Sensor device for detecting metal wall thickness by pulsed eddy current

A sensor device and pulsed eddy current technology, which is applied to measurement devices, electromagnetic measurement devices, electrical devices, etc., can solve the problems that the sensor device cannot be shielded by external environmental factors, the frequency component of the excited spatial electromagnetic field is single, and the detection data has a large influence, etc. Achieving the effect of enriching frequency components, improving detection sensitivity and improving detection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

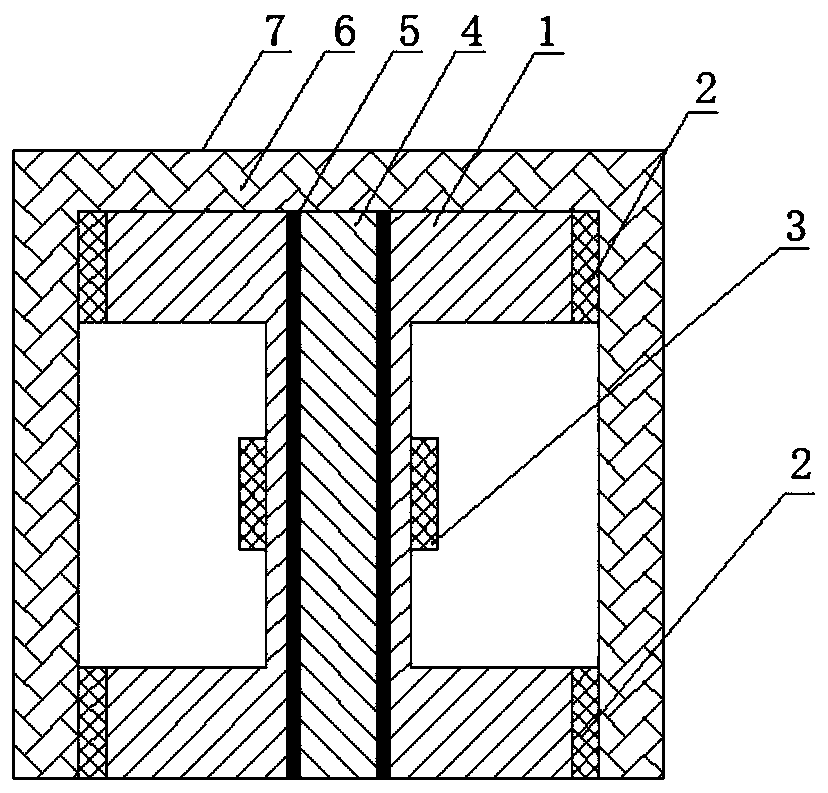

[0021] Such as figure 1 As shown: the present invention provides a pulsed eddy current sensor device for detecting metal wall thickness, which consists of an I-shaped frame 1, an excitation coil 2, a detection coil 3, a cylindrical magnetic core 4, a tetrafluorocloth 5, a shielding layer 6, and a casing 7.

[0022] The excitation coil 2 is installed at both ends of the I-shaped frame 1, the connection mode between the excitation coils 2 is series connection, the detection coil 3 is installed at the center of the I-shaped frame 1, and the cylindrical magnetic core 4 is installed at the center of the I-shaped frame 1. The central hole, the cylindrical magnetic core 4 is wrapped by tetrafluoro cloth 5, the shielding layer 6 is installed on the outside of the I-shaped skeleton 1, and the whole sensor is located in the shell 7.

[0023] The excitation coil 2 is w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com