Membrane separation combination zero-emission system for deeply treating desulfurization wastewater with whole membrane method

A technology for desulfurization wastewater and advanced treatment, which is applied in gaseous effluent wastewater treatment, multi-stage water treatment, water/sewage treatment, etc. It can solve the problems of high frequency of cleaning and downtime for maintenance, no practical value, and easy crystallization. Achieve the effect of realizing resource utilization, improving wastewater treatment efficiency, and ensuring stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

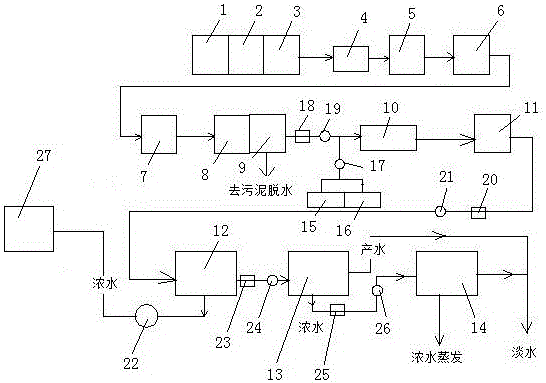

[0017] like figure 1 The full-membrane method shown is a membrane separation combined zero-emission system for the advanced treatment of desulfurization wastewater, including a pre-treatment water tank, a water quality adjustment water tank 5, a first reaction tank 6, a sedimentation water tank 7, and a second reaction tank connected in sequence through pipelines. Tank 8, concentrated water tank 9, TMF component 10, product water tank 11 and NF component 12, the product water outlet of the NF component 12 is connected to the SWRO component 13 through the pipeline, and the concentrated water outlet of the SWRO component 13 is connected to the DTRO component through the pipeline The 14 pieces in the group are connected and communicated, and the concentrated water outlet of the NF assembly 12 is connected and communicated with the waste water collection tank 27 through a pipeline. The pipeline between the concentrated water tank 9 and the TMF assembly 10 is provided with a first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com