Gas solution supply device and method executed by gas solution supply device

A supply device and gas supply technology, applied in the direction of gas/steam and liquid mixing, dissolution system, liquid degassing general layout, etc., can solve the difficulty of high concentration of ozone water, difficulty in suppressing the change of ozone water delivery pressure, difficulty in Increase the pressure of the gas-liquid separator and other problems to achieve the effect of suppressing the fluctuation of the delivery pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

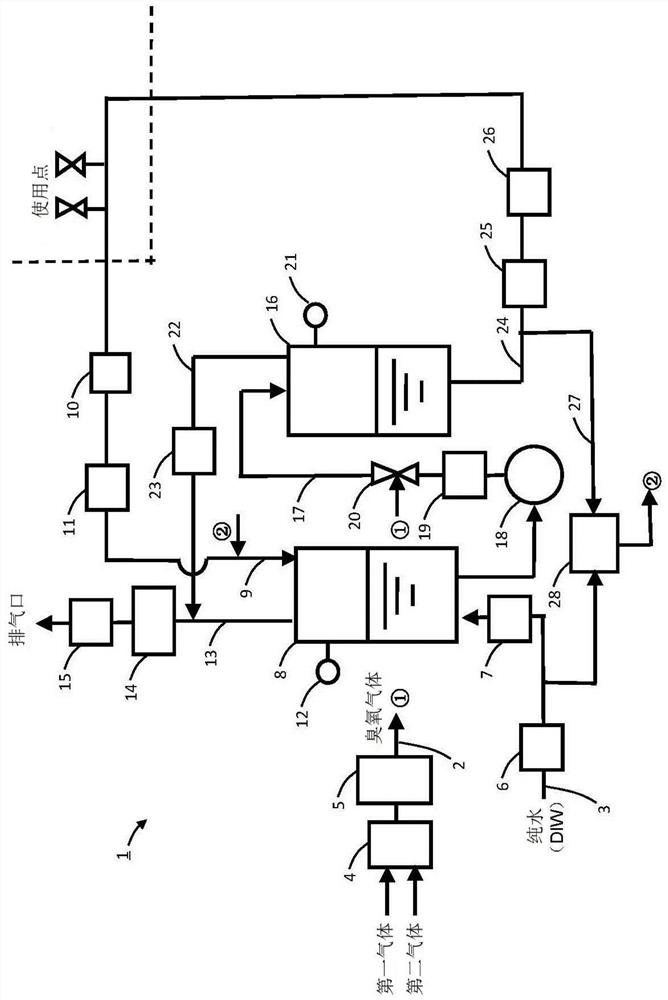

[0070] The structure of the ozone water supply apparatus which concerns on 1st Embodiment of this invention is demonstrated, referring drawings. figure 1 It is explanatory drawing which shows the structure of the ozone water supply apparatus of this embodiment. Such as figure 1 As shown, the ozone water supply device 1 includes a gas supply line 2 for supplying ozone gas as a raw material of ozone water, and a liquid supply line 3 for supplying pure water (DIW) as a raw material of ozone water.

[0071] A first gas (for example, oxygen gas) and a second gas (for example, carbon dioxide gas, nitrogen gas, or a mixed gas of carbon dioxide gas and nitrogen gas) serving as a raw material of ozone gas are supplied to the gas supply line 2 . A gas flow regulator 4 and an ozone generator 5 are provided on the gas supply line 2 . The gas flow regulator 4 adjusts the flow of the first gas and the second gas respectively. The ozone generator 5 generates ozone gas from the source gas ...

no. 2 approach

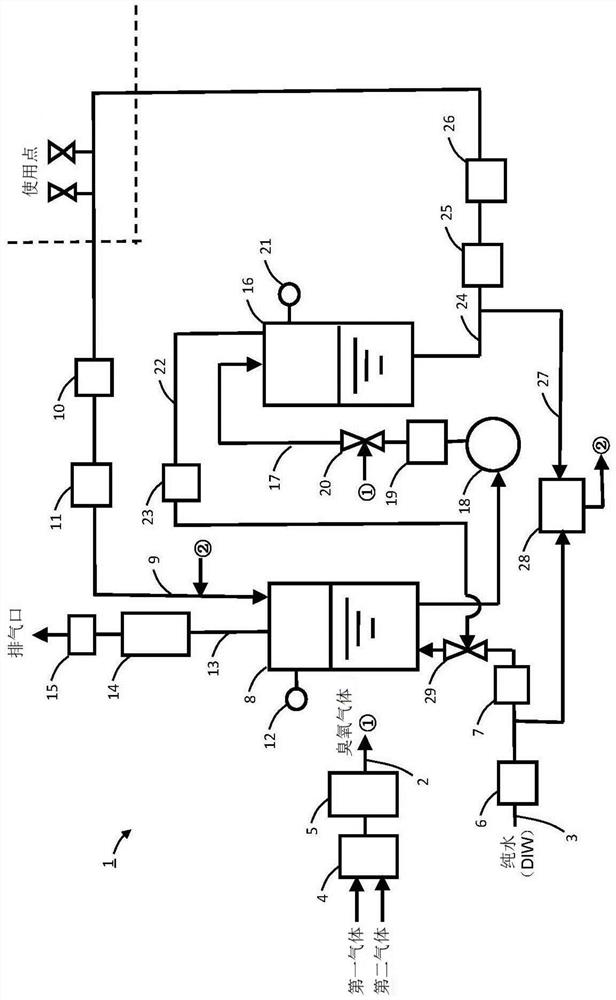

[0085] Next, an ozone water supply device 1 according to a second embodiment of the present invention will be described. Here, the difference between the ozone water supply apparatus 1 of 2nd Embodiment and 1st Embodiment is demonstrated centering. Here, unless otherwise mentioned, the structure and operation of this embodiment are the same as those of the first embodiment.

[0086] figure 2 It is explanatory drawing which shows the structure of the ozone water supply apparatus 1 of this embodiment. Such as figure 2 As shown, in this embodiment, the second gas dissolving nozzle 29 is provided on the liquid supply line 3 , and the discharge line 22 from the second gas-liquid separator 16 is connected to the second gas dissolving nozzle 29 . The second gas dissolving nozzle 29 dissolves undissolved excess ozone gas discharged from the second gas-liquid separator 16 in the pure water supplied to the liquid supply line 3 . Ozone water is supplied from the liquid supply line ...

no. 3 approach

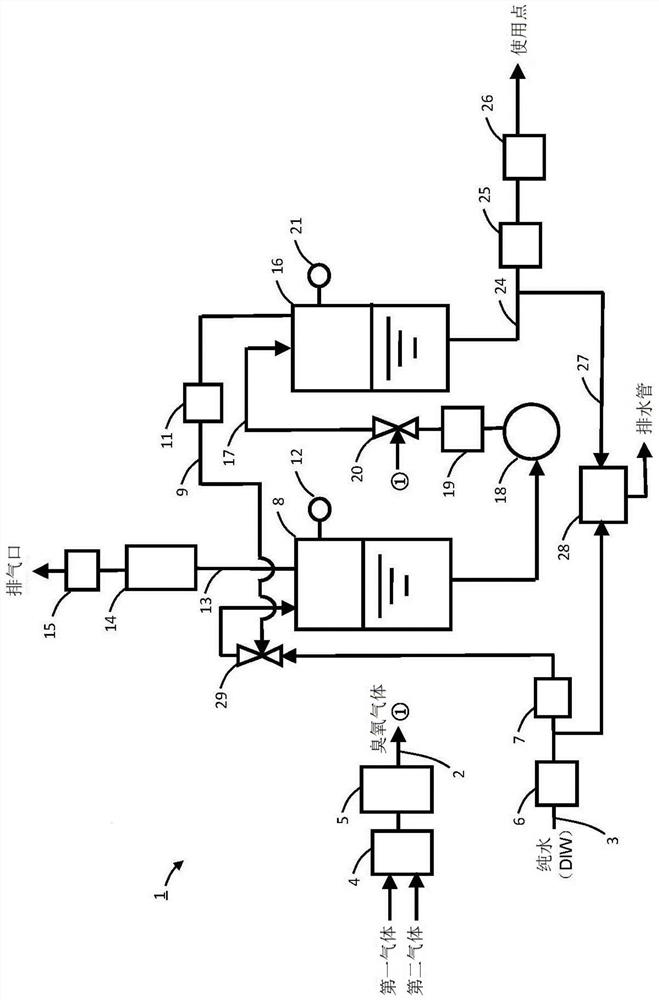

[0091] Next, an ozone water supply device 1 according to a third embodiment of the present invention will be described. Here, the difference between the ozone water supply apparatus 1 of 3rd Embodiment and 2nd Embodiment is demonstrated centering. Here, unless otherwise mentioned, the structure and operation of this embodiment are the same as those of the second embodiment.

[0092] image 3It is explanatory drawing which shows the structure of the ozone water supply apparatus 1 of this embodiment. Such as image 3 As shown, in this embodiment, the circulation supply line 9 which circulates the ozone water which is not used at the point of use and supplies this ozone water to the 1st gas-liquid separator 8 is not provided. Therefore, compared with the first embodiment and the second embodiment, the pressure of the first gas-liquid separator 8 can be increased, and the concentration of ozone water can be made high.

[0093] In the ozone water supply device 1 of the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com