A single-motor two-degree-of-freedom light-following solar heat collector and its heat collection method

A technology of solar heat collecting plate and solar heat, which is applied in the field of solar heat collecting, can solve the problems of complicated equipment and inconvenientness, and achieve the effects of stable light tracking, simple structure, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

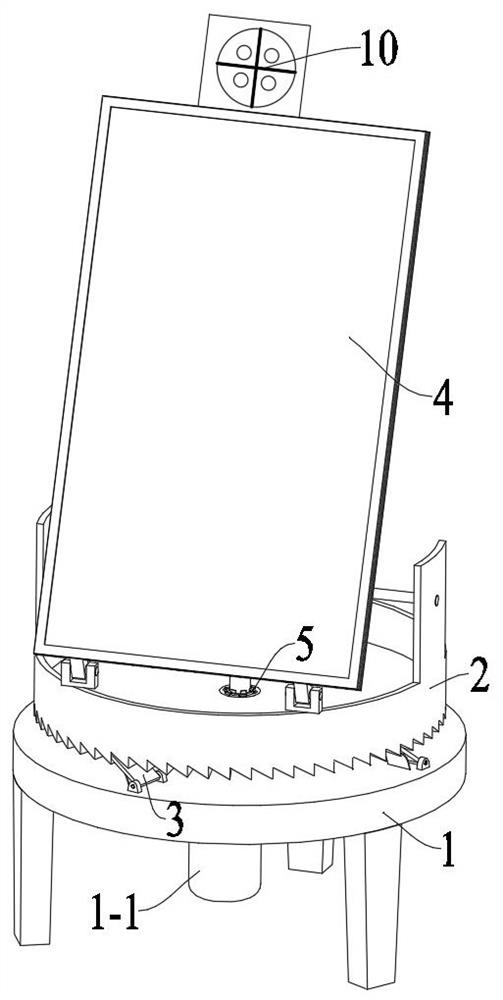

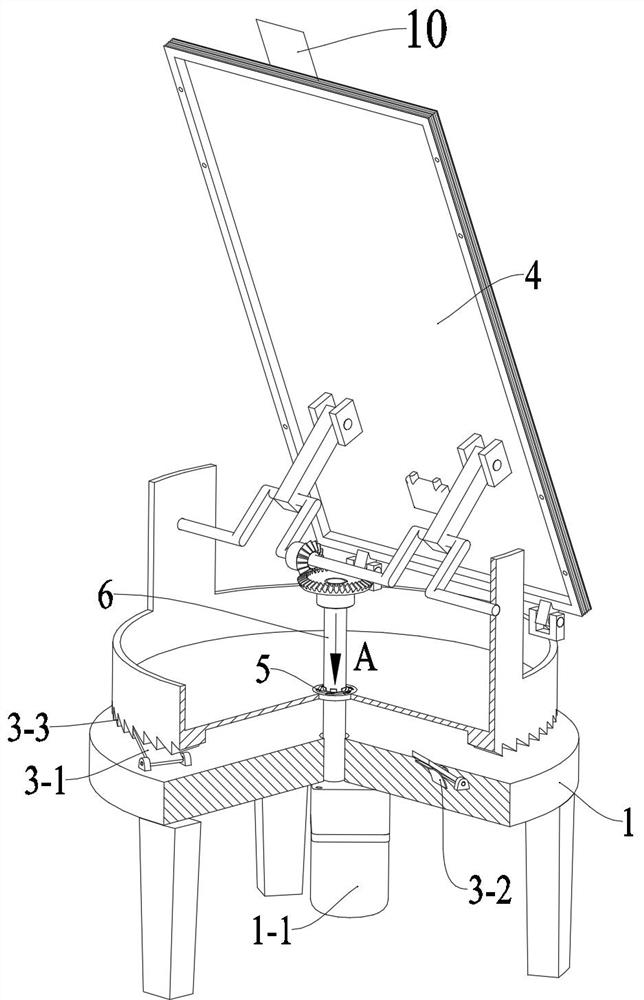

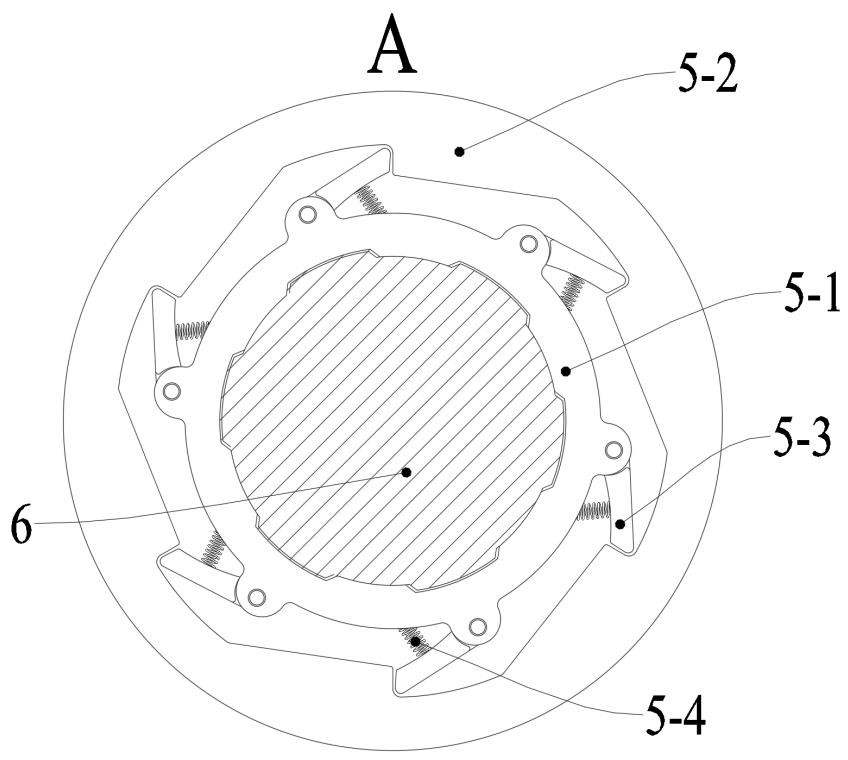

[0034] Such as figure 1 and 2 As shown, a single-motor two-degree-of-freedom light-following solar thermal collector includes a base 1, a driving motor 1-1, a revolving disk 2, a first ratchet and pawl mechanism 3, a second ratchet and pawl mechanism 5, and a central shaft 6. Pitch transmission assembly, solar heat collector plate 4, light tracking detection module 10 and controller. The driving motor 1-1 is connected to the controller through a motor driver. The light intensity sensor in the light tracking detection module 10 is connected to the controller.

[0035]The epicyclic disk 2 is installed above the base 1, and forms a rotating pair with the base 1 through a thrust bearing, which is vertically arranged with a common axis. A first ratchet and pawl mechanism 3 is arranged between the turntable 2 and the base 1 so that the turntable 2 and the base 1 can only rotate in one direction. The vertically arranged central rotating shaft 6 and the base 1 form a revolving pai...

Embodiment 2

[0051] The difference between this embodiment and Embodiment 1 is that two one-way bearings are used to replace the first ratchet and pawl mechanism 3 and the second ratchet and pawl mechanism 5 respectively; thus, the forward and reverse rotation of the drive motor can be realized respectively to realize the solar thermal collector plate Adjustment of pitch angle and azimuth angle.

Embodiment 3

[0053] The difference between this embodiment and Embodiment 1 is that a speed reducer is added between the driving motor and the central rotating shaft to further improve the precision of light tracking.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com