Production process and device of a thin prepreg

A technology of prepreg and production process, which is applied in the field of copper clad laminates, can solve the problems of low pass rate and low production efficiency of ultra-thin prepreg, and achieve the effects of saving materials, reducing uneven stress, and ensuring production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

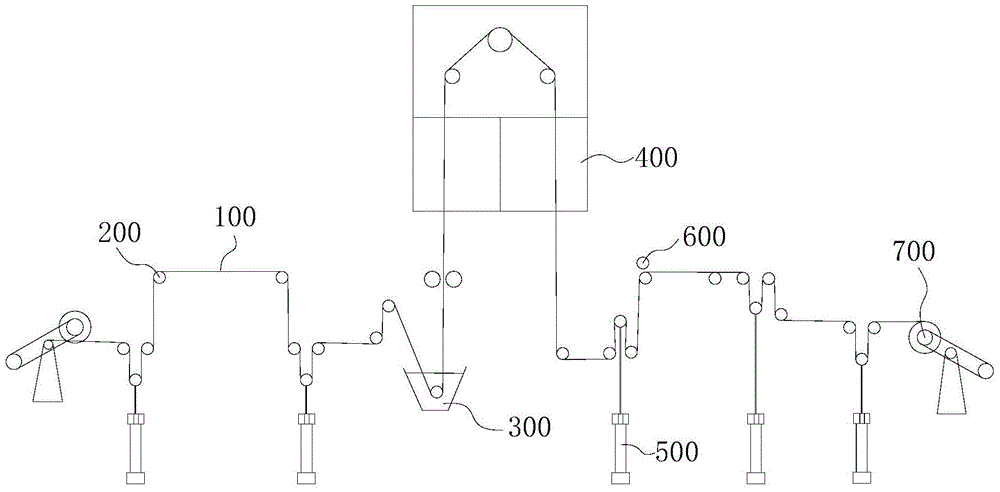

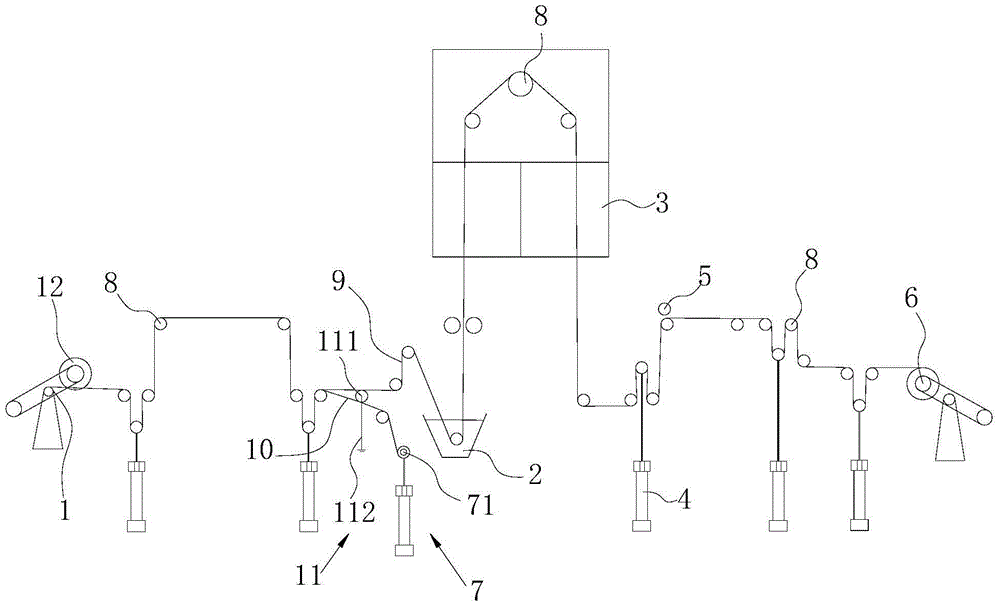

[0049] Such as figure 2 As shown, the embodiment of the present invention provides a kind of production device of thin prepreg, and it comprises sending unit 1, glue tank 2, oven 3, cooling device 4, edge cutting device 5 and winding device 6 arranged in sequence, in the glue tank 2 and the sending unit 1 and on the side adjacent to the glue tank 2, a film separation and recovery device 7 is set, and a composite coil 12 is arranged on the sending unit 1, and the composite coil 12 is a composite of a reinforced film 10 and a reinforced material 9, namely One side of the reinforcing material 9 is lined with a layer of reinforcing film 10. After the composite roll 12 is unrolled, it is sent to the side of the glue tank 2 through the roller 8, and the end of the reinforcing film 10 away from the sending unit 1 is wound on the film separation On the recovery roller 71 of the recovery device 7 , the end of the reinforcing material 9 away from the sending unit 1 is sent into the glu...

Embodiment 2

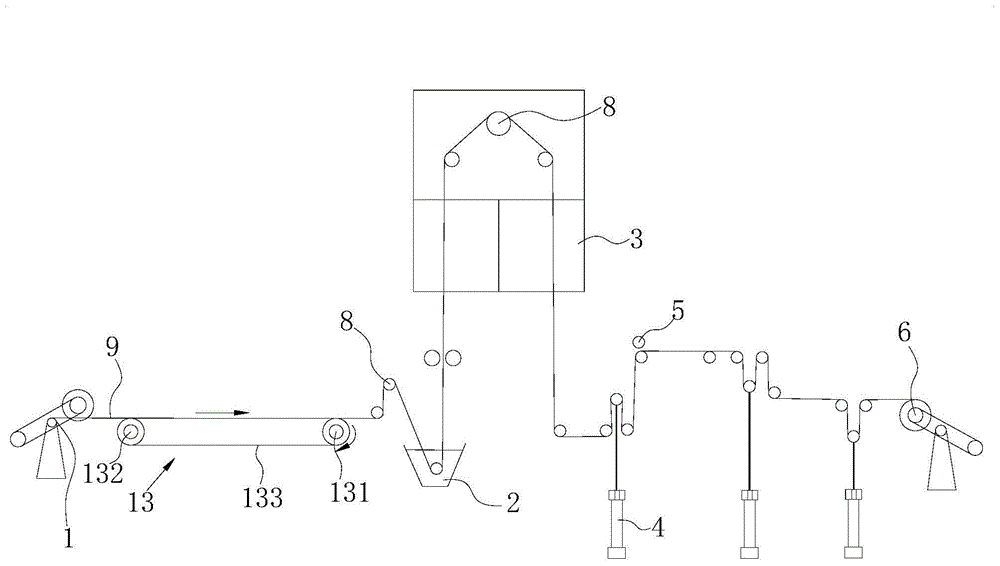

[0063] Such as image 3 As shown, the embodiment of the present invention provides a kind of production device of thin prepreg, and it comprises sending unit 1, glue tank 2, oven 3, cooling device 4, edge cutting device 5 and winding device 6 arranged in sequence, in the glue tank 2 and the sending unit 1 are provided with a traction device, the traction device is an endless conveyor belt 13, and the endless conveyor belt 13 is driven by a power device to perform uniform circular motion.

[0064] Specifically, the endless conveyor belt 13 includes a driving wheel 131, a driven wheel 132, and a conveyor belt 133 arranged on the driving wheel 131 and the driven wheel 132. The conveyor belt 133 circulates under the action of the driving wheel 131 and the driven wheel 132. The power device is connected to realize uniform rotation around its own axis through the power device.

[0065] In the present embodiment, reinforcing material 9 is glass fiber cloth, and the unit weight of gl...

Embodiment 3

[0075] The structure of this embodiment is basically the same as that of Embodiment 2. The only difference is that the traction device used in Embodiment 3 is a transmission steel wire. This traction device includes two transmission steel wires that are parallel to each other. The transmission steel wire is moved from the sending unit toward the glue tank at a constant speed, and the reinforcing material is fixed on the transmission steel wire through a fixing member. In this embodiment, the fixing member is a fixing clip.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com