Patents

Literature

88 results about "Whole membrane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Any lipid bilayer that completely encloses some structure, and all the proteins embedded in it or attached to it. Examples include the plasma membrane and most organelle membranes. [GOC:dos]

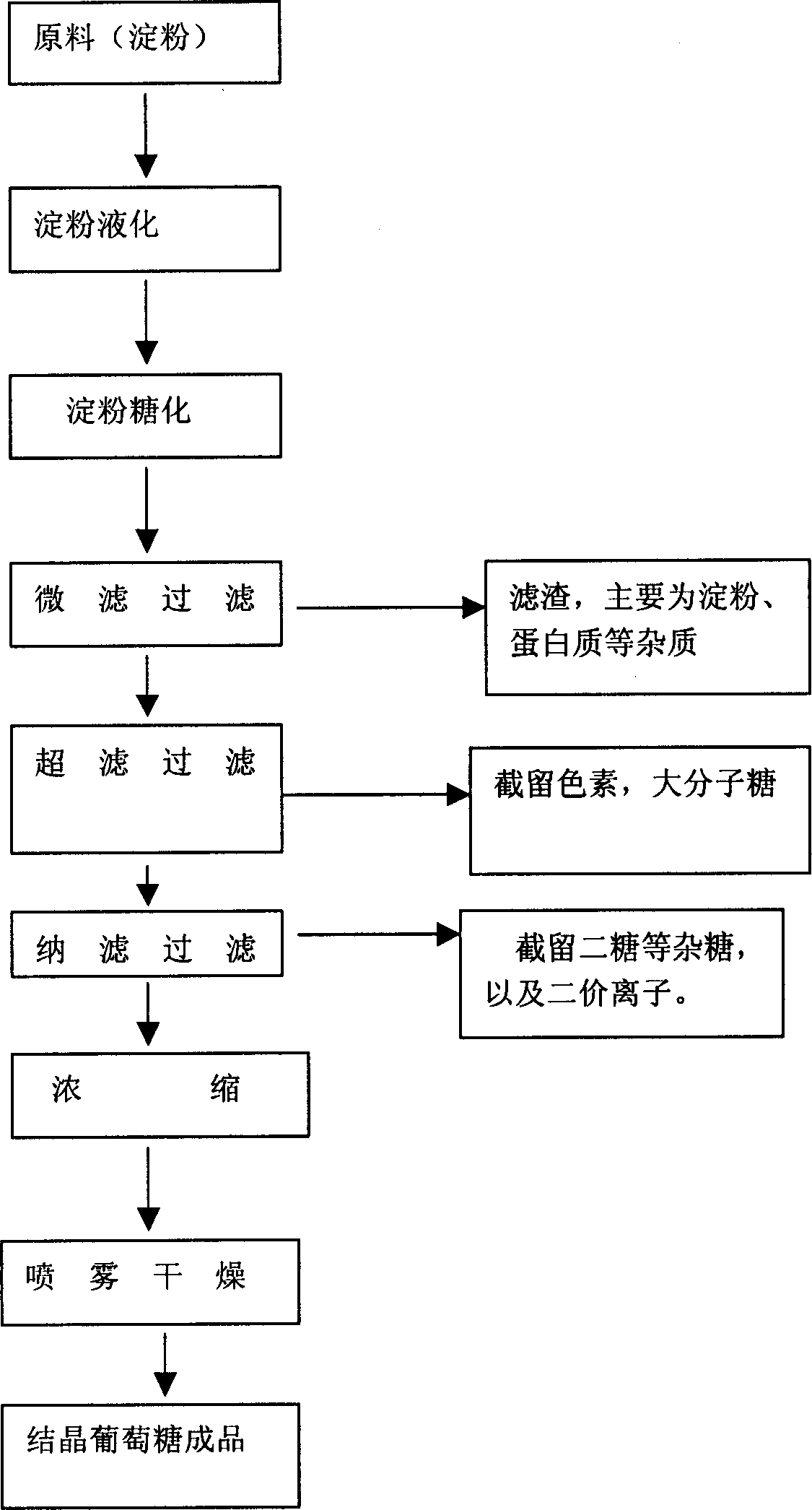

Crystalline glucose producing process based on whole membrane method

ActiveCN1810994AImprove qualityNo pollution in the processInvert sugar productionGlucose productionUltrafiltration

Owner:SANDA FILM SCI & TECH XIAMEN

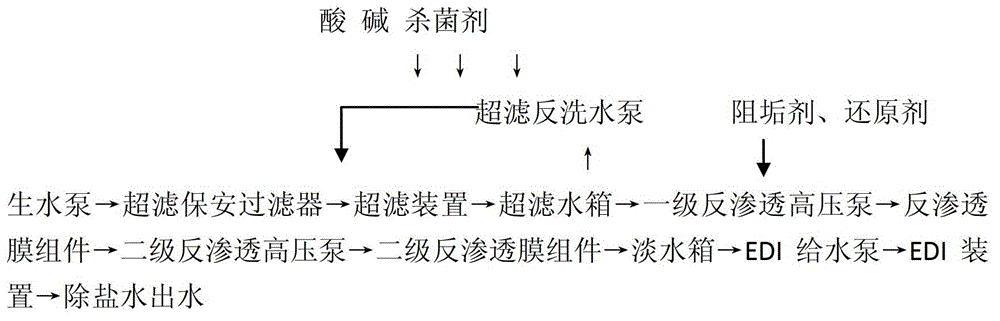

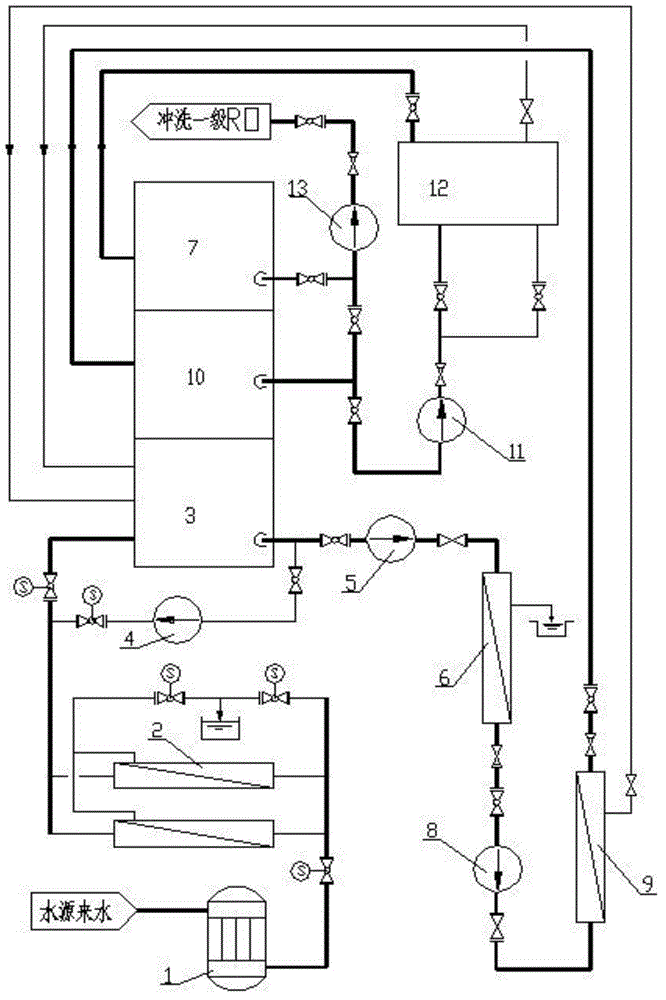

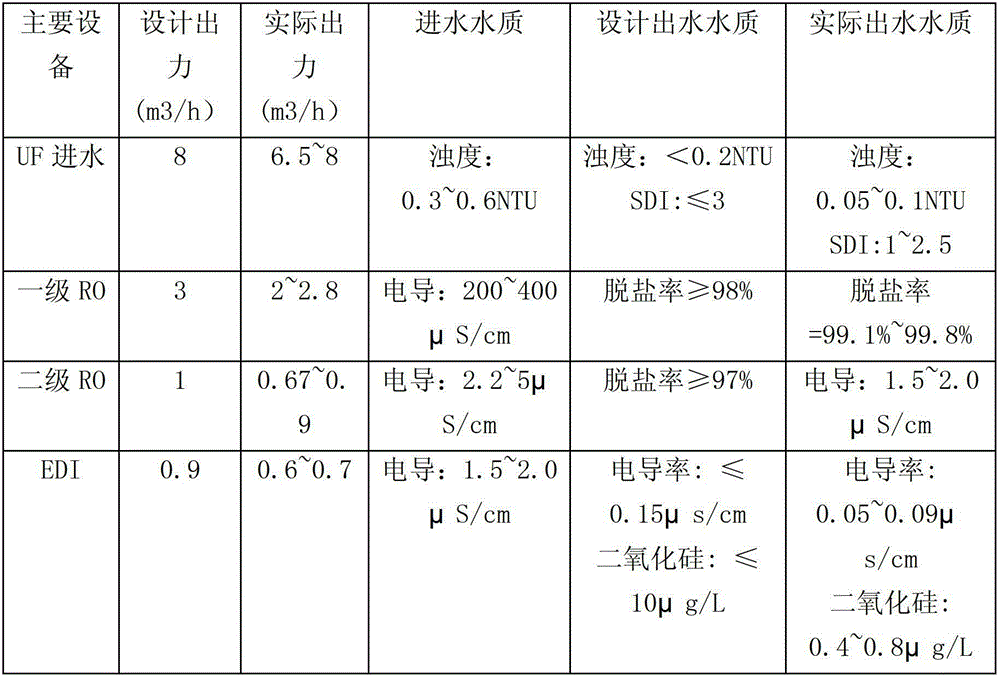

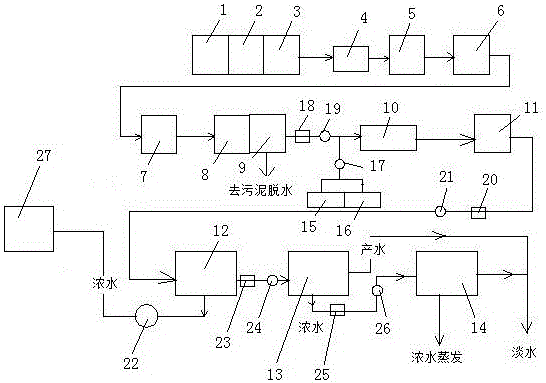

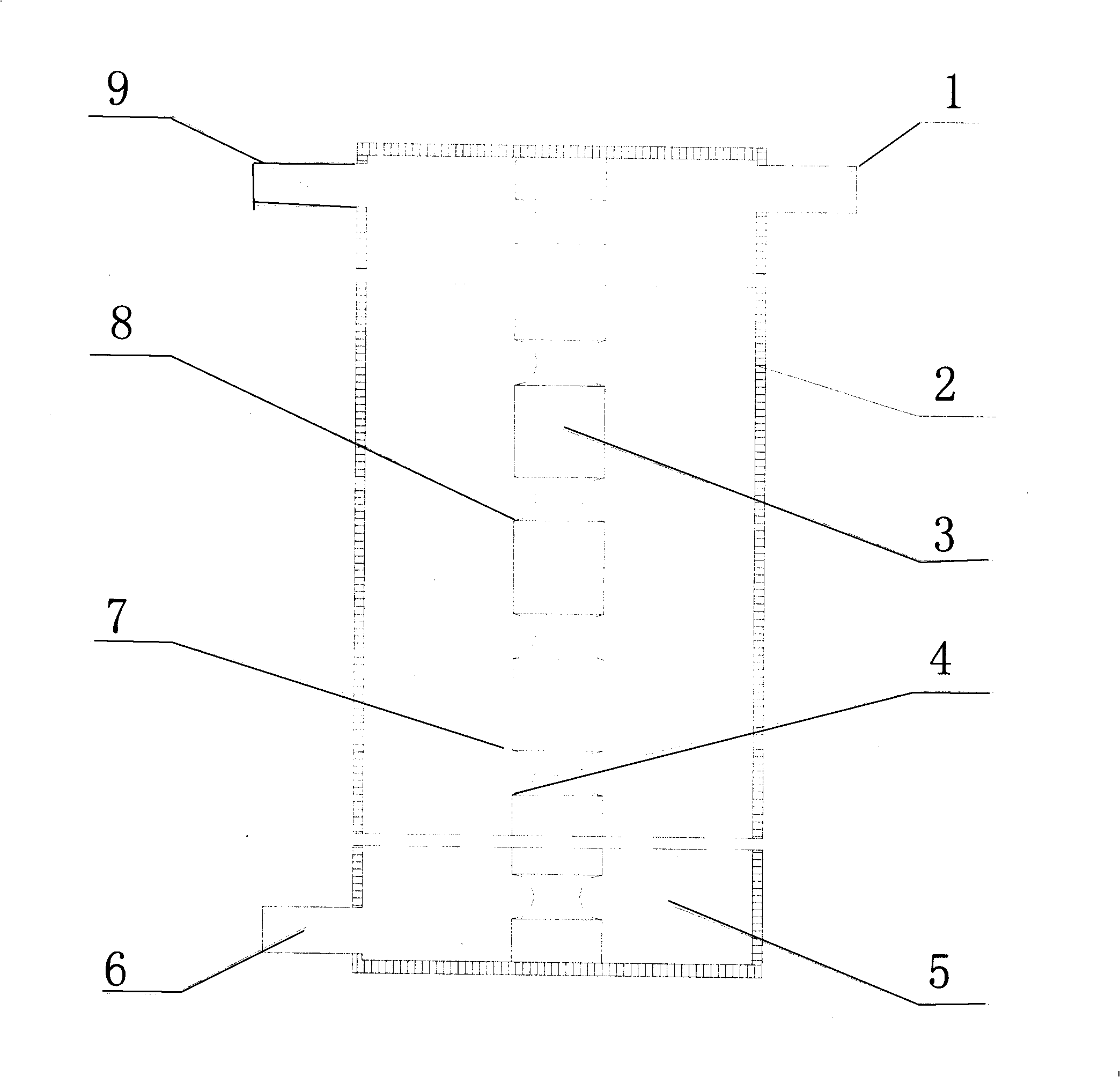

Whole-membrane-process water treatment integration device

InactiveCN102942265AMaximize utilizationAdaptive to water quality fluctuationsMultistage water/sewage treatmentSaline waterFiltration membrane

The invention discloses a whole-membrane-process water treatment integration device. The whole-membrane-process water treatment integration device is characterized in that 'whole-membrane-process' water treatment components are integrated into a small-size device, and comprise a raw water pump, an ultra-filtration safety filter, an ultra-filtration membrane component, an ultra-filtration water tank, an ultra-filtration backwashing water pump, reverse-osmosis high-pressure pumps, reverse-osmosis membrane components, a fresh-water tank, an EDI (Electrodeionization) water feeding pump, an EDI membrane block, an acid dosing device, an alkali dosing device, a bactericide device, a scale inhibitor device, a reducing-agent device, a valve, pipelines and a PLC (Programmable Logic Control) control system; the ultra-filtration device consisting of the raw water pump, the ultra-filtration safety filter and the ultra-filtration membrane component, the ultra-filtration water tank, the first-stage reverse-osmosis high-pressure pump, the reverse-osmosis membrane component, the second-stage reverse-osmosis high-pressure pump, the second-stage reverse-osmosis membrane component, the fresh-water tank, the EDI water feeding pump and the EDI device are connected by the pipelines in the following sequence till the desalting water is discharged; and the ultra-filtration backwashing waterpump is arranged to be connected with the ultra-filtration membrane component for backwashing; and the acid dosing device, the alkali dosing device and the bactericide device are respectively connected to the ultra-filtration device.

Owner:NANJING CEC ENVIRONMENTAL ENGINEERING CO LTD

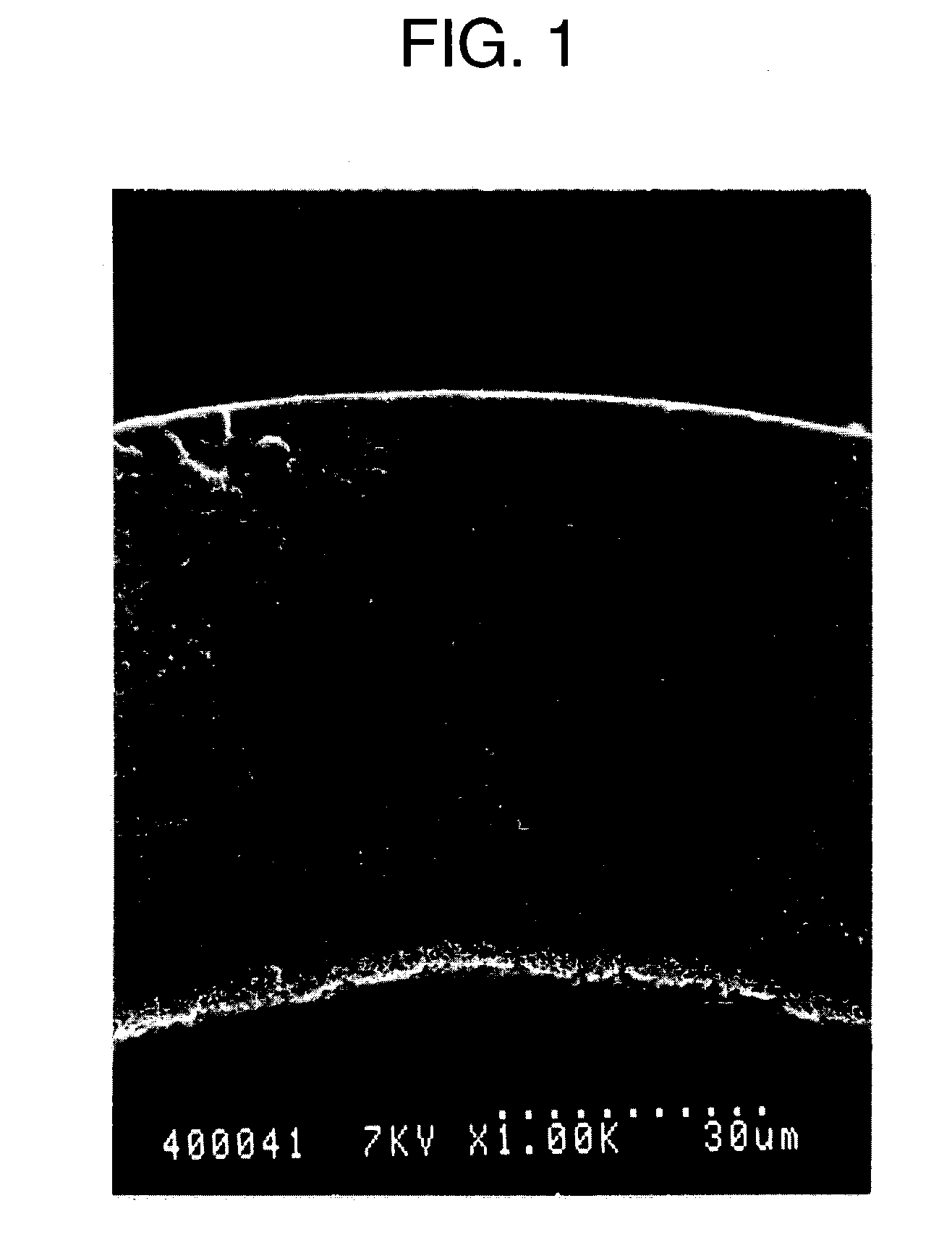

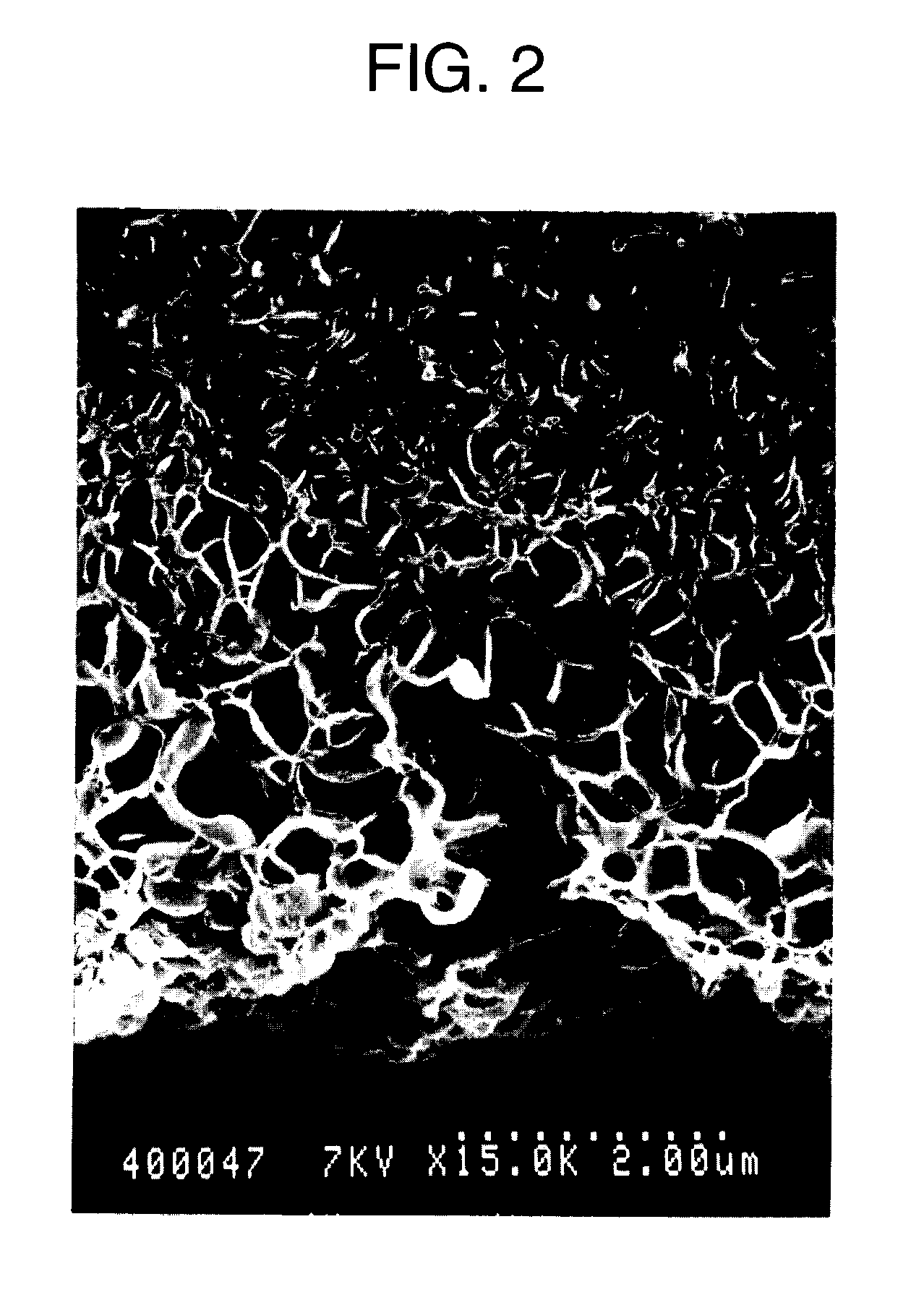

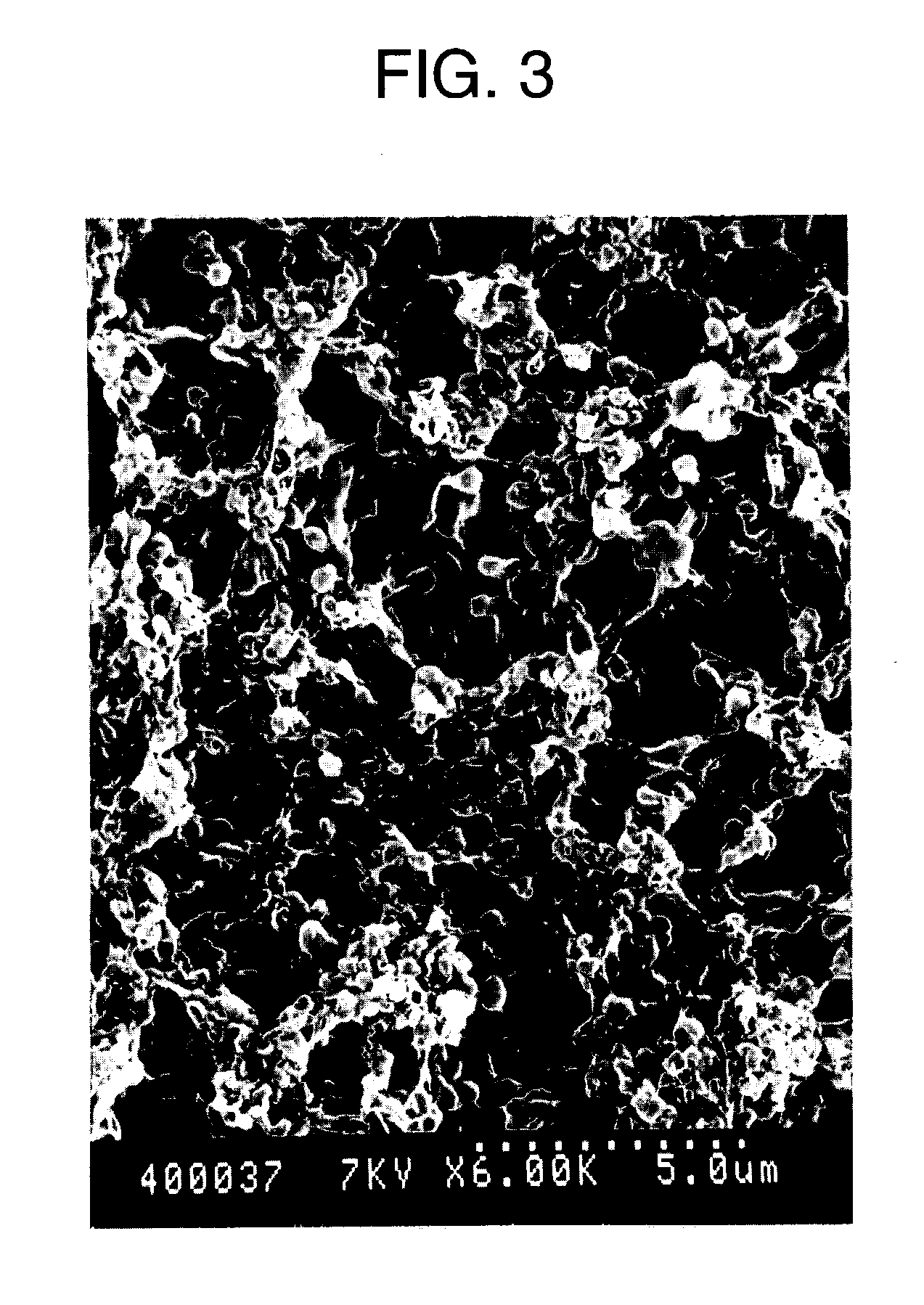

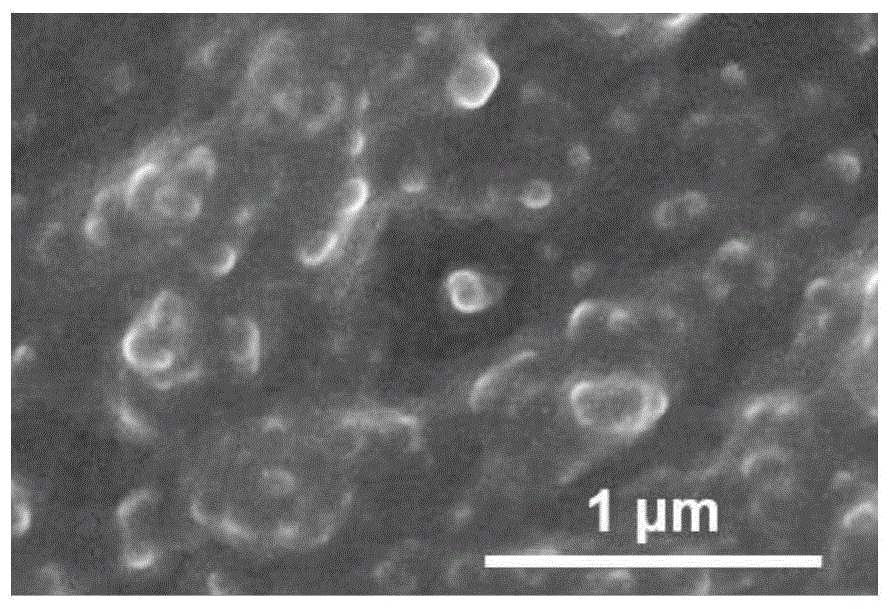

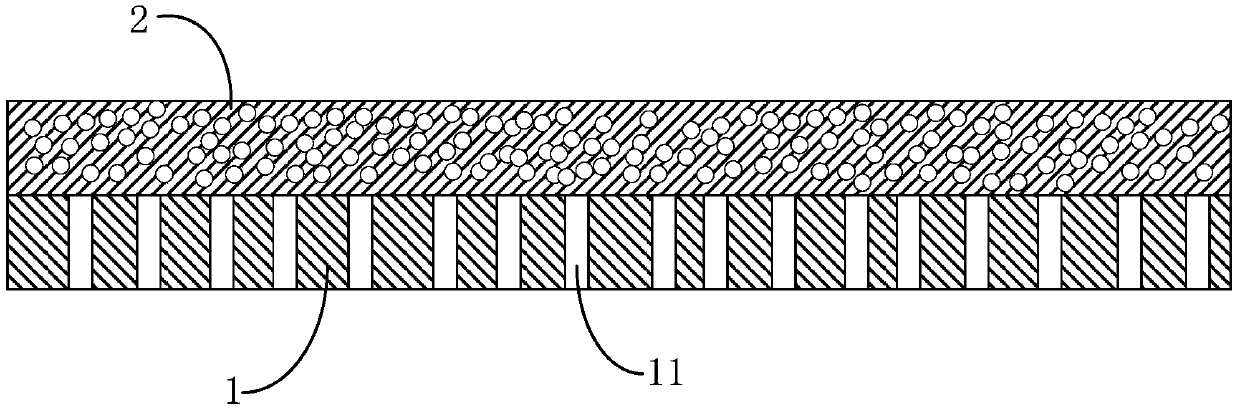

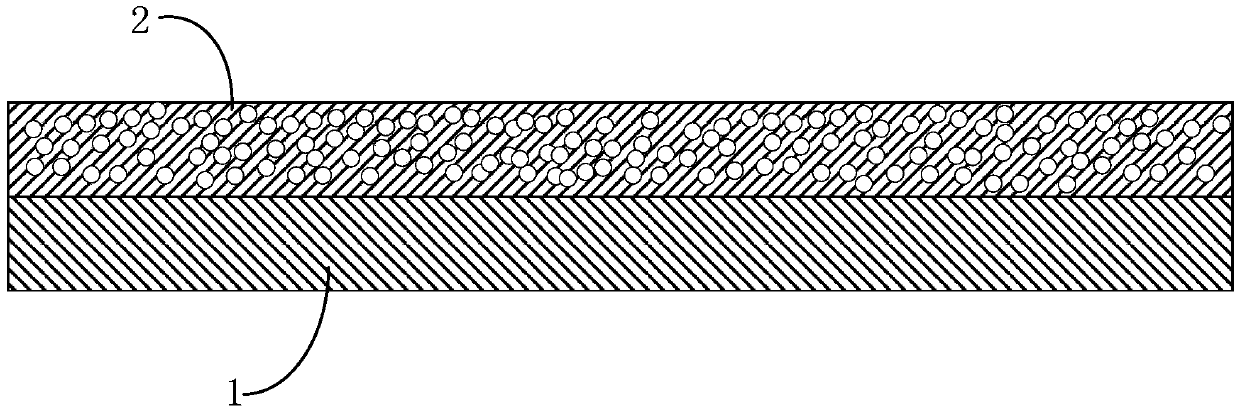

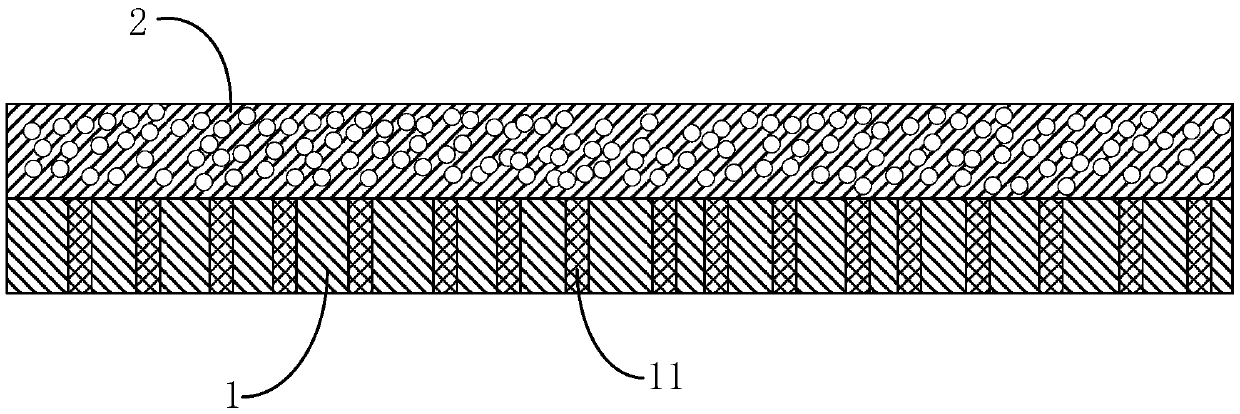

Multilayer microporous membrane

InactiveUS7140496B2Improve breathabilitySufficient performanceMembranesSemi-permeable membranesFine structureCrystallography

A multilayer microporous membrane containing a thermoplastic resin, comprising a coarse structure layer with a higher open pore ratio and a fine structure layer with a lower open pore ratio, wherein said coarse structure layer is present at least in one membrane surface having a thickness of not less than 5.0 μm, a thickness of said fine structure layer is not less than 50% of the whole membrane thickness, and said coarse structure layer and said fine structure layer are formed in one-piece.

Owner:ASAHI KASEI MEDICAL CO LTD

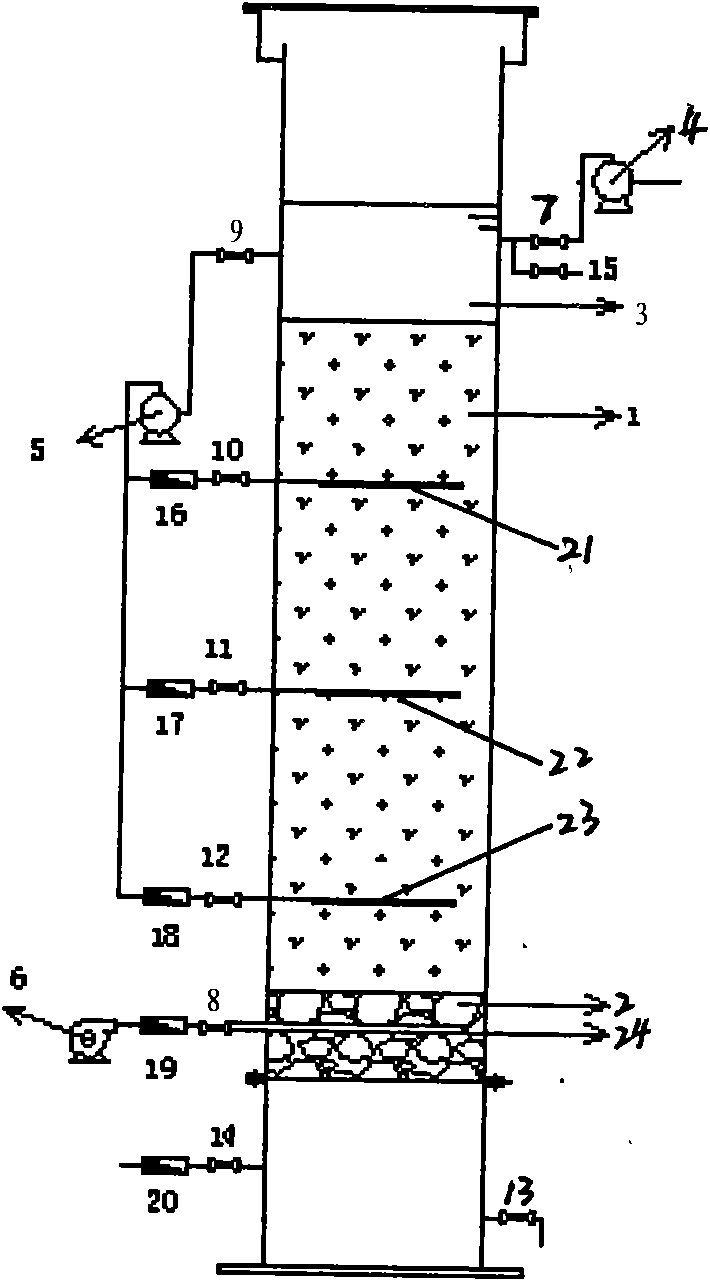

Method for hanging membrane in sludge internal circulation biological filter

InactiveCN101580297AImprove adhesionHigh film-hanging efficiencySustainable biological treatmentBiological water/sewage treatmentHigh concentrationLoad resistance

The invention provides a method for hanging a membrane in a sludge internal circulation biological filter. The method comprises the following steps: mixing acclimated sludge and wastewater, adding nutrition, and injecting into the biological filter for aeration; at the same time, stepwise starting internal circulation from bottom to top along the height direction of the filter, and making microorganisms fully contacted with a filter material and attached to the filter material for growth; after a period of culture, discharging mixed liquor, adding high concentration wastewater to continue aeration culture, and exciting the activity of the attached microorganisms; and after a membrane is formed, discharging the high concentration wastewater, continuously introducing water, and making the hydraulic load from low to high until forming a stable biological membrane. The method utilizes current disturbance action formed by the internal circulation of the sludge and water mixed liquor in the biological filter to overcome sludge deposition, strengthens the adhesive ability of the microorganisms on the surface of the filter material, improves local membrane hanging effect, and improves the whole membrane hanging efficiency of the filter and the shock load resistance of the biological membrane.

Owner:SHANDONG UNIV

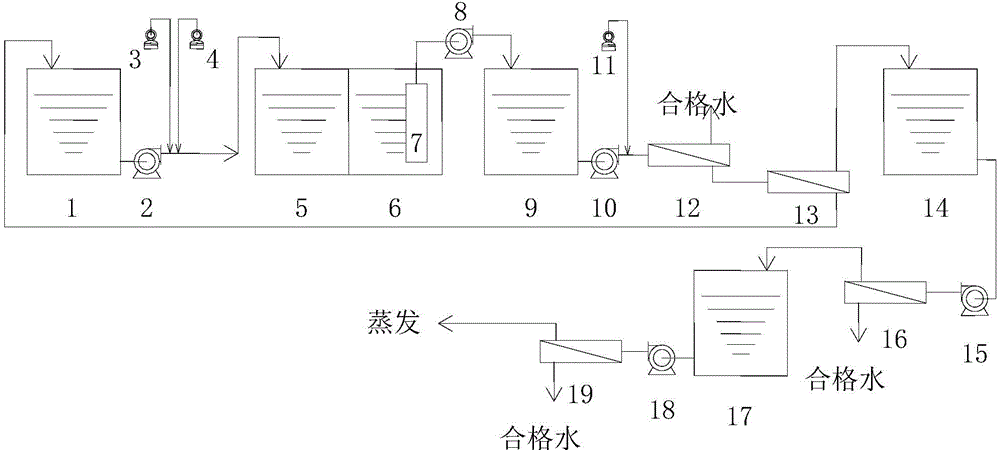

Method for treating reverse osmosis concentrated water and circulating wastewater by whole membrane method

ActiveCN104609610AReduce hardnessReduce salt contentScale removal and water softeningTreatment involving filtrationWater qualityProduced water

The invention discloses a method for treating reverse osmosis concentrated water and circulating wastewater by a whole membrane method, and belongs to the technical field of wastewater treatment and reclaimed water reuse. The method disclosed by the invention comprises the following steps: regulating the water amount and the water quality of wastewater by using a regulating tank; adding alkali to react with magnesium and calcium ions in a reaction tank to generate crystals of magnesium hydroxide and calcium carbonate; adding a mixed solution into a ceramic membrane filtering device; after the crystals of the magnesium hydroxide and calcium carbonate are filtered by a ceramic membrane, performing filter-pressing processing on a concentrated solution by using a plate frame; regulating the filtrate by adding an acid, and adding the regulated filtrate into a first-stage reverse osmosis device; recycling reverse osmosis pure water; adding the reverse osmosis pure water into a nano-filter; returning the concentrated water which is subjected to nano-filtration to the regulating tank; concentrating the water produced by the nano-filtration by using a second-stage reverse osmosis device; recycling the reverse osmosis produced water; further concentrating the concentrated water in a forward osmosis device; recycling the water produced by the forward osmosis; evaporating a trace amount of remaining concentrated water in an evaporator, and using the trace amount of remaining concentrated water in other ways, so as to finally realize zero emission of the wastewater.

Owner:山东泰禾环保科技股份有限公司

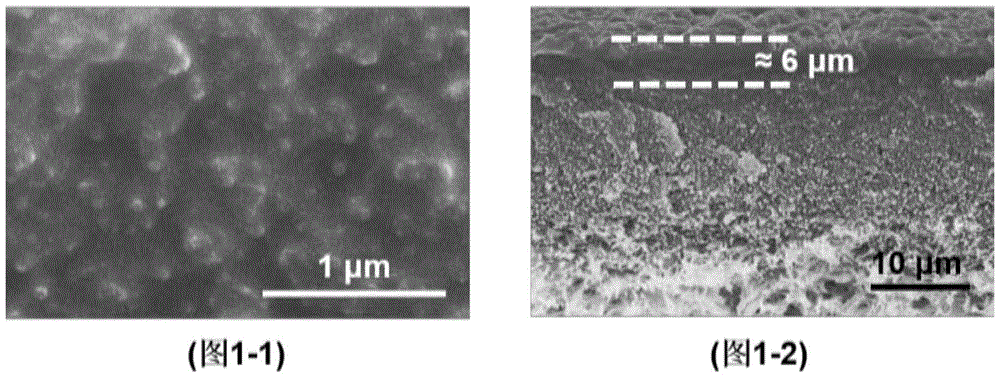

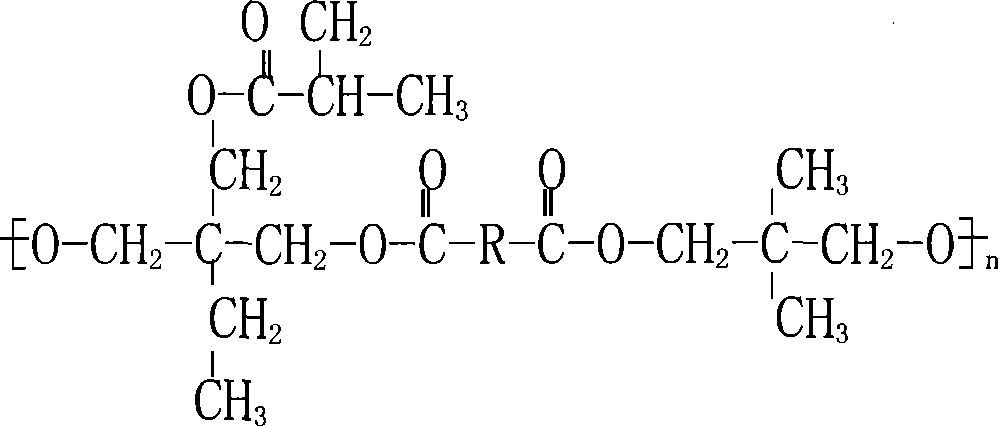

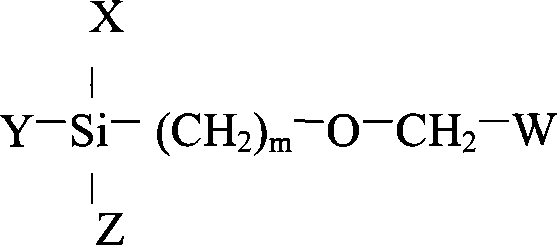

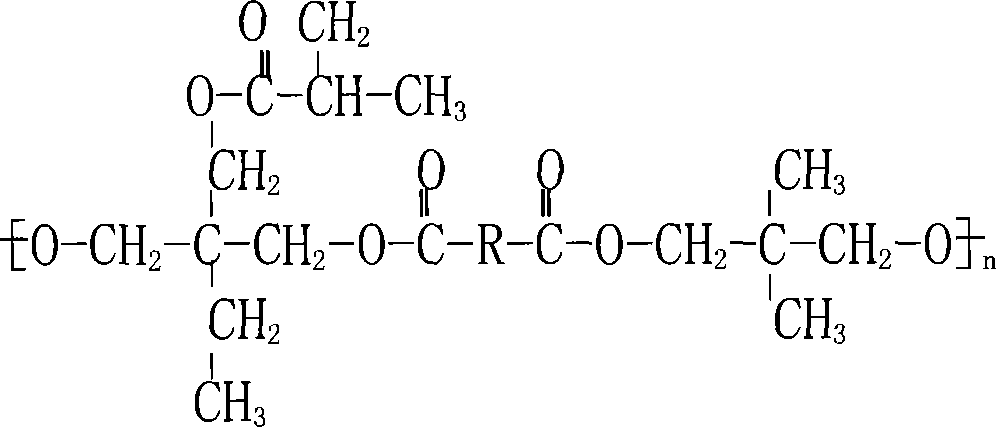

Preparation method for nanoscale dispersive high-performance organic/inorganic hybrid membrane

InactiveCN105688682AShort manufacturing timeImprove production efficiencySemi-permeable membranesMembranesDispersityCross-link

The invention discloses a preparation method for a nanoscale dispersive high-performance organic / inorganic hybrid membrane and belongs to the technical field of membrane separation. The method comprises the steps that liquid-state low polymers are selected as membrane liquid A, and quantitative hydrophobic inorganic nano-particles are evenly dispersed in a curing agent solution to form suspension liquid B; a pretreated porous base membrane is fixed to a membrane carrying table and rotates at a constant speed; the membrane liquid A and the suspension liquid B are sprayed on the surface of the porous base membrane in an atomized mode; at a certain temperature, the liquid-state low polymers are subjected to a quick cross-linking reaction on the surface of the porous base membrane, and the nanoscale dispersive high-performance organic / inorganic hybrid membrane is obtained. Through the method, agglomeration of the inorganic nano-particles in the process that the low polymers react to form the membrane can be effectively avoided, the nano-particles are dispersed at the nanoscale in a separation layer, and the organic / inorganic hybrid membrane with high dispersity and high performance can be prepared within an extremely short period of time; moreover, in the whole membrane preparation process, the process is environmentally friendly, operation is simple, and large-scale preparation is easy.

Owner:BEIJING UNIV OF TECH

Method for processing low radioactive waste liquid by continuous electrodeionization

The invention relates to a method for processing low radioactive waste liquid by continuous electrodeionization, which is characterized by comprising the following steps: alternately arranging an anion exchange membrane and a cation exchange membrane between a negative electrode and a positive electrode; filling ion exchange resin between the ion exchange membranes to form fresh water chambers; forming a concentrated water chamber between adjacent fresh water chambers; alternately arranging the fresh water chambers and the concentrated water chambers to form a whole membrane pile; filling 20-60 percent of alkalescence anion exchange resin, 30-50 percent of strongly acidic cation resin and 10-30 percent of strongly basic anion resin into the fresh water chambers; applying direct current voltage at both ends of the membrane pile and leading the direction of an electric field to be perpendicular to the ion exchange membranes. The low radioactive waste liquid enters into the fresh water chambers, and nuclide ions generate directional migration under the action of a direct current electric field in a resin phase and enter the concentrated water chambers by the anion exchange membrane and the cation exchange membrane. The alkalescence anion exchange resin is added into the membrane pile, and the processing efficiency is greatly improved by fully utilizing the high selectivity of theresin on transition metal ions on the premise of not changing equipment.

Owner:TSINGHUA UNIV

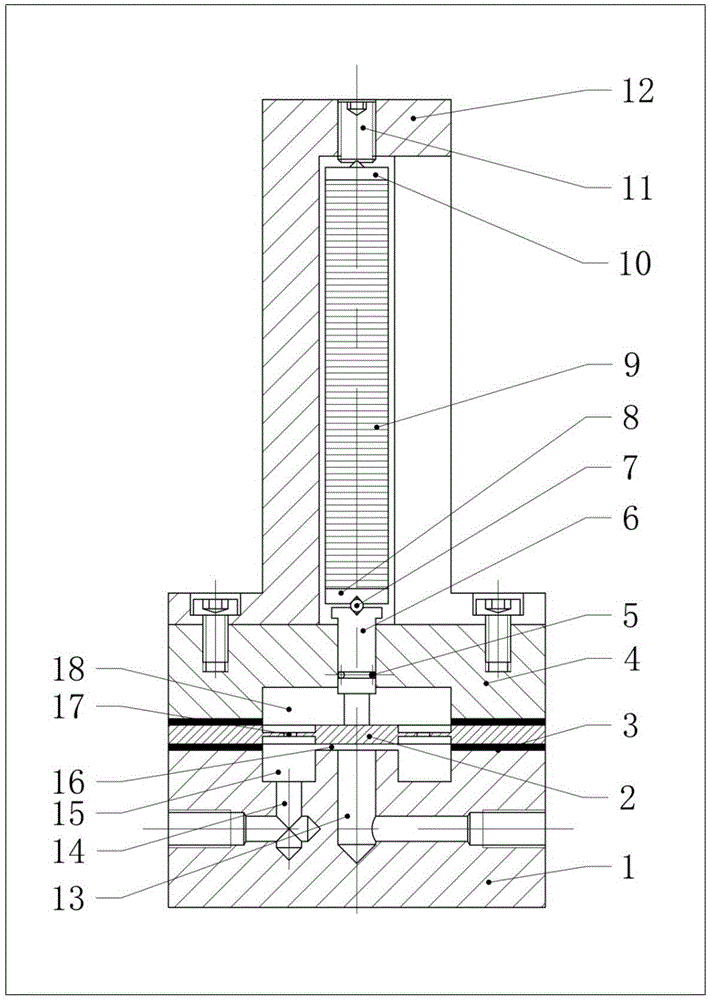

Membrane servo valve driven by piezoelectric ceramics

InactiveCN105370958AHigh response frequencyEasy to controlDiaphragm valvesOperating means/releasing devices for valvesElectricityEngineering

The invention discloses a membrane servo valve driven by piezoelectric ceramics. The membrane servo valve comprises an upper valve body and a lower valve body, wherein a membrane is arranged between the upper valve body and the lower valve body; a cylindrical balancing oil cavity is formed between the upper valve body and the membrane; a ring-shaped throttling oil cavity is formed between the membrane and the lower valve body; the balancing oil cavity and the throttling oil cavity are communicated with each other; an ejector rod vertically penetrates through a space between the upper valve body and the balancing oil cavity; one end of the ejector rod is arranged with a set spacing distance to the membrane, or in contact with the membrane; one of the piezoelectric ceramics used for pushing the ejector rod to move is arranged at the other end of the ejector rod. The membrane servo valve has the benefits that through precise control of a throttling interval, the pressure and the flow can be precisely and actively controlled; the center of the membrane is set to be a central island shape, the central island shape is rigid, and a deformation zone around the central island shape is flexible, so as to improve the dynamic frequency of the membrane; meanwhile, the throttling interval control precision is improved, and the whole membrane servo valve is simple in structure, reliable in function and low in manufacturing cost.

Owner:SHANDONG UNIV

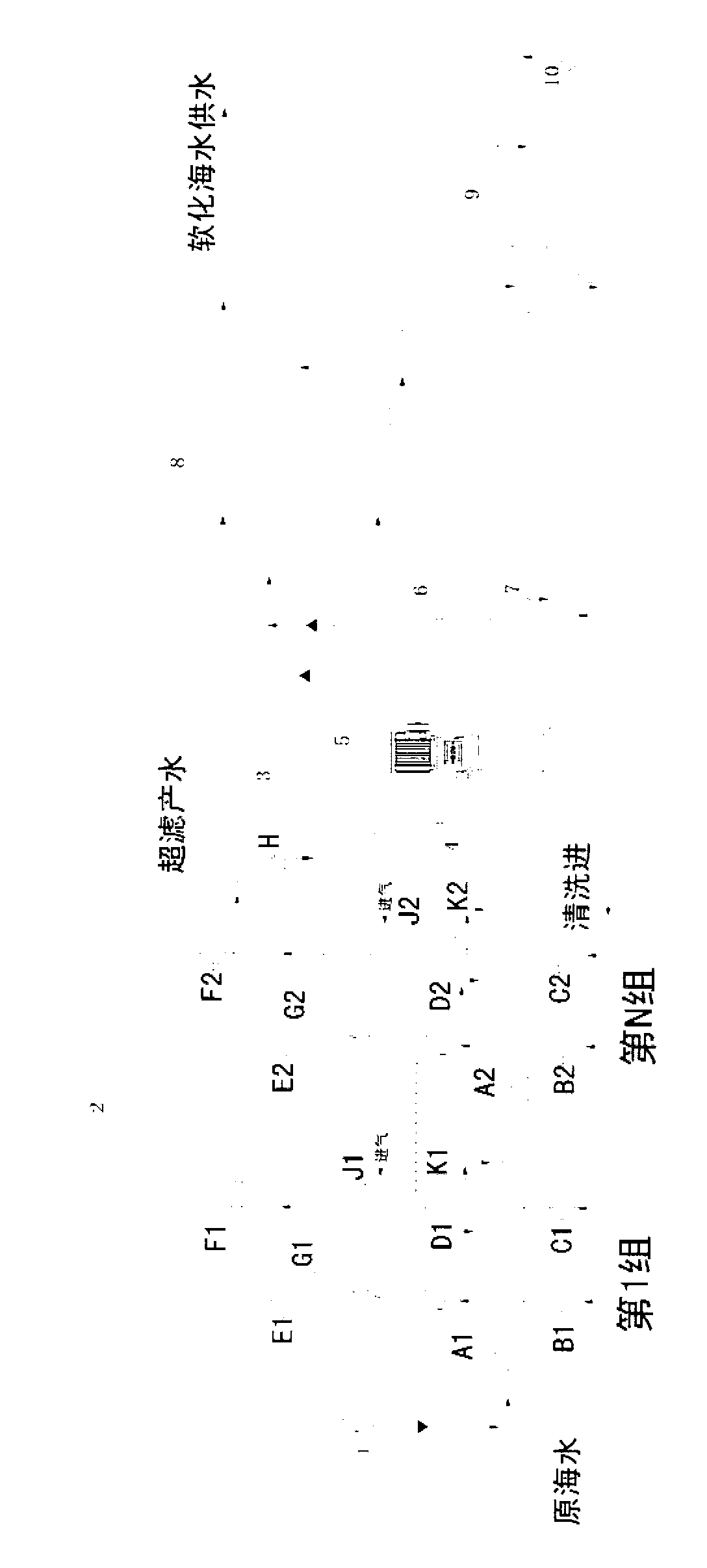

Cleaning method of ultrafiltration membrane in sea water desalination by whole membrane technology

ActiveCN103212300ALarge water supplyReduce operating pressureSemi-permeable membranesGeneral water supply conservationWater desalinationUltrafiltration

The invention belongs to the technical field of sea water desalination and water treatment, and relates to a cleaning method of an ultrafiltration membrane in sea water desalination by the whole membrane technology. The cleaning method comprises the following steps of: transporting pre-treated sea water to a raw water inlet of an ultrafiltration device; mixing with ultrafiltration circulating concentrated water transported by an ultrafiltration circulating pump, wherein the mixture enters into the ultrafiltration device to be filtered to obtain ultrafiltration water entering into a closed ultrafiltration water buffer tank; then, transporting the ultrafiltration water by a low pressure pump, wherein one part of the water flowing through a security filter is pressurized by a high pressure pump and enters into a nanofiltration / reverse osmosis device through a check valve, while the residual water enters into an energy recovering device and exchanges energy with concentrated water of the nanofiltration / reverse osmosis device, then is transported to the nanofiltration / reverse osmosis device through the pressurizing pump to prepare nanofiltration / reverse osmosis water; feeding nanofiltration / reverse osmosis water after energy exchange into an ultrafiltration cleaning water tank, and discharging residual concentrated water through an overflow opening on the upper part of the ultrafiltration cleaning water tank. The cleaning method is reliable in process, simple and convenient to operate, lower in energy consumption, good in economic and social benefits and environment-friendly.

Owner:OCEAN UNIV OF CHINA

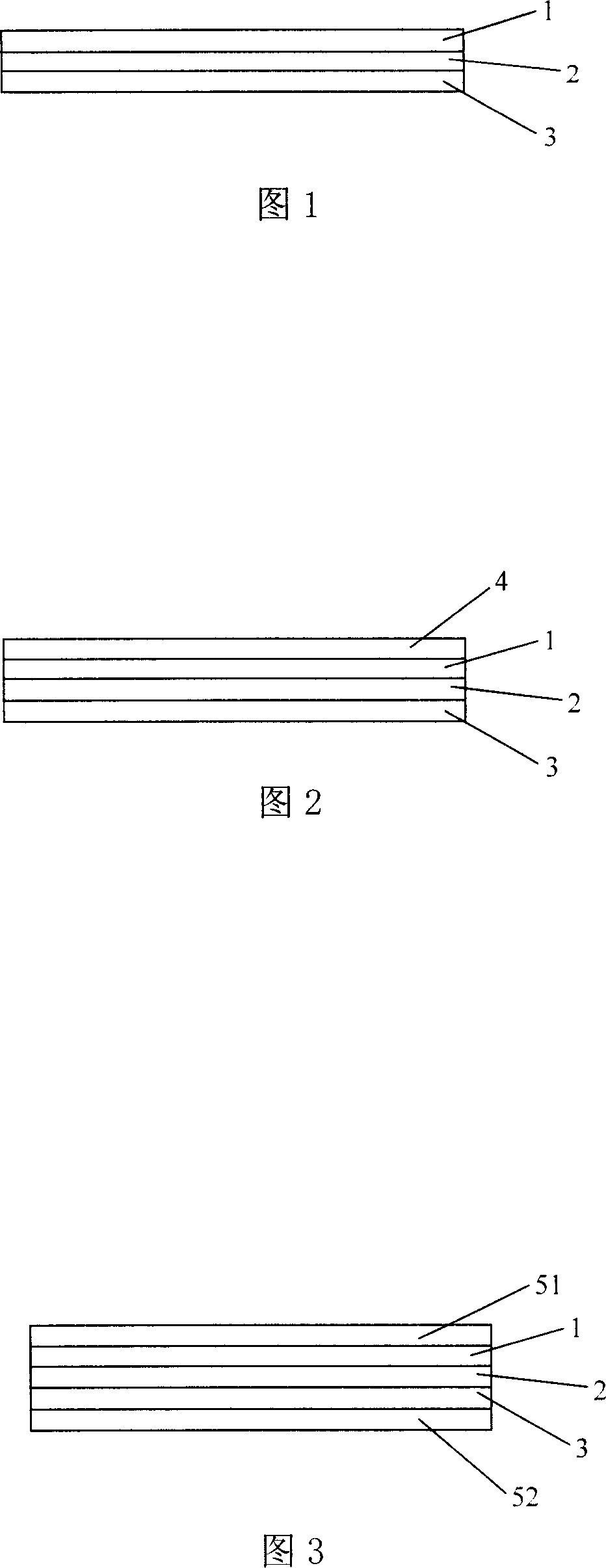

B-type moistube manufactured through one-step forming method, manufacturing method of B-type moistube and application of B-type moistube

InactiveCN103623950AEasy to produceHigh degree of automationWatering devicesSpray nozzlesCapillary networkAgricultural irrigation

The invention provides a B-type moistube manufactured through a one-step forming method, a manufacturing method of the B-type moistube and application of the B-type moistube. An existing moistube is a novel irrigation water supply device which is manufactured with a functional new material semi-permeable membrane serving as a core material. A huge number of microporous networks are distributed on the semi-permeable membrane, water outlet network points appear on the whole membrane wall after the membrane is filled with water, moisture can be slowly released out of the membrane, the amount of the released water depends on the energy difference of the two sides of the membrane, the larger the energy difference is, the larger the amount of the released water is, and therefore the amount of the released water can be controlled by adjusting pressure in the membrane. According to the B-type moistube for agricultural irrigation, tube bodies formed by the tube wall are equal in diameter, the tube wall is a thick-wall single-layer tube wall, the tube body is the moistube wall which is provided with the capillary network and is produced through once extrusion forming conducted by an extrusion tube making machine and corresponding auxiliary machines and through extraction conducted by an extraction machine. The B-type moistube is used for agricultural water-saving type irrigation.

Owner:SHENZHEN MOISTUBE IRRIGATION TECH

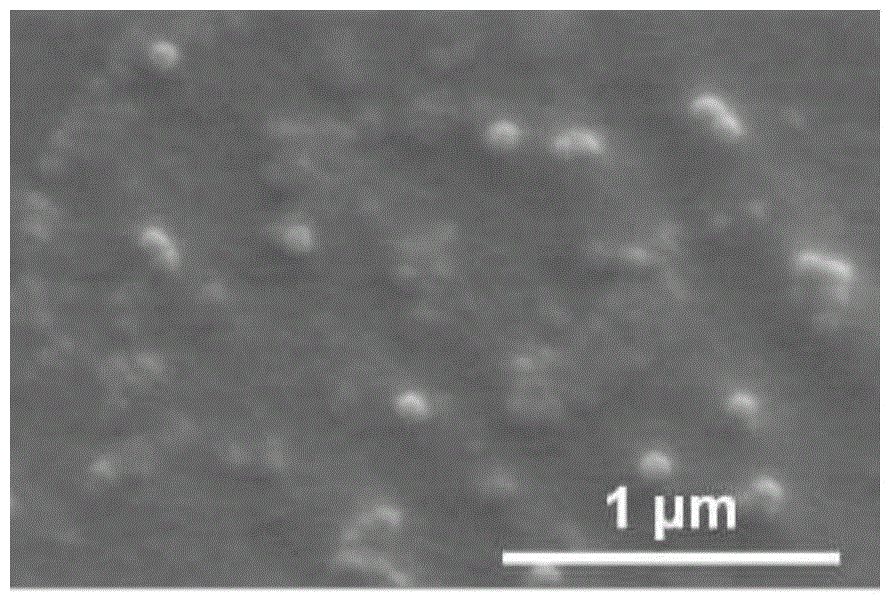

Polyamide forward osmosis membrane for water treatment

ActiveCN108339403AAvoid enteringReduce concentration polarizationMembranesSemi-permeable membranesPolyamideThin layer

The invention provides a polyamide forward osmosis membrane for water treatment. The composite polyamide forward osmosis membrane with an asymmetric sandwich structure is designed, i.e., a high-throughput polyamide separating layer and a high-selectivity polyamide separating layer are respectively designed on two sides of a polysulfone supporting layer; then the high-selectivity polyamide separating layer is designed into two thin layers; on one thin layer close to the polysulfone supporting layer, dopamine is added into a water-phase monomer, so that the throughout of the whole membrane is improved; water-phase and oil-phase monomer types of the polyamide separating layers on two sides of the polysulfone supporting layer are selected, so that the best performance of the membrane is ensured.

Owner:杭州水管家环保技术有限责任公司

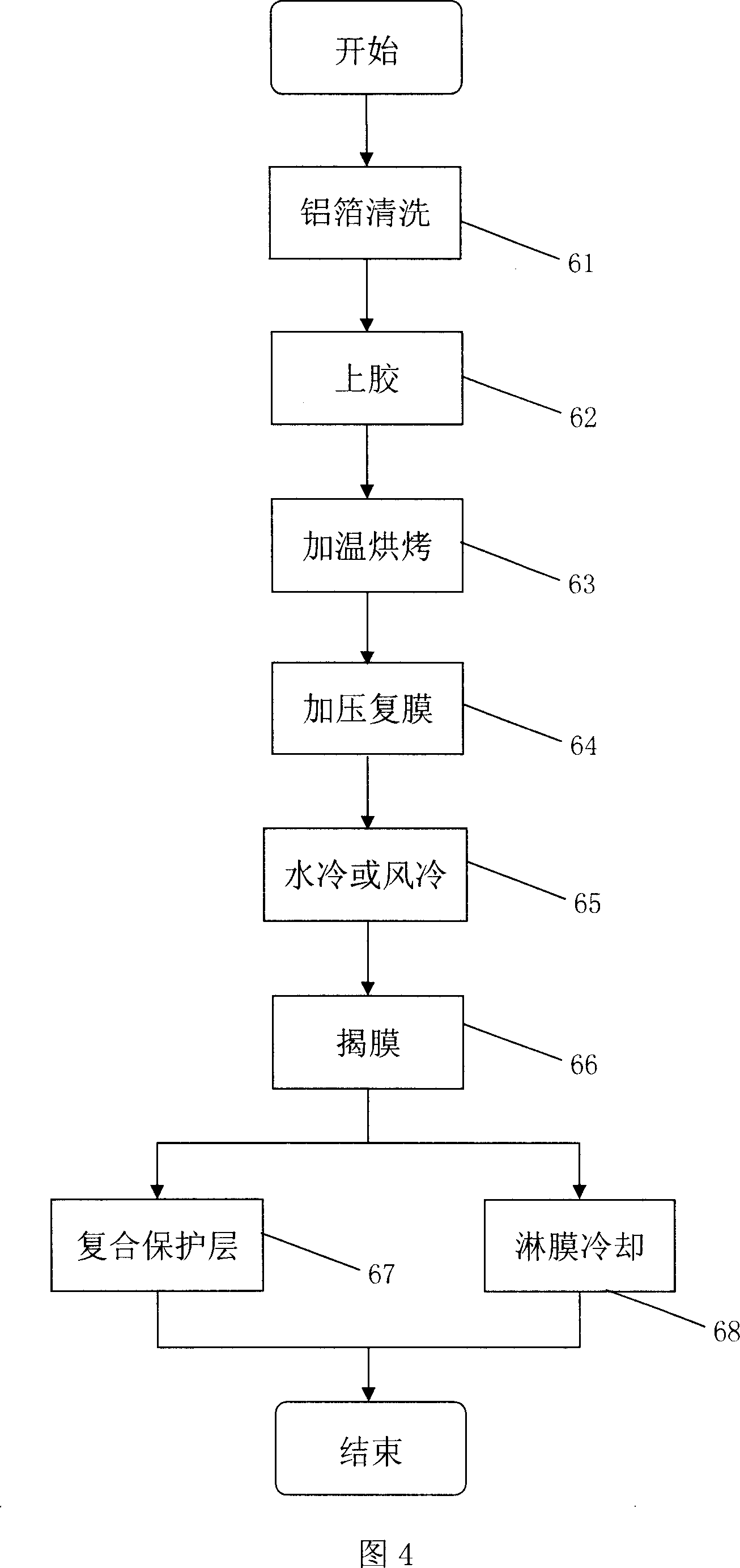

Laser anti-fake aluminium-foil and making method

InactiveCN101069999AImprove high temperature resistanceWon't crackLaminationLamination apparatusLaser patterningWater cooling

The invention discloses a laser anti-counterfeiting aluminum foil and its preparation method. The anti-counterfeiting aluminum foil contains a delomorphic aluminum plating layer, an adhesive layer and a metal aluminum foil layer overlapping successively. The preparation method mainly contains washing, gluing, heating, pressing, covering membrane, water or wind cooling and removing membrane etc. of the aluminum foil. The invention transfers the laser anti-counterfeiting membrane onto the aluminum foil by using new-type BOPP. The BOPP substrate membrane has good temperature and age resistance, soft materials, without coating transparent shape-separating layer and simple technology. Transferring the anti-counterfeiting membrane onto the aluminum foil can avoid the laser patterns disappearing or destroying. The whole membrane has good temperature resistance and is uneasy to craze. The invention can be applied in many fields such as packing bag and building materials etc. It has extensive application range and good market value.

Owner:沈文爱

Method for extracting L-isoleucine through whole membrane technology

ActiveCN106220521AIncrease incomeSimple processOrganic compound preparationMicroorganismsFlocculationFiltration membrane

The invention belongs to the technical field of base acid production, and discloses a method for extracting L-isoleucine through whole membrane technology. The method comprises the following steps: step 1) filtering through a micro-filtration membrane and removing impurities through flocculation; step 2) filtering through an ultra-filtration membrane, step 3) concentrating through a reverse osmosis membrane; step 4) concentrating and crystallizing. The membrane technology is combined with the flocculation agent to remove the impurities, the process is simple and feasible, and the yield and the purity of the product are greatly improved.

Owner:SHANDONG FUFENG FERMENTATION CO LTD

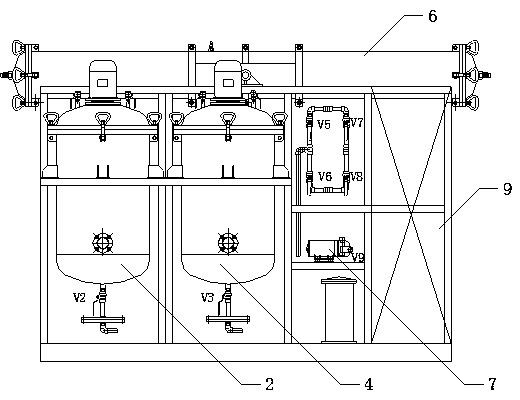

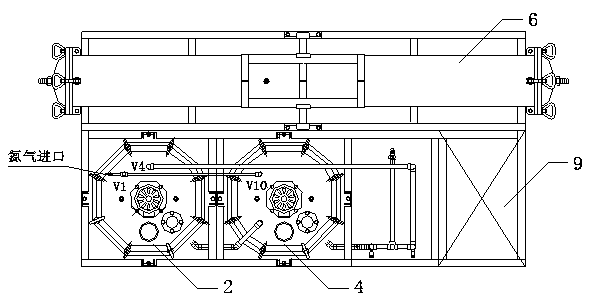

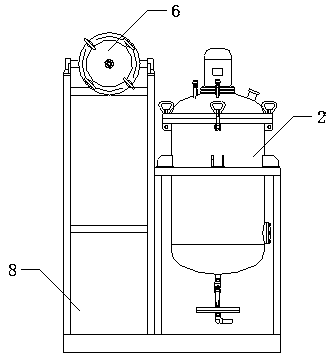

Tubular micro-filtration membrane production equipment

InactiveCN104289113APerformance impactImprove performanceSemi-permeable membranesFiltration membraneAdditive ingredient

The invention discloses tubular micro-filtration membrane production equipment which comprises an ingredient storage tank and a membrane storage tank connected with the ingredient storage tank, and also comprises a nitrogen cylinder connected with the ingredient storage tank through a first valve, wherein the nitrogen cylinder is connected with the membrane storage tank through a tenth valve; a sintering tube device is arranged in the rear of the membrane storage tank; a discharging tank is connected to the sintering tube device; a vacuum pump is connected to the discharging tank; the sintering tube device is respectively connected with the upper and lower ends of the sintering tube device through a fifth valve and a sixth valve; a fourth valve is connected to the ingredient storage tank; and a seventh valve and an eighth valve are respectively led out of the fourth valve and are connected with the upper and lower ends of the sintering tube device. According to the equipment, when polyvinylidene fluoride tubular micro-filtration membranes are produced, membrane fluid can permeate into pores of the whole wall thickness of the supporting tube, and the membrane fluid is tightly combined with the whole body of the porous supporting tube. Because microfiltration membranes are formed on the wall thickness of the whole membrane tube from interior to exterior, the phenomena of wear, peeling and perforations are avoided.

Owner:武汉尚远环保股份有限公司

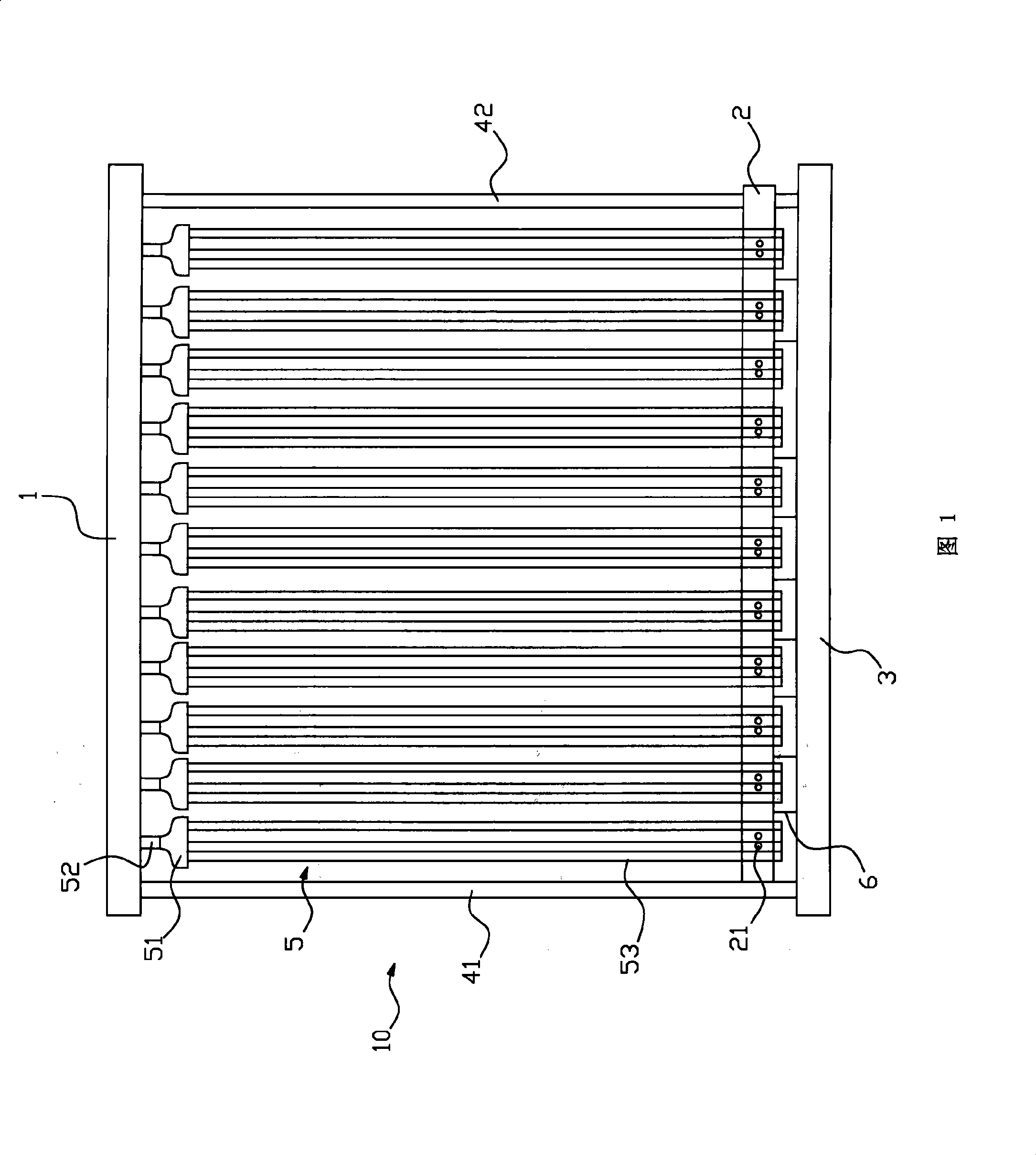

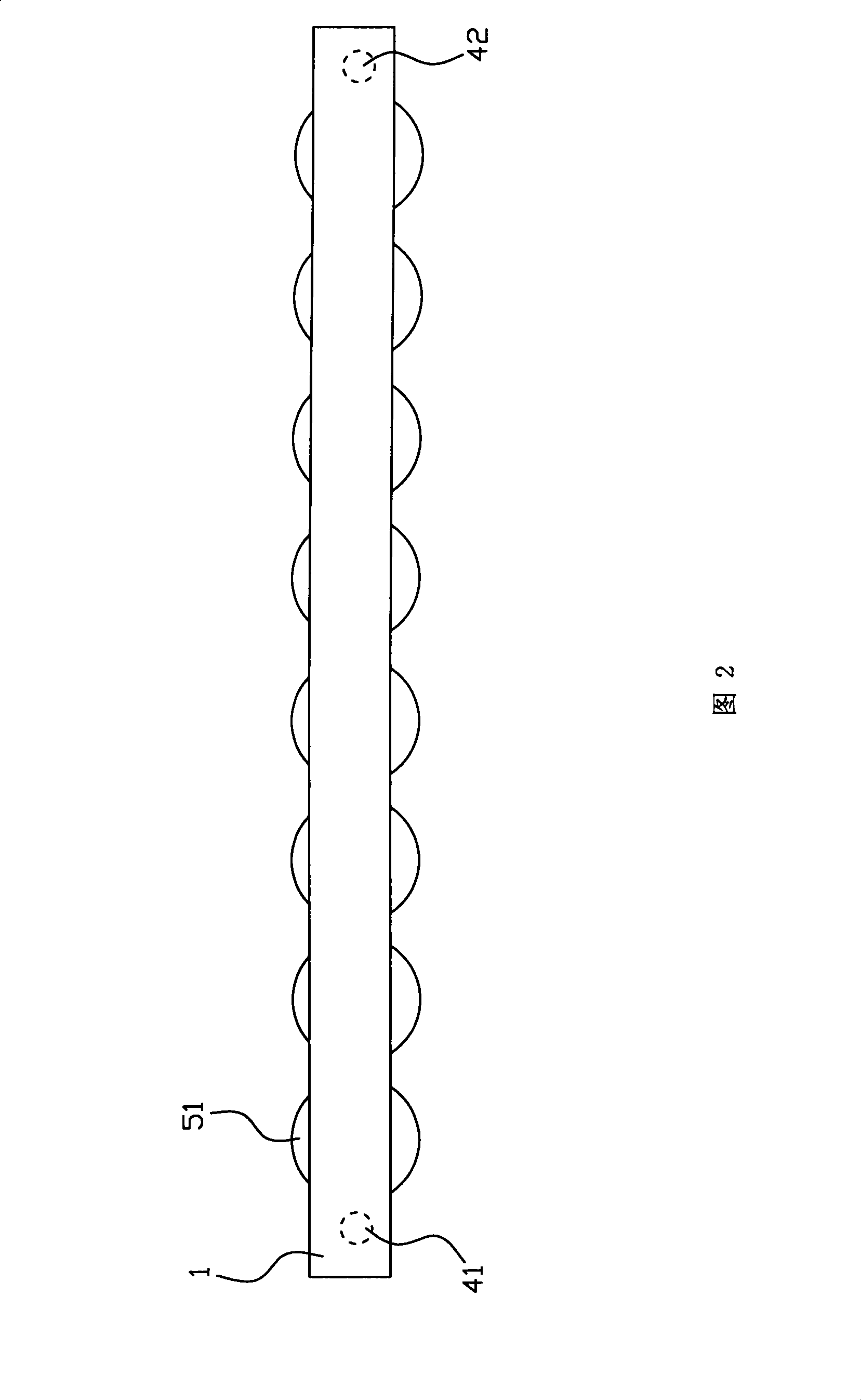

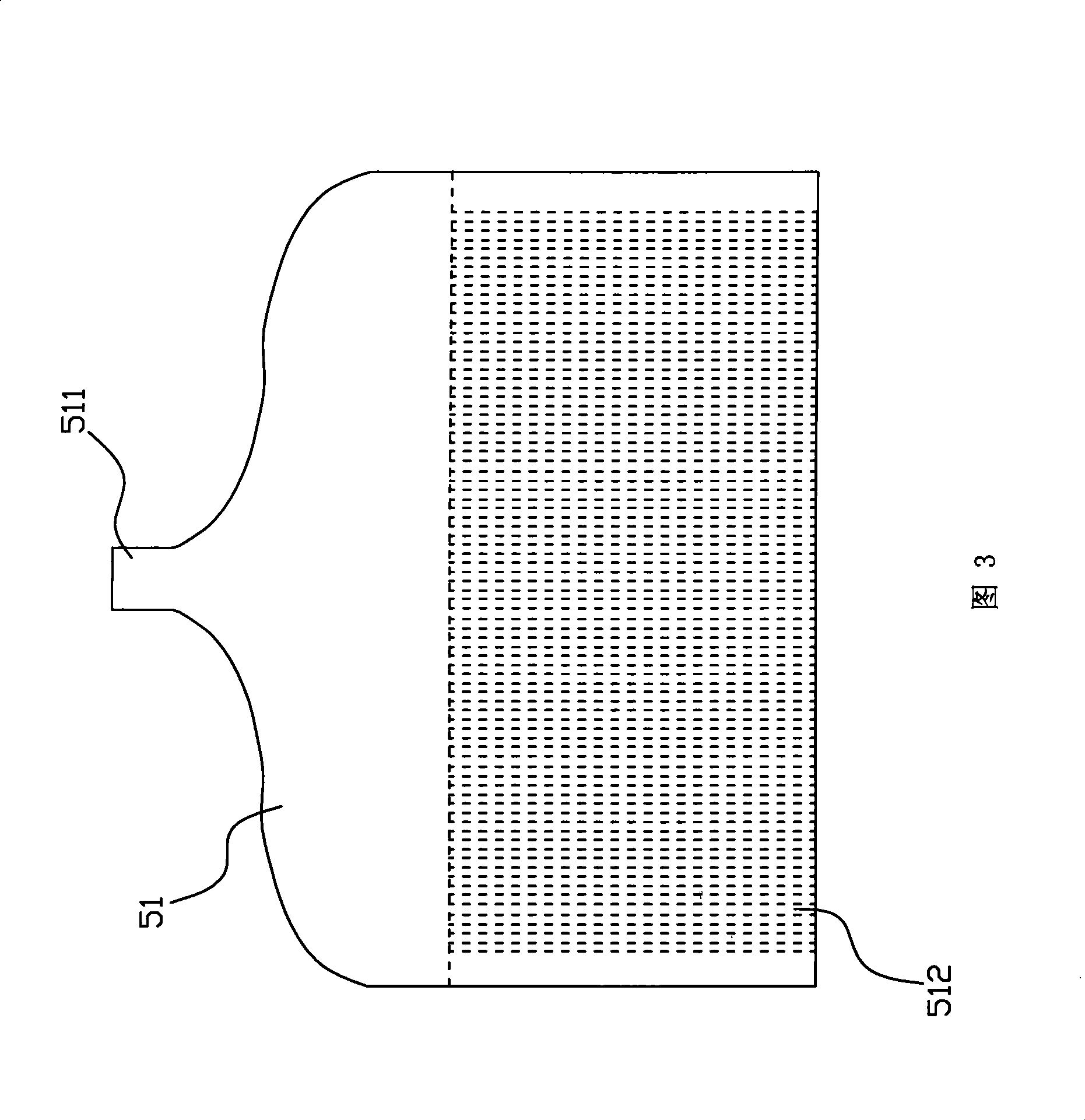

Hollow fiber membrane filtering assembly

InactiveCN101362053ANot easy to foulNot easy to damageSemi-permeable membranesHollow fibre membraneFiber

The invention relates to a hollow fiber porous membrane filter component which comprises a water outlet pipe connected with a water suction pump and used for discharging filtered water, a membrane bundle cup used for connecting a hollow fiber membrane bundle and communicated with the water outlet pipe by a water outlet hose, an aeration pipe communicated with air supply and provided with aeration holes on the surrounding wall, and the hollow fiber membrane bundle immersed in sewage to be treated and arranged in a U-shape form, with the two ends connected with the membrane bundle cup and the bending part arranged on the aeration pipe. The aeration holes on the aeration pipe are arranged at positions corresponding to the bending part of the hollow fiber membrane bundle. The component has the advantages that the membrane surface of the whole membrane bundle is not easy to be fouled and blocked, the connecting root part of the membrane bundle is not easy to be damaged, the structure is simple and easy to be maintained, scale production is easy to form and the like.

Owner:XIAMEN LEEBAM MEMBRANE TECH

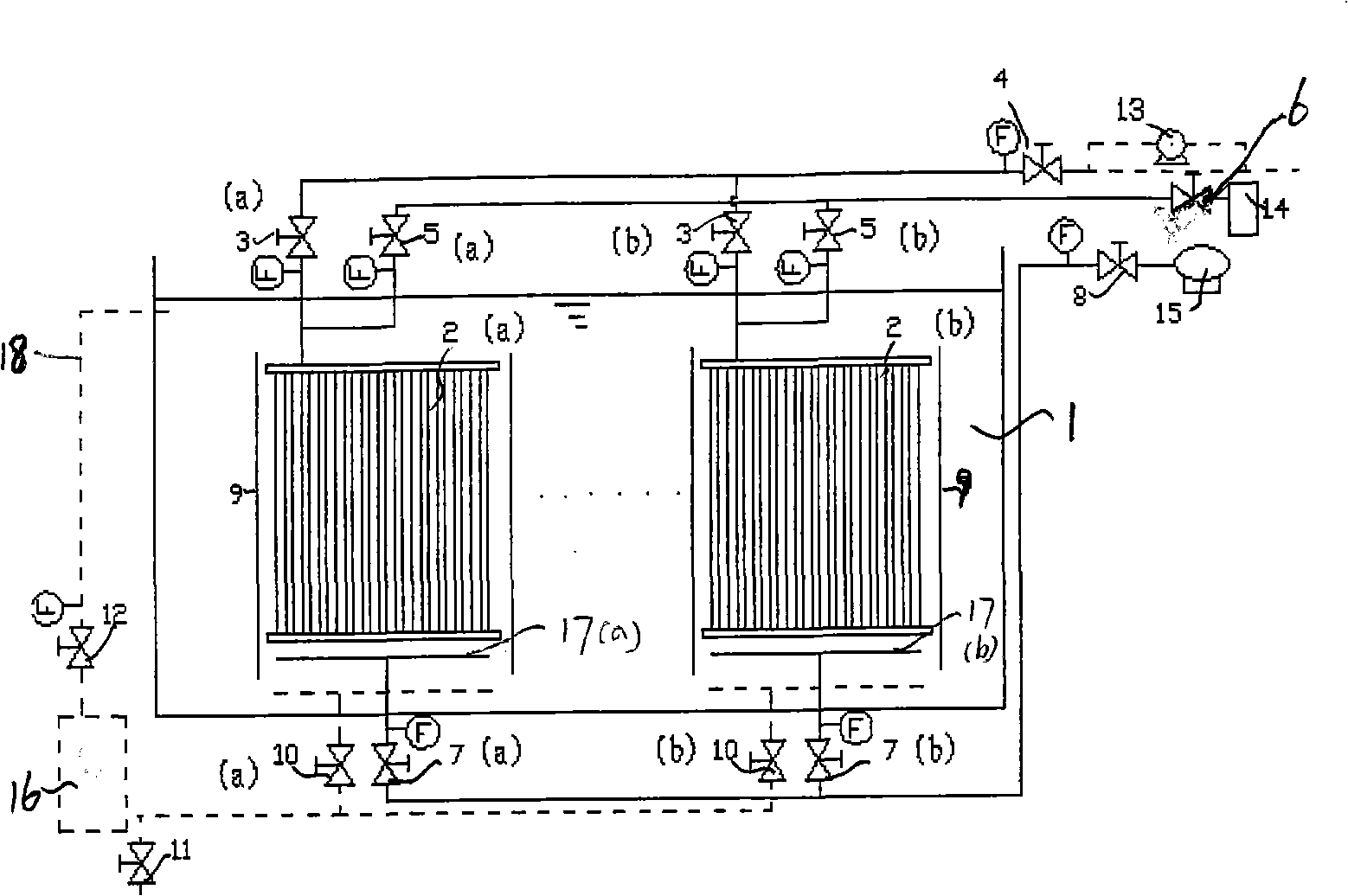

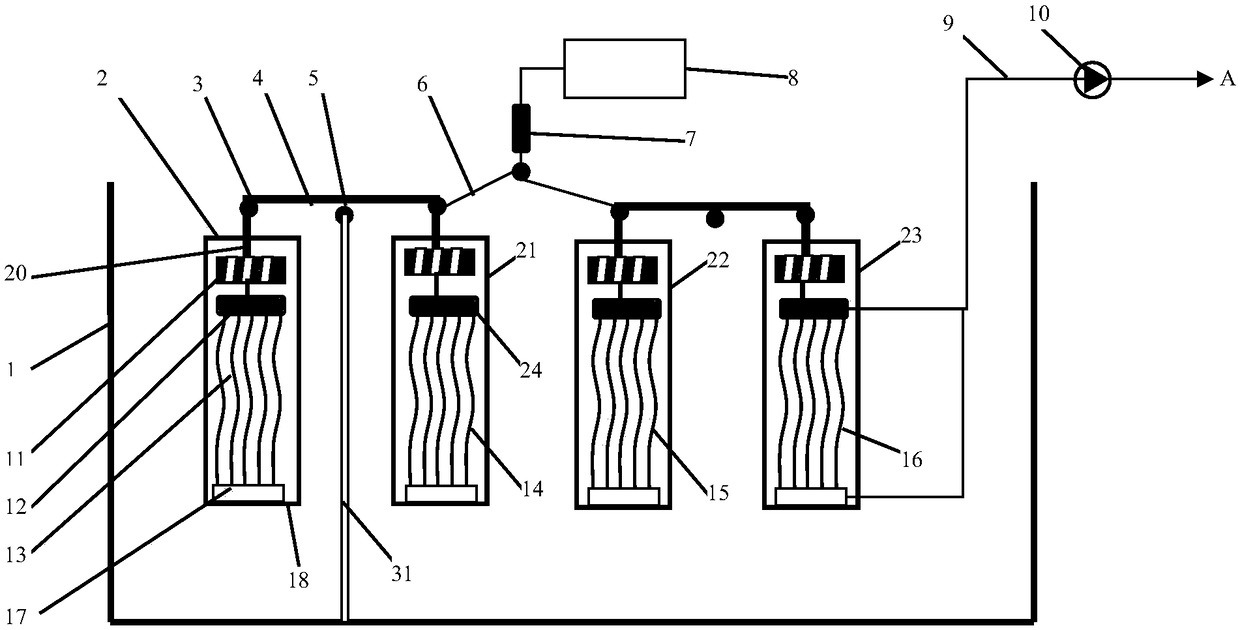

Immersion type hyperfiltration membrane technique operated in the same diaphragm cell and various membrane units

InactiveCN101406808AExtended cleaning cycleImprove running stabilityUltrafiltrationWater/sewage treatment bu osmosis/dialysisFiltrationControl manner

The invention discloses a process for the separate operation of membrane units in a same membrane cisterna of an immersed type ultrafiltration membrane. The process is carried out through an operating device. The operating process comprises membrane air purge, back flushing and concentrated water treatment. The operating device comprises the membrane cisterna; two or more than two groups of membrane units are arranged in the membrane cisterna; separating and enclosing devices are arranged between the membrane units; a water producing device and a back flushing device are arranged on the upper part of each membrane unit; and an air purging device and a drainage device are arranged below each membrane unit. The process adopts a control mode of the equipartition of a cleaning interval for the membrane units in the same membrane cisterna, thereby achieving the continuous uninterrupted production of the whole membrane cisterna. When the membrane units in the same membrane cisterna run below the optimum membrane flux, water production is automatically balanced under the same transmembrane pressure difference, thereby improving the operating stability of a system. For a filtration system with more membrane units, the process carries out back flushing through a water tower (water tank) so as to reduce the energy consumption of the system.

Owner:PACIFIC WATER TREATMENT ENG +1

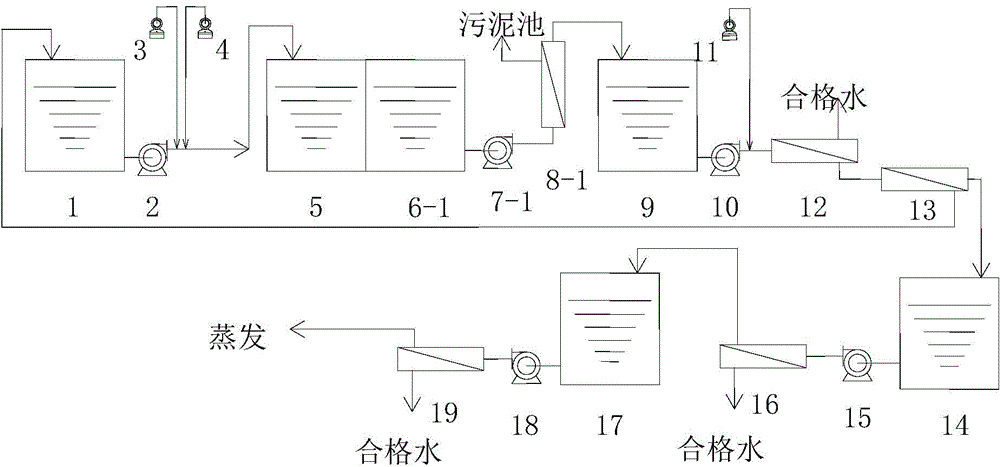

Membrane separation combination zero-emission system for deeply treating desulfurization wastewater with whole membrane method

InactiveCN105712536ASave waterRealize resource utilizationSpecific water treatment objectivesWater softeningResource utilizationFiltration

The invention belongs to the technical field of treatment of desulfurization wastewater and particularly provides a membrane separation combination zero-emission system for deeply treating desulfurization wastewater with a whole membrane method. The system comprises a pretreatment water tank, a water quality regulating water tank, a first reaction tank, a sedimentation water tank, a second reaction tank, a concentrated water tank, an TMF (tubular micro-filtration) assembly, a produced water tank and an NF (nanofiltration) assembly which are sequentially communicated through a pipeline, wherein a produced water outlet of the NF assembly is connected and communicated with an SWRO (seawater reverse osmosis) assembly through a pipeline, a concentrated water outlet of the SWRO assembly is connected and communicated with a DTRO (disk tubular reverse osmosis) assembly through a pipeline, and a concentrated water outlet of the NF assembly is communicated with a wastewater collecting tank through a pipeline. With the adoption of the membrane separation combination zero-emission system for deeply treating desulfurization wastewater with the whole membrane method, the pure water recovery rate is higher, the occupied area is small, the cost is low, resource utilization is realized, membrane assemblies cannot be blocked by dirt, stable operation of the membrane system is guaranteed, the wastewater treatment efficiency is improved, resource waste is avoided, and meanwhile, unnecessary environmental pollution is reduced.

Owner:国能朗新明环保科技有限公司

Functional liquid coating used for magnesium aluminium alloy base material

InactiveCN101070450AEasy to useGood performance balanceLiquid surface applicatorsPolyester coatingsSalt resistanceHeat resistance

The present invention relates to a functional liquid paint used in magnesium backer. It consists of base body and face budge. They all includes special property modification alkyd resin liquid paint, which has good interlamellar clunging, good gloss and color retention, high abrasive resistance, salt spray resistance, and cold and heat resistance. It needs only one set of production equipment, so the cost is largely reduced. The baking temperature of base bedye is reduced from 200Deg.c in present technique to 140Deg.c-160Deg.c; the energy cost is largely reduced. The thickness covered of base bedye is reduced from 50-80 micro in present technique to 25-30 micro, the cost of paint is reduced and when repaint the whole membrane changes little, which is good for the latter equipment.

Owner:HENGFENG COATING TAICANG

PET heavy-ion microporous composite membrane for lithium battery and preparation method thereof

InactiveCN105514329AMake up for the defect that is prone to heavy holesMake up for the defect of resistance to lithium dendrite punctureCell seperators/membranes/diaphragms/spacersLi-accumulatorsFilm basePole piece

The invention discloses a PET heavy-ion microporous composite membrane for a lithium battery and a preparation method thereof. The PET heavy-ion microporous composite membrane comprises a microporous PET film with first micro-holes and a multi-micropore material layer with second micropores. The multi-micropore material layer is obtained by curing molding of macromolecule resin and inorganic oxide particles. The preparation method comprises the steps that the macromolecule resin, the inorganic oxide particles and a solvent are mixed to form a colloid material, a PET film base material is coated with the colloid material and cured and molded to form a semifinished product, and irradiation of the semifinished product and an alkaline solution etching reaction are performed to obtain a finished product. The multi-micropore material layer is not etched during micropore PET film forming etching and has the micropore structure where lithium ions can freely migrated, the defect that micropores in a traditional micropore PET film are likely to be superposed is overcome, the purpose of resisting lithium dendrites punctures and pole piece particle puncture is achieved, the whole membrane electrolyte wettability is improved, the pore diameter design range of straight micropores of the micropore PET film is larger, and the production efficiency is high.

Owner:허난구오안일렉트릭머터리얼컴퍼니리미티드

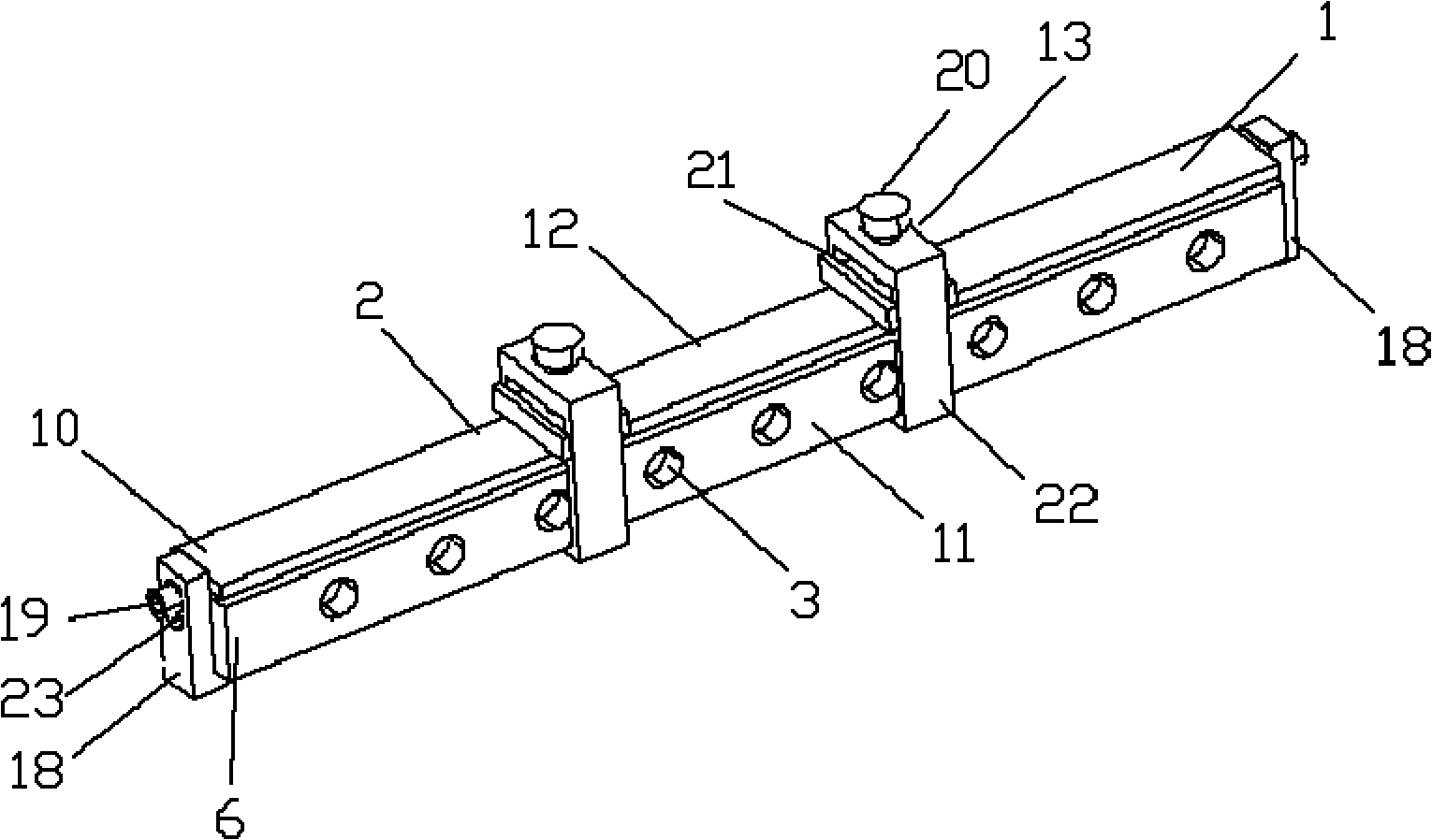

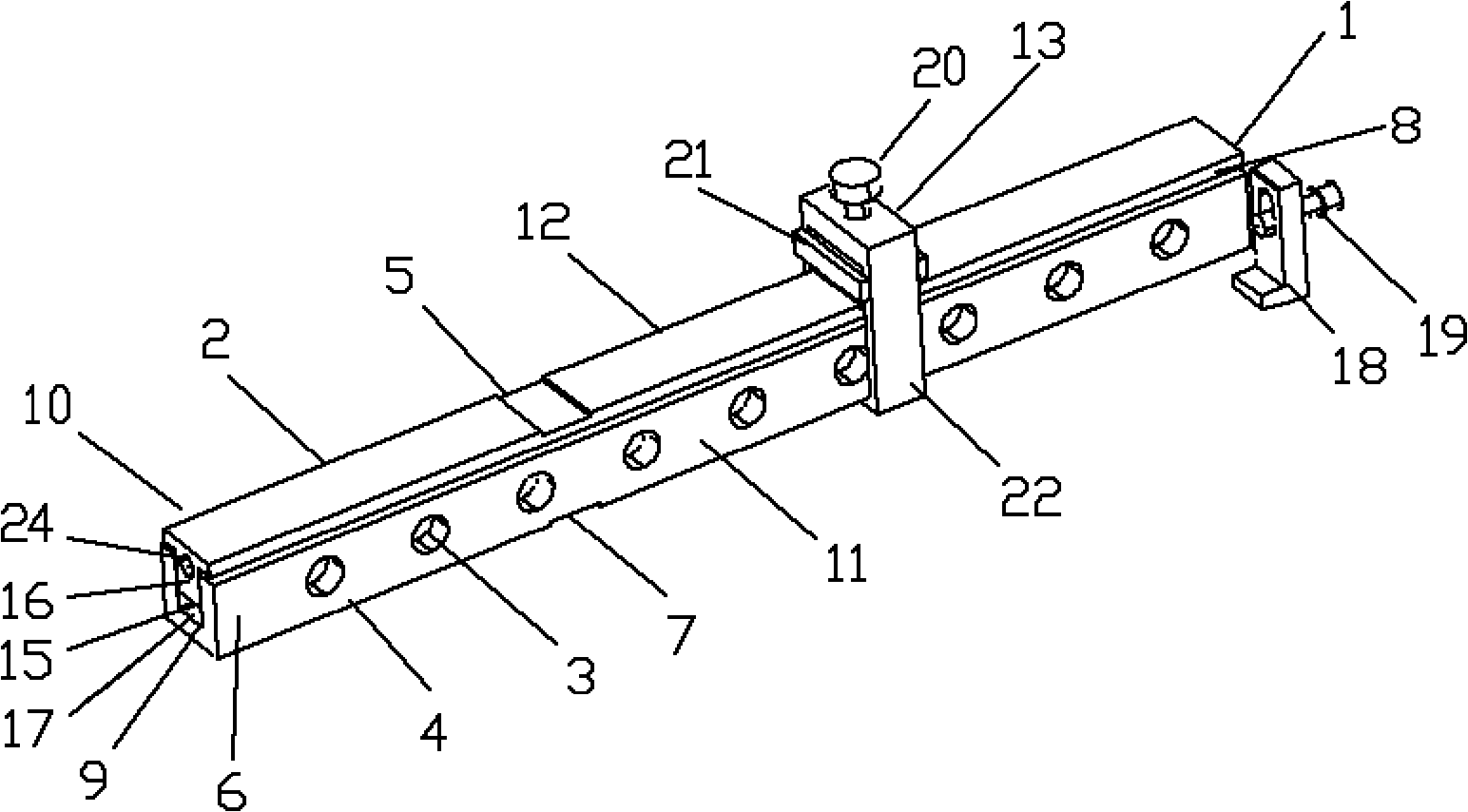

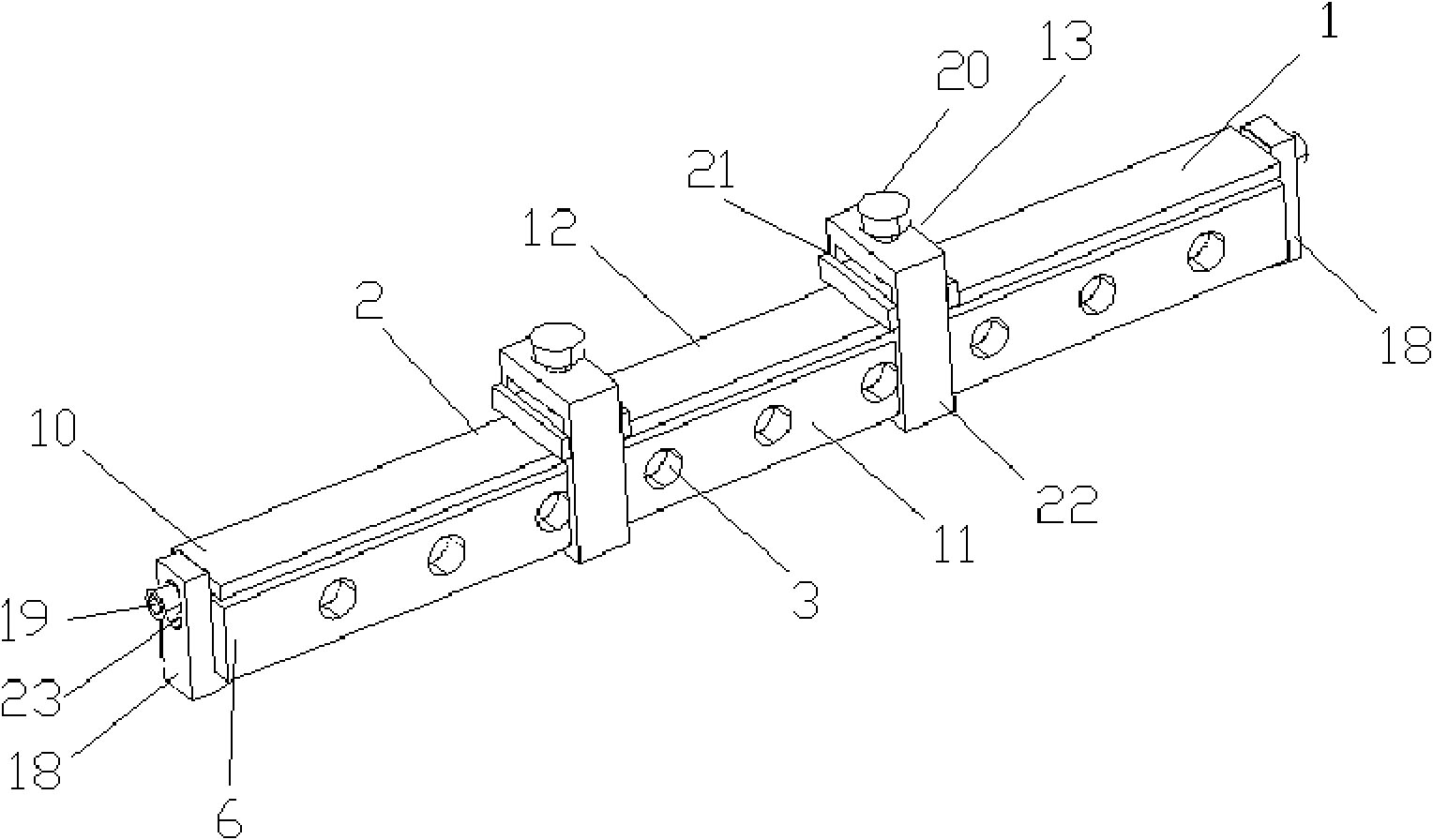

Magnetic core heat treatment clamp

InactiveCN102560011AReasonable structureHigh strengthInductances/transformers/magnets manufactureEngineeringImpurity

The invention relates to a magnetic core heat treatment clamp. The clamp comprises a magnetic core forming die (1) and a combined fastening clamp (14), wherein the magnetic core forming die (1) comprises a concave slot body (11), a pressing plate (2) matched with a concave straight slot (15) of the concave slot body (11) and an L-shaped fastener (18) fixed at the end part of the pressing plate, wherein two side walls (6) of the concave slot body (11) are respectively provided with a group of air holes (3), and the fastening clamp (14) as a combination of locking and fastening clamps (13) is used for clamping the concave slot body (11) and the pressing plate (2). The magnetic core heat treatment clamp has the advantages of reasonable whole structure, small deformation, suitability for working at high temperature for a long term, uniformity in force borne by a whole membrane, good forming quality of a magnetic core rod structure, precise size, small error, reasonable arrangement of a ventilation structure of the heat treatment clamp, good ventilation effect, good membrane heat treatment quality and no impurity pollution to a magnetic core membrane of the magnetic core heat treatment clamp made of the same material under a high-temperature environment.

Owner:NAT SPACE SCI CENT CAS

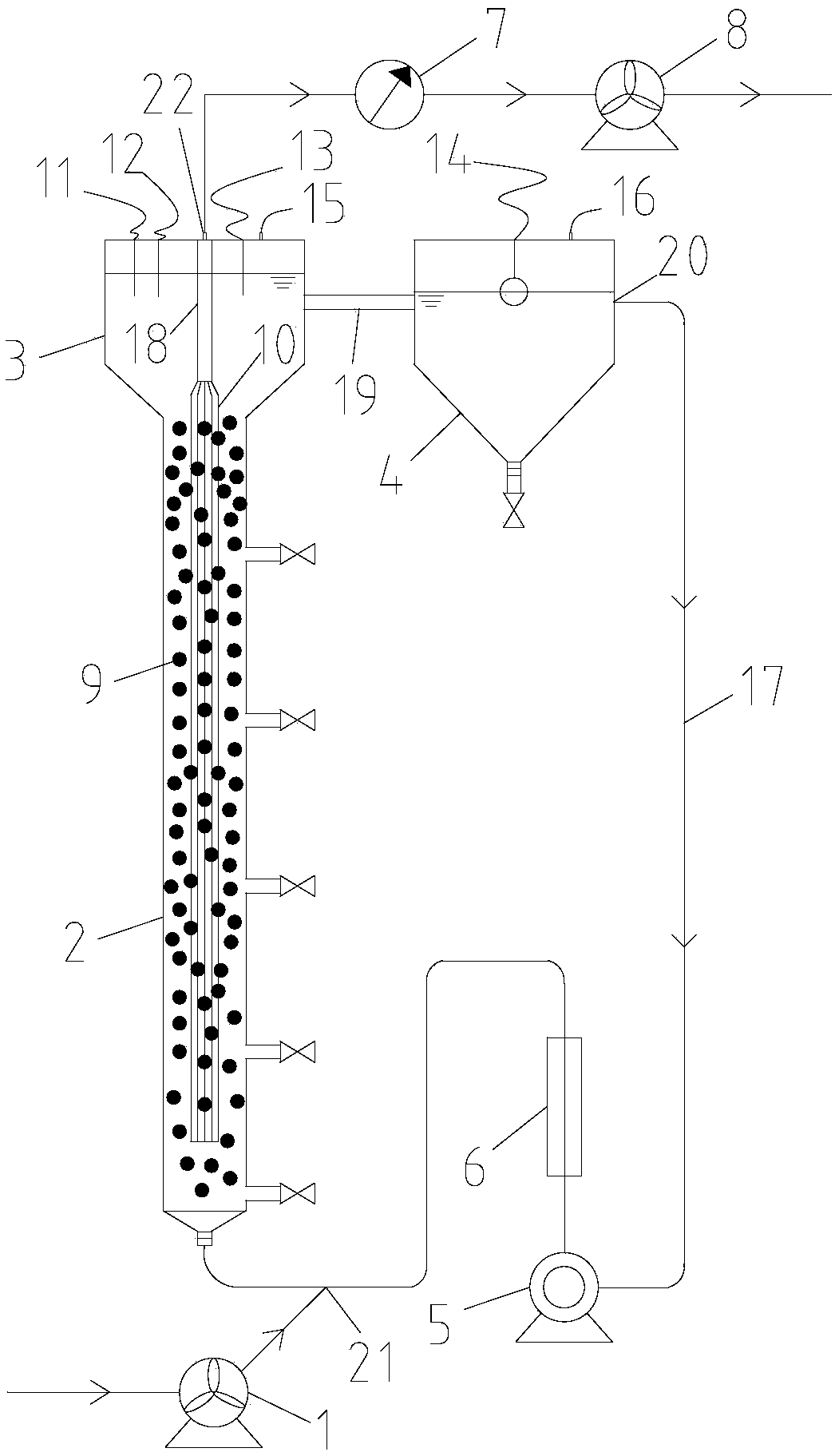

Efficient anaerobic granular sludge bed membrane bioreactor capable of self-supplying energy and operation method

PendingCN108408890AGuaranteed uptimeReduce pollutionWater treatment parameter controlTreatment with anaerobic digestion processesPeristaltic pumpMembrane bioreactor

The invention discloses an efficient anaerobic granular sludge bed membrane bioreactor capable of self-supplying energy and an operation method, the membrane bioreactor comprises a main reaction column, settling chambers and a circulating pipeline. The main reaction column internally comprises anaerobic granular sludge and a hollow fiber membrane, the settling chambers comprise a pH electrode, anORP electrode, a DO electrode and a liquid level controller, a circulating magnetic pump, a rotor flow meter and a water inlet are mounted on the circulating pipeline. Continuous water inlet is conducted through a water inlet peristaltic pump, water outlet is controlled by the liquid level controller, and intermittent water inlet is performed. The efficient anaerobic granular sludge bed membrane bioreactor has the advantages that organic matters can be effectively recycled in sewage treatment, and the energy self-supplying of the whole membrane bioreactor is realized. The matched operation method can effectively reduce membrane pollution when the stability of the anaerobic granular sludge is maintained.

Owner:BEIJING UNIV OF TECH

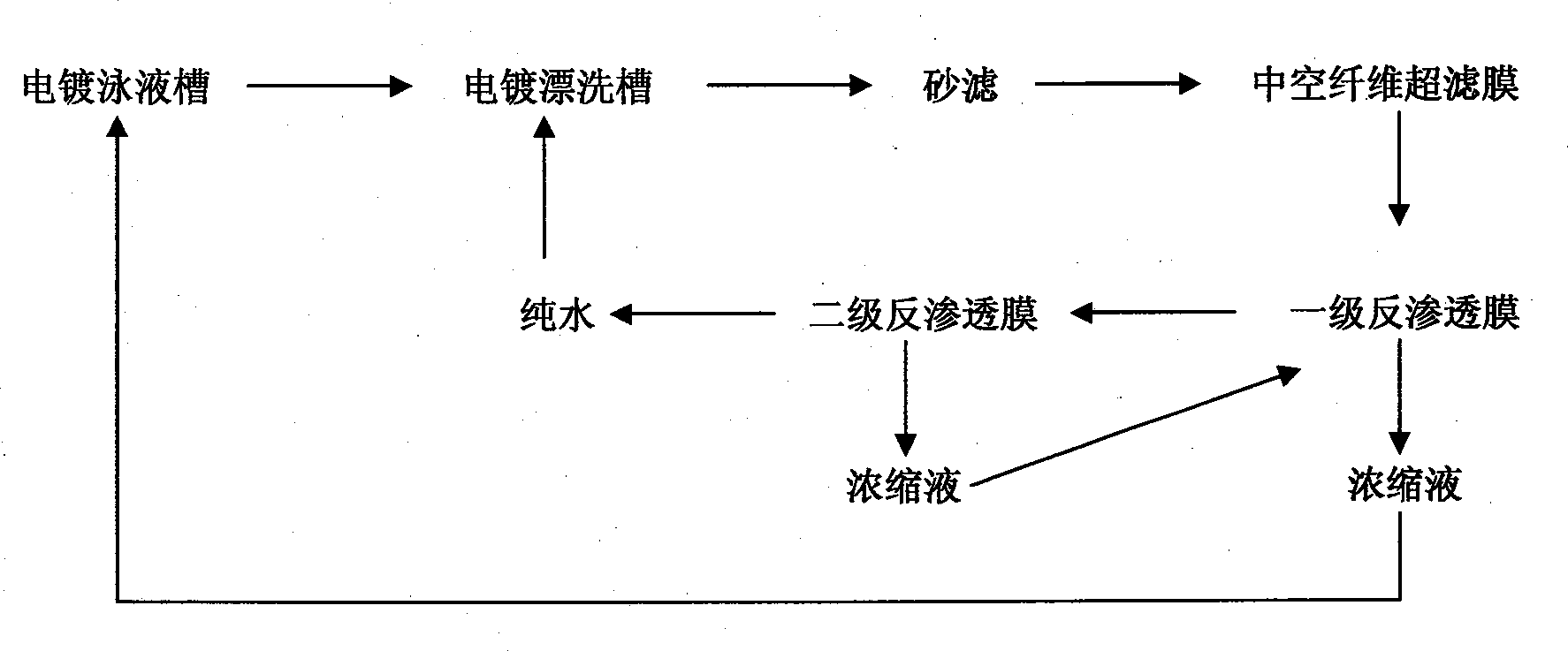

Whole membrane treatment method of electroplating chromeplating waste water

ActiveCN103130348ASolve the problem of membrane oxidation degradationSolve problems such as secondary pollutionWaste water treatment from metallurgical processWater/sewage treatment bu osmosis/dialysisFiberUltrafiltration

A whole membrane treatment method of electroplating chrome plating waste water comprises the following treatment steps of: 1) rinsing: rinsing electroplating chromeplated parts with clear water in a rinsing tank after being electroplated through a chromeplating electrophoresis liquid tank to obtain rinsed liquid; (2) sand filtration: treating the rinsed liquid in the rinsing tank by a sand filtration tank to remove suspension, colloid, flocculate, mud sand, rust, and the like to obtain sand-filtered liquid; (3) hollow fiber ultrafiltration membrane treatment; (4) reverse osmosis treatment: performing reverse osmosis concentration treatment of the clear liquid by a reverse osmosis device; (5) cyclic operation of the above steps. The method has the advantages that the problem of secondary pollution caused by traditional chemical precipitation methods is solved; the problem of membrane oxidation and degradation due to hexavalent chromium ions is solved; the method meets the new discharge national standard; the whole process flow operation is simple and convenient; waste water in the whole process is in a recycle state, and is not discharged to the outside at all; and the whole process reaches the standard of zero discharge.

Owner:深圳市立威塑胶五金制品有限公司

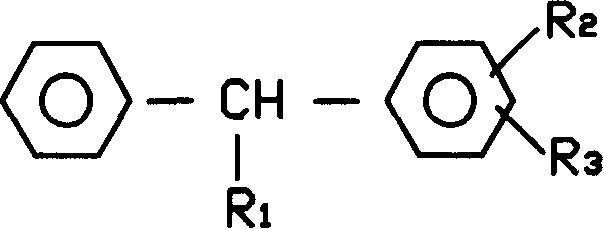

Diarylane insulating oil

InactiveCN1861767AIncrease aromaImprove stabilityFixed capacitor dielectricThickenersMembrane complexHigh intensity

A diaryl alkane isolating oil, the molecule structure formula of it is I, the R1, R2 and R3 represents H or CH3 separately. This isolating oil can be as the immersion oil of some condenser, and it can be as the immersion of paper mediator, paper membrane complex mediator and whole membrane mediator. It especially is suitable to the immersion of high pressure whole polypropylene membrane. The aromatic and fat element of this invention are optimizing combination, and this improves the aroma of the isolating oil further and decreases the viscosity of the isolating oil at low temperature, so the electric field resistance of the isolating oil during the whole usage processes is stable. It can be applied to the higher intensity of working electric field.

Owner:西安电力电容器研究所

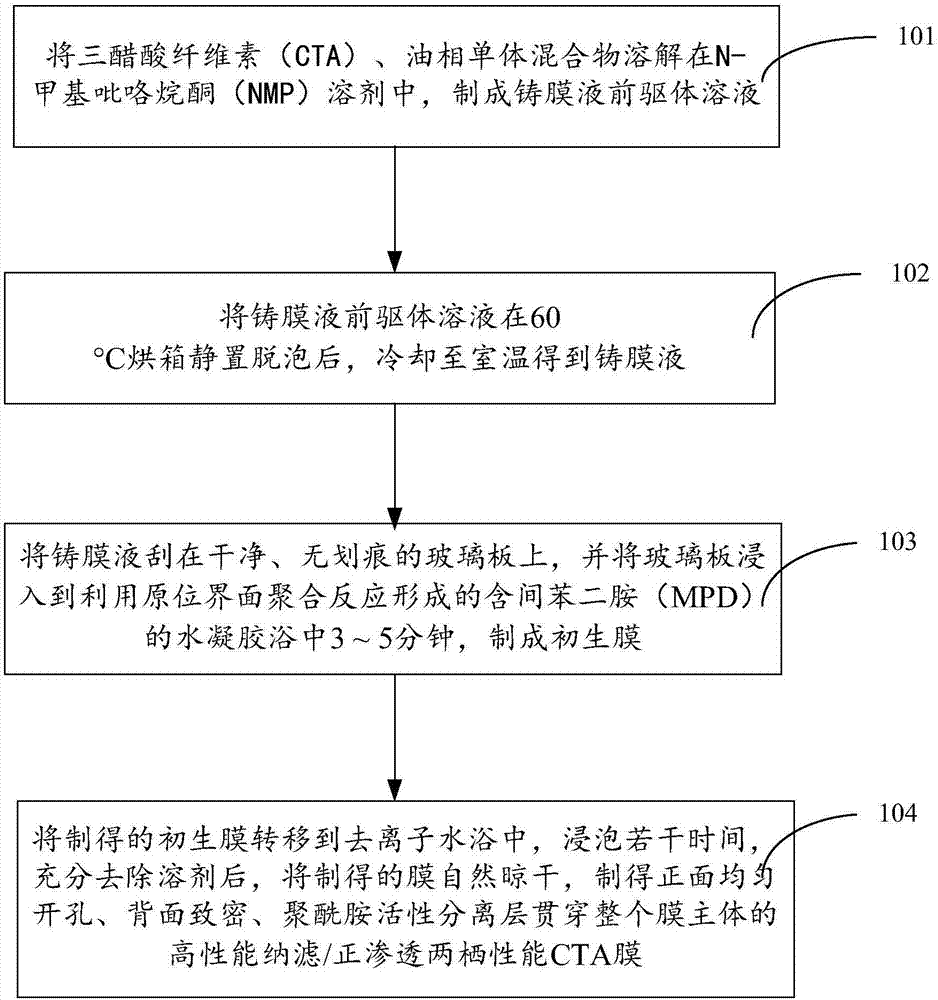

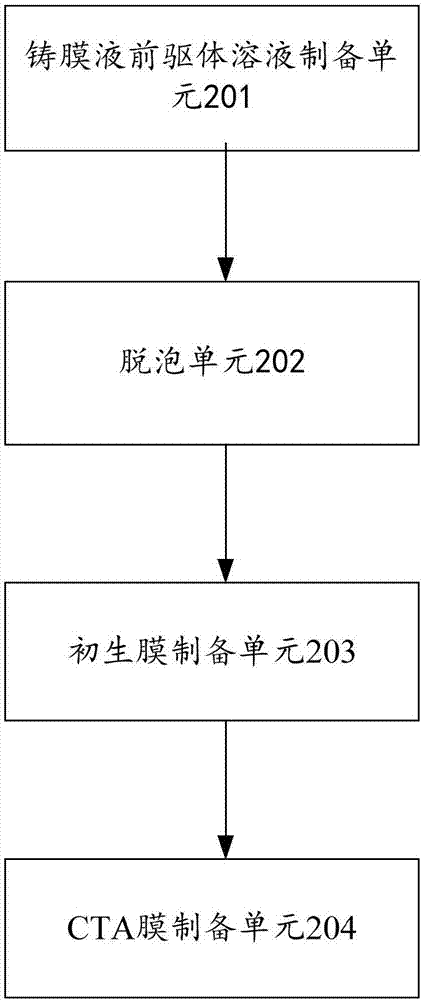

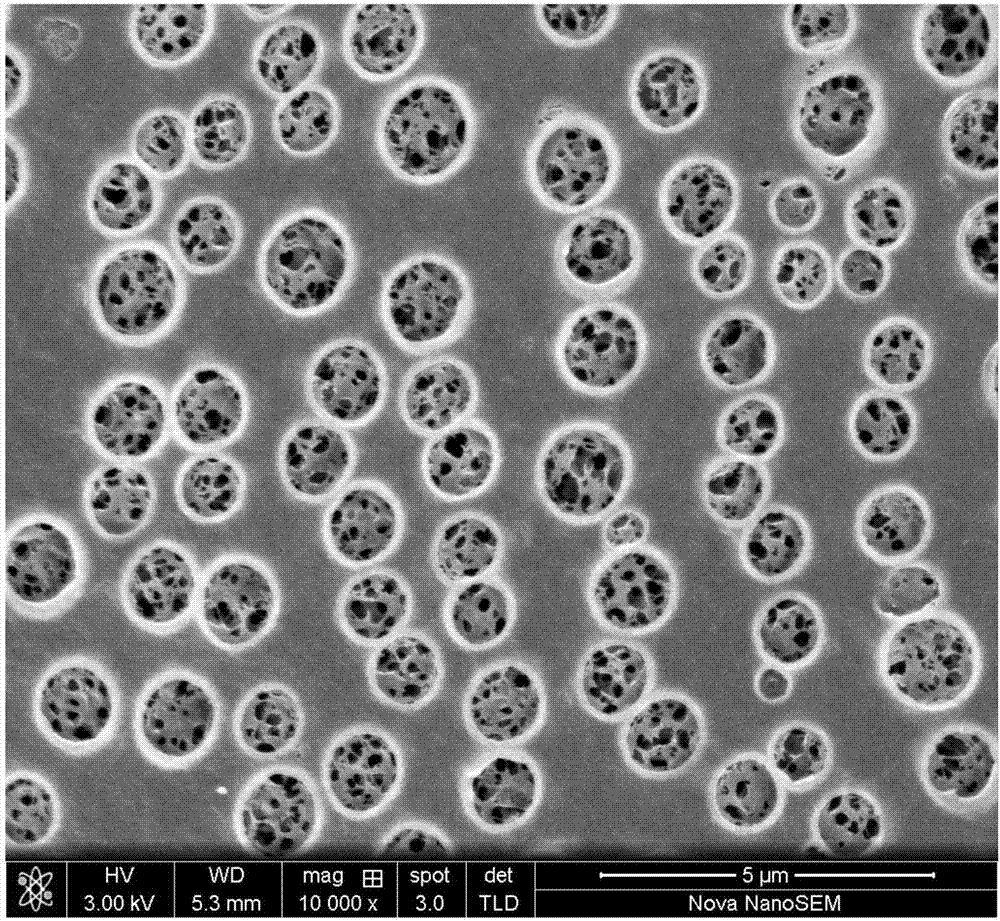

Method for preparing nanofiltration/forward osmosis amphibious performance CTA membrane and apparatus thereof

ActiveCN107376667ARealize the structureRealize performance regulationSemi-permeable membranesWater bathsCellulose acetate

The invention discloses a method for preparing nanofiltration / forward osmosis amphibious performance CTA membrane and an apparatus thereof. The method comprises the following steps: 1) dissolving a mixture of cellulose triacetate and an oil-phase monomer in a N-methyl 2 pyrrolidone solvent to prepare a casting liquid precursor solution; 2) performing standing on the casting liquid precursor solution for defoaming, and cooling the casting liquid precursor solution to room temperature to obtain the casting liquid; 3) scraping the casting liquid on a clean and non-scratch plate, immersing the plate in a gel bath formed by using an in-situ interface polymerization reaction for gelling, and performing an in-situ interface polymerization reaction during a gelling process to prepare a primary membrane; and 4) transferring the primary membrane to a deionized water bath, immersing the primary membrane for a while, fully removing the solvent, and naturally drying the prepared membrane to obtain the high-performance nanofiltration / forward osmosis amphibious performance CTA membrane having the characteristics of uniform opening on a right side and compactness of a back side, and has a polyamide active separating layer capable of penetrating a whole membrane main body.

Owner:SHANGHAI MUNICIPAL WATER RESOURCES DEV & UTILIZATION NAT ENG CENT

Method for treating membrane distillation water

The invention provides a processing method for membrane distilled water, wherein the relatively high temperature of the material liquid ready to be processed is kept by utilizing the heat absorbed by wall surfaces from the environment, and the material liquid ready to be processed is evaporated on one side of a hydrophobicity microporous membrane, and the material liquid steams on the material liquid side in membrane holes are forced to flow toward the distillate side in membrane holes, and the material liquid steams on the distillate side in the membrane holes are condensed on the distillate side, and the relatively low temperature of the distillate is kept by wet wall surfaces, and then the wet heat is emitted into the environment. The method can not only automatically acquire heat from the environment to heat the material liquid, but also automatically acquire cold sources from the environment to cool the distillate, so that the whole membrane distillation process does not need manual intervention; the method can not only continuously process the material liquid, but also constantly obtain the distillate; the method can not only be realized without the sun, but also be implemented at night; the method can be used in small scale as well as large scale.

Owner:EAST CHINA UNIV OF SCI & TECH

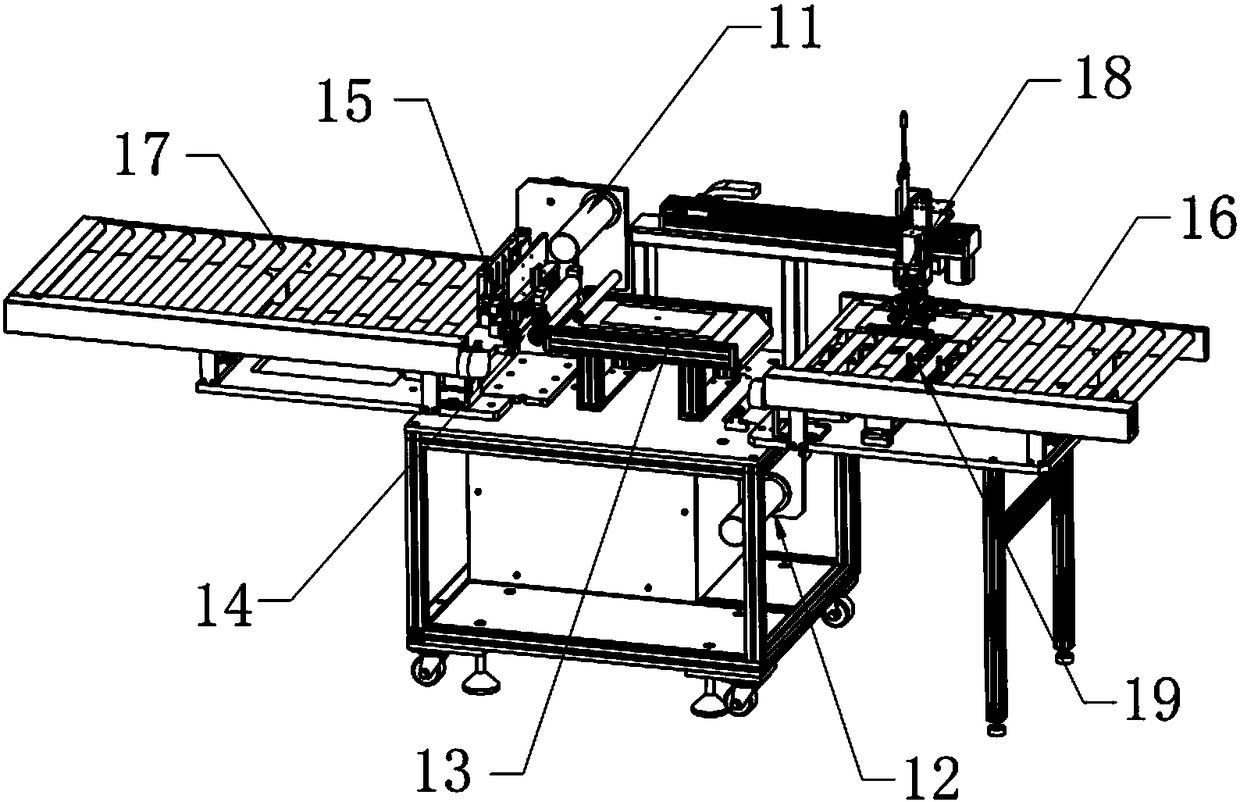

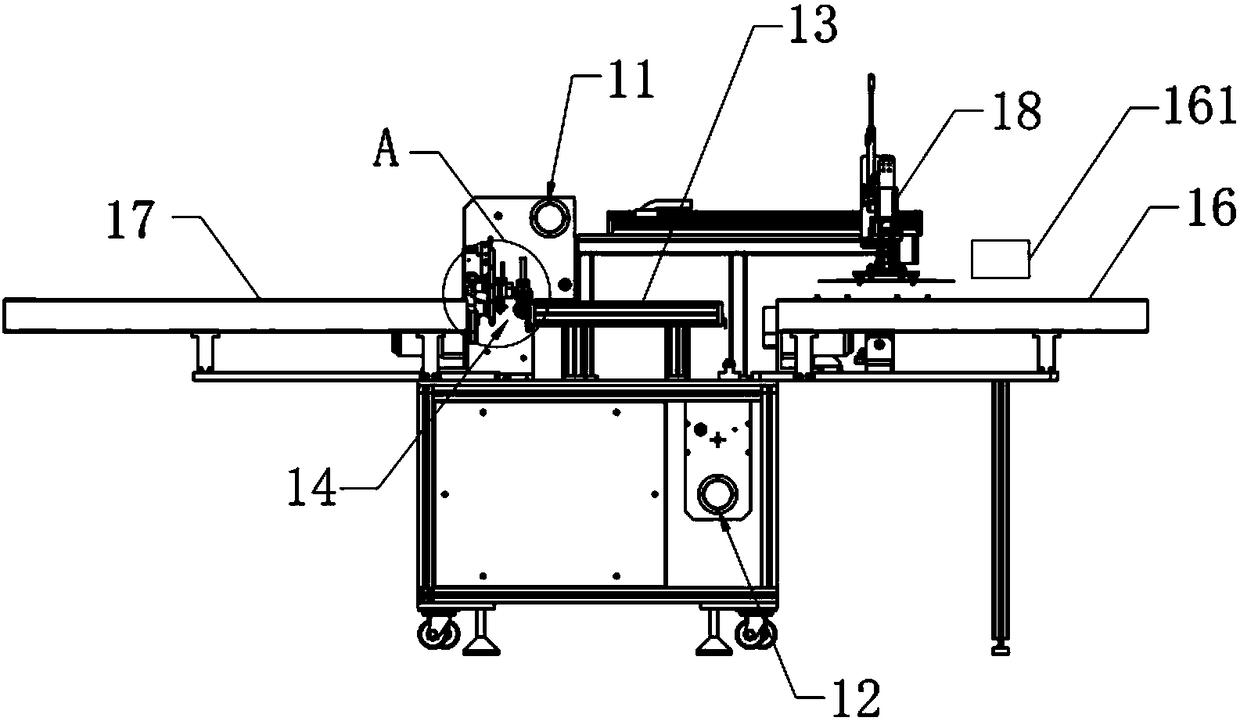

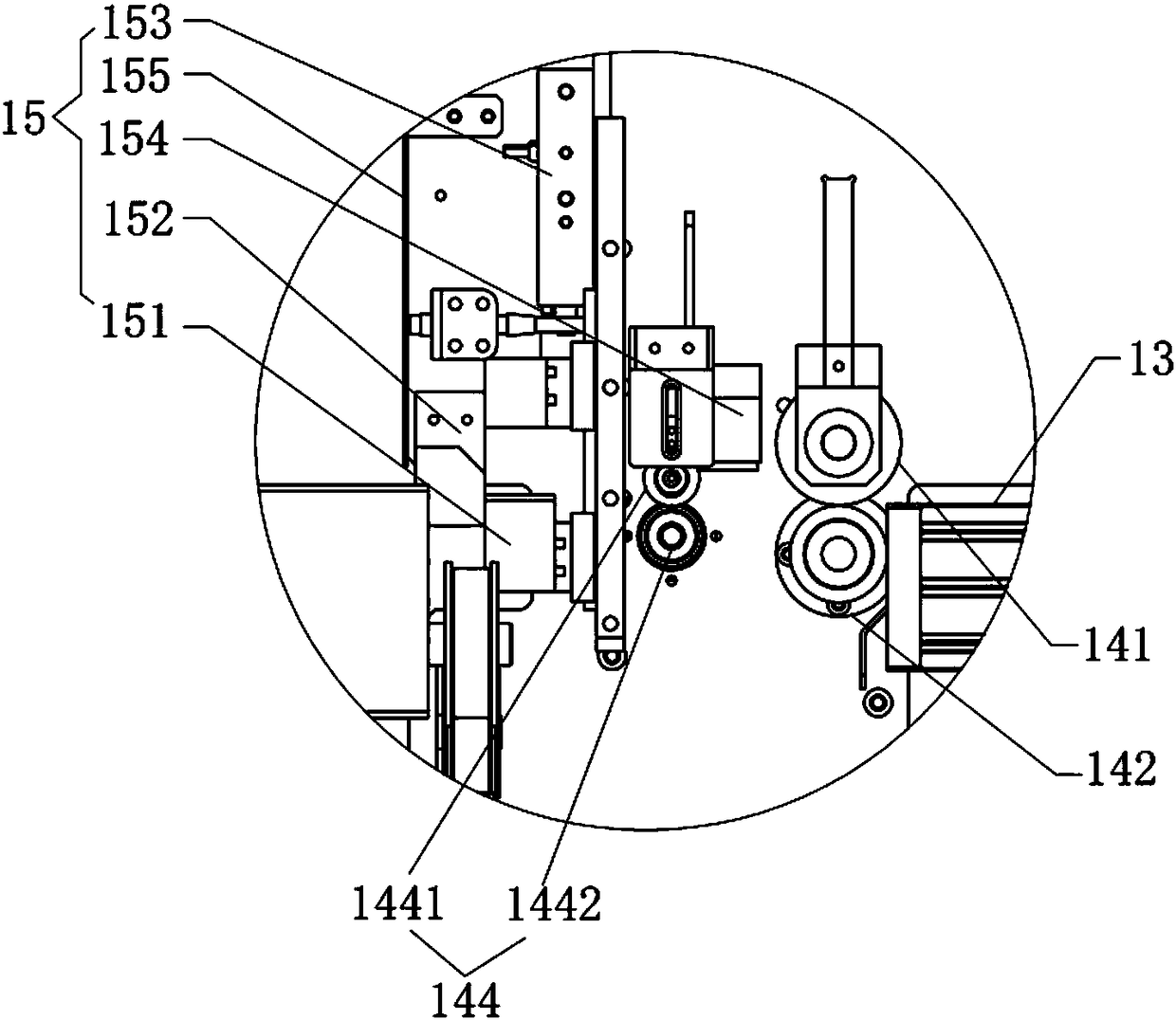

Membrane coating mechanism of backlight source

PendingCN108583982AImprove quality and efficiencyImprove film application efficiencyWrapping material feeding apparatusEngineeringMembrane feeding

The invention relates to the technical field of backlight source processing equipment, and in particular to a membrane coating mechanism of a backlight source. The mechanism comprises an upper membrane feeding component, a lower membrane feeding component, a material receiving platform for placing the external backlight source, a membrane pressing device for driving the backlight source placed bythe receiving platform to move and pressing an upper membrane and a lower membrane on the front and rear sides of the backlight source and a membrane shearing device arranged at a discharge end of themembrane pressing device, wherein the upper membrane feeding component is used for conveying the external upper membrane to the membrane pressing device and the lower membrane feeding component is used for conveying the lower membrane to the membrane pressing device via the tabletop of the receiving platform. The mechanism disclosed by the invention has the advantages that the structural design is reasonable; the whole membrane coating process is automatically completed and the automation degree is high; a traditional manual membrane sticking mode is completely replaces; the labor intensity of workers is greatly reduced; the labor cost is saved; and the membrane sticking quality and efficiency of the backlight source are increased.

Owner:ANHUI ZHONGXIAN INTELLIGENT ROBOT CO LTD

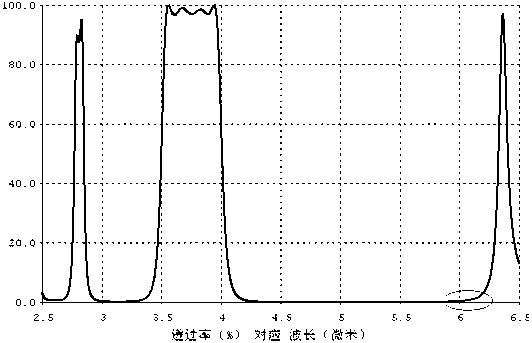

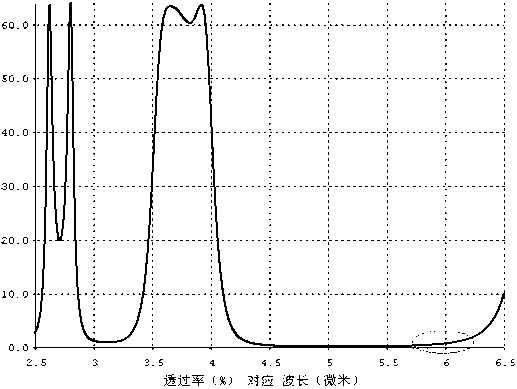

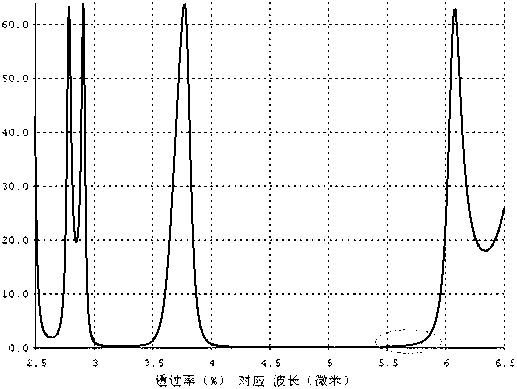

Method for adjusting out-of-band cut-off width of bandpass filter with multicavity structure

ActiveCN102798914AExcellent spectral characteristic curveOptical filtersBandpass filteringLight filter

The invention discloses a method for adjusting the out-of-band cut-off width of a bandpass filter with a multicavity structure. According to the method, the cut-off width of the filter is adjusted by changing the thickness of a membrane layer M made of a material which is the same as that of a spacer layer by adjusting reflection layers in a plurality of Fabry-Boron bandpass membrane systems forming the bandpass filter with the multicavity structure. During actual application, the filter generally needs a relatively big cut-off width; the cut-off width of the bandpass filter in a long wave direction can be increased by increasing the thickness of the M; the increased value of the thickness of the M is required to be less than 0.5 time of the thickness of the original membrane layer; and through adjustment, the cut-off width of the bandpass filter with the multicavity structure in the long wave direction can be increased by over 9 percent. The method has the advantages that the membrane systems of the filter are relatively simple, and a spectral characteristic curve is good, the structure of the whole membrane system is not required to be changed because of slight error of the cut-off width, and the number of membrane layers is not required to be additionally increased.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

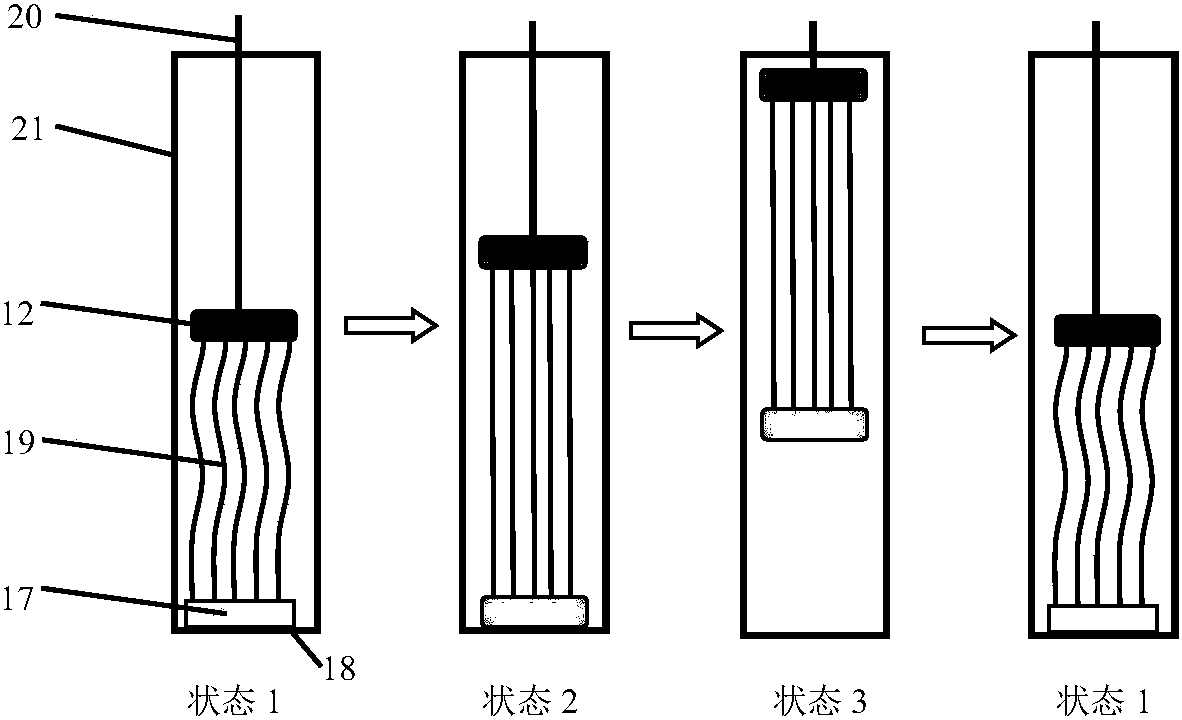

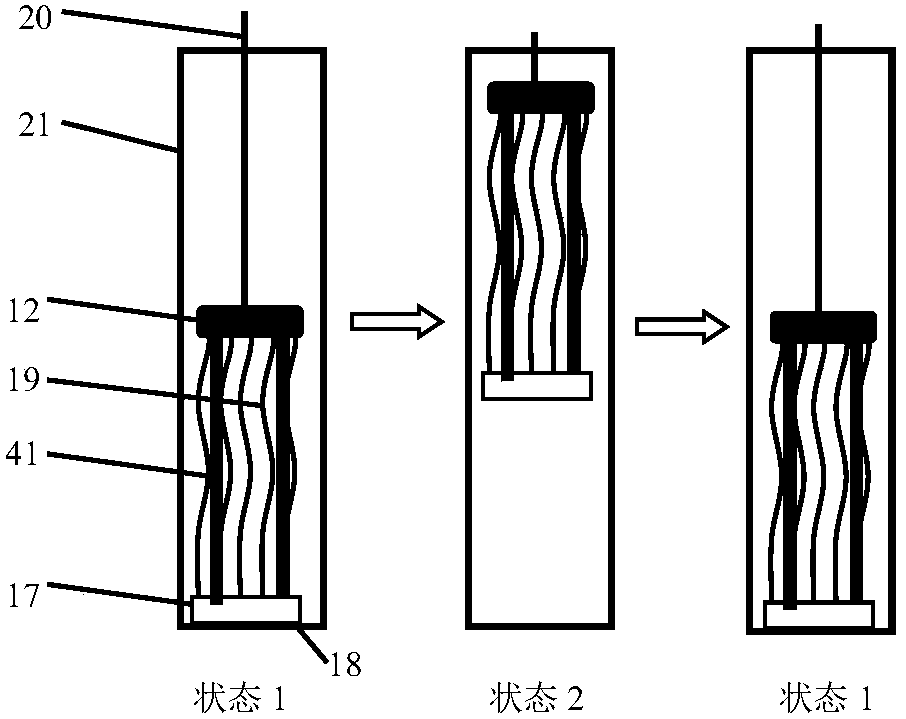

Immersed membrane separation device and operating method thereof

InactiveCN108310980AGood pollution control effectReduce pollutionSemi-permeable membranesTreatment with anaerobic digestion processesChemical reactorMembrane bioreactor

The invention relates to an immersed membrane separation device and an operating method thereof. By virtue of the mechanical lifting action and the natural gravity sinking action of a traction motor,a membrane unit positioned in a membrane frame periodically moves up and down; and by virtue of the contact shear action of membrane filament surfaces and water, the effect of controlling membrane pollution is achieved, so that the membrane separation device can stably operate for a long term. The membrane unit has two movement modes: (1) the upper end and the lower end of the membrane unit do notsynchronously rise or sink, and hollow fiber membrane filaments are periodically loosened or tightened; and (2) the upper end and the lower end of the membrane unit are fixed at a mutual distance through a pull rod or a rope, the membrane filaments are kept to be in a certain loosened state, and the whole membrane unit synchronously moves up and down for a certain distance. The immersed membraneseparation device and the operating method thereof provided by the invention can be applied to aerobic membrane bioreactors, anaerobic membrane bioreactors and membrane chemical reactors.

Owner:TIANJIN POLYTECHNIC UNIV

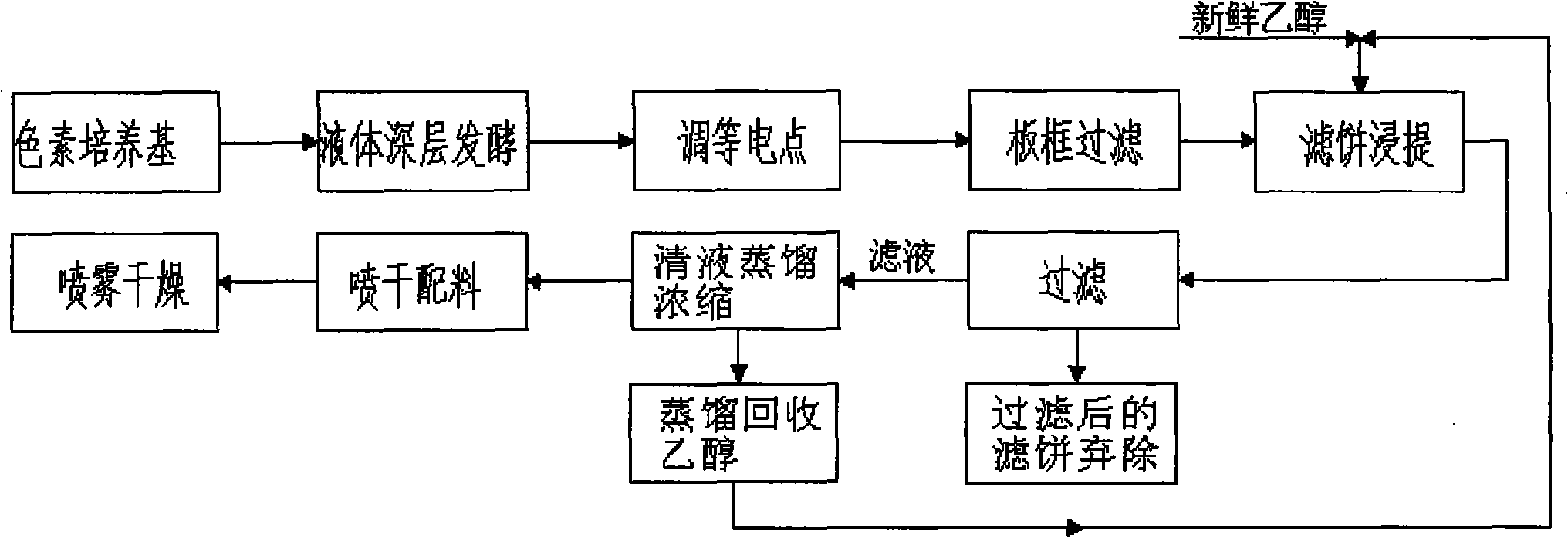

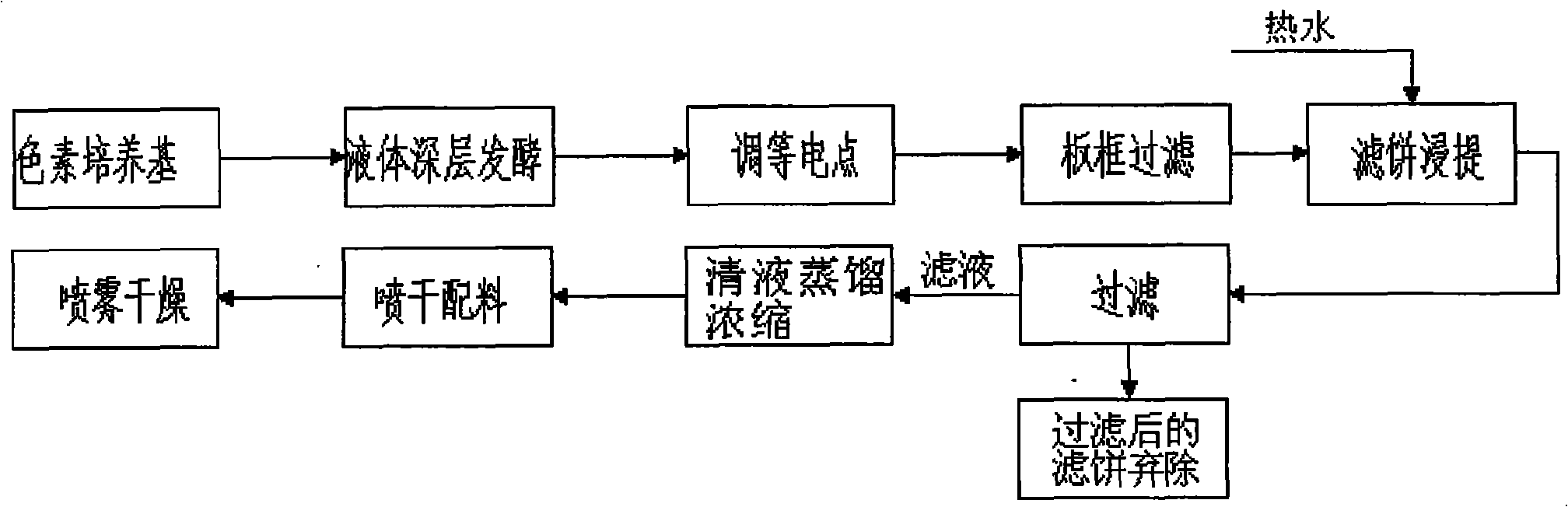

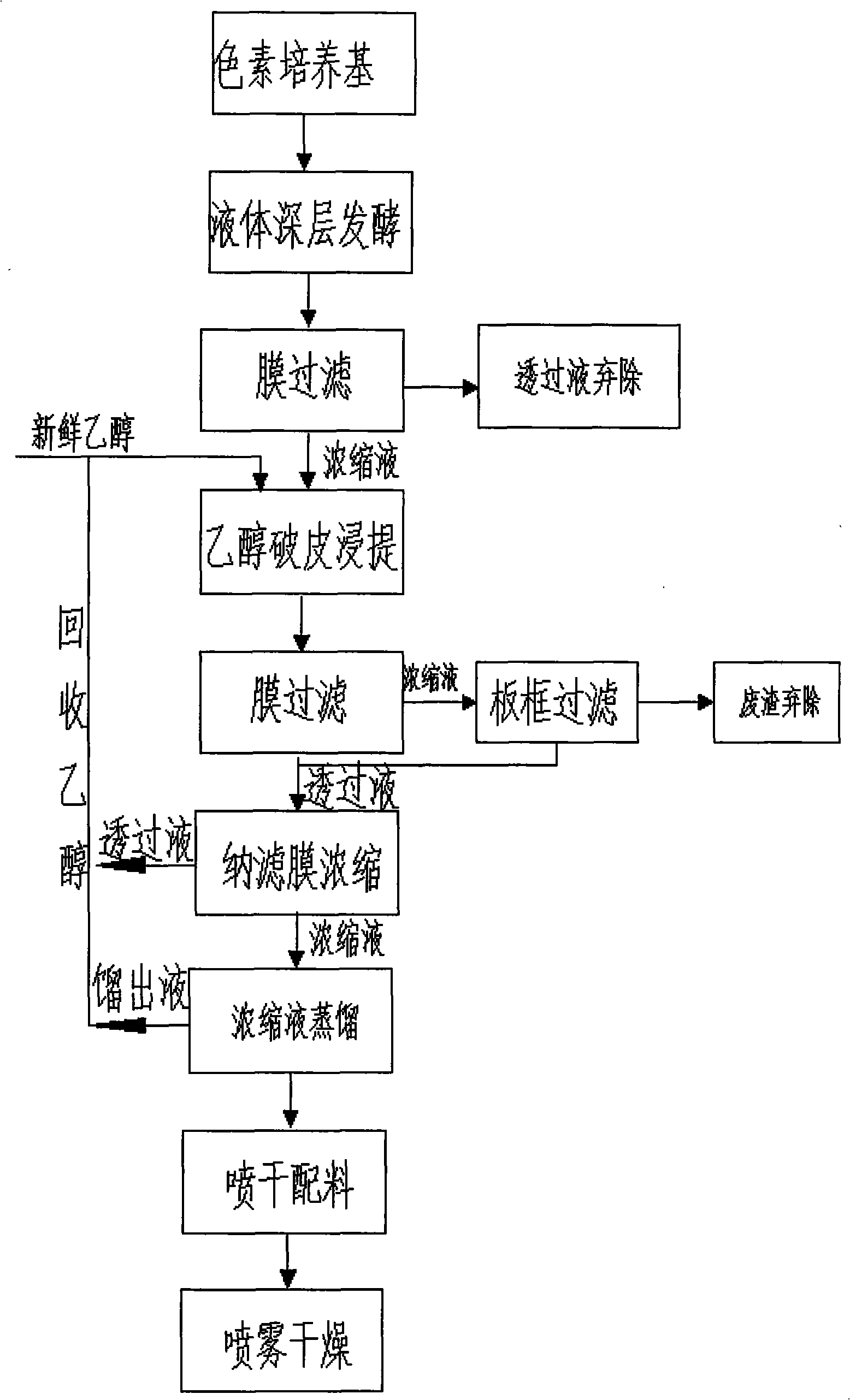

Technological process for producing red pigment by integrated membrane system

InactiveCN101348802ASignificant progressProminentlyMicroorganism based processesNatural dyesFiltration membraneSolvent

The invention provides a technological method for producing monascus red pigment by adoption of the whole membrane technology. The method comprises the following steps: a monascus strain is inoculated into the prior fermentation medium for liquid submerged fermentation; an ultrafiltration membrane or a micro-filtration membrane is used for filtering a fermentation broth most of which is removed, and then ethanol or hot water or another solvent is added into concentrated solution for leaching; an ultrafiltration membrane or a micro-filtration membrane is used for filtering a leaching liquor, and clarifying solution is obtained; a nano-filtration membrane is used for concentrating and removing partial water and ethanol or water; as for alcohol extraction of the monascus red pigment, concentrated feed is distilled and a small amount of ethanol is removed, and then finished products are obtained after mixture and spray drying of the concentrated feed; and as for water extraction of the monascus red pigment, the finished products are obtained after mixture and spray drying of the concentrated feed. The method selects the ultrafiltraiton membranes or the micro-filtration membranes with different filtration precisions to process the fermentation broth and the leaching liquor and uses the nano-filtration membrane to concentrate the clarifying solution instead of using plates and frames for filtration, dose not require adjusting the isoelectric point, eliminates the influence of chemical medicines, improves the product yield and the quality and the color value of the finished products, and has low energy consumption, low cost, high benefit and high application value.

Owner:广州中科建禹环保有限公司

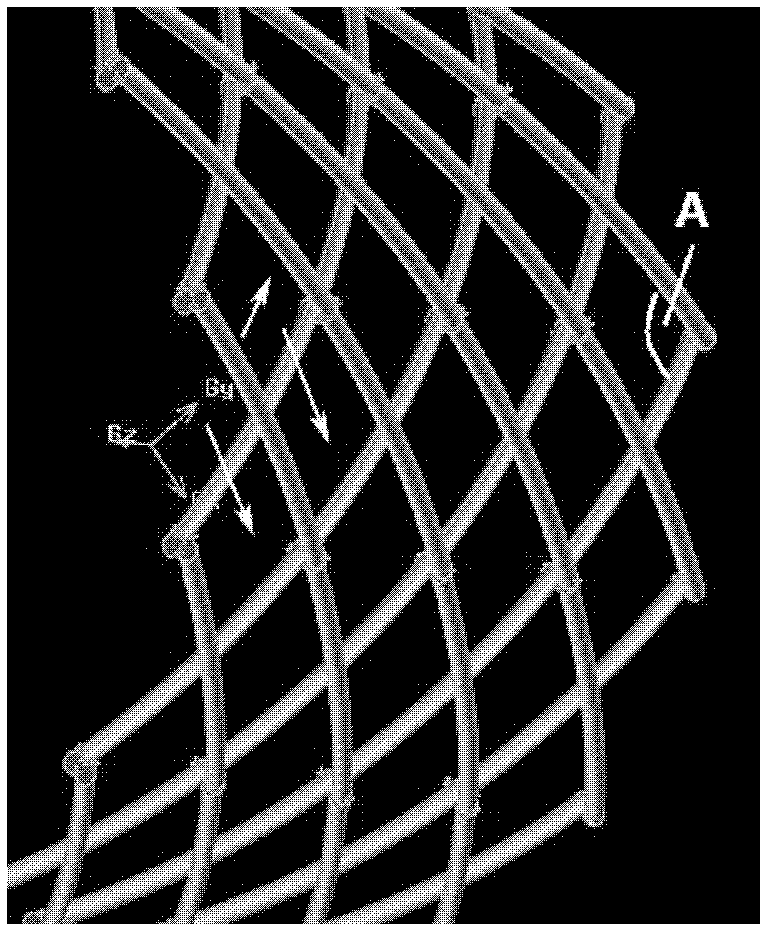

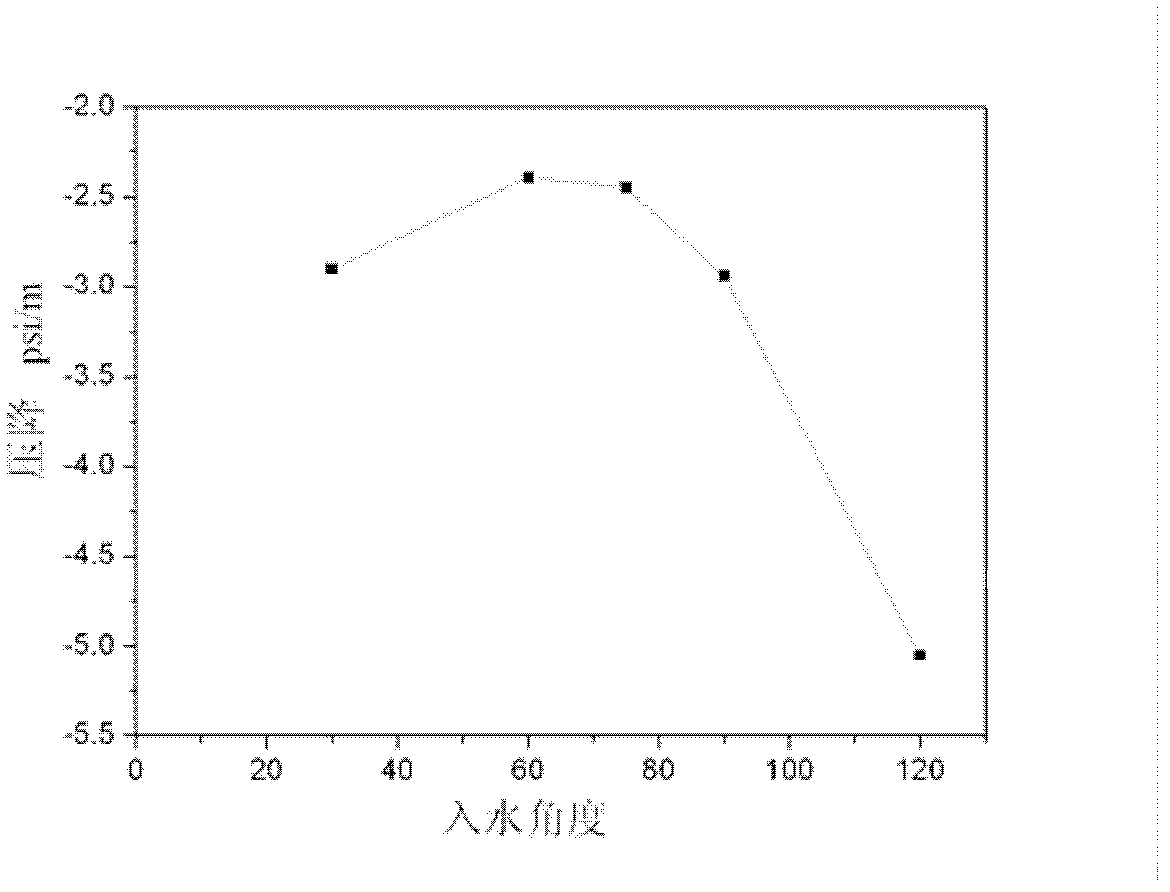

Low-pressure-drop spiral coil type membrane element

InactiveCN102580557ALow flow resistanceSmall pressure lossSemi-permeable membranesFlow resistivityEngineering

The invention relates to a membrane element design method capable of reducing running presser drop of a single spiral coil type membrane and system and a low-pressure-drop membrane element optimized and designed with the method. In a process coiling the membrane element, coiling page number, length of each page, width of a water inlet runner and a water inlet angle of the membrane element are comprehensively designed according to total membrane area. In a running process using the single membrane elements with the same size and the same membrane area, water inlet resistance is smallest, flow resistance of inlet water in the membrane element is smallest, pressure loss is smallest, and accordingly energy consumption of the whole membrane casing and the system is reduced. Compared with the prior art, pressure drop of the low-pressure-drop membrane element is reduced by 50% to 55%, and energy consumption of the system is greatly reduced.

Owner:SHANDONG JOZZON MEMBRANE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com