Process for extracting crude heparin sodium through nanofiltration membrane concentration

A technology of nanofiltration membrane and heparin sodium, which is applied in the field of heparin sodium production, can solve the problem of inability to remove finer insoluble particles and water-soluble protein nucleic acid, reduce resin adsorption pressure, and inability to remove insoluble particles and water-soluble protein nucleic acid And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

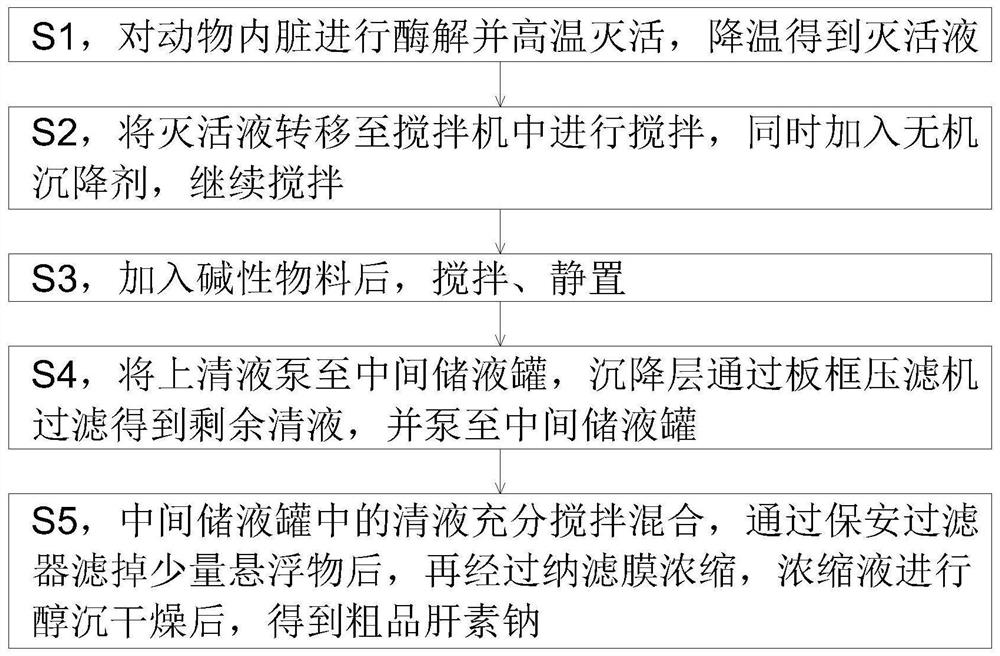

Method used

Image

Examples

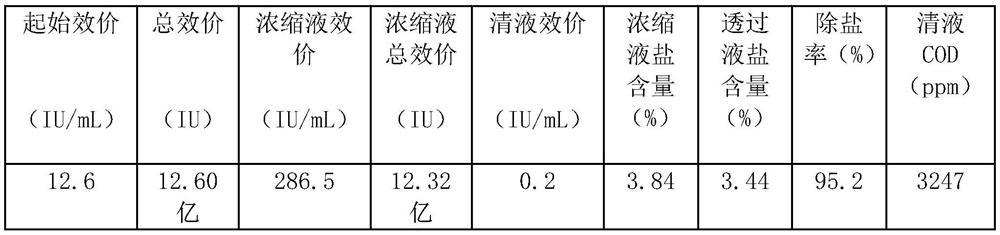

Embodiment 1

[0026] will be 10m 3Pump the high-temperature inactivation solution after enzymatic hydrolysis of pig small intestine into the stirring settling tank, cool it to a temperature of 35°C with a cold water coil, take a sample to detect the titer of the inactivation solution, and add 12 kg of calcium chloride and magnesium chloride within 20 minutes while stirring 8 kg, after the addition is completed, continue to stir for 40 minutes, detect the concentration of calcium and magnesium ions by the calcium and magnesium ion online analyzer, slowly add the calculated amount of sodium carbonate, make the calcium and magnesium ions fully generate insoluble carbonate, continue to stir for 25 Minutes later, cool the inactivation solution to 15°C under stirring, keep it warm for 10 hours, drain the supernatant, pump it to the intermediate liquid storage tank, and filter the remaining sedimentation layer through a plate and frame filter press to obtain the clarified liquid pumped to the above...

Embodiment 2

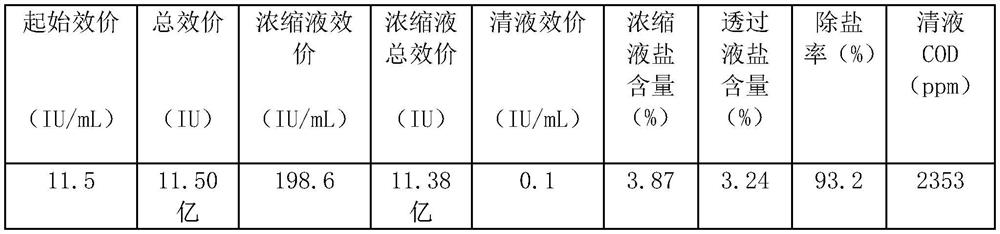

[0032] will be 10m 3 Pump the high-temperature inactivation solution after enzymatic hydrolysis of the volume of pig small intestine into the stirring settling tank, use a cold water coil to cool to a temperature of 45°C, take a sample to detect the titer of the inactivation solution, and add 9 kg of calcium chloride and magnesium chloride within 30 minutes while stirring 13 kg, after the addition is completed, continue to stir for 30 minutes, detect the concentration of calcium and magnesium ions by the calcium and magnesium ion online analyzer, slowly add the calculated amount of sodium carbonate, make the calcium and magnesium ions fully generate insoluble carbonate, continue to stir for 45 Minutes later, cool the inactivation solution to 0°C under stirring, keep it warm for 6 hours, drain the supernatant, pump it to the intermediate liquid storage tank, and filter the remaining sedimentation layer through a plate and frame filter press to obtain the clarified liquid pumped ...

Embodiment 3

[0038] will be 10m 3 Pump the high-temperature inactivation solution after enzymatic hydrolysis of pig small intestine into the stirring settling tank, cool it to a temperature of 35°C with a cold water coil, take a sample to detect the titer of the inactivation solution, and add 12 kg of calcium chloride and magnesium chloride within 20 minutes while stirring 8 kg, after the addition is completed, continue to stir for 40 minutes, detect the concentration of calcium and magnesium ions by the calcium and magnesium ion online analyzer, slowly add the calculated amount of sodium carbonate, make the calcium and magnesium ions fully generate insoluble carbonate, continue to stir for 25 Minutes later, cool the inactivation solution to 20°C under stirring, keep it warm for 12 hours, drain the supernatant, pump it to the intermediate liquid storage tank, and filter the remaining sedimentation layer through a plate-and-frame filter press to obtain the clarified liquid pumped to the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com