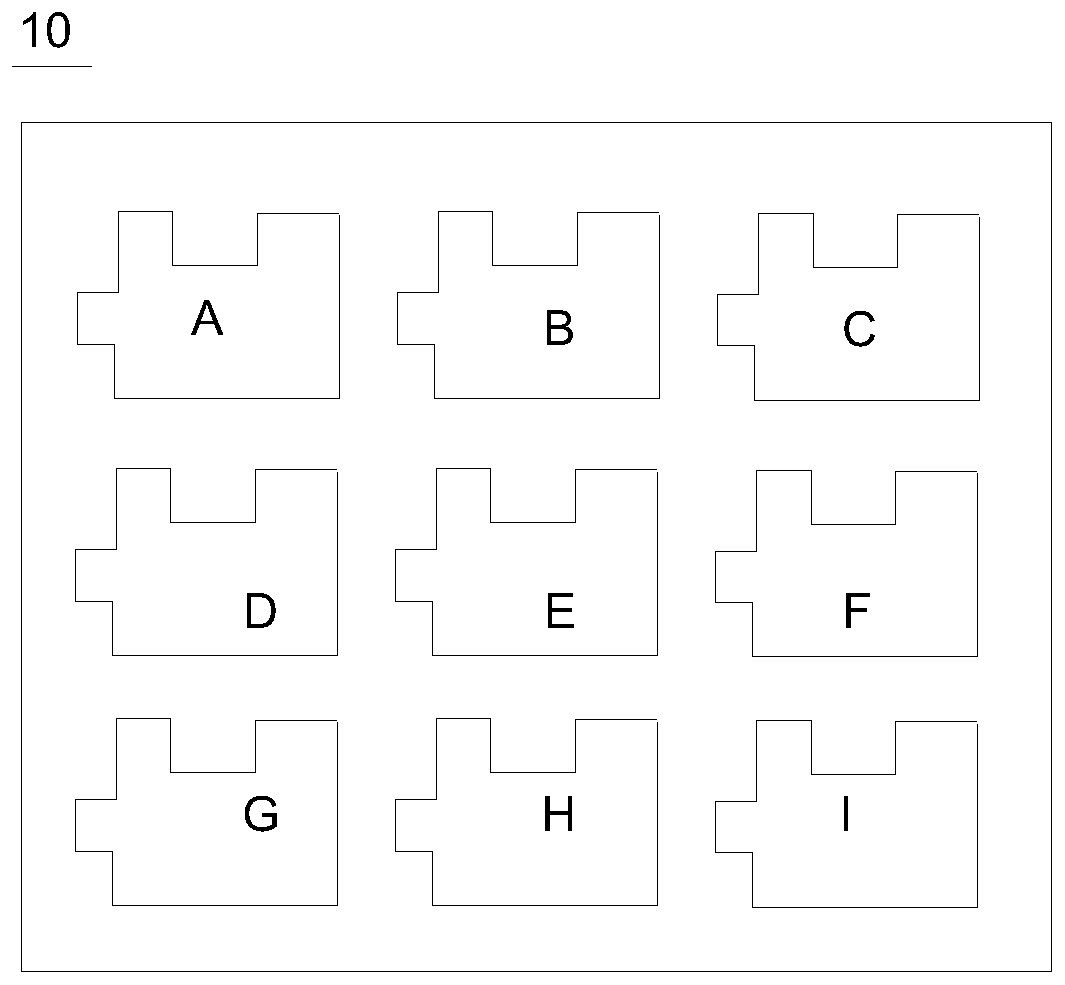

[0018] refer to image 3 As shown, this embodiment provides a method for forming a unit plate with a single-segment plate edge. The unit plate with a single-line segment plate edge refers to the unit plate edges in four directions of the unit plate, one direction The one-unit plate edge is a single-segment plate edge, and the three-unit plate edges in the other three directions are all multi-line segment plate edges. The jigsaw shown in this embodiment has nine identical unit boards (A, B, C, D, E, F, G, H, I) arranged in a matrix on the jigsaw board, and the nine unit boards constitute cell board array. Cut along the edge of the unit board on the jigsaw board, so that each unit board on the jigsaw board is separated and independent. The order of cutting the unit boards out of the jigsaw one by one is as follows:

[0019] (1) First cut the unit board on the jigsaw board that is located on the outer periphery of the unit board array and at the corner of the unit board array....

Embodiment 2

[0027] refer to Figure 4 As shown, the present embodiment provides a method for forming a unit panel with two single-segment panel edges. The unit panel with two single-line segment panel edges refers to the unit panel edges in four directions of the unit panel, two The two unit plate edges in one direction are single-segment plate edges, and the two unit plate edges in the other two directions are multi-line segment plate edges. The jigsaw shown in this embodiment has nine identical unit boards (A, B, C, D, E, F, G, H, I) arranged in a matrix on the jigsaw board, and the nine unit boards constitute cell board array. Cut along the edge of the unit board on the jigsaw board, so that each unit board on the jigsaw board is separated and independent. The order of cutting the unit boards out of the jigsaw one by one is as follows:

[0028] (1) First cut the unit board on the jigsaw board that is located on the outer periphery of the unit board array and at the corner of the uni...

Embodiment 3

[0038] refer to Figure 5 As shown, the present embodiment provides a method for forming a unit panel with three single-segment panel edges. The unit panel with three single-segment panel edges refers to the unit panel edges in four directions of the unit panel, three The three-unit plate edges in one direction are single-segment plate edges, and the unit plate edges in the other direction are multi-line segment plate edges. The jigsaw shown in this embodiment has nine identical unit boards (A, B, C, D, E, F, G, H, I) arranged in a matrix on the jigsaw board, and the nine unit boards constitute cell board array. Cut along the edge of the unit board on the jigsaw board, so that each unit board on the jigsaw board is separated and independent. The order of cutting the unit boards out of the jigsaw one by one is as follows:

[0039] (1) First cut the unit board on the jigsaw board that is located on the outer periphery of the unit board array and at the corner of the unit boar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com