Wet static dedusting device

A technology of wet electrostatic precipitator and spray device, applied in electrostatic effect separation, external electrostatic separator, solid separation, etc., can solve the problems of unsatisfactory dust removal and purification effect, influence of dust removal effect, failure of wet electrostatic precipitator, etc., to achieve dust removal. The effect of good purification effect, ensuring stability, improving service life and use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

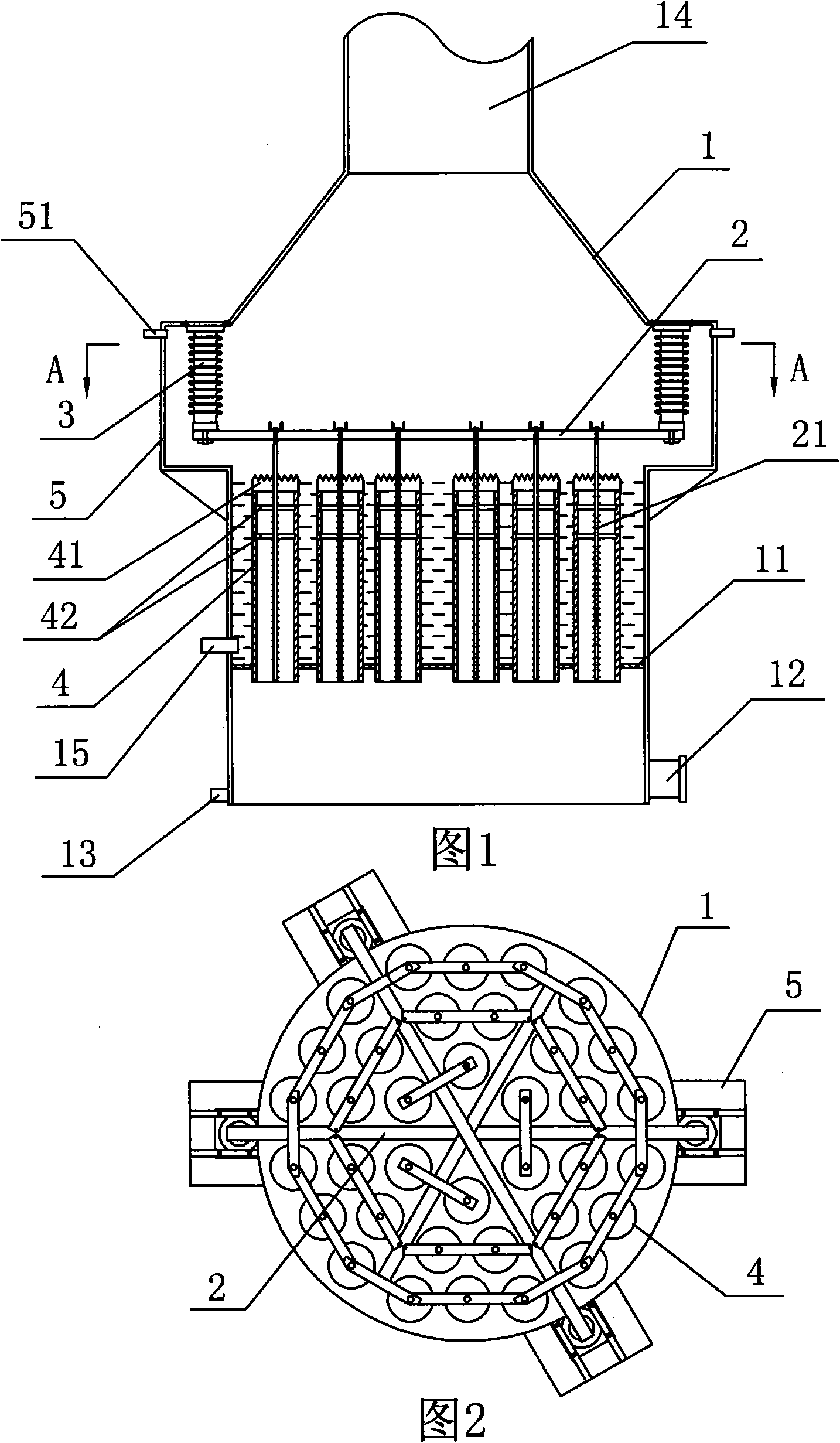

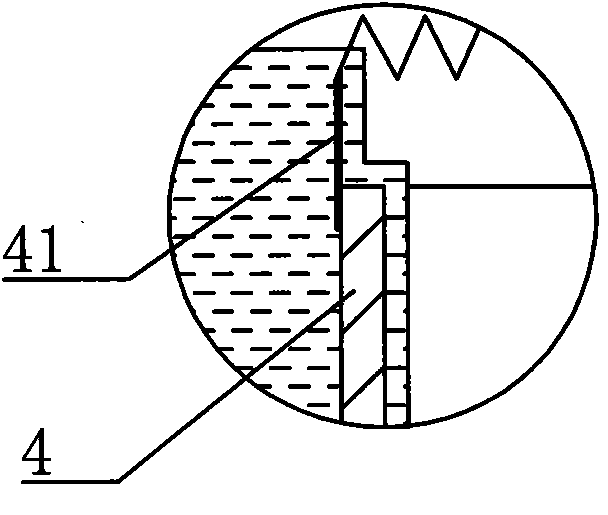

[0023] As shown in the figure, a wet electrostatic precipitator includes a tower body 1, an electrode bracket 2 and an insulating support 3, the electrode bracket 2 is installed in the tower body 1, and the electrode bracket 2 is electrically connected to an external high-voltage power supply (not shown in the figure) , the electrode bracket 2 is fixedly provided with a plurality of suspended electrode rods 21, the electrode rods 21 are covered with a hollow condenser pipe 4, and the inner wall of the condenser pipe 4 is provided with two annular grooves 42 with a certain distance, the tower body 1. The inner seal is fixedly provided with a partition plate 11 that divides the tower body 1 into upper and lower parts. The condenser pipe 4 is fixedly arranged on the partition plate 11 and its lower end passes through the partition plate 11. The upper end of the condenser pipe 4 is fixedly sleeved with A zigzag water distribution ring 41, the tower body 1 is provided with a water i...

Embodiment 2

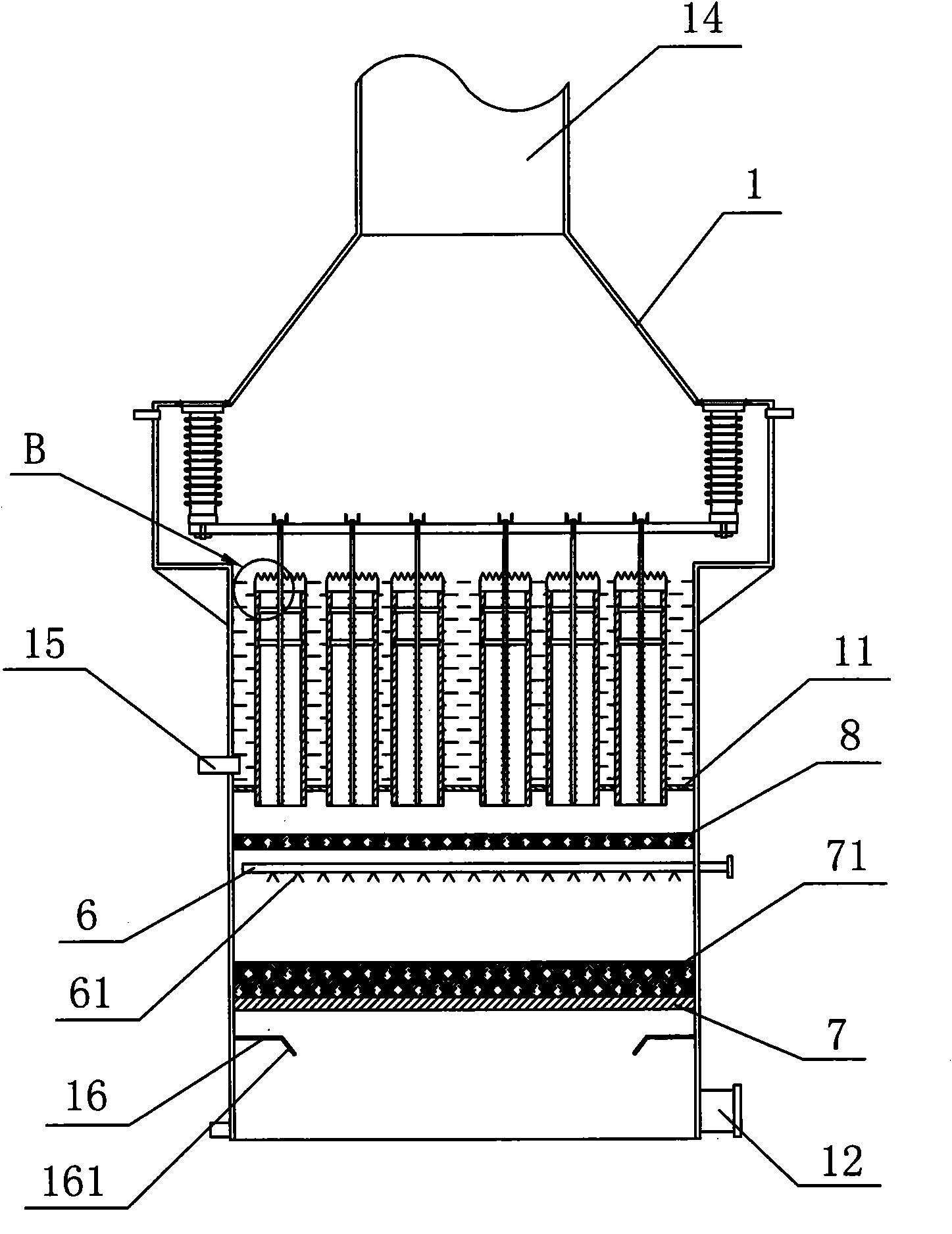

[0025] As shown in the figure, the other structures are the same as those in Embodiment 1, the difference is that a spraying device is arranged in the tower body 1, and the spraying device is arranged under the partition plate 11, and the spraying device includes fixedly arranged in the tower body 1 The spray pipe 6 and the filter screen support 7, the filter screen support 7 is provided with a filter screen 71, the spray pipe 6 is arranged on the top of the filter screen 71, and the spray pipe 6 is provided with a plurality of downward spraying nozzles 61, An anti-splash water layer 8 is arranged between the partition plate 11 and the spray pipe 6, the exhaust gas inlet 12 and the sewage outlet 13 are arranged below the filter screen 71, and the ring-shaped guide ring 16 is fixedly arranged in the tower body 1 to guide the flow. The ring 16 is arranged above the exhaust gas inlet 12 , and the inner ring of the guide ring 16 is integrally provided with a sloping plate 161 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com