An integrated motor reduction drive system for helicopter empennage

A drive system and helicopter technology, applied in the field of helicopters, can solve problems such as difficult installation and maintenance, large vibration and noise, and large energy loss, and achieve the effects of ensuring stable operation, increasing power-to-weight ratio, and high-stable motor control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

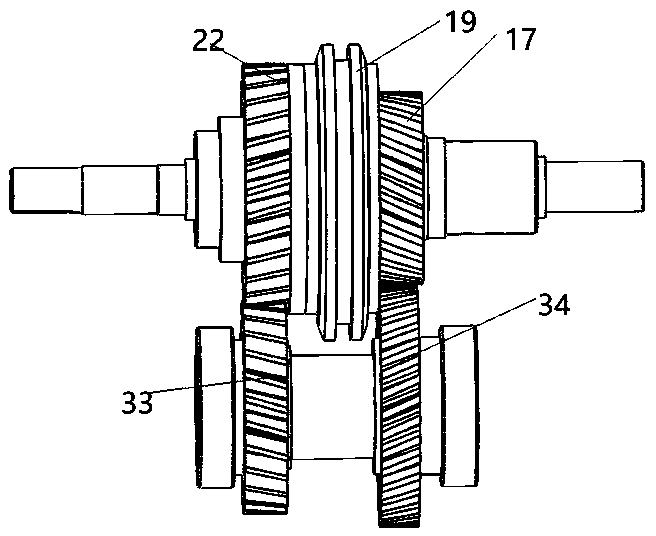

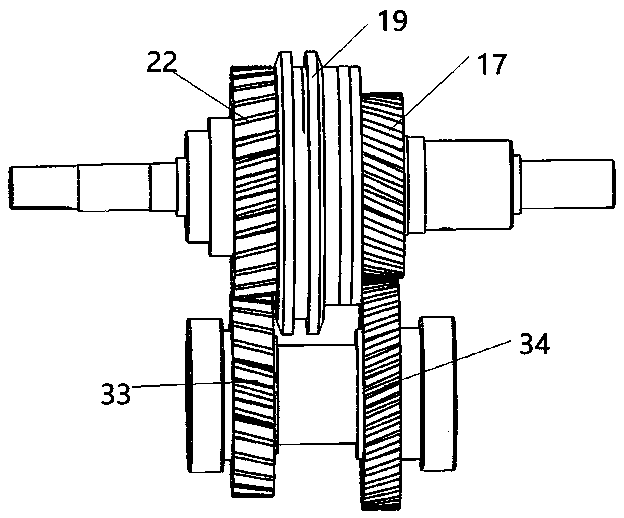

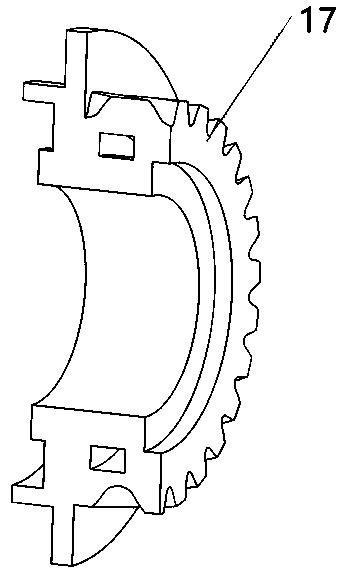

[0037] see figure 1 with figure 2 , an integrated motor reduction drive system for a helicopter empennage includes a disc motor and a two-speed transmission mechanism. The disc motor includes a stator 4 , a rotor 5 , a roller bearing 7 , a bearing bracket 9 and a middle box 2 , and the roller bearing 7 is sleeved on the bearing bracket 9 and coaxially located in the motor casing 3 with the rotor 5 . The two-speed transmission mechanism includes a gearbox body 1, an output shaft 28, a first-speed driving gear 17, a first-speed driven gear 34, a second-speed driving gear 22, a second-speed driven gear 33, an intermediate shaft 32 and a synchronizer 19. The output shaft 28 and the intermediate shaft 32 are located in the gearbox body 1 in parallel, the output end of the output shaft 28 is located outside the gearbox body 1, and the output shaft 28 on the side of the output end is fixedly installed in the gearbox body through the fourth roller bearing 27 1, the output end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com