Chemical mechanical polishing cleaning solution and use method thereof

A chemical machinery and cleaning liquid technology, applied in the field of cleaning liquid, can solve the problems of reducing cleaning work efficiency, adverse production efficiency, increasing the complexity of cleaning process, etc., to achieve the effect of simple cleaning work and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

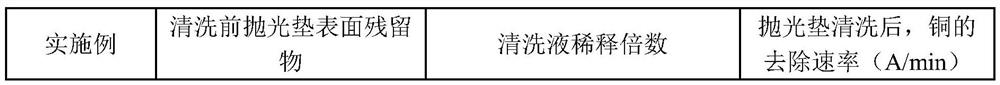

Examples

Embodiment Construction

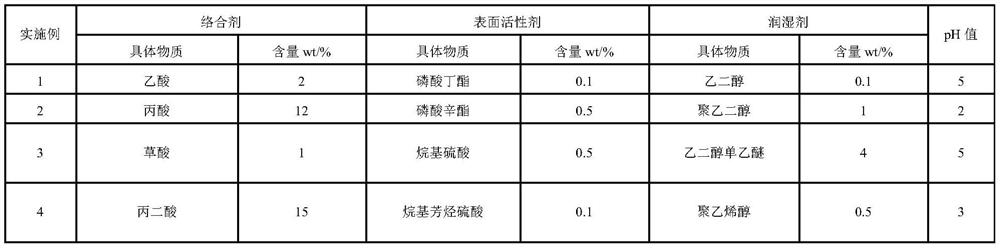

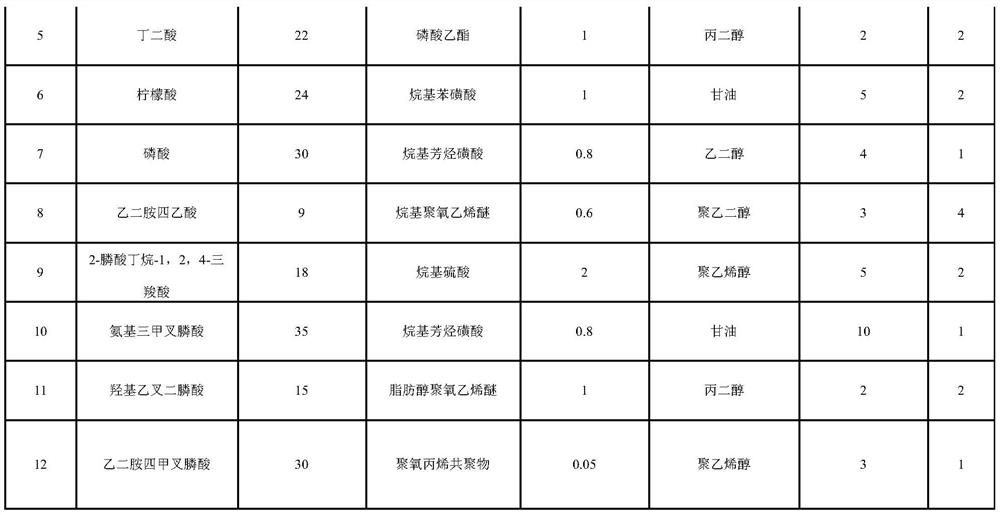

[0022] In order to better understand the technical scheme of the present invention, the following examples will further illustrate the method provided by the present invention, but the present invention is not limited to the listed examples, and should also be included in the claims of the present invention any other known changes.

[0023] A chemical mechanical polishing cleaning liquid, comprising complexing agent, surface active agent, wetting agent, pH adjusting agent, and the balance is water.

[0024] Specifically, wherein the complexing agent is inorganic acid, organic acid, organic phosphonic acid, amino acid and / or organic amine, selected from one or more of the following: acetic acid, propionic acid, oxalic acid, malonic acid, succinic acid , citric acid, phosphoric acid, ethylenediaminetetraacetic acid, 2-phosphonic acid butane-1,2,4-tricarboxylic acid, aminotrimethylenephosphonic acid, hydroxyethylidene diphosphonic acid, ethylenediaminetetramethylenephosphonic aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com