Patents

Literature

31results about How to "Achieve high concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

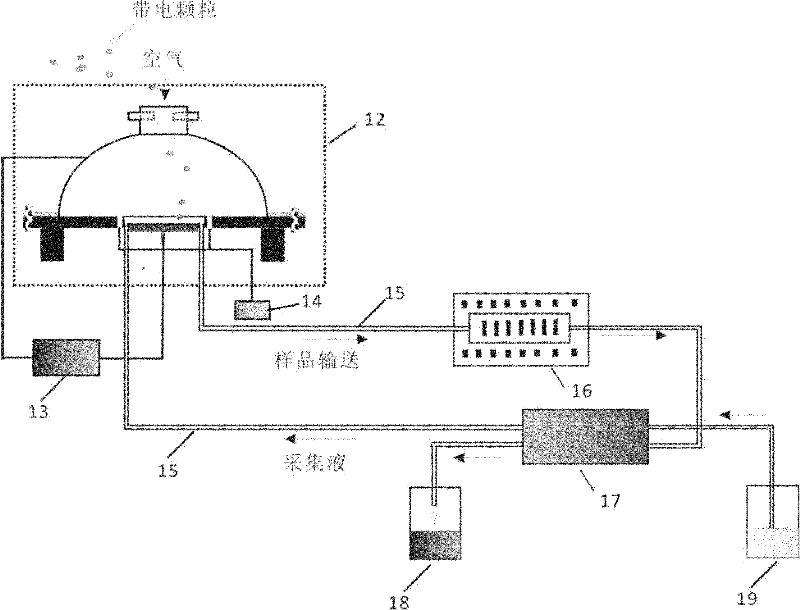

Electrostatic field-based air sampler and sampling method thereof

ActiveCN102109423AAchieve high concentrationAchieve integrationWithdrawing sample devicesPreparing sample for investigationPeristaltic pumpLiquid medium

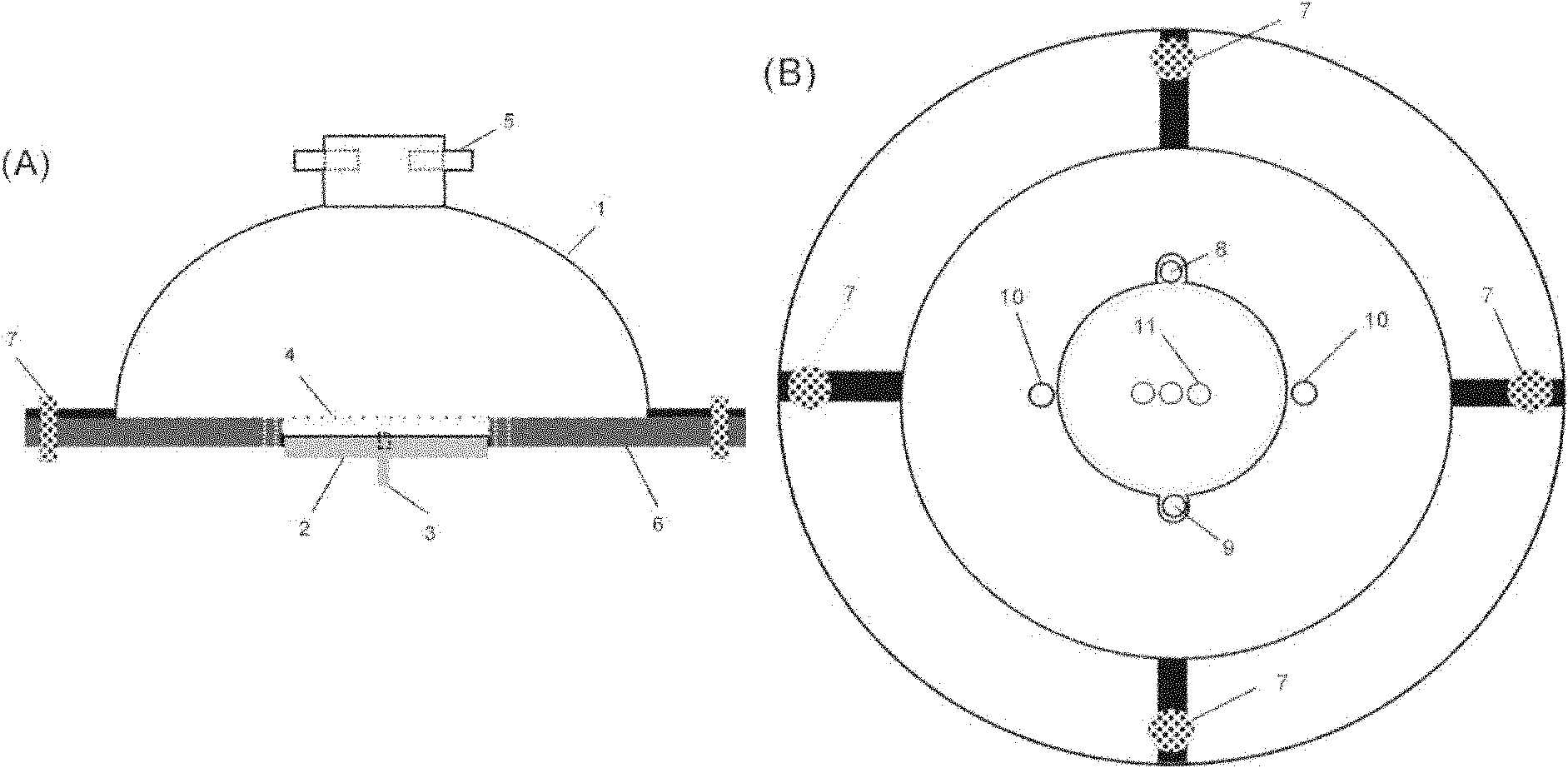

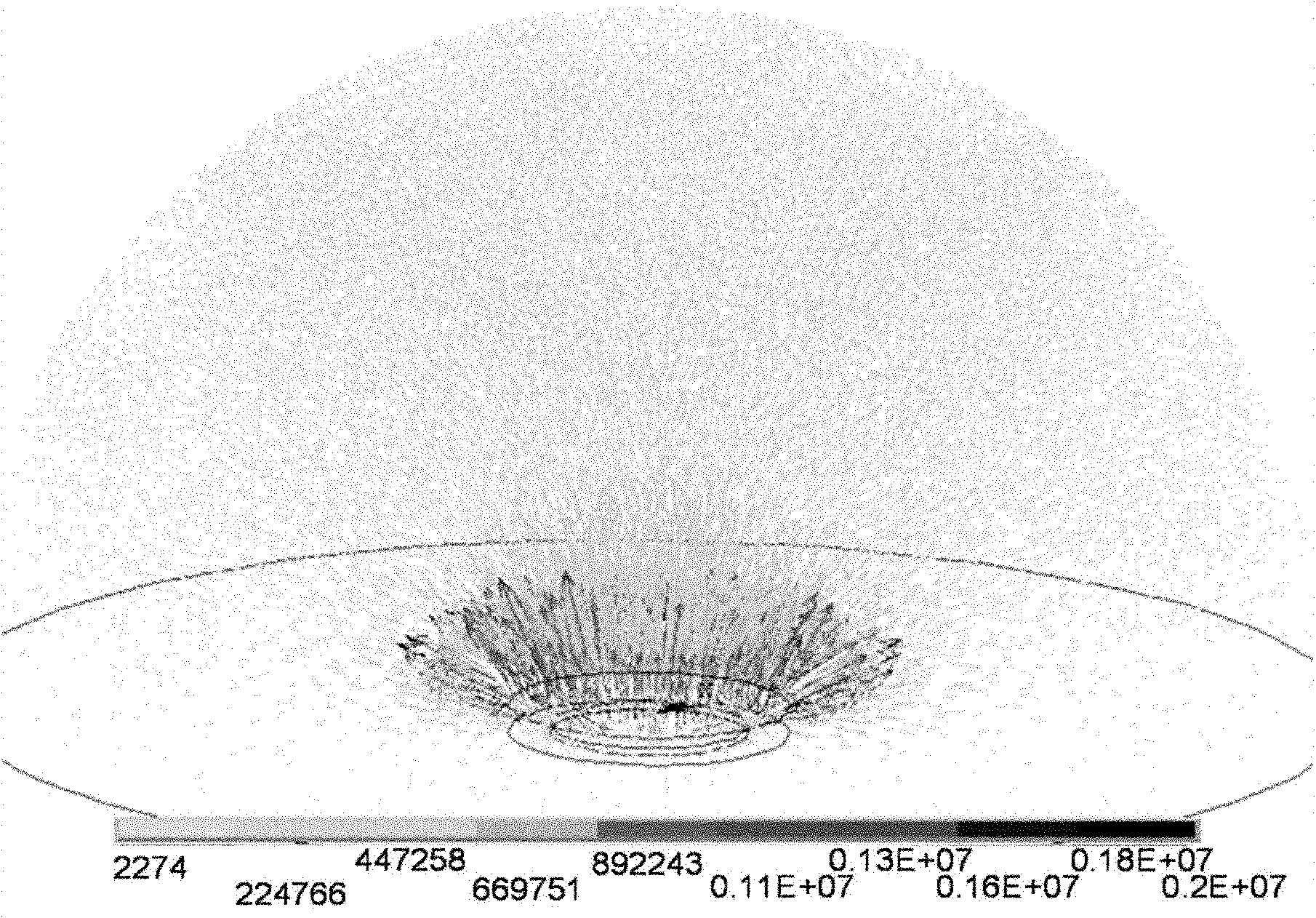

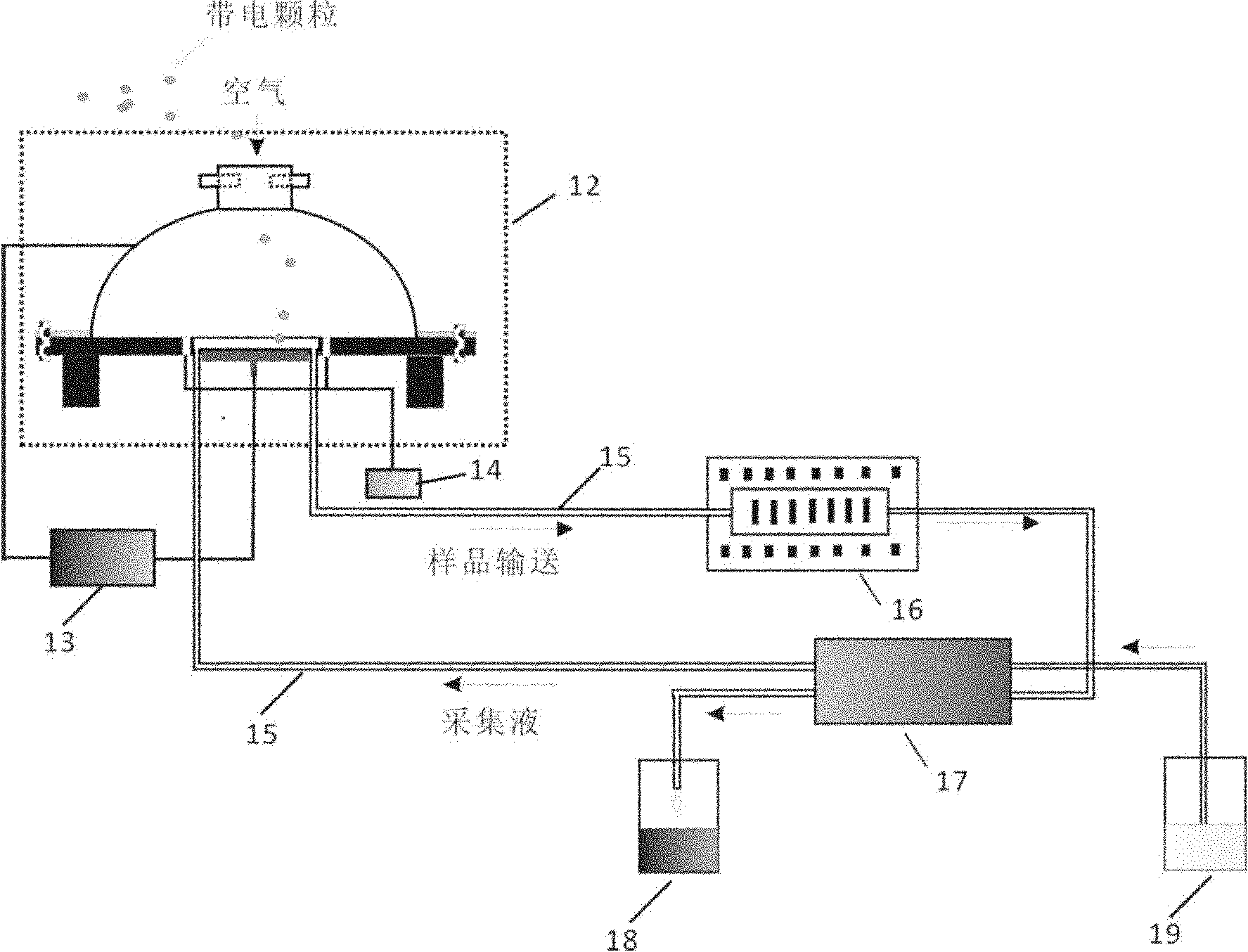

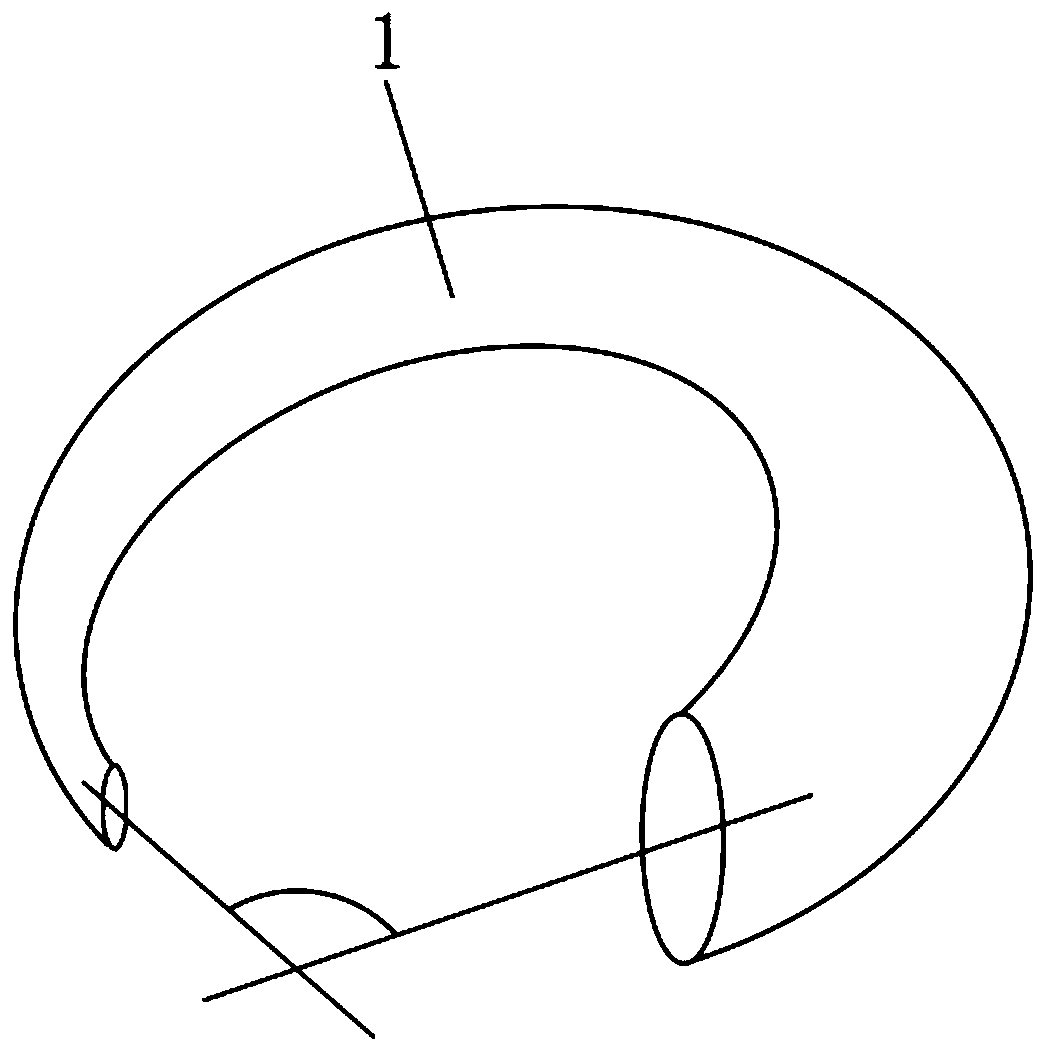

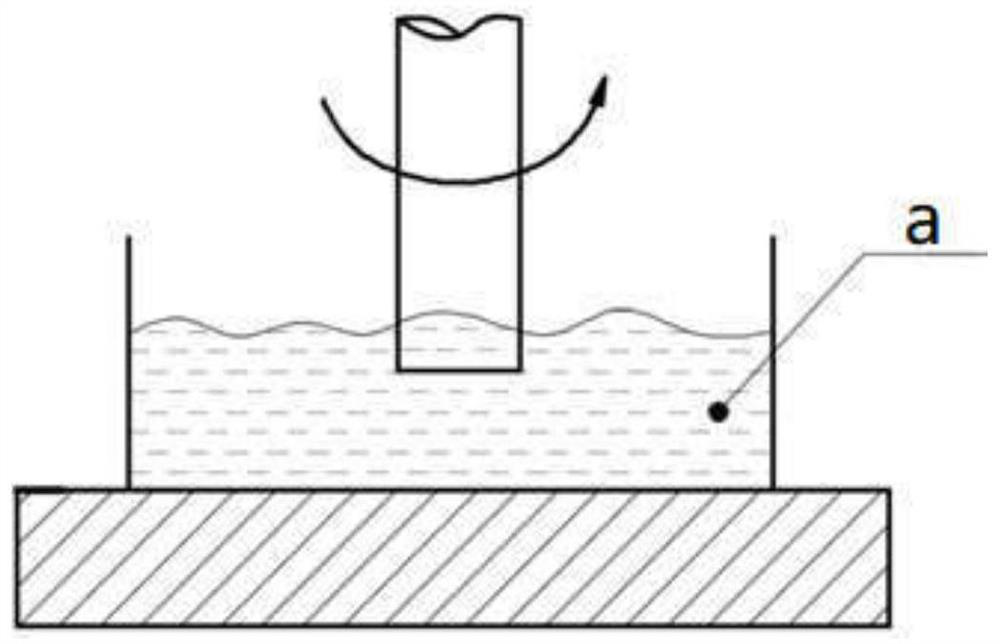

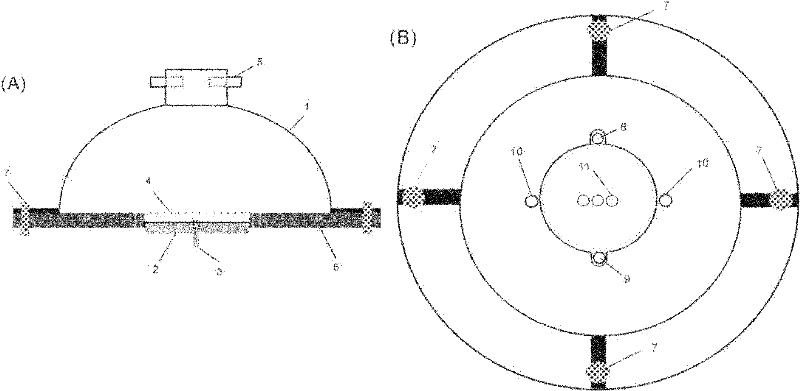

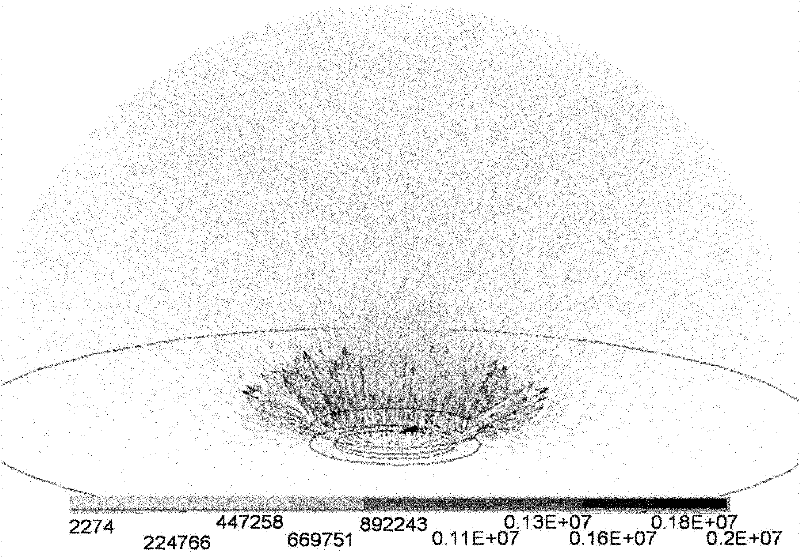

The invention discloses an electrostatic field-based air sampler and a sampling method thereof. The air sampler mainly comprises a hemispherical electrode (1), a round electrode (2) and a sampling tank (4). Microorganisms with electric charges in air in a sampling space are concentratedly deposited in a liquid medium in a relatively small area in the center of a hemisphere along the direction of an electrostatic field under the action of the electrostatic field, and an air sample is dynamically conveyed under the drive of a micro peristaltic pump simultaneously. The defects that efficiency is low, an automatic sample conveying system is not provided and the like in the prior art are overcome, and the air sample is sampled to the trace liquid medium through the electrostatic field by a novel electrostatic field sampling method, and is dynamically conveyed to a biological / chemical sensor through an inlet and outlet. The air sample is highly concentrated, and the air sampler can be integrated with the sensor and has a good application prospect in the fields of environment monitoring and the like.

Owner:北京鼎蓝科技有限公司

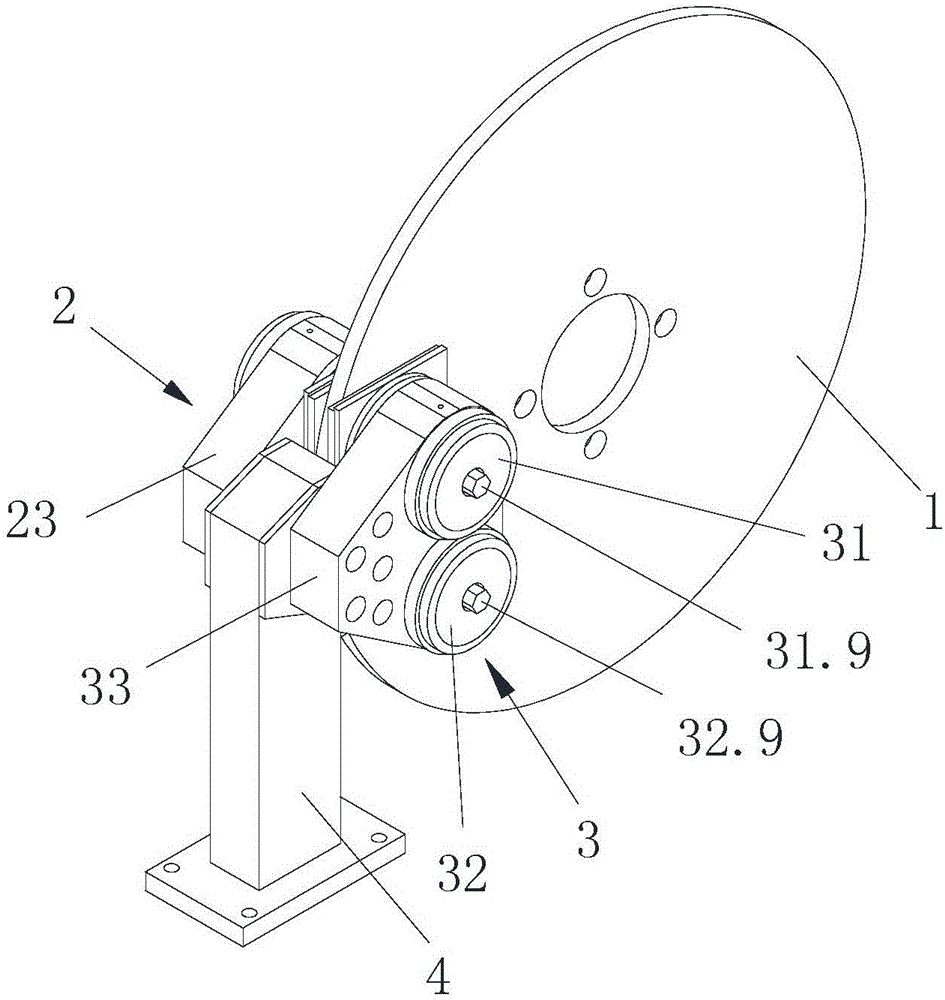

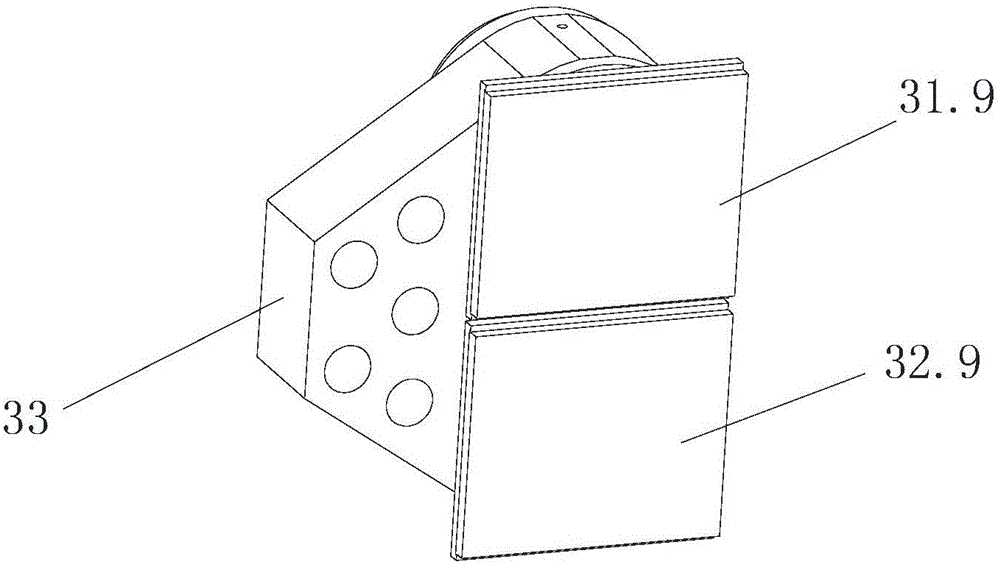

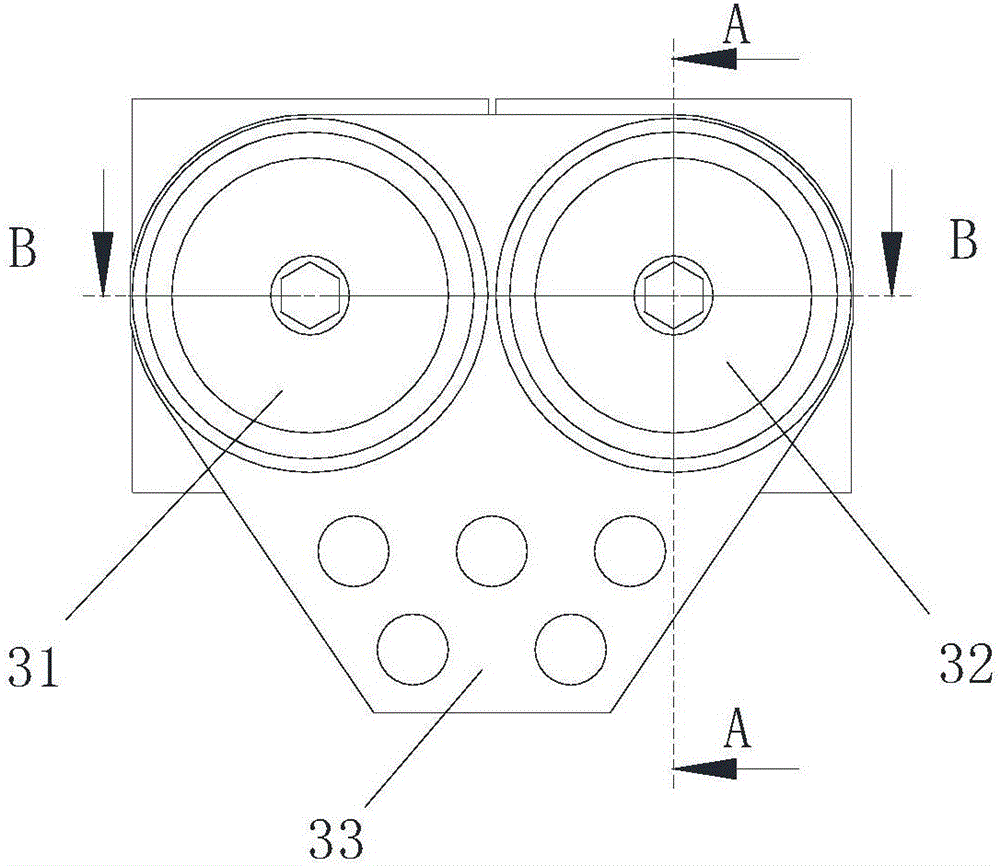

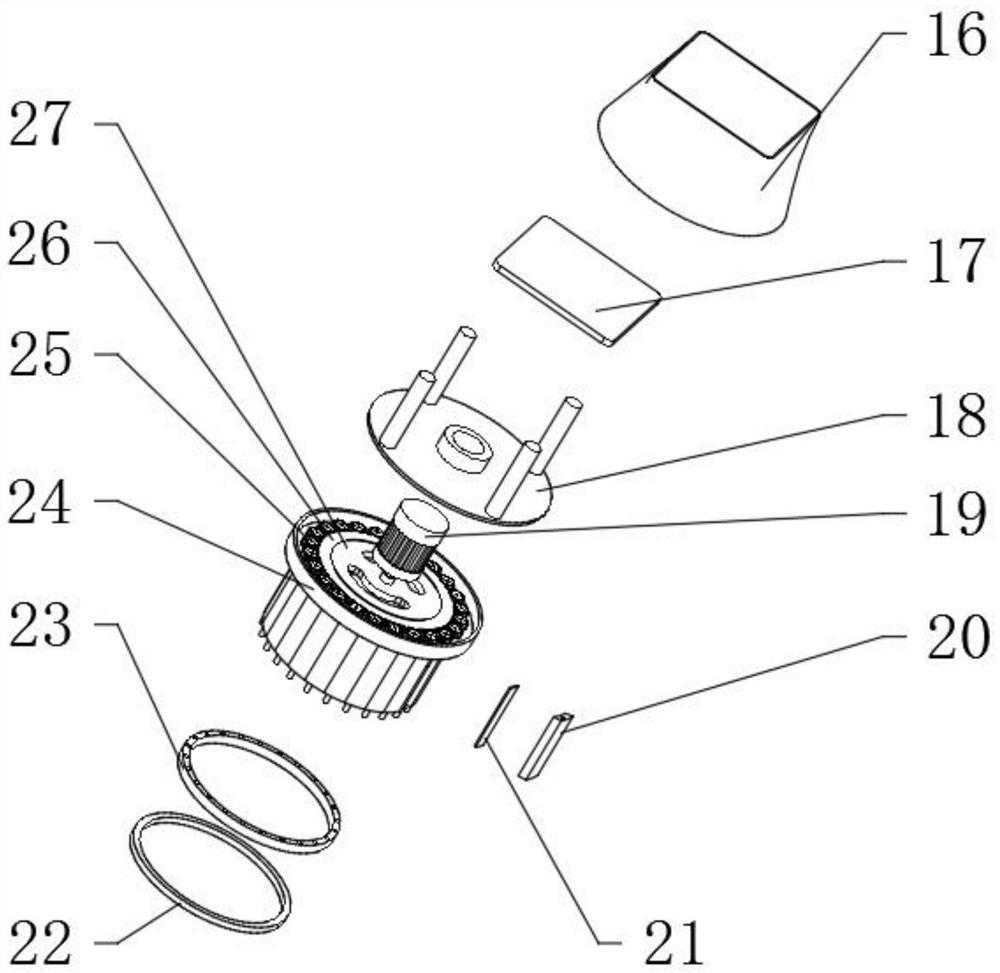

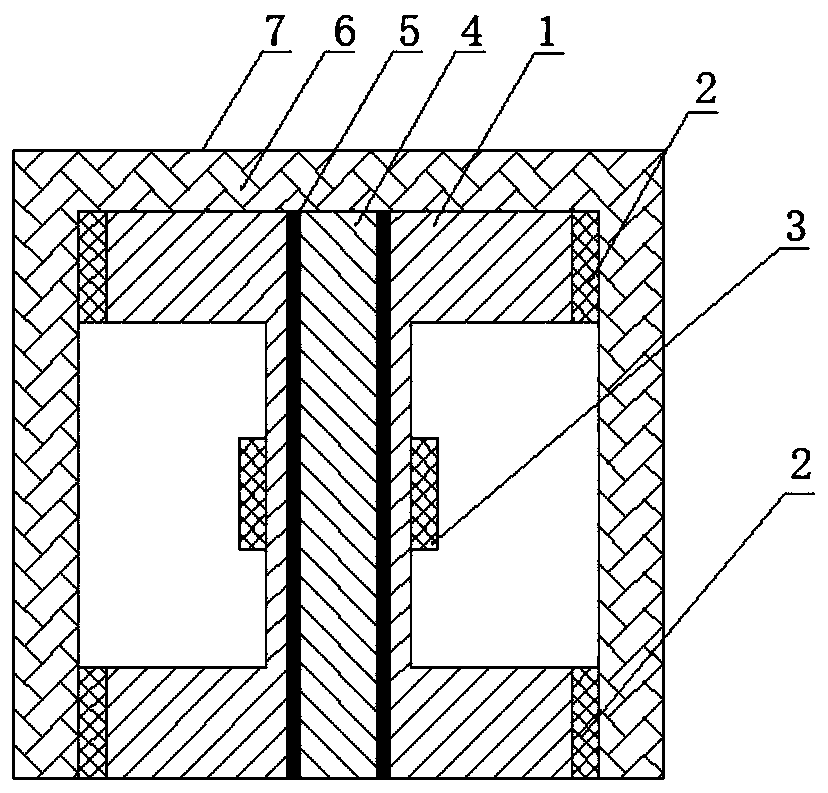

Disk type braking device with grading braking function

InactiveCN105889367ACompact structureReduce volumeAxially engaging brakesBrake actuating mechanismsBrake torqueBrake pad

The invention discloses a disk type braking device with a grading braking function. The disk type braking device with the grading braking function comprises a braking disk; one side of the braking disk is provided with a first braking head used for generating braking torque for the braking disk; the other side of the braking disk is provided with a second braking head used for generating braking torque for the braking disk, and the second braking head and the first braking head are of the same structure and are opposite in position; the second braking head and the first braking head each comprise a base frame, a first brake head and a second brake head, and the first brake heads and the second brake heads are arranged on the base frames, wherein the first brake head of the first braking head and the first brake head of the second braking head are symmetrical to each other, and the second brake head of the first braking head and the second brake head of the second braking head are symmetrical to each other; and the disk type braking device further comprises a force applying mechanism driving the first braking head and the second braking head to act, the force applying mechanism drives the first braking head or the second braking head to act so as to achieve trapezoidal grading braking on loads, the force applying mechanism drives the first braking head and the second braking head to act at the same time so as to achieve trapezoidal grading braking on the loads, and the force applying mechanism does not drive the first braking head or the second braking head to act so as achieve trapezoidal grading braking on the loads. The structure of the two braking heads is adopted for the disk type braking device, and trapezoidal grading braking on the loads can be achieved.

Owner:SHANDONG KEDA ELECTROMECHANICAL TECH CO LTD

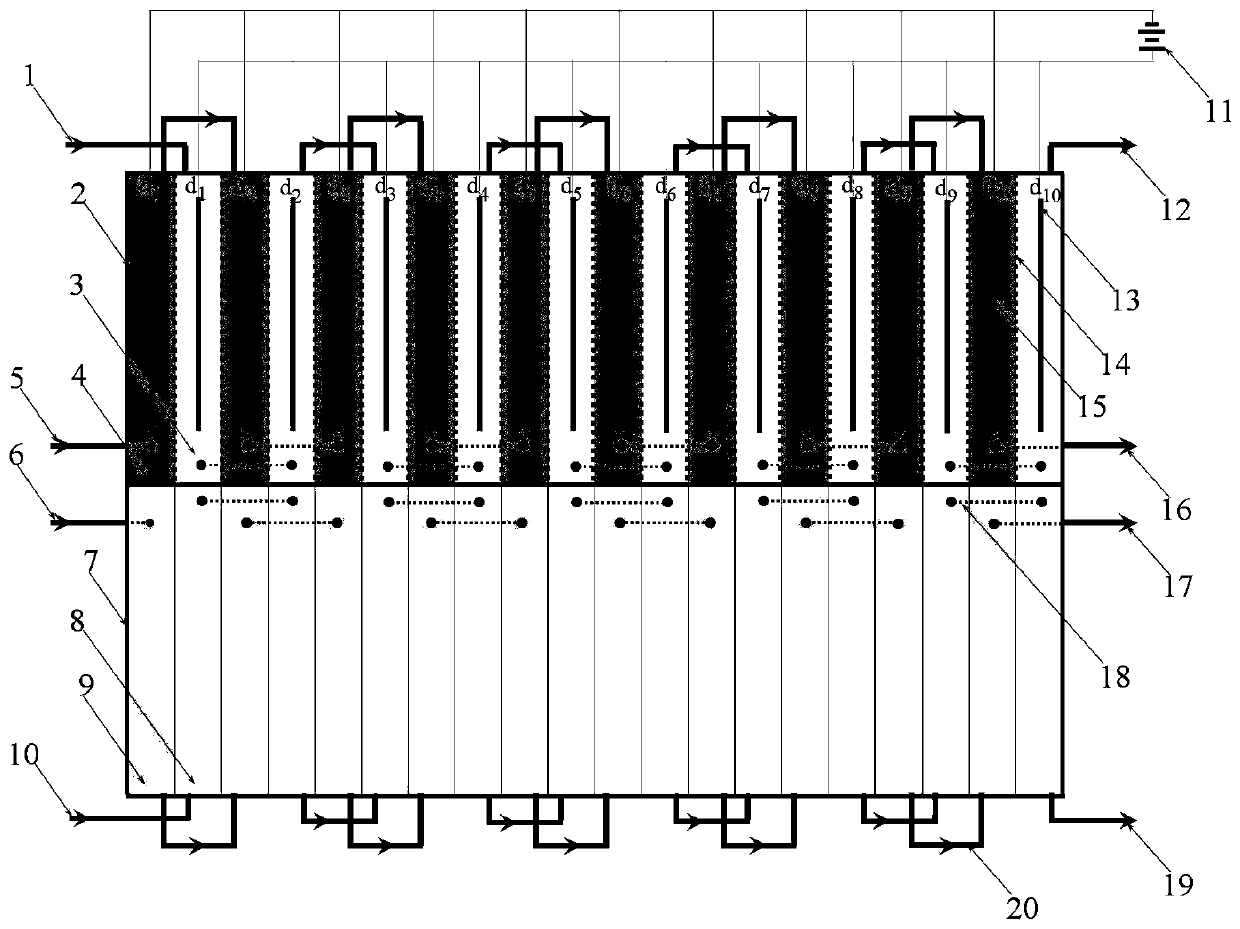

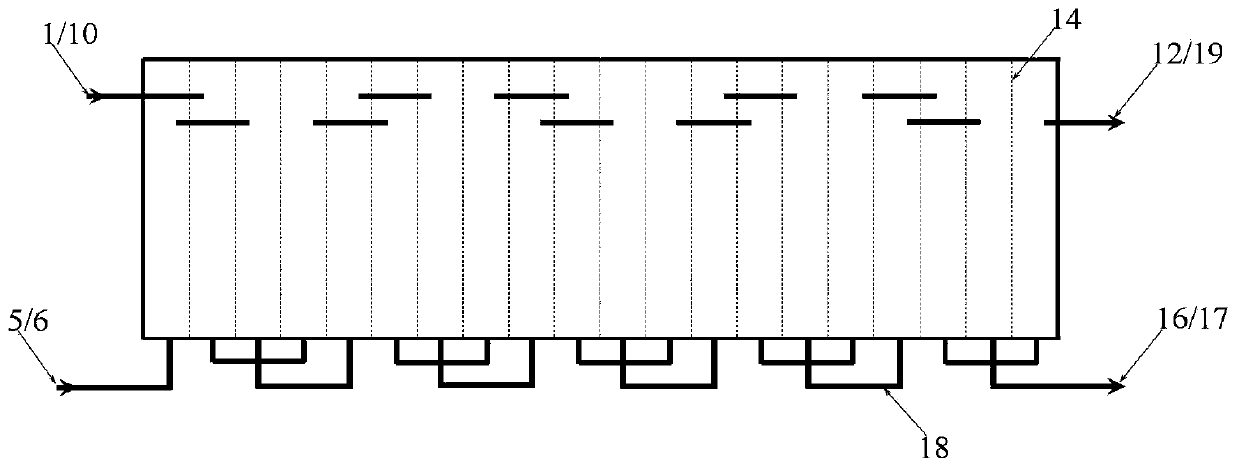

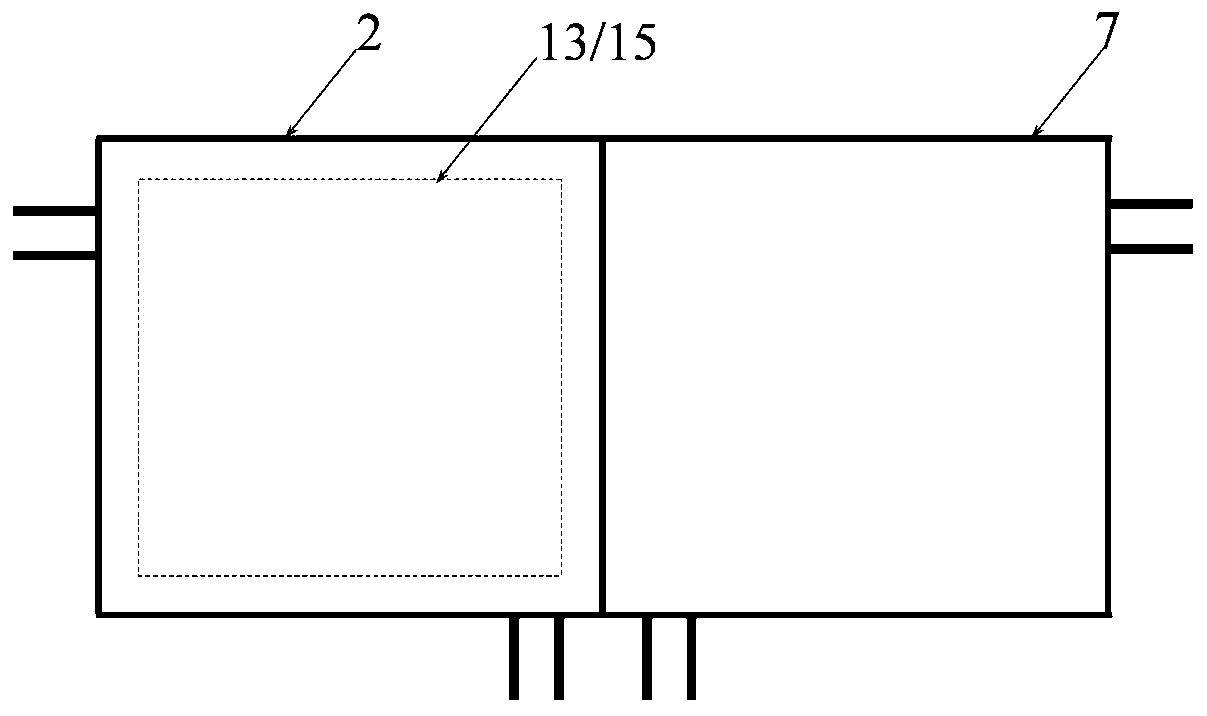

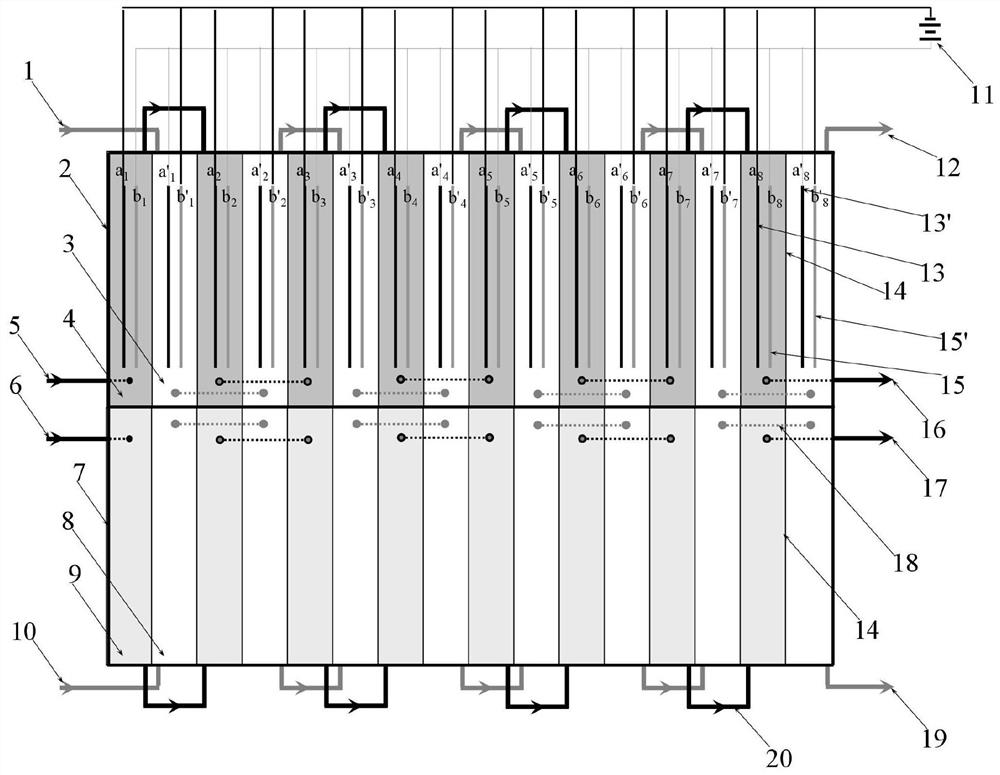

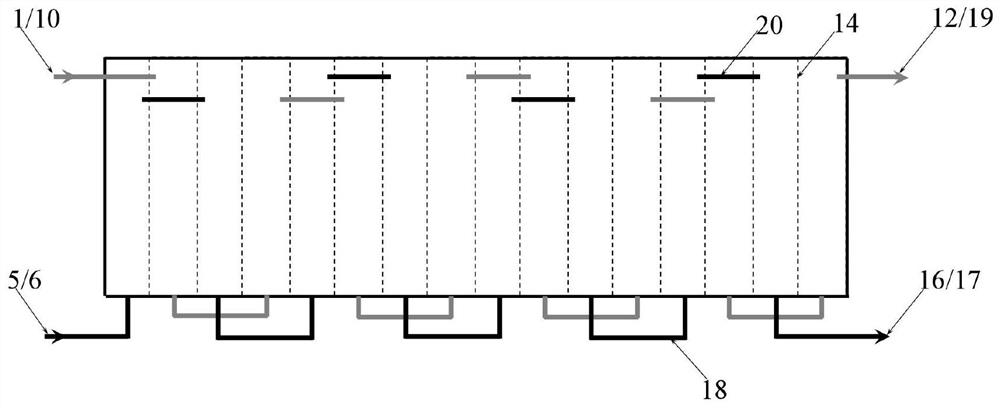

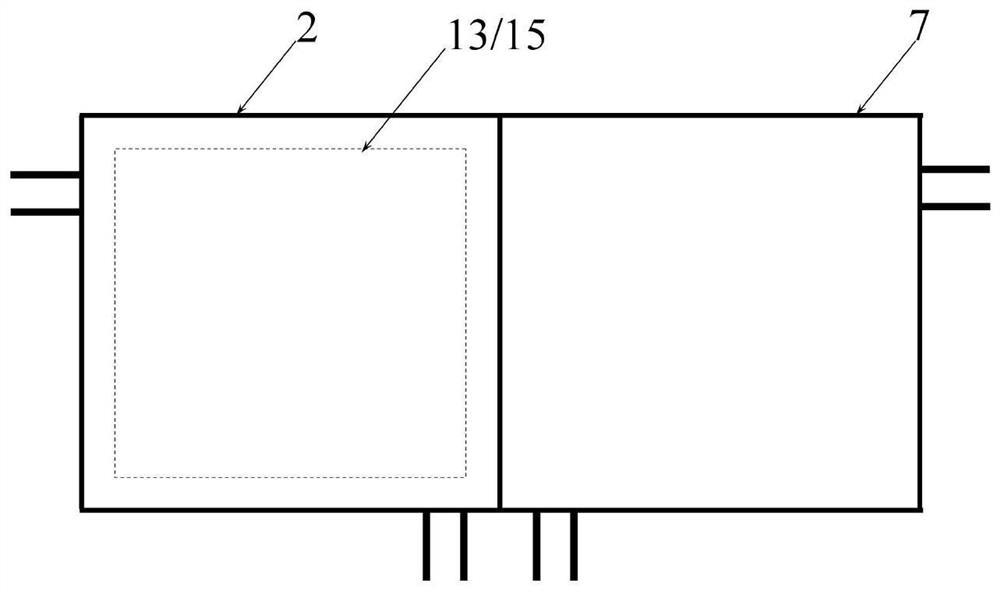

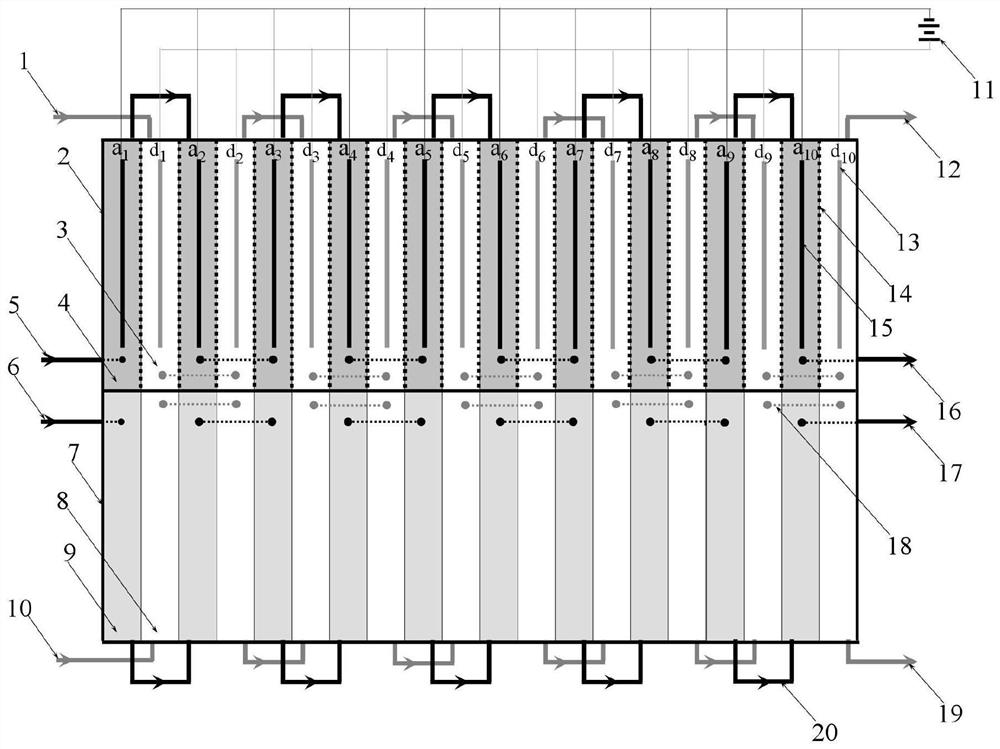

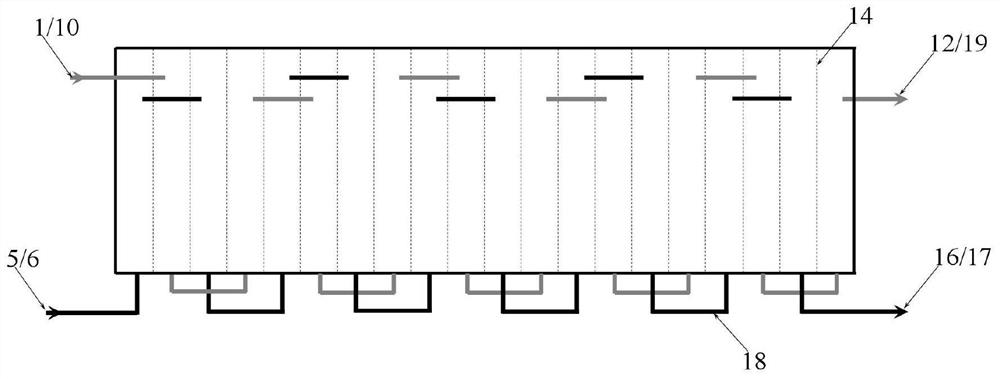

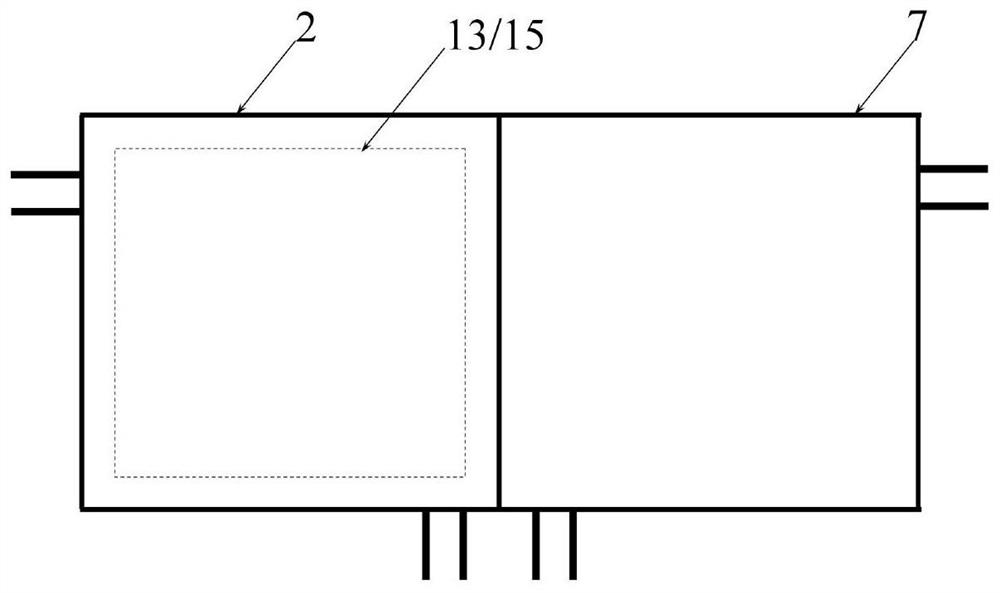

Diaphragm-free electrochemical lithium extracting system and method

ActiveCN110643831AAchieve high concentrationContinuous separabilityProcess efficiency improvementElectrolysisElectrochemistry

The invention relates to a diaphragm-free electrochemical lithium extracting system and method. The system is mainly composed of an electrolysis tank, a washing tank, a power supply, and a series of desorption lithium batteries and electronic balance electrodes, wherein the electrolysis tank is divided by a series of partition plates into raw material pools and recovery pools at sequential alternating positions, and the different raw material pools and the different recovery pools are connected in series through connecting pipes correspondingly. A to-be-extracted lithium raw material and recovery liquid are introduced into the raw material pools and the recovery pools correspondingly, and the electrodes are switched between the raw material pools and the recovery pools, so lithium is separated out of the raw material and enriched in the recovery liquid. By means of the system, the grade of the electrolysis tank can be easily improved or lowered, or the position exchange frequency of the electrodes is controlled, and therefore the lithium extracting requirement of different lithium-containing solutions is met. According to the system, in the lithium extracting process, a raw material circuit and a recovery liquid circuit are independent of each other and continuously operate, and therefore the continuous electrochemical lithium extracting can be realized. In addition, since onlythe regular movements of the electrodes are related in the lithium extracting process, automatic operation is easily realized.

Owner:TIANJIN UNIV OF SCI & TECH +1

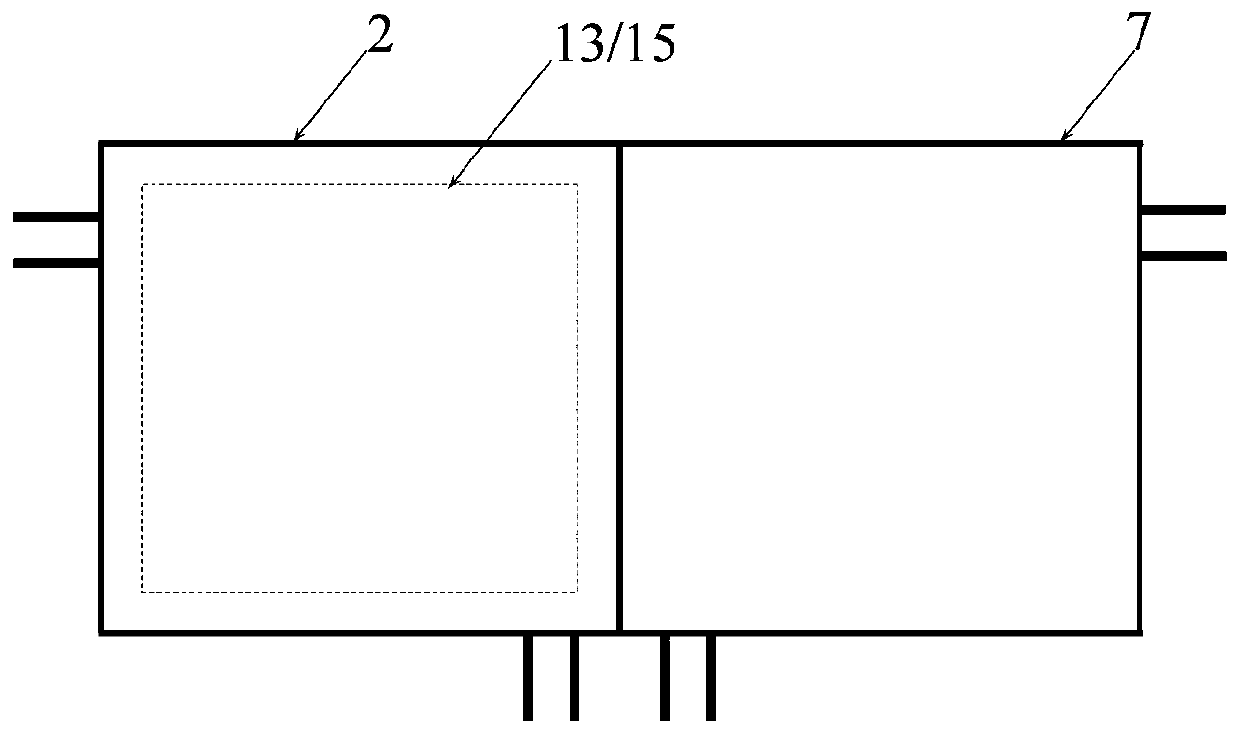

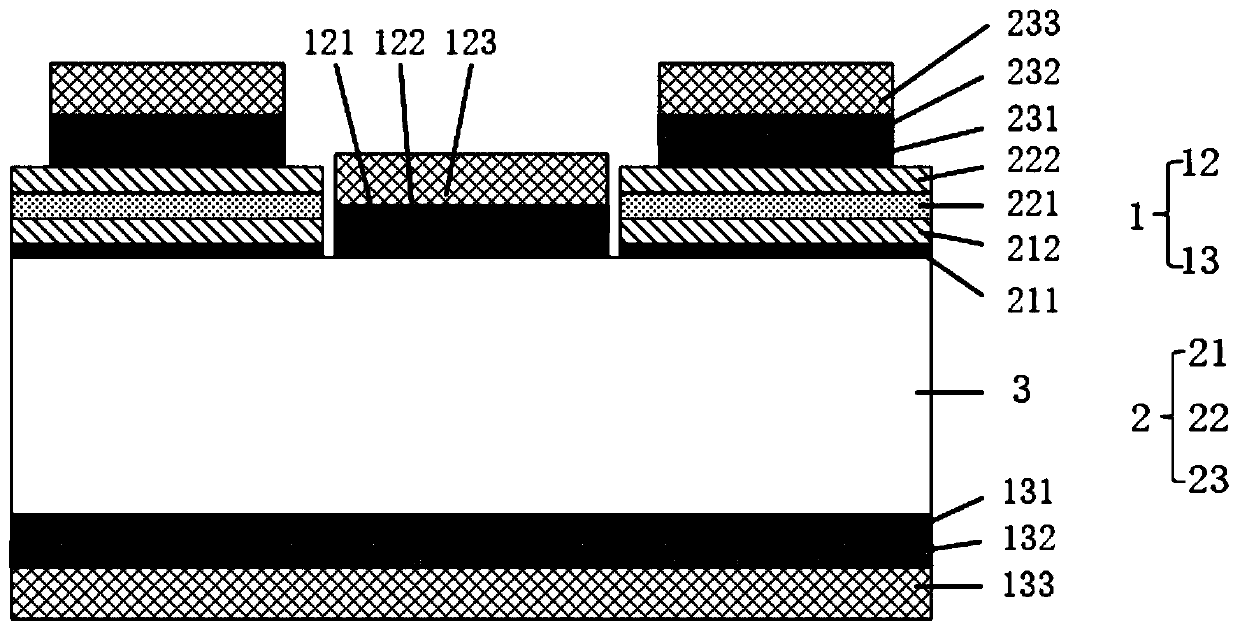

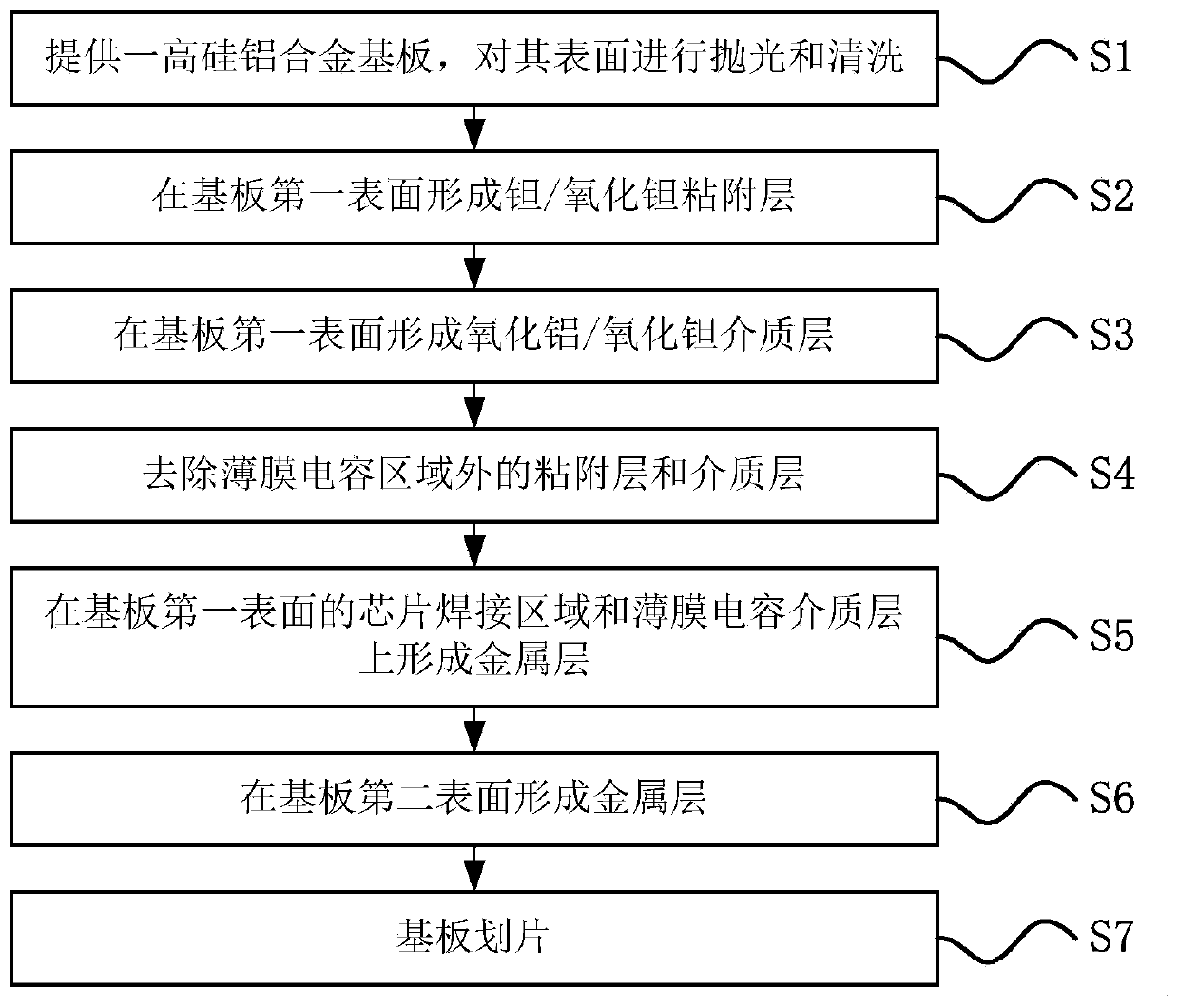

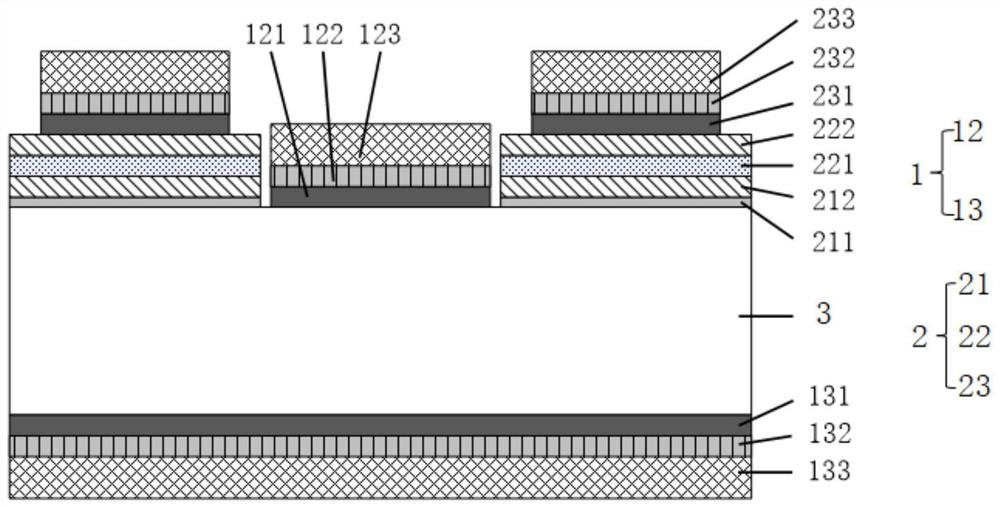

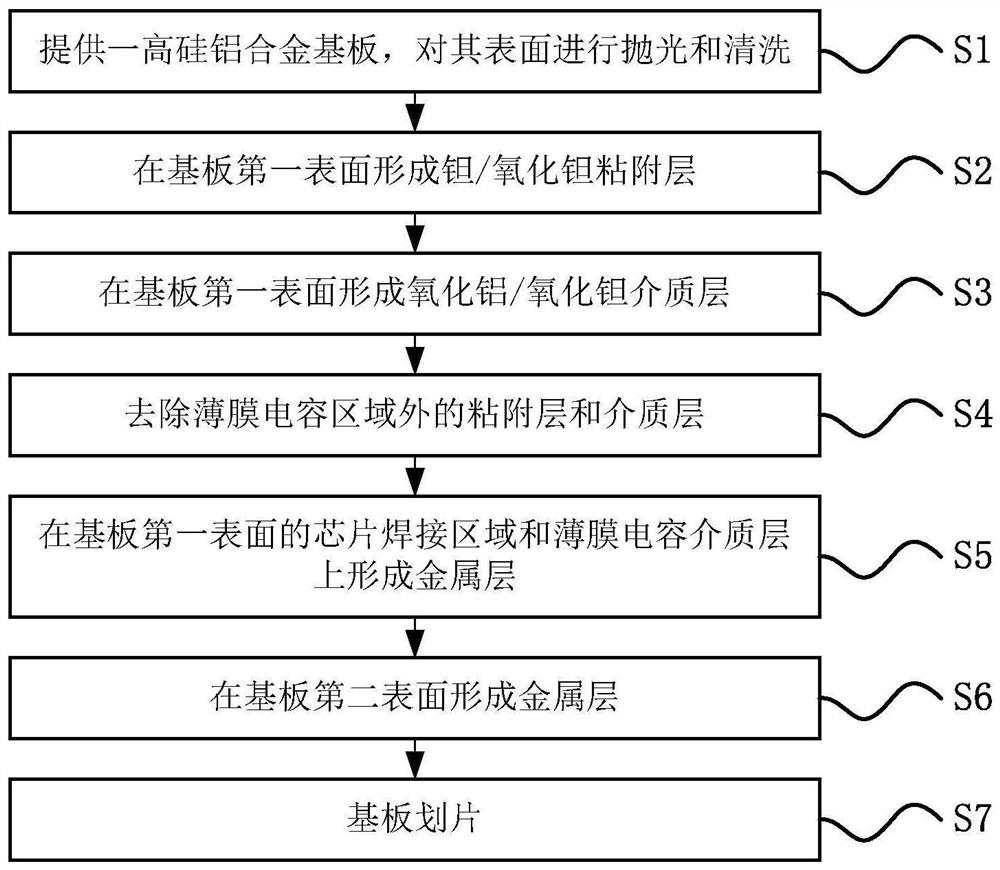

Microwave power amplifier chip carrier and preparation method thereof

ActiveCN111146155AImprove thermal conductivityAchieve high concentrationSemiconductor/solid-state device detailsSolid-state devicesCapacitanceAlloy substrate

The invention discloses a microwave power amplifier chip carrier and a preparation method thereof. The microwave power amplifier chip carrier comprises a high silicon aluminum alloy substrate, a chipcushion block and a film capacitor; the chip cushion block comprises a chip welding metal layer and a carrier welding metal layer, and the film capacitor comprises a bonding layer, a dielectric layerand an electrode metal layer. The manufacturing method comprises the following steps: providing the high silicon aluminum alloy substrate with a polished surface, and sequentially forming the bondinglayer and the dielectric layer in a thin film capacitor region on the first surface of the substrate; forming the metal layer on the chip welding area on the first surface of the substrate and the surface of the thin-film capacitor dielectric layer; after a carrier welding metal layer is formed on the second surface of the substrate, performing scribing. According to the microwave power amplifierchip carrier and the manufacturing method provided by the invention, the microwave power amplifier chip cushion block and the chip capacitor are integrated into a whole, the manufacturing process steps of a microwave assembly can be effectively reduced, the process difficulty is reduced, and in addition, the chip carrier also has excellent heat dissipation performances, grounding performances andreliability.

Owner:SHANGHAI SPACEFLIGHT ELECTRONICS & COMM EQUIP RES INST

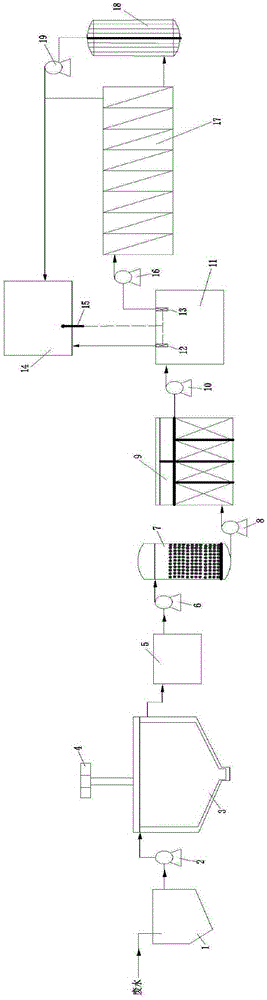

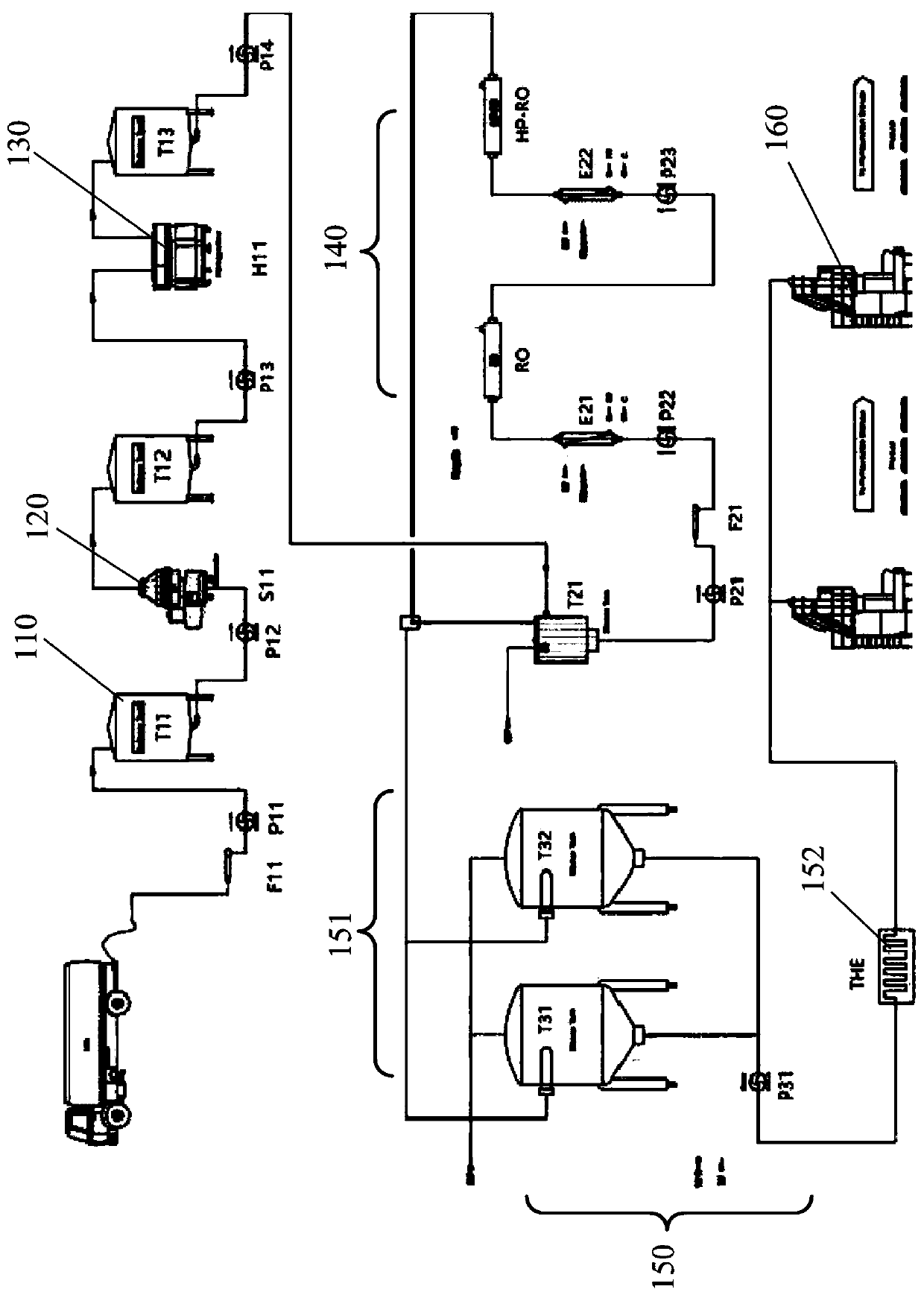

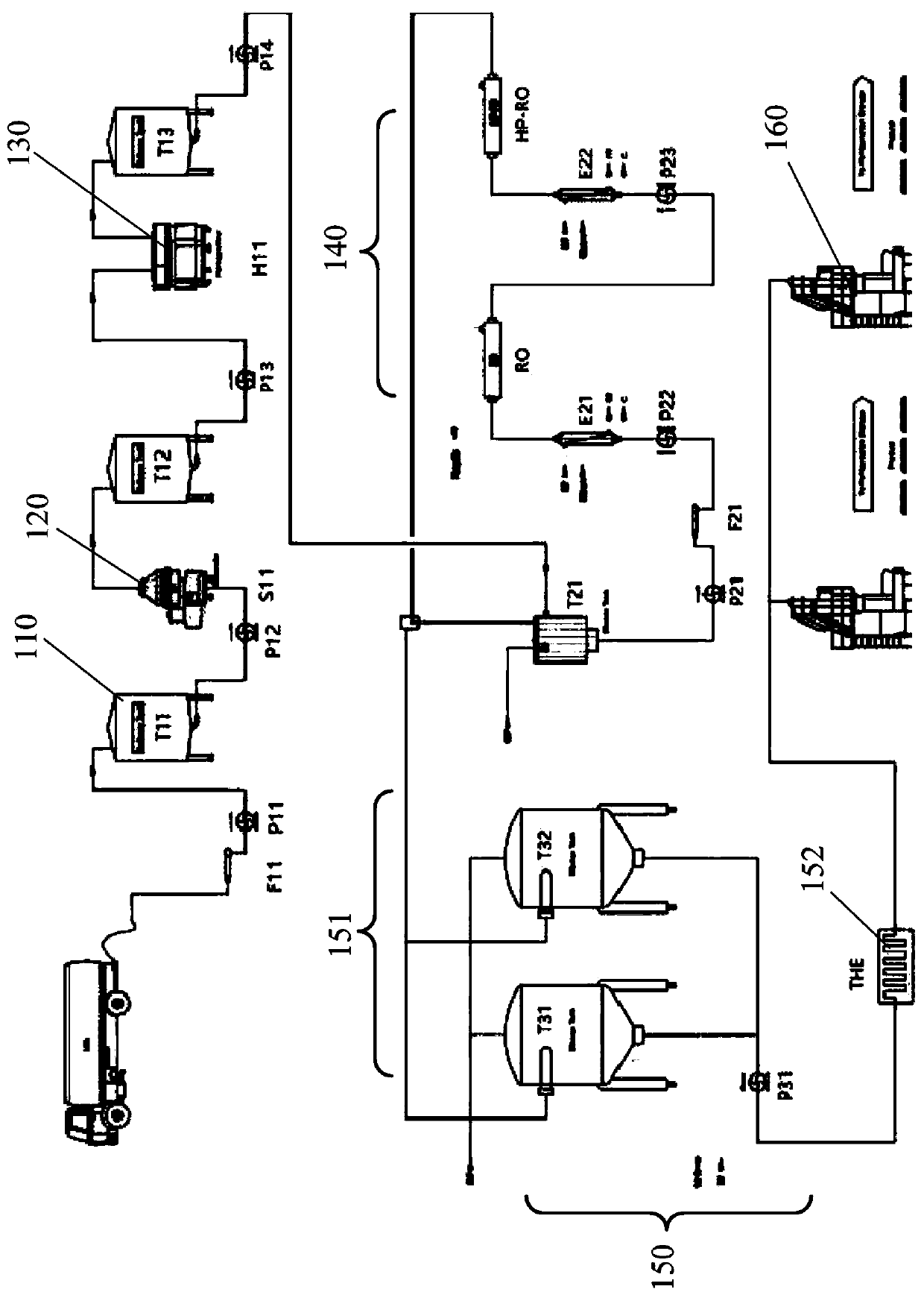

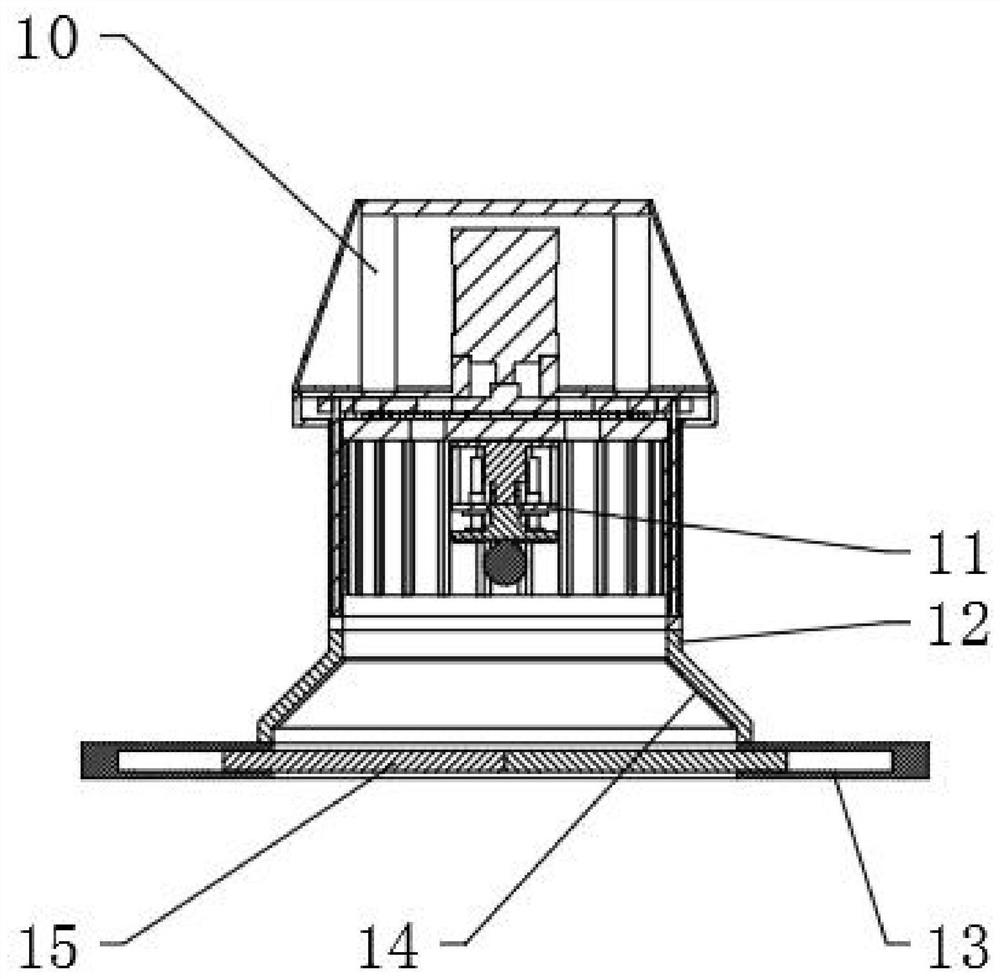

Treatment device and method capable of achieving waste water zero discharge of power plant with large water volume

InactiveCN105254066AExtended service lifeGood removal effectMultistage water/sewage treatmentWater savingEcological environment

The invention relates to a treatment device and method capable of achieving waste water zero discharge of a power plant with large water volume. By means of the treatment device and method, the technical feasibility and the economic feasibility of large water volume waste water zero discharge can be simultaneously met, and large water volume waste water zero discharge engineering application of the power plant is made to be possible. Meanwhile, reused water can be used as replenished water of water bodies such as recycling cooling water from the power plant and industrial water, the water taking amount of the power plant can be decreased, the applied water cost is reduced, discharge of water body pollutants is completely eradicated, and the ecological environment is protected to the maximum extent.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

High salt wastewater softening and concentrating device and method

PendingCN109851139AReduce dosage and costReduce volume and costScale removal and water softeningMultistage water/sewage treatmentUltrafiltrationHigh rate

The invention discloses a high salt wastewater softening and concentrating device and method. The device comprises a coagulating tank, whose outlet end is connected to the inlet end of a micro filtration system; an ultrafiltration system, whose inlet end is connected to the outlet end of the micro filtration system, wherein the outlet end of the ultrafiltration system is connected to the inlet endof a nano filtration system; a reverse osmosis system, whose inlet end is connected to the outlet end of the nano filtration system, wherein the outlet end of the reverse osmosis system is connectedto a reverse osmosis produced water pipeline; and an electrodialysis system, whose inlet end is connected to the reverse osmosis system, wherein the outlet end of the electrodialysis system is connected to an electrodialysis concentrated water pipeline. The invention also relates to a method that uses the device mentioned above to carry out high salt wastewater softening and concentrating. The provided method and device can selectively separate Ca<2+> from wastewater and recover excess softening agent; the addition amount of softening agent is reduced, the cost is reduced therefore, and high-rate concentration of wastewater is realized.

Owner:DATANG ENVIRONMENT IND GRP

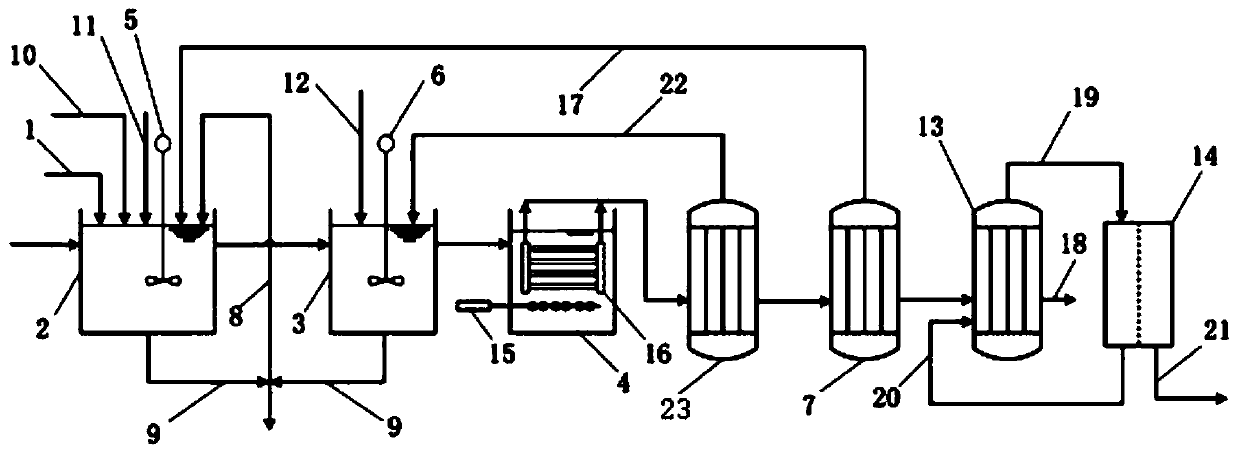

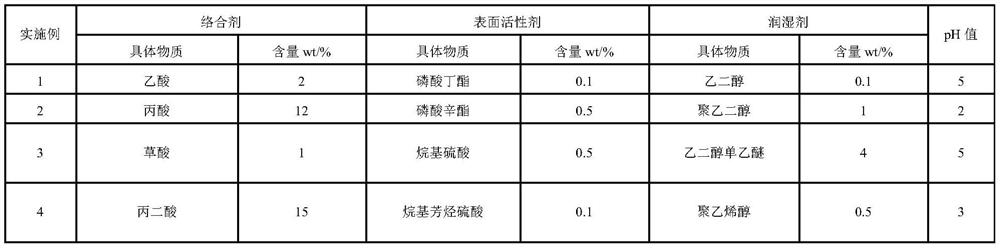

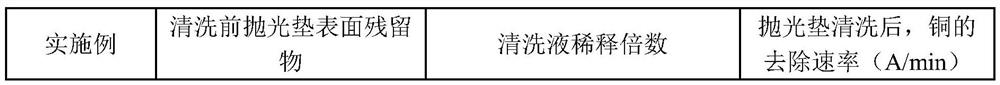

Chemical mechanical polishing cleaning solution and use method thereof

PendingCN113881510AAchieve high concentrationMeet cleaningInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsActive agentPhysical chemistry

The invention discloses a chemical mechanical polishing cleaning solution and a use method thereof. The cleaning solution comprises a complexing agent, a surfactant, a wetting agent, a pH regulator and the balance of water. The chemical mechanical polishing cleaning solution is a highly concentrated cleaning solution, and can simultaneously clean a wafer and a polishing pad after chemical mechanical polishing by adjusting the dilution ratio.

Owner:万华化学集团电子材料有限公司

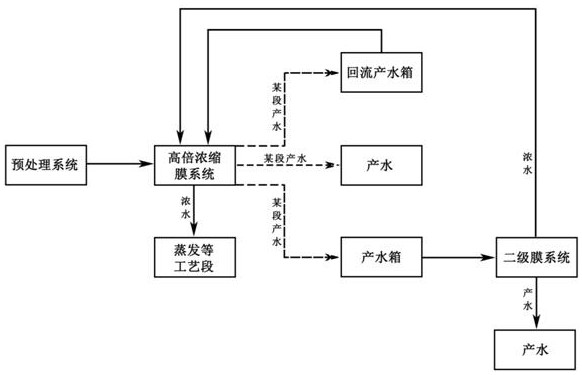

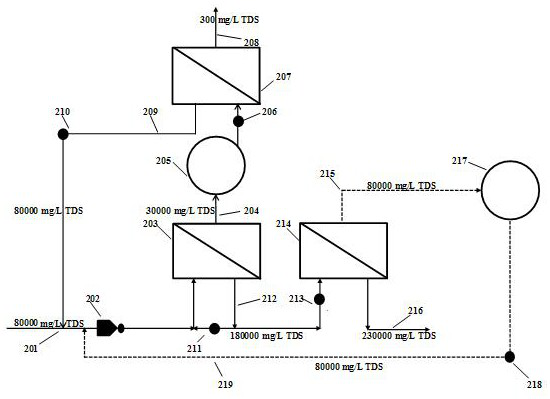

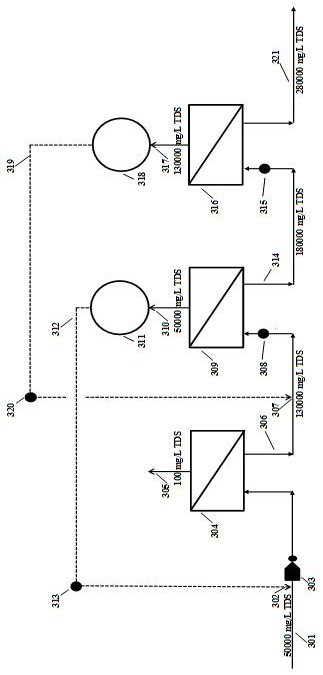

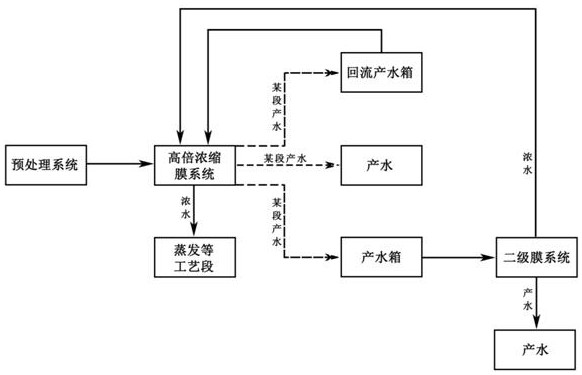

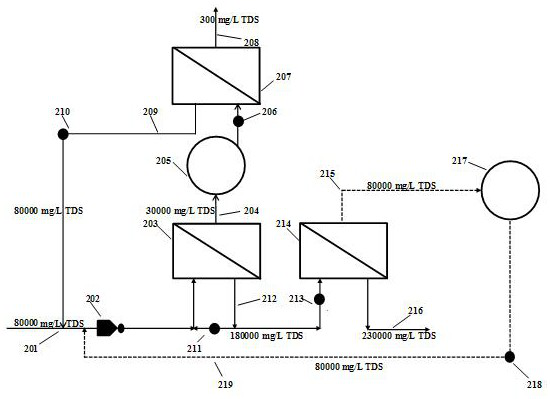

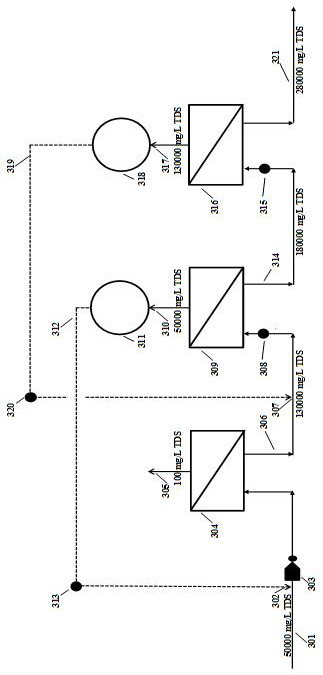

Membrane system for realizing high-power concentration

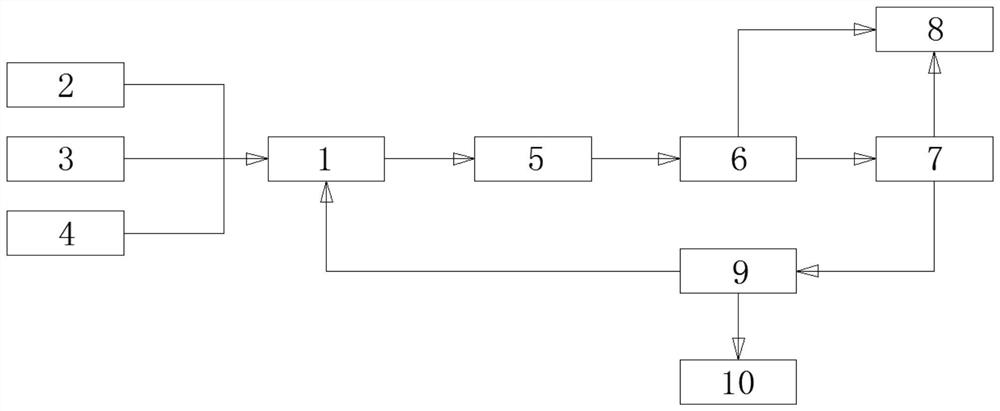

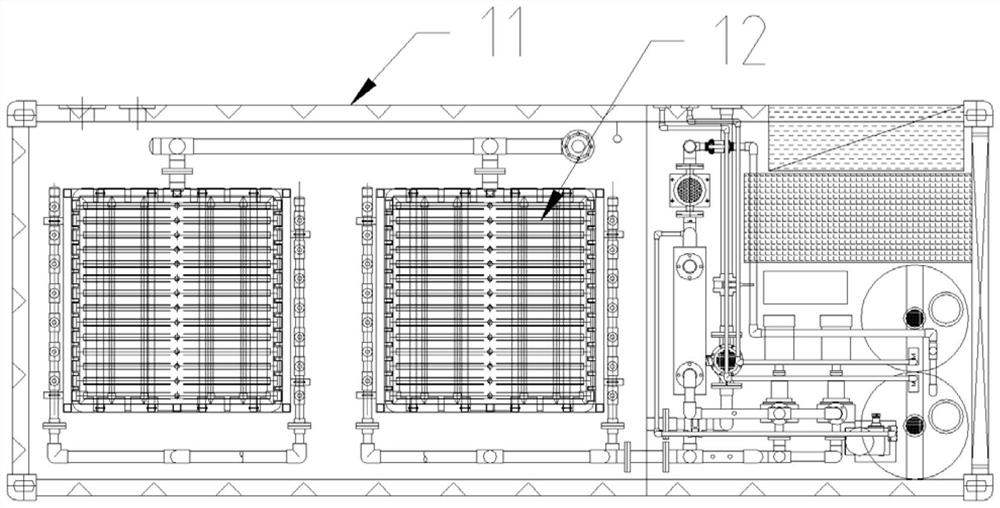

ActiveCN112340938AChange the rejection rateAchieve high concentrationGeneral water supply conservationWater contaminantsDesalinationWater production

The invention discloses a membrane system for realizing high-power concentration, and belongs to the technical field of water pollution treatment. The system comprises a pretreatment system, a high-concentration membrane system, a water production tank and a secondary membrane system. The pretreatment system is connected with the high-concentration membrane system, the high-concentration membranesystem is connected with the water production tank, and the water production tank is connected with the secondary membrane system; and in addition, the water production tank is connected with the high-concentration membrane system, and the secondary membrane system is connected with the high-concentration membrane system. According to the system, the osmotic pressure difference between a concentrated water side and a water production side is reduced by controlling the desalination rate of the membrane assembly, so that high-power concentration is realized under relatively low operation pressure, and the highest concentration can be close to a saturated state.

Owner:烟台金正环保科技有限公司

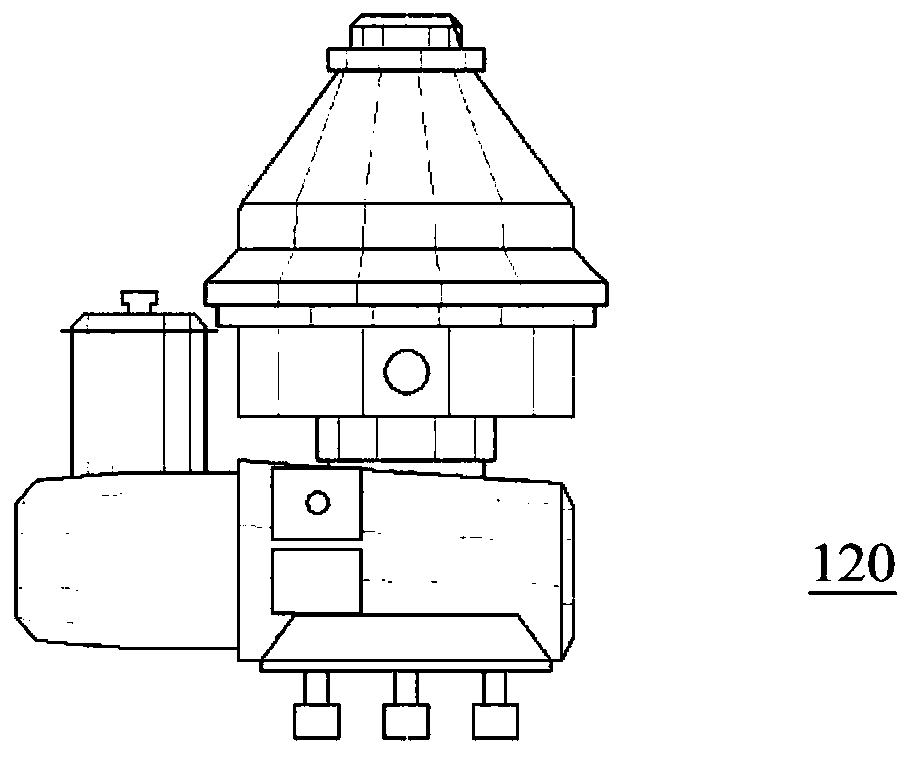

Concentration equipment

PendingCN111213713AImprove efficiencyHigh energy consumptionMilk preparationMilk preservationReverse osmosisMechanical engineering

The invention discloses material liquid concentration equipment. The material liquid concentration equipment comprises a temporary storage unit, a homogenizing unit and a concentration unit, wherein the temporary storage unit comprises a storage container to store material liquid to be concentrated; the homogenizing unit is arranged in the downstream part of the temporary storage unit, and is usedfor exerting scheduled temperature and scheduled pressure to the material liquid, so that the material liquid is refined under the effect of pressure and impact and is uniformly and mutually mixed; the concentration unit is arranged in the downstream part of the homogenizing unit, and sequentially comprises a low-pressure reverse osmosis film processing unit and a high-pressure reverse osmosis film processing unit; reverse osmosis concentration treatment is performed on the material liquid which flows past by the low-pressure reverse osmosis film processing unit under first predetermined pressure; the reverse osmosis concentration treatment is performed on the material liquid which flows past by the high-pressure reverse osmosis film processing unit under second predetermined pressure; and the first predetermined pressure is smaller than the second predetermined pressure. According to the material liquid concentration equipment disclosed by the invention, the low-pressure reverse osmosis film processing unit and the high-pressure reverse osmosis film processing film are arranged, so that material liquid can be quickly and efficiently concentrated.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Compound bed regenerated wastewater resource recycling system

InactiveCN112079491ATaking into account both economic and environmental benefitsReduce energy consumptionSpecific water treatment objectivesScale removal and water softeningIon exchangeChemistry

The invention relates to a resource recycling process and a resource recycling system for compound bed regenerated wastewater. The resource recycling system for the compound bed regenerated wastewateris used for treating regenerated wastewater generated by ion exchange regeneration. According to the invention, a membrane separation and concentration system and a bipolar membrane system are sequentially arranged; the membrane separation and concentration system is used for carrying out quality-divided recycling on the composite bed ion exchange resin regeneration wastewater, and the bipolar membrane system is used for treating a concentrated solution of the membrane separation and concentration system to obtain acid and alkali which are recycled for the system. The system has the advantages that sulfate radicals are efficiently concentrated with low energy consumption, the salt concentration of acid and alkali prepared by a bipolar membrane is guaranteed, the rest monovalent brine suchas sodium chloride, sodium nitrate and the like is concentrated by a reverse osmosis system and sent to the bipolar membrane to prepare acid and alkali, and mixed acid can be prepared or sulfuric acid and hydrochloric acid can be respectively prepared according to the difference of inlet water quality; reasonable arrangement is realized according to the treatment characteristics of respective membranes; and the energy consumption of the whole system is greatly reduced while efficient concentration is realized.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT

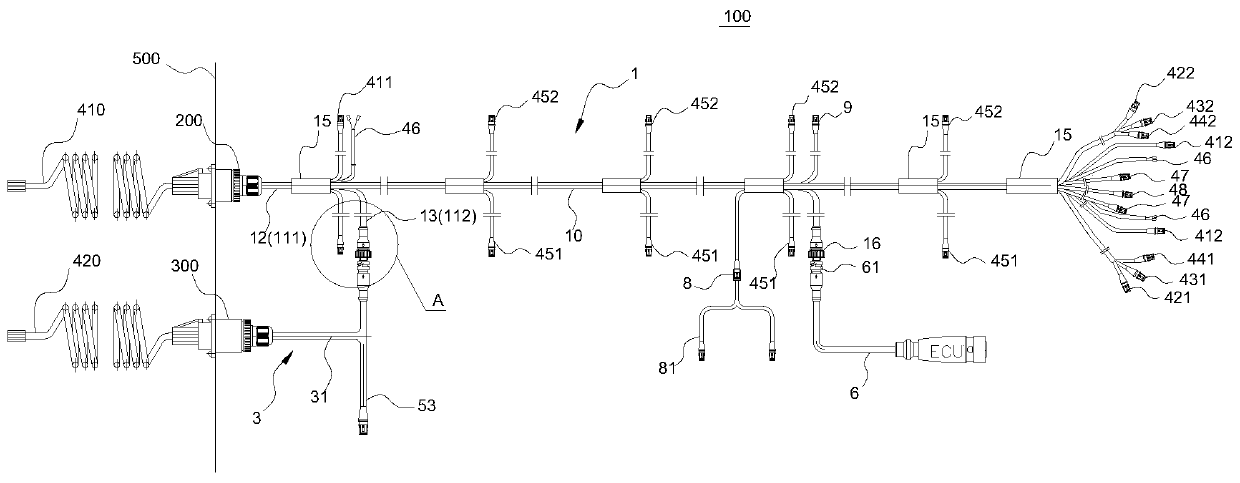

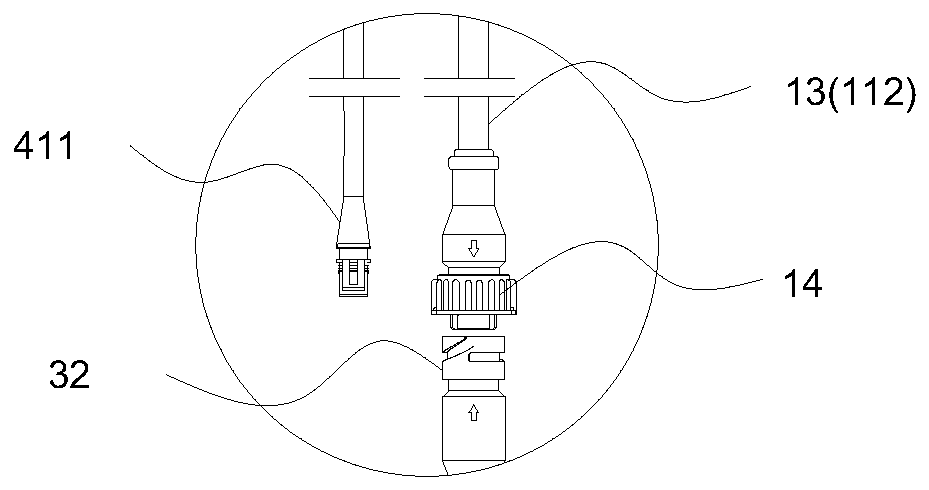

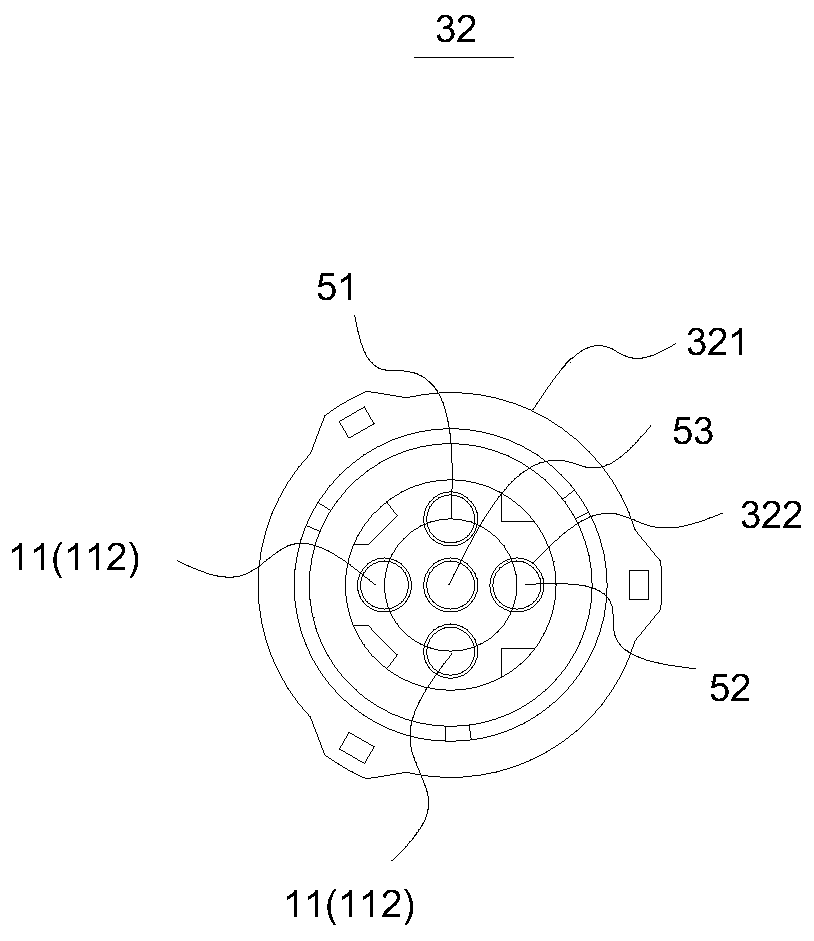

Semitrailer and semitrailer wire harnesses thereof

PendingCN111585130AAchieve high concentrationOptimize layoutVehicle connectorsCouplings bases/casesWire wrapLight fixture

The invention provides a semitrailer wire harness. The semitrailer wire harnesses comprise a main wire harness and a branch wire harness, the main wire harness comprises a grounding wire, a pluralityof first wires, a plurality of second wires and a shell wrapping the wires into a whole. One wiring end of the grounding wire is divided into two strands, namely a first strand of grounding wire wiring end and a second strand of grounding wire wiring end; the wiring end of the first strand of grounding wire and the wiring ends of the plurality of first wires are used for being connected with a seven-core socket together so as to be connected with different lamps of a light assembly of the semitrailer; the branch wire harness comprises a plurality of third wires wrapped together; one end of each of the plurality of third wires is correspondingly connected with the wiring end of the second strand of grounding wire and the wiring ends of the plurality of second wires respectively; the other ends of the third wires are used for being connected with a five-core socket unit together so as to be connected with a braking system of the semitrailer. In this way, the semitrailer wire harnesses bind the wires used for supplying power to the light assembly and the brake system of the semitrailer together, and the high concentration of the wire harnesses is achieved.

Owner:CIMC VEHICLES (GROUP) CO LTD

Concentration method and equipment

PendingCN111213712AImprove efficiencyHigh energy consumptionMilk preparationMilk preservationReverse osmosisProcess engineering

The invention relates to a concentration method and equipment, in particular to the concentration method and equipment for concentrating dairy products by adopting a reverse osmosis technology. The concentration method comprises a step of performing reverse osmosis concentration treatment on raw milk by using a reverse osmosis film, wherein the reverse osmosis concentration treatment comprises low-pressure reverse osmosis concentration treatment and high-pressure reverse osmosis concentration treatment; the low-pressure reverse osmosis concentration treatment means that the reverse osmosis concentration treatment on feeding materials is carried out by adopting a first predetermined pressure, and the high-pressure reverse osmosis concentration treatment means that the reverse osmosis concentration treatment on the feeding materials by adopting a second predetermined pressure, and the first predetermined pressure is less than the second predetermined pressure. The concentration equipmentcomprises a temporary memory unit, a homogenizing unit and corresponding concentration units. Through arrangement of a low-pressure reverse osmosis concentration treatment unit and a high-pressure reverse osmosis concentration treatment unit, feed liquid can be concentrated quickly and effectively.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

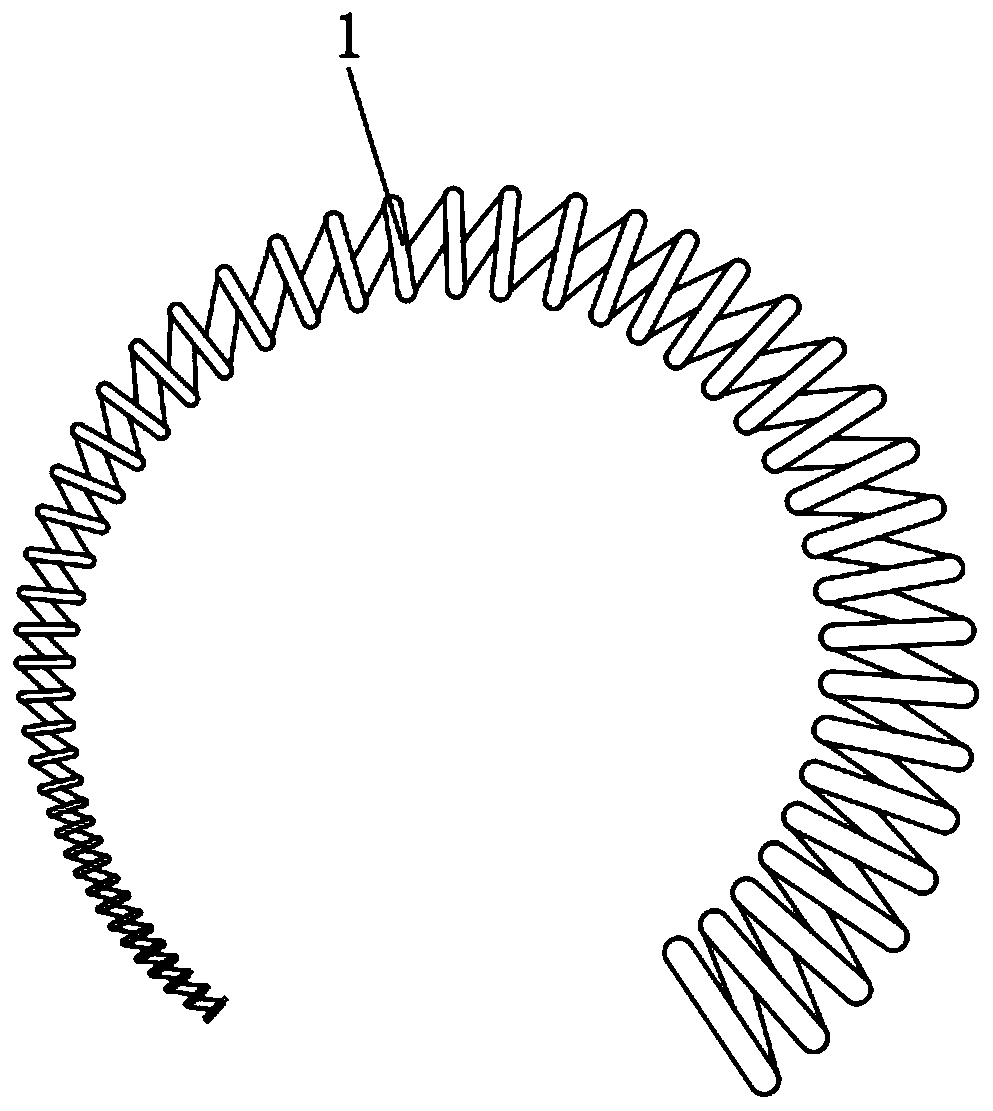

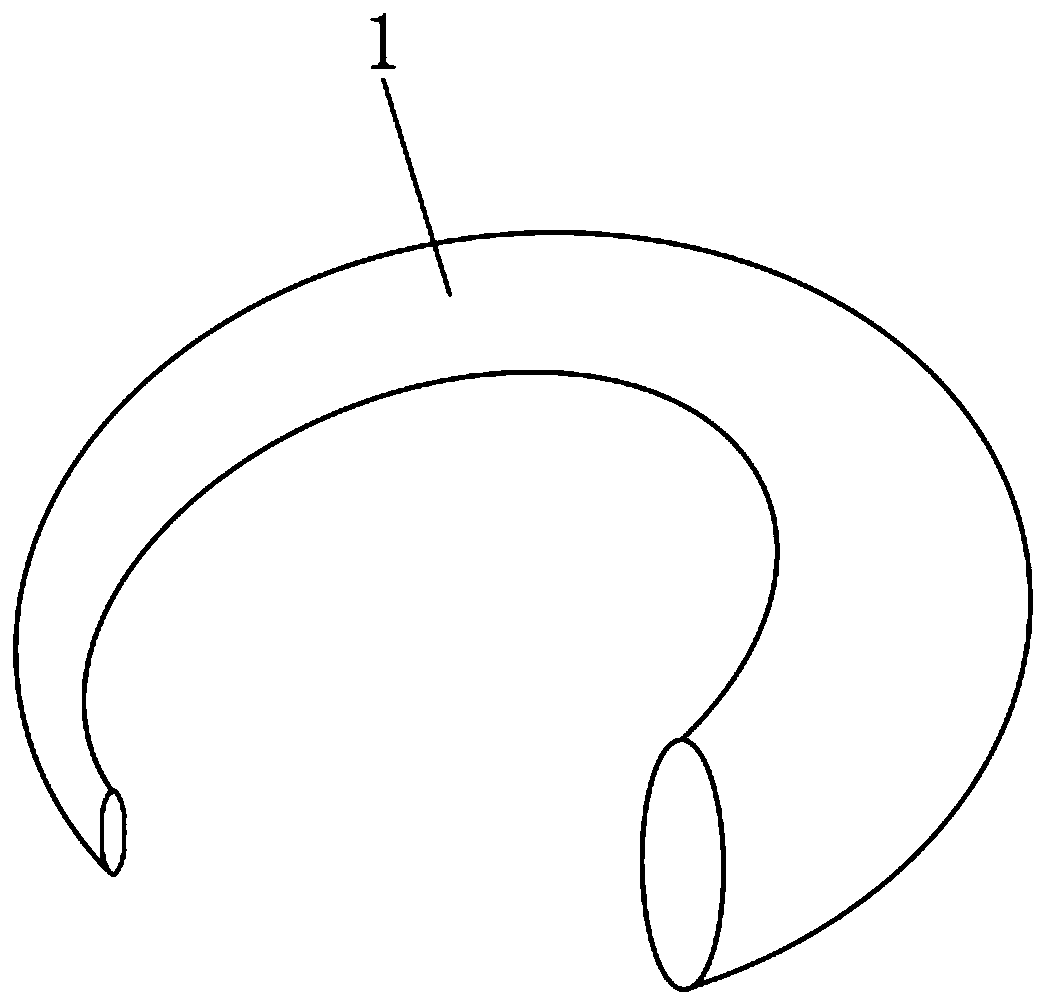

Ox horn-like transcranial magnetic stimulation coil capable of increasing magnetic field depth

PendingCN111388868AAdd depthAchieve high concentrationElectrotherapyMagnetotherapy using coils/electromagnetsMaterials scienceMagnetic brain stimulation

The present invention discloses an ox horn-like transcranial magnetic stimulation coil capable of increasing the magnetic field depth. The coil comprises a coil body; the coil body is in an arc horn shape formed by a lead wire in a surrounding manner; the coil body continuously forms an arc shape; openings in the two ends of the coil body are opposite; the whole coil body forms an ox horn-like structure in a surrounding manner; the distance between central points of the cross sections of the two ends of the coil body is 5-20 cm; the inner diameters of the openings in two ends of the coil bodyare both 1-25 cm; and a vertical axial included angle between the cross sections of the two ends of the coil body is 0-180 DEG C. By arranging the ox horn-like coil, a magnetic line of force can be constrained and self-guided; and compared with an existing transcranial magnetic stimulation coil, the ox horn-like transcranial magnetic stimulation coil can achieve the effects of highly centralizingmagnetic stimulation, increasing the depth of magnetic stimulation and improving the utilization rate of a magnetic field, and also can achieve the effect of improving the biological effect.

Owner:杨绍杰

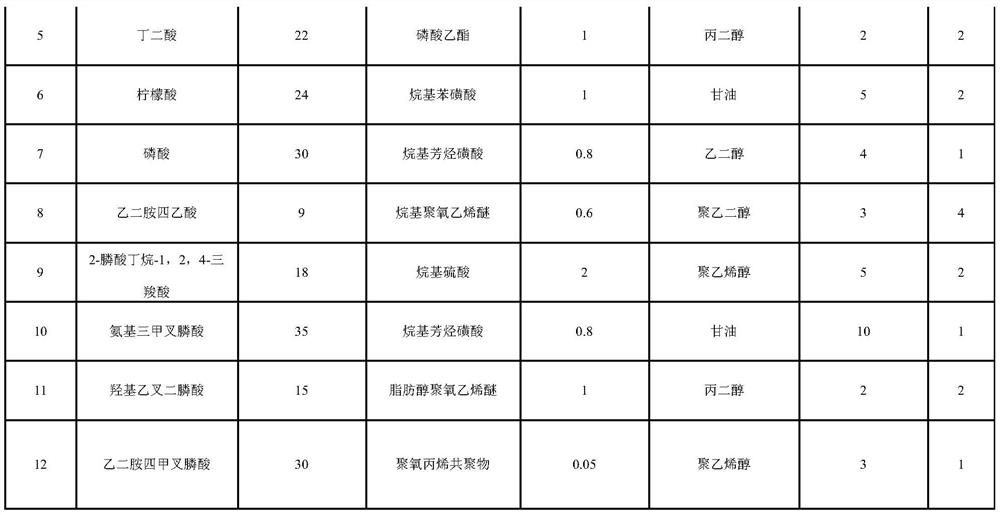

Electroplating wastewater whole membrane method process and device

PendingCN113264629AAchieve recyclingNo pollution in the processWaste water treatment from metallurgical processMultistage water/sewage treatmentCyanideProcess engineering

The invention discloses an electroplating wastewater whole membrane method process and a device, belongs to the technical field of electroplating wastewater treatment, and solves the problems that in the prior art, an electroplating wastewater treatment and discharge process does not reach the standard in discharge and wastes a lot of resources. The device comprises a comprehensive adjusting tank; an inlet of the comprehensive adjusting tank is communicated with a reduction pretreatment tank, a cyanide breaking pretreatment tank and a primary sedimentation tank which are connected in parallel, an outlet of the comprehensive adjusting tank is communicated with an immersed ultrafiltration system, the immersed ultrafiltration system is connected with a roll-type RO system, the roll-type RO system is connected with a DTRO system, the DTRO system and the roll-type RO system are both connected with a water recovery device, the DTRO system is also connected with an evaporative crystallization system, the evaporative crystallization system is connected with a metal recovery device, and the evaporative crystallization system is communicated with the comprehensive regulating reservoir. According to the invention, zero discharge of wastewater treatment is realized, resources are saved, and the treatment efficiency is improved.

Owner:四川省创飞格环保技术有限公司

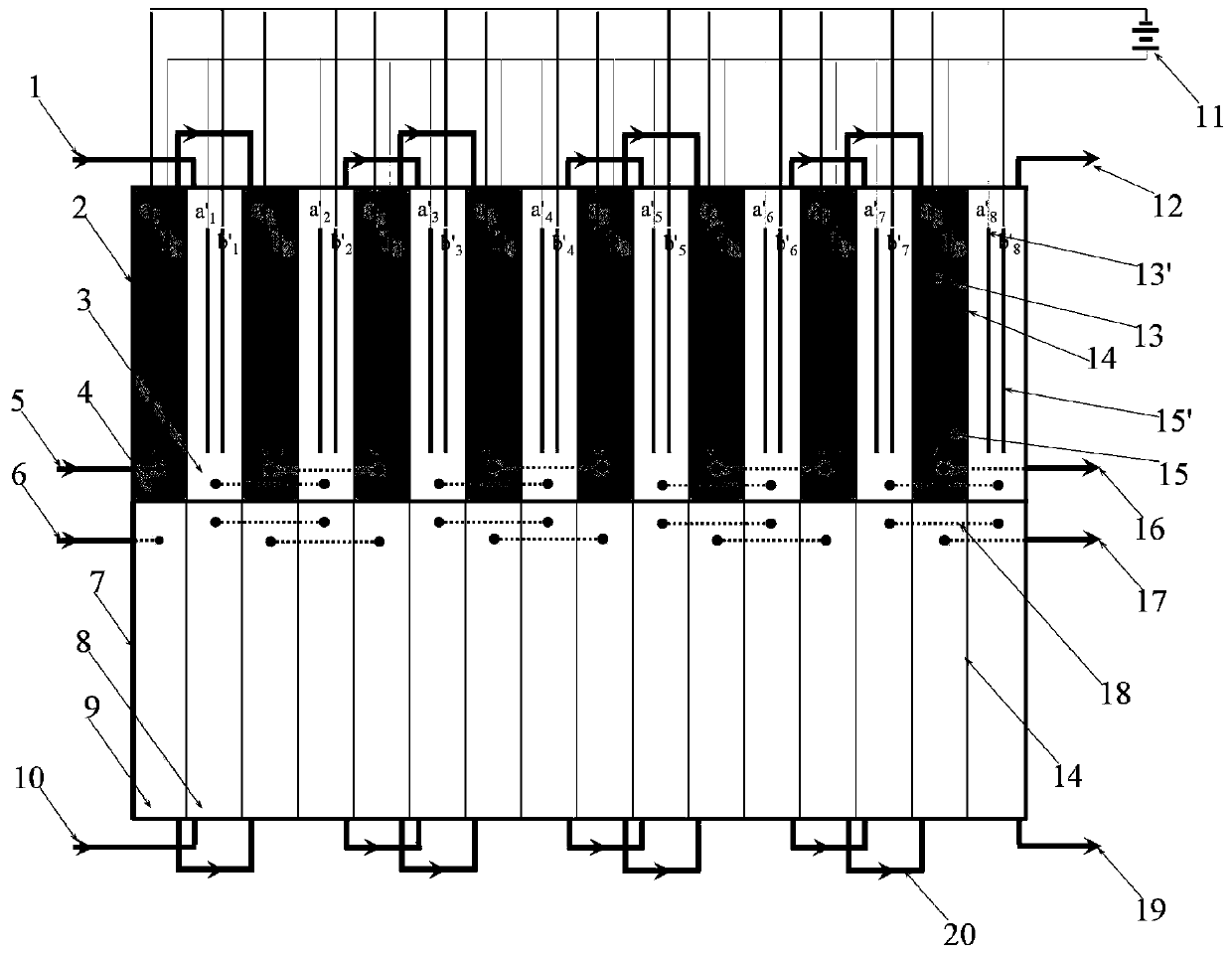

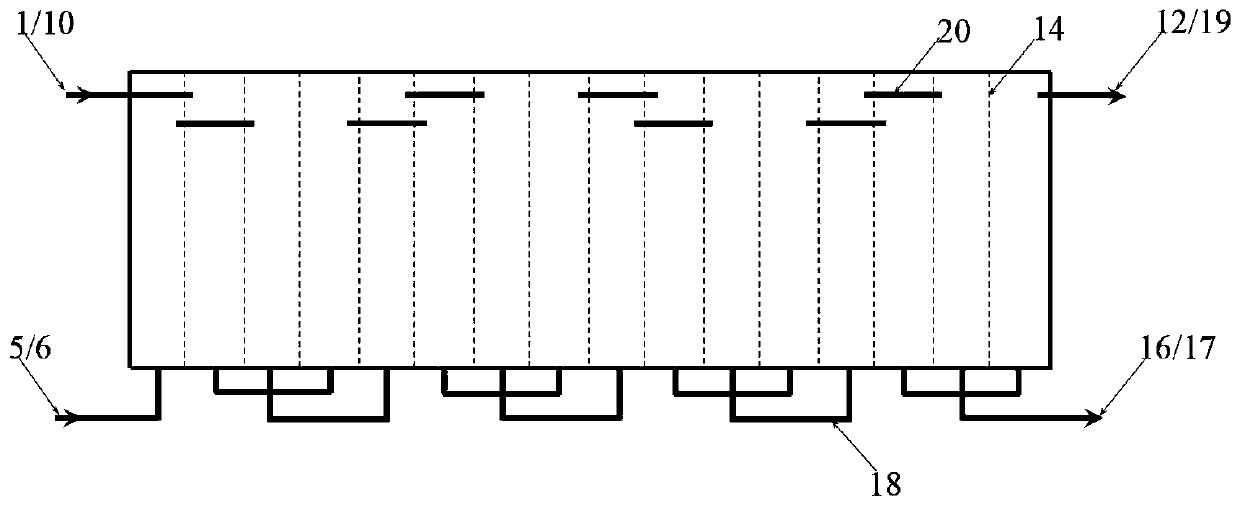

Continuous ion pump lithium extraction device and lithium extraction method thereof

ActiveCN110724832AAchieve high concentrationGreen separabilityCellsProcess efficiency improvementIon-exchange membranesElectric energy

The invention relates to a continuous electrochemical lithium extraction device based on an anion exchange membrane and a lithium extraction method thereof. The device is mainly composed of a power supply, an electrode, an electrolytic tank, a washing tank, anion exchange membranes and the like, the electrolytic tank is divided into a series of raw material pools and recovery pools by a series ofanion exchange membranes, the positions of the raw material pools and the recovery pools are alternately, and different raw material pools and recovery pools communicate sequentially and respectively.Under the action of a pump, the raw material and the recovery liquid are respectively pumped into the raw material pools and the recovery pools, and the lithium in the raw material is transferred andenriched in the recovery liquid through the control of the electrode position. The device is simple in composition and operation, only electric energy is consumed in the lithium recovery process, andthe use of any other toxic reagent does not be involved, so the continuous ion pump lithium extraction device and the lithium extraction method thereof is a green and efficient lithium extraction device and lithium extraction method.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Energy-saving environment-friendly street lamp device with high luminous flux

PendingCN113074347APrevent leakageAchieve high concentrationMechanical apparatusOutdoor lightingEngineeringLuminous flux

The invention discloses an energy-saving environment-friendly street lamp device with high luminous flux, belonging to the technical field of street lamps. The invention aims to overcome the problem that an existing street lamp is poor in condensation effect. The device specifically comprises a base, a placement plate and a lamp body mechanism, wherein a vertical frame is fixedly connected to the outer wall of the top of the base, an adjusting assembly is fixedly connected to the outer wall of one side of the top of the vertical frame, the placement plate and a bottom plate are both installed on the ground, and the lamp body mechanism comprises a refraction assembly and a bulb. According to the invention, the lamp body mechanism is arranged, the refraction assembly and the bulb are matched with each other, a grid motor is in an in-situ state, and a grid plate forms an annular closed space, so light emitted by the bulb is collected and light leakage is avoided; and meanwhile, the relative position of the bulb is fixed, the light is continuously refracted by a refraction plate in the annular closed space, and most of light rays are transmitted to the bottom through a ferrule, so high light gathering is achieved, luminous flux is improved, light rays are concentrated through the ferrule, and lighting effect is enhanced.

Owner:曾淑云

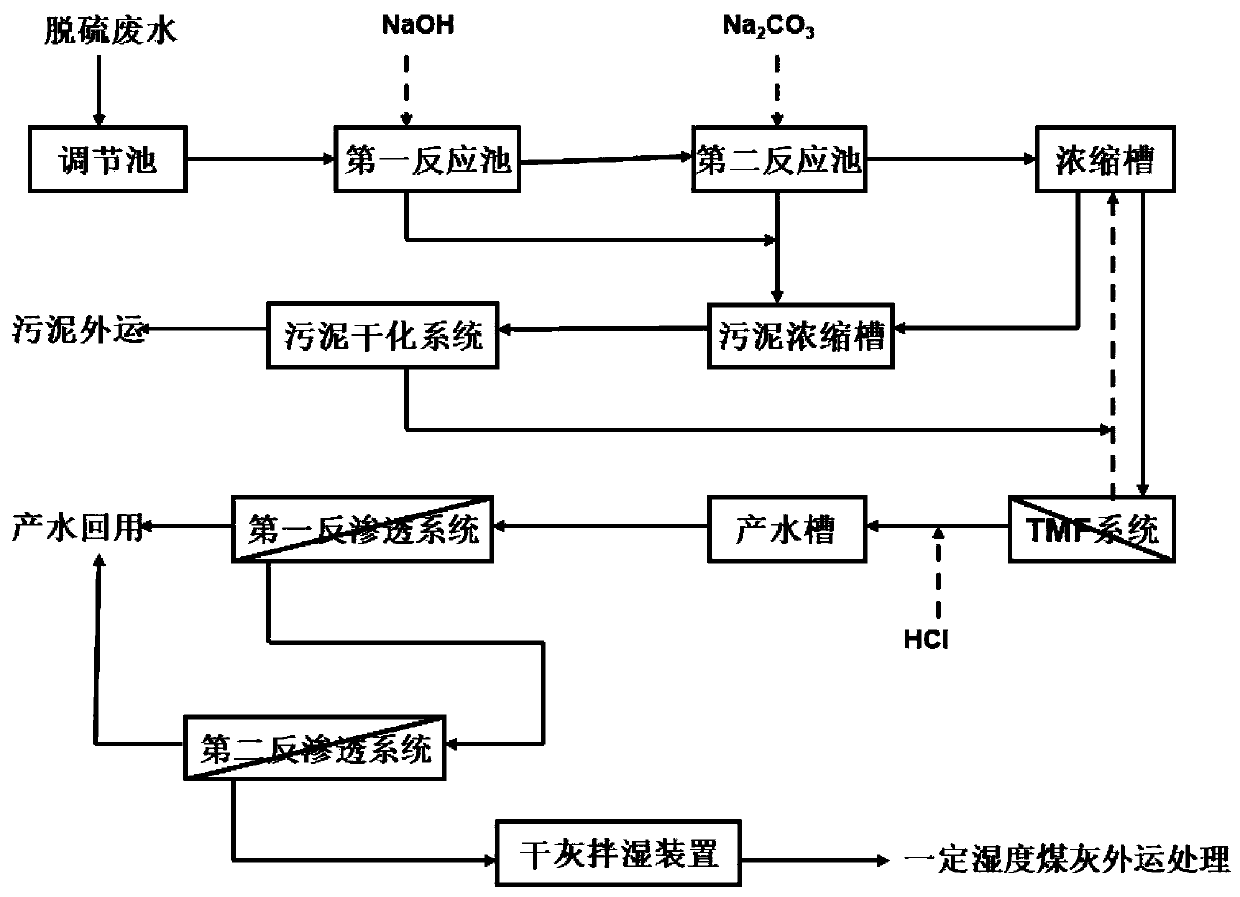

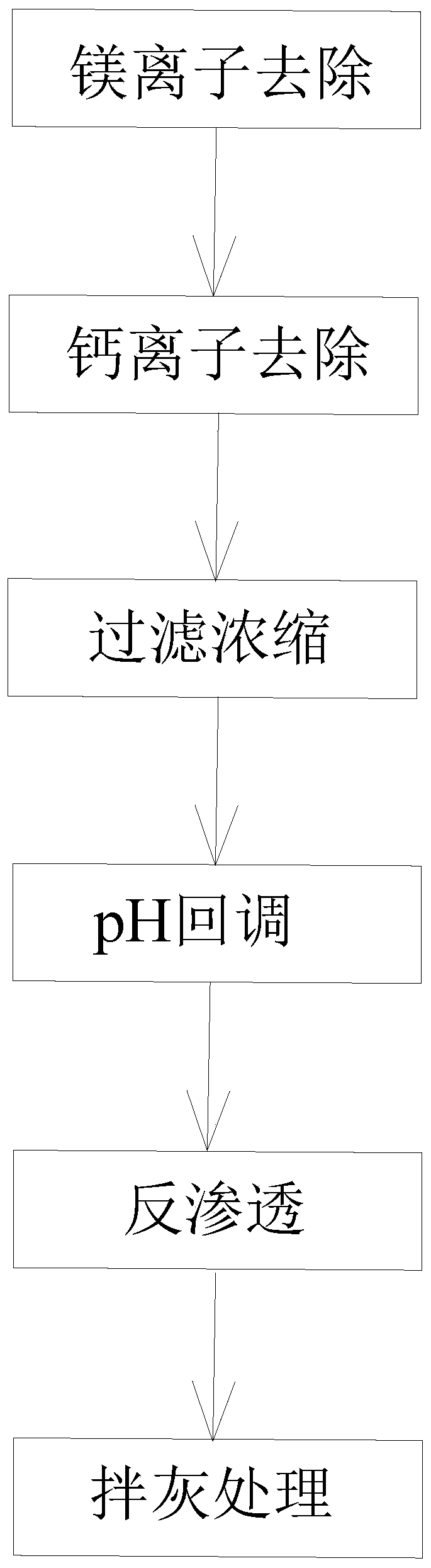

Wastewater treatment method

InactiveCN110818126AReduce the cost of dosingReduce productionWater contaminantsTreatment involving filtrationFiltrationReverse osmosis

The invention discloses a wastewater treatment method. Wastewater is recycled and used after steps of magnesium ion removal, calcium ion removal, filtration concentration, pH correction, reverse osmosis and ash mixing treatment. The wastewater treatment method has low cost of softening chemicals, no evaporation crystallization is needed, and the wastewater has a high water resource utilization rate.

Owner:SUNUP ENVIRONMENTAL TECH CO LTD

Microwave power amplifier chip carrier and preparation method thereof

ActiveCN111146155BImprove thermal conductivityAchieve high concentrationSemiconductor/solid-state device detailsSolid-state devicesCapacitanceAlloy substrate

The invention discloses a microwave power amplifier chip carrier and a preparation method thereof. The microwave power amplifier chip carrier includes: a high-silicon aluminum alloy substrate, a chip pad and a film capacitor, wherein the chip pad includes a chip welding metal layer and a carrier welding metal layer. Film capacitors include adhesive layers, dielectric layers, and electrode metal layers. The manufacturing method includes the following steps: providing a surface-polished high-silicon aluminum alloy substrate, sequentially forming an adhesive layer and a dielectric layer in the film capacitor region on the first surface of the substrate; forming a metal layer on the surface of the substrate; and performing scribing after forming a carrier welding metal layer on the second surface of the substrate. The microwave power amplifier chip carrier and manufacturing method provided by the present invention integrate the microwave power amplifier chip pad and the chip capacitor into one body, which can effectively reduce the manufacturing process steps of microwave components and reduce the difficulty of the process. In addition, the chip carrier also has excellent heat dissipation performance, grounding performance and reliability.

Owner:SHANGHAI SPACEFLIGHT ELECTRONICS & COMM EQUIP RES INST

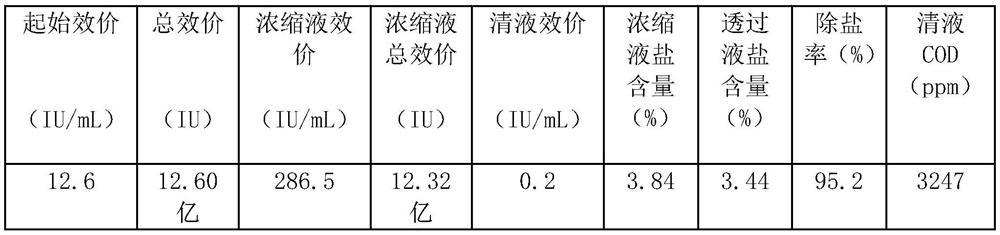

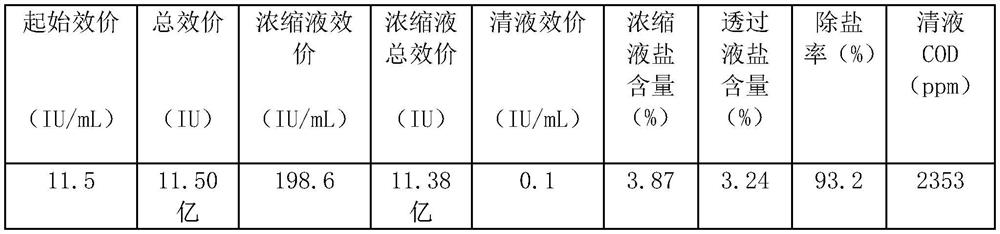

Preparation method of clavulanic acid tert-butylamine salt

The invention relates to a preparation method of a clavulanic acid tert-butylamine salt. The preparation method comprises the steps: acidifying a water solution of clavulanic acid, and then, extracting clavulanic acid from the water solution of clavulanic acid by using an organic solvent unmixed with water to obtain a clavulanic acid extracting solution; then, carrying out a mixed reaction on theclavulanic acid extracting solution and tert-butylamine serving as an organic amine donor to form a salt, carrying out standing for layering, and collecting a heavy phase to obtain a clavulanic acid tert-butylamine salt solution with high concentration; and finally, adding a cosolvent into the clavulanic acid tert-butylamine salt solution, and carrying out anti-solvent crystallization, filtration,washing and drying to obtain the clavulanic acid tert-butylamine salt. The preparation method of the clavulanic acid tert-butylamine salt disclosed by the invention is simple and convenient to operate, low in energy consumption and capable of reducing the preparation cost, and the quality of a product is high.

Owner:SHANXI WEIQIDA PHARMA IND

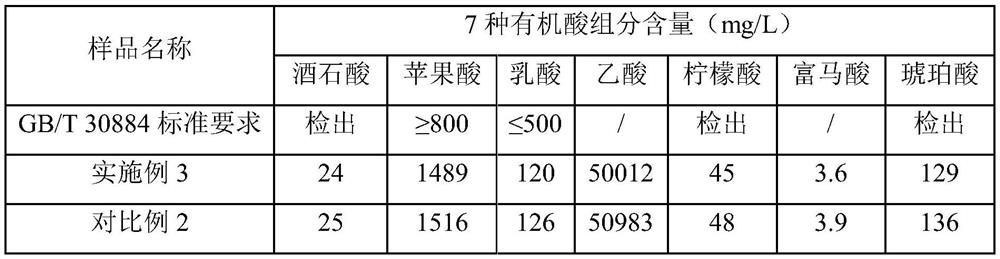

Bi-component apple vinegar beverage main agent as well as preparation method and application thereof

PendingCN111700193AReduce batching processWell mixedFood ingredient as taste affecting agentFood ingredient as mouthfeel improving agentBiotechnologyHigh-fructose corn syrup

The invention discloses a bi-component apple vinegar beverage main agent. The beverage main agent comprises a main agent A and a main agent B. The main agent A comprises concentrated apple vinegar, high fructose corn syrup A, honey, sodium citrate A and caramel color A in a specific ratio, and the main agent B comprises apple vinegar, edible salt, sucralose, sodium citrate B, caramel color B and edible essence in a specific ratio. By mixing and concentrating ingredients with great influence on taste and flavor in advance, an apple vinegar beverage with consistent flavor and stable quality canbe obtained according to standardized operation, and the beverage is low in transportation cost and good in storage performance. The invention further discloses a preparation method of the bi-component apple vinegar beverage main agent, the beverage main agent is stable in performance, easy and convenient to operate and high in production efficiency, and large-scale production can be achieved. Theinvention also discloses an application of the bi-component apple vinegar beverage main agent in rapid preparation of apple vinegar beverages, rapid blending production of the apple vinegar beveragesin different beverage factories can be realized, and the flavor and the quality are stable.

Owner:广东天地壹号食品研究院有限公司

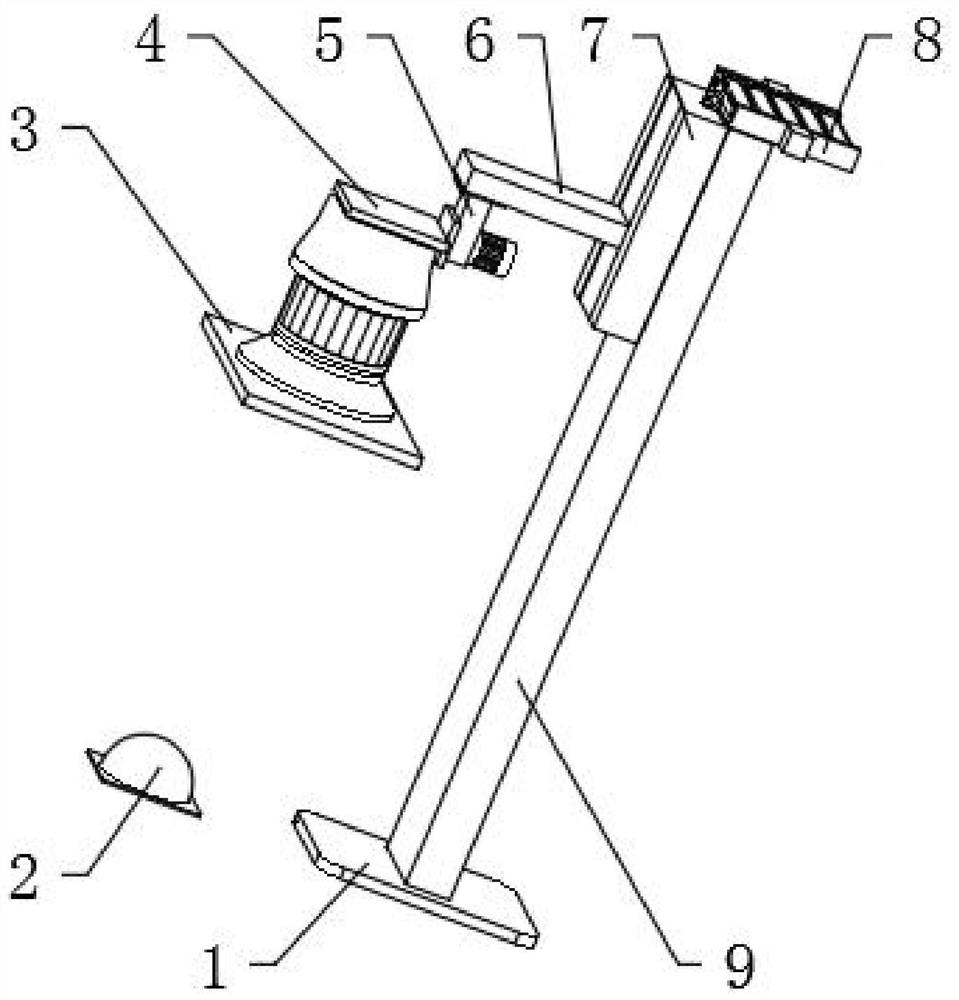

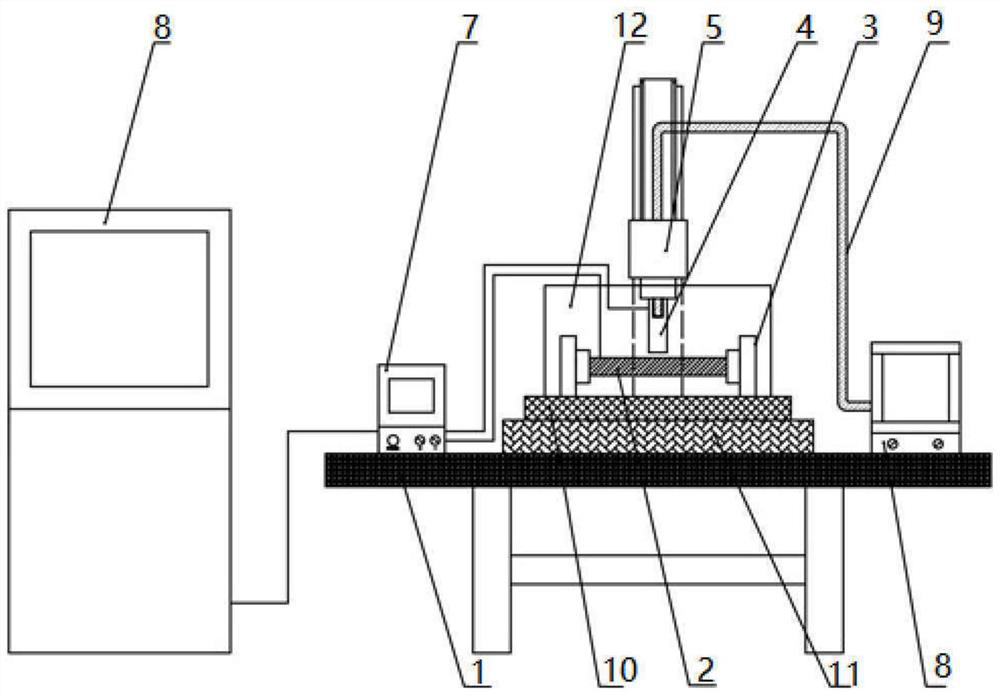

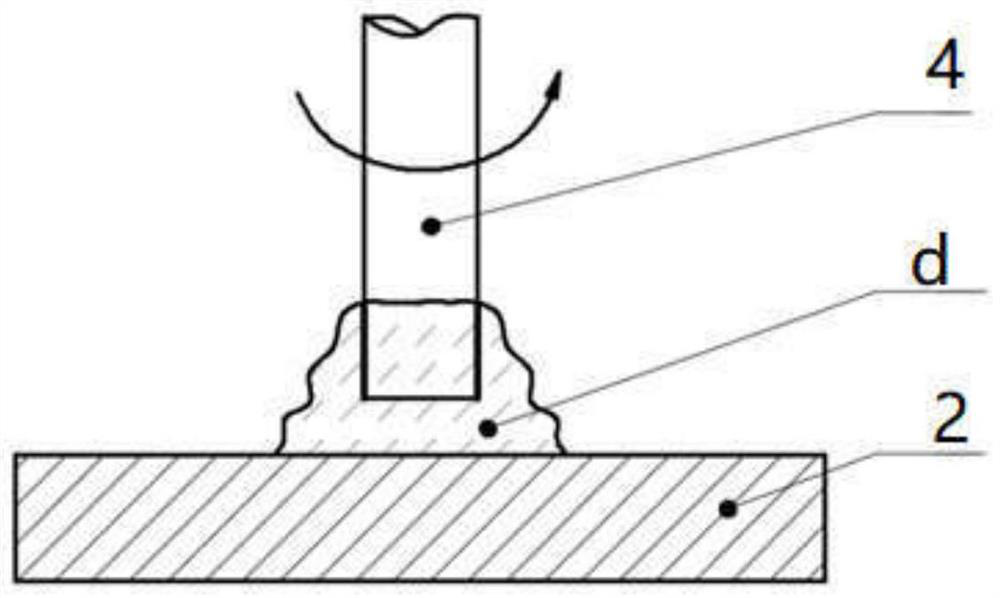

Field-domain-concentrated direct-writing type micro-electrochemical machining method and field-domain-concentrated direct-writing type micro-electrochemical machining device

ActiveCN114247944AControl flow characteristicsImprove concentrated corrosion (localization ability) abilityMachining working mediaMachining working media supply/regenerationElectrolytic agentMetallurgy

The invention discloses a field-domain-concentrated direct-writing type micro-electrochemical machining method and device. The method comprises the following steps that a workpiece is clamped on a workbench through a clamping mechanism; placing the high-molecular polymer particles in an electrolytic medium preparation mechanism, and dissolving, diluting and mixing the high-molecular polymer particles by the electrolytic medium preparation mechanism to form a viscous electrolytic medium; the tail end of the conveying pipe is guided to the position above the workpiece through a position adjusting mechanism; conveying a viscous electrolytic medium to the workpiece through a conveying pipe, wherein the electrolytic medium is vertically arranged on the workpiece; driving a tool to move above the workpiece through a main shaft driving mechanism, so that the tool is inserted into the electrolytic medium; adjusting the distance between the tool and the workpiece; switching on a power supply and performing electrolytic machining on the surface of the workpiece. The high-molecular polymer material is used as a component of the electrolytic medium, the flow characteristic of the electrolyte is controlled, the concentrated corrosion capacity is improved, stray corrosion is reduced, and the direct effect of field domain concentration is achieved.

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV

Sensor device for detecting metal wall thickness by pulsed eddy current

PendingCN110926323AHigh energyRich in frequency componentsUsing electrical meansElectrical/magnetic thickness measurementsSignal qualityEddy current

The invention discloses a sensor device for detecting metal wall thickness by pulsed eddy current. The device comprises an I-shaped framework, excitation coils are respectively arranged at two ends ofa horizontal framework of the I-shaped framework, detection coils are arranged at the two ends of a vertical framework of the I-shaped framework, a center hole is formed in the center of the upper portion of the I-shaped framework, a cylindrical magnetic core is installed in the center hole, the outer side of the cylindrical magnetic core is wrapped with polytetrafluoroethylene cloth, a shieldinglayer of a square structure is arranged on the outer side of the I-shaped framework, and the shielding layer is located in the shell. The excitation electromagnetic field energy is large; the frequency components are rich, a space electromagnetic field can be highly concentrated, the detection rate of local corrosion and hole-shaped corrosion is improved, the shielding effect on the external environment is achieved, interference of detection signals is reduced, the filtering effect on the detection signals is achieved, the signal quality is improved, effective detection data are further obtained, and the detection sensitivity is improved.

Owner:SHAANXI TECHN INST OF DEFENSE IND

A diaphragm-free electrochemical lithium extraction system and lithium extraction method thereof

ActiveCN110643831BAchieve high concentrationEasy to separateProcess efficiency improvementPhysical chemistryLithium electrode

The invention relates to a continuous electrochemical lithium extraction system without a diaphragm and a lithium extraction method thereof. The system is mainly composed of an electrolytic tank, a washing tank, a power supply, a series of lithium absorbing and desorbing electrodes and an electronic balance electrode. Among them, the electrolytic cell is divided by a series of separators into raw material pools and recovery pools which alternate in sequence, and different raw material pools and recovery pools are connected in series through connecting pipes. The lithium raw material to be extracted and the recovery solution are respectively introduced into the raw material pool and the recovery pool, and lithium is separated from the raw material and enriched in the recovery solution by switching electrodes between the raw material pool and the recovery pool. The system is easy to increase or decrease the number of electrolytic cell stages, or control the frequency of electrode position exchange, so as to meet the lithium extraction requirements of different lithium-containing solutions. In the process of lithium extraction, the raw material and recovery liquid circuits are independent and run continuously, so continuous electrochemical lithium extraction can be realized. In addition, since the lithium extraction process only involves the regular movement of electrodes, it is easy to realize automatic operation.

Owner:TIANJIN UNIV OF SCI & TECH +1

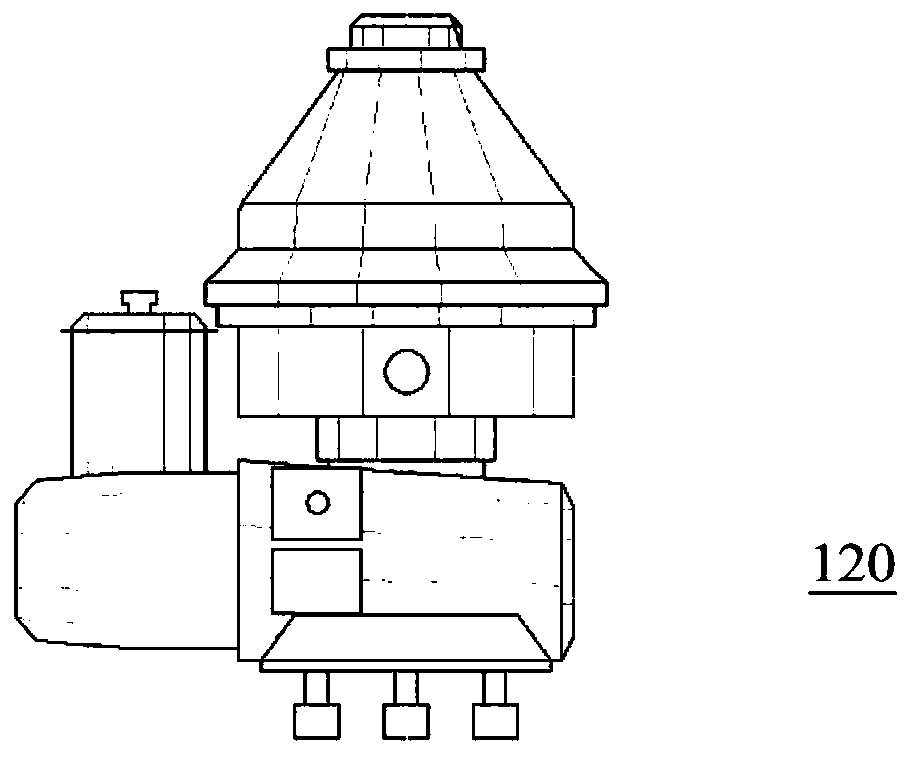

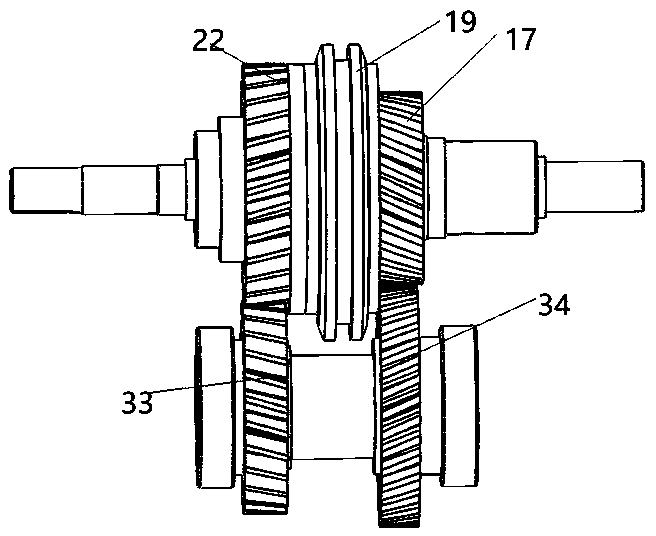

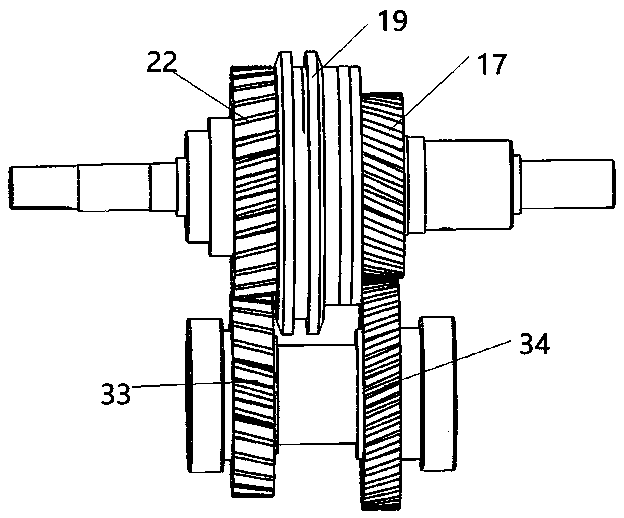

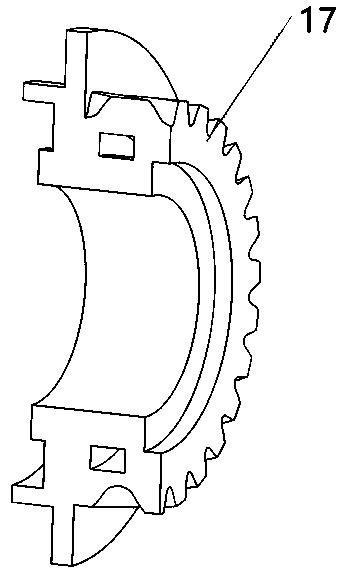

An integrated motor reduction drive system for helicopter empennage

ActiveCN108058824BAchieve high concentrationAchieve balanceToothed gearingsEfficient propulsion technologiesMotor speedReduction drive

Owner:HEFEI UNIV OF TECH

Electrostatic field-based air sampler and sampling method thereof

ActiveCN102109423BAchieve high concentrationAchieve integrationWithdrawing sample devicesPreparing sample for investigationPeristaltic pumpLiquid medium

The invention discloses an electrostatic field-based air sampler and a sampling method thereof. The air sampler mainly comprises a hemispherical electrode (1), a round electrode (2) and a sampling tank (4). Microorganisms with electric charges in air in a sampling space are concentratedly deposited in a liquid medium in a relatively small area in the center of a hemisphere along the direction of an electrostatic field under the action of the electrostatic field, and an air sample is dynamically conveyed under the drive of a micro peristaltic pump simultaneously. The defects that efficiency islow, an automatic sample conveying system is not provided and the like in the prior art are overcome, and the air sample is sampled to the trace liquid medium through the electrostatic field by a novel electrostatic field sampling method, and is dynamically conveyed to a biological / chemical sensor through an inlet and outlet. The air sample is highly concentrated, and the air sampler can be integrated with the sensor and has a good application prospect in the fields of environment monitoring and the like.

Owner:北京鼎蓝科技有限公司

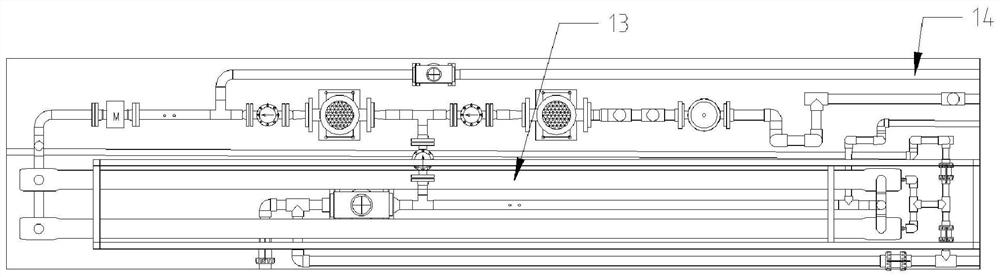

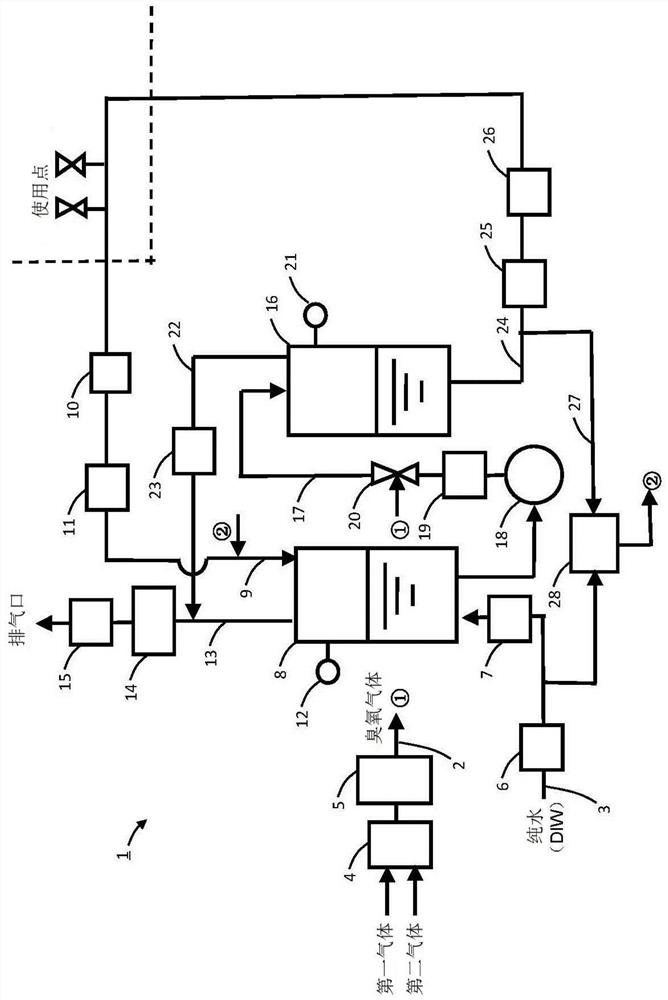

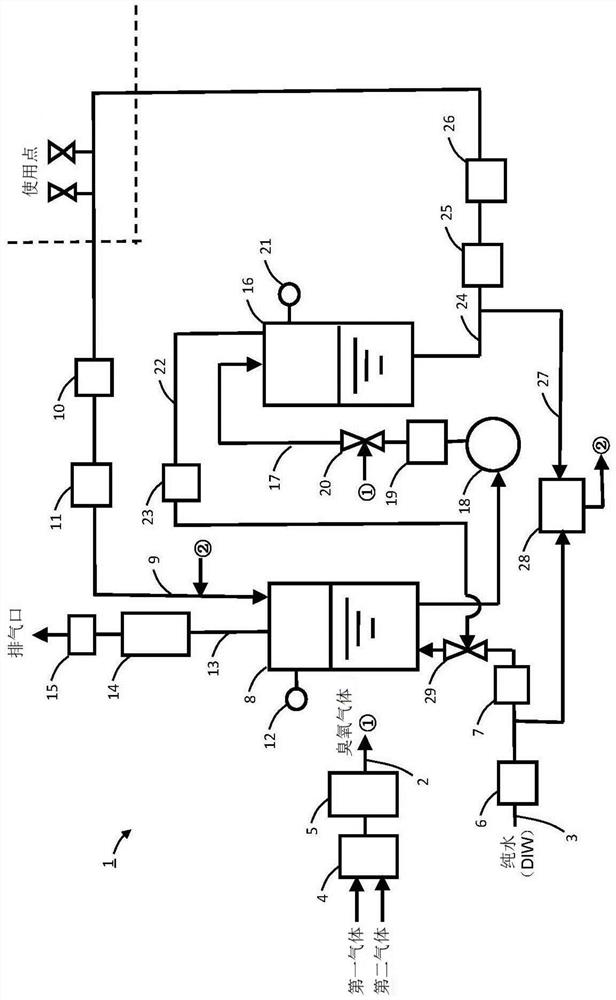

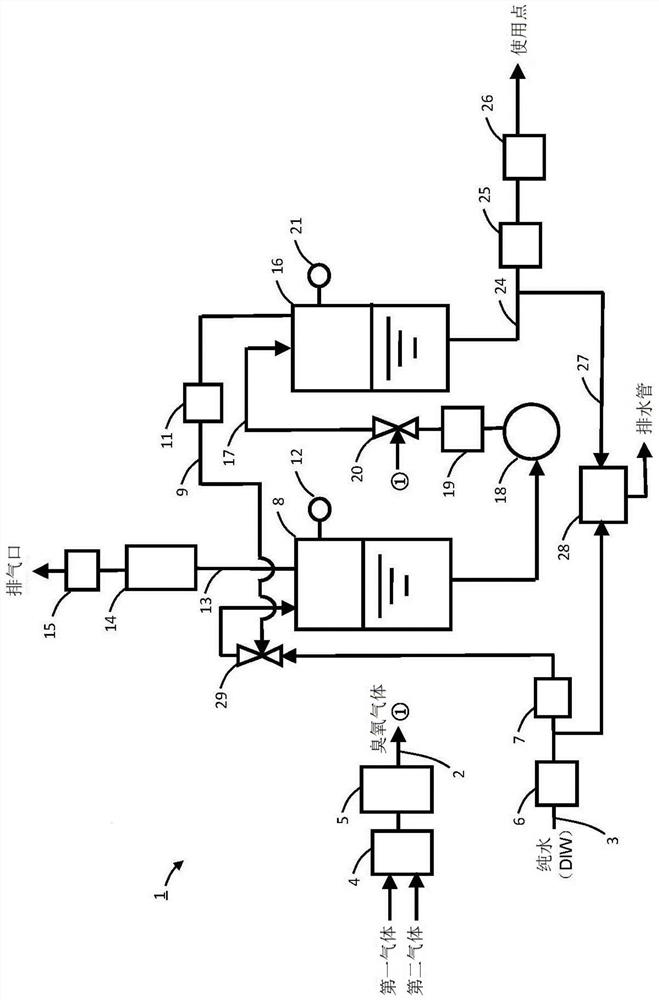

Gas solution supply device and method executed by gas solution supply device

PendingCN114272776AAchieve high concentrationSuppresses fluctuations in delivery pressureFlow mixersDissolving systemsVapor–liquid separatorEnvironmental engineering

The invention provides a dissolved gas solution supply device and a method executed by the dissolved gas solution supply device, which can realize high concentration of the dissolved gas solution and can restrain fluctuation of sending pressure of the dissolved gas solution. A dissolved gas solution supply device (1) is provided with: a first gas-liquid separator (8) that stores a dissolved gas solution; a second gas-liquid separator (16) that is provided downstream of the first gas-liquid separator and stores a dissolved gas solution to be supplied to a point of use; and an intermediate line (17) that is provided between the first gas-liquid separator and the second gas-liquid separator. A booster pump (18) which is provided in the intermediate line and which raises the pressure of the gas-dissolved solution supplied from the first gas-liquid separator to the second gas-liquid separator; and a gas supply line (2) which supplies a gas that is a raw material for the gas-dissolved solution. And a gas dissolving unit (20) that is provided in the intermediate line and that dissolves the gas supplied from the gas supply line in the gas-dissolved liquid supplied from the first gas-liquid separator.

Owner:EBARA CORP

A continuous ion pump lithium extraction device and lithium extraction method

ActiveCN110724832BAchieve high concentrationEasy to separateCellsProcess efficiency improvementIon-exchange membranesIon pump

The invention relates to a continuous electrochemical lithium extraction device and a lithium extraction method based on an anion exchange membrane. The device is mainly composed of power supply, electrodes, electrolytic tank, washing tank, anion exchange membrane and so on. The electrolytic cell is divided into a series of raw material pools and recovery pools by a series of anion exchange membranes, wherein the positions of the raw material pools and the recovery pools are alternated in turn, and different raw material pools and different recovery pools are connected in sequence. Under the action of the pump, the raw material and the recovery liquid are pumped into the raw material pool and the recovery pool respectively, and the lithium in the raw material is transferred and enriched in the recovery liquid by controlling the position of the electrode. The composition and operation of the device are simple, and only electric energy is consumed in the lithium recovery process, and the use of any other toxic reagents is not involved, so it is a green and efficient lithium extraction device and lithium extraction method.

Owner:TIANJIN UNIV OF SCI & TECH +1

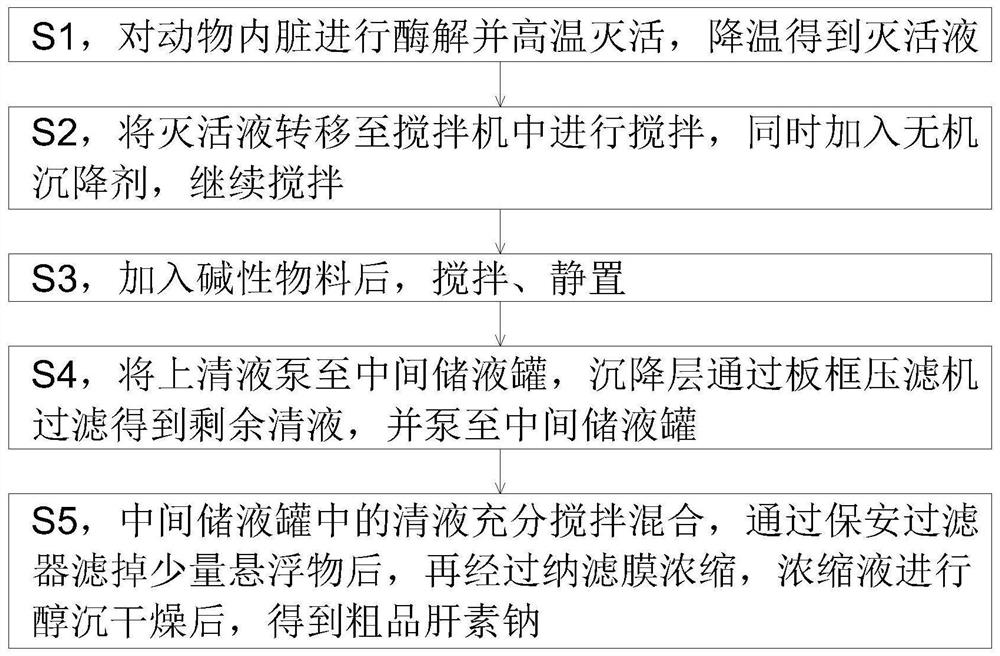

Process for extracting crude heparin sodium through nanofiltration membrane concentration

The invention relates to the technical field of heparin sodium production, and discloses a process for extracting crude heparin sodium through nanofiltration membrane concentration, wherein the process comprises the following steps: S1, carrying out enzymolysis and high-temperature inactivation on animal viscera, and cooling to obtain an inactivated solution; S2, transferring the inactivated solution into a stirrer for stirring, adding an inorganic settling agent at the same time, and continuously stirring; S3, adding an alkaline material, stirring, and standing; S4, pumping the supernate into a middle liquid storage tank, filtering a settling layer through a plate-and-frame filter press to obtain residual clear liquid, and pumping the residual clear liquid into the middle liquid storage tank; and S5, fully stirring and mixing the clear liquid in the intermediate liquid storage tank, filtering out a small amount of suspended matters through a security filter, concentrating through a nanofiltration membrane, and carrying out alcohol precipitation and drying on the concentrated solution to obtain a crude heparin sodium product. The process is characterized in that an inorganic settling agent is adopted to remove turbid substances in the inactivated solution, a disc tube type nanofiltration membrane is adopted to remove salt and small molecular impurities in the clear liquid, heparin sodium is concentrated, and then the heparin sodium crude product is obtained through alcohol precipitation and drying processes.

Owner:重庆博万生物制药有限公司

A Membrane System Realizing High Concentration

ActiveCN112340938BChange the rejection rateAchieve high concentrationGeneral water supply conservationWater contaminantsHigh concentrationDesalination

The invention discloses a membrane system for realizing high concentration, and belongs to the technical field of water pollution treatment. The system includes a pretreatment system, a high concentration membrane system, a water production tank, and a secondary membrane system. The pretreatment system is connected to the high concentration membrane system, the high concentration membrane system is connected to the water production tank, and the water production tank is connected to the secondary membrane system; in addition, the water production tank is connected to the high concentration membrane system, and the secondary membrane system is connected to the high concentration membrane system. The system reduces the osmotic pressure difference between the concentrated water and the product water side by controlling the desalination rate of the membrane module, so as to achieve high concentration at a lower operating pressure, and the highest concentration can reach a state close to saturation.

Owner:烟台金正环保科技有限公司

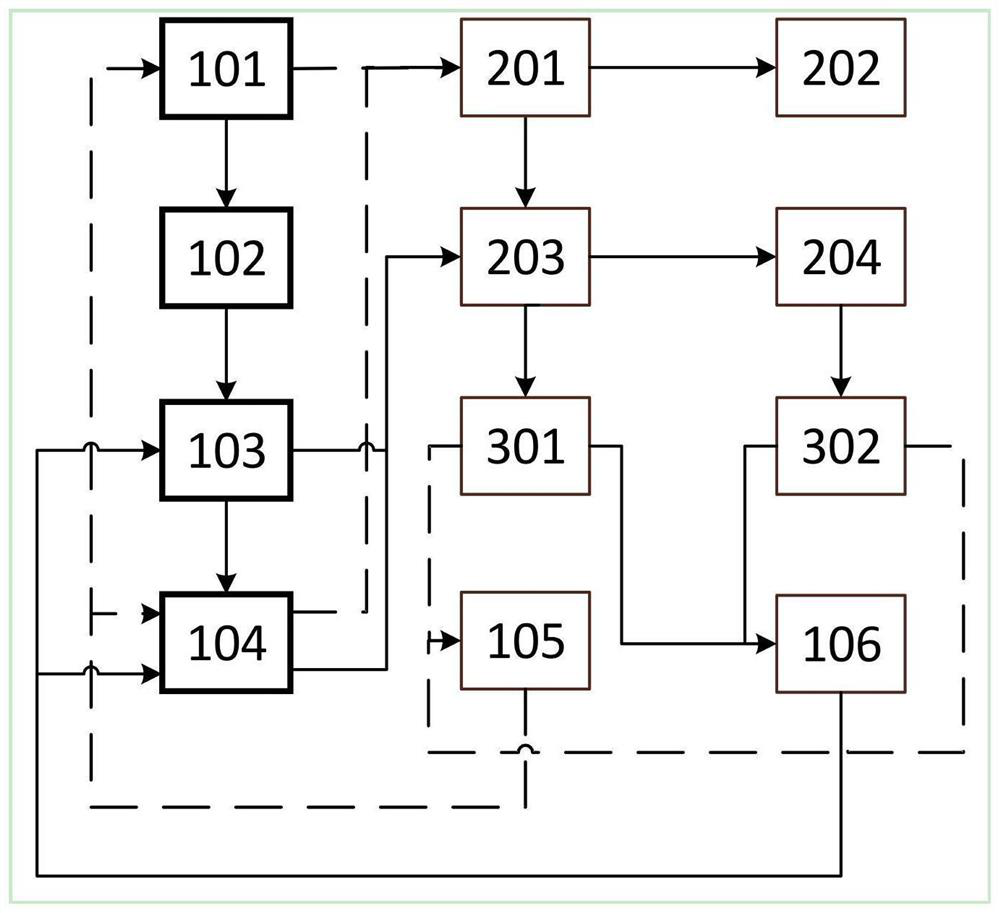

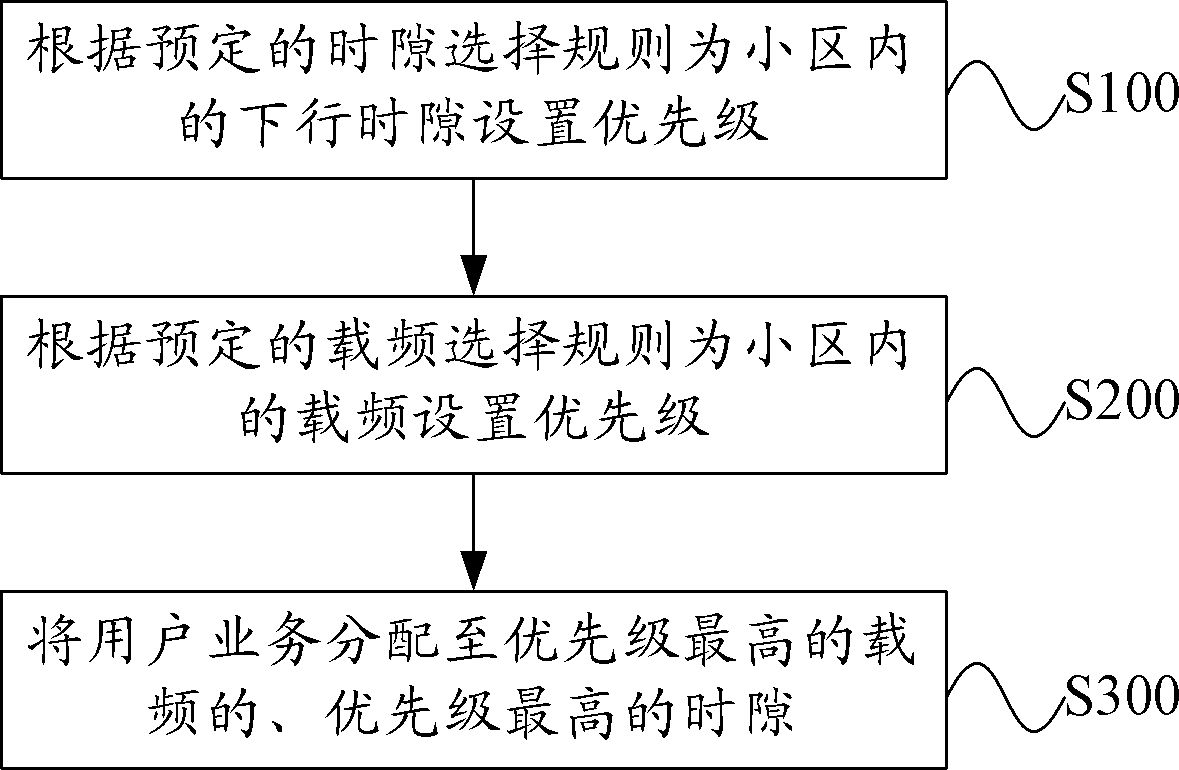

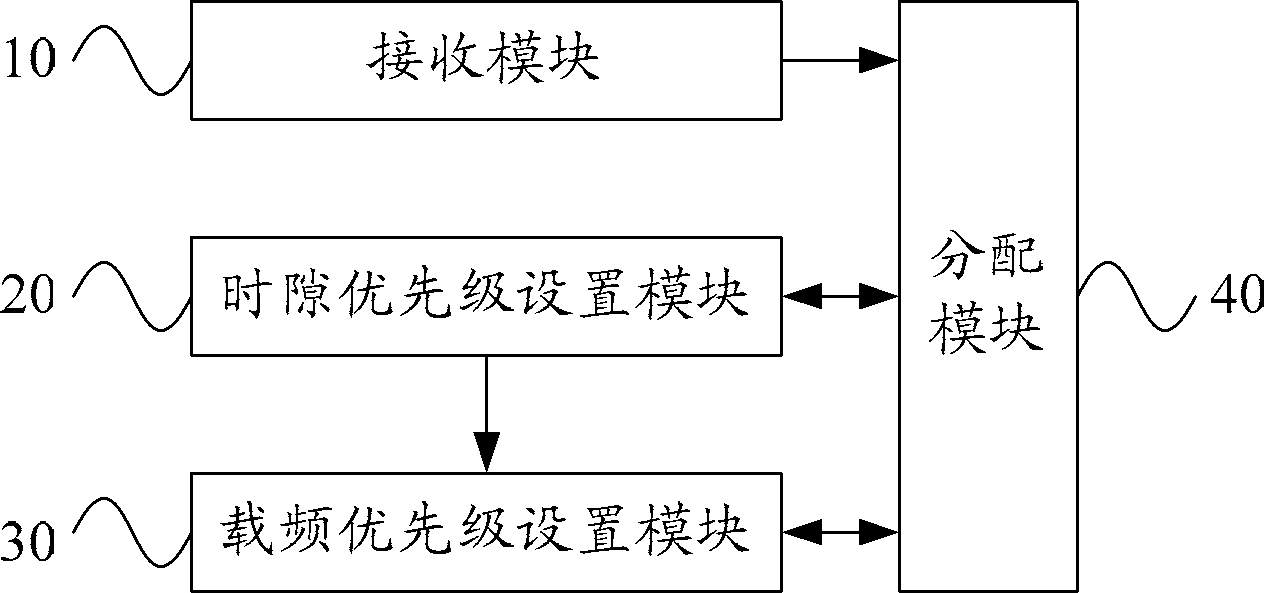

Method and device for integrating resources

InactiveCN102638890BAchieve high concentrationAchieve high efficiency and energy savingEnergy efficient ICTHigh level techniquesSpecific timeSynchronization code division multiple access

The invention provides a method and device for integrating resources. The method for integrating resources comprises the following steps of: setting a priority level for a downlink time slot in a cell according to a predetermined time slot selecting rule; setting a priority level for carrier frequency in the cell according to a predetermined carrier frequency selecting rule; and distributing the user service to the carrier frequency with the highest priority level and the time slot with the highest priority level. According to the method and device for integrating resources, the priority levels of the time slot and the carrier frequency in the cell are set according to the predetermined time slot selecting rule and the predetermined carrier frequency selecting rule, and the user is distributed to the specific time slot of the specific carrier frequency in consideration of the time slot centralization and the carrier frequency centralization when the channel is distributed for users in response to the calling request initiated by the users, thereby realizing the highly centralized user distribution and achieving high efficiency and energy conservation of a TD-SCDMA (Time Division-Synchronization Code Division Multiple Access) system.

Owner:TD TECH COMM TECH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com