Flocculation washing machine

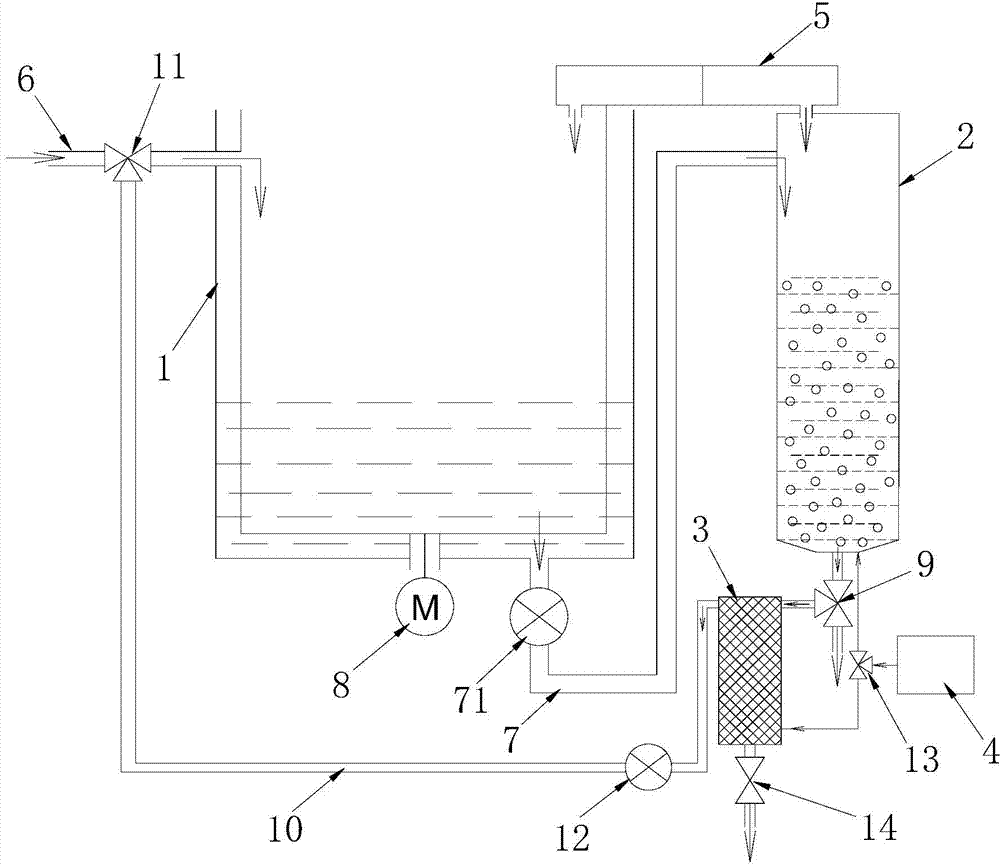

A flocculation washing machine and washing machine technology, applied in the field of washing machines, can solve the problems of unusable and unrecyclable washing water, and achieve the effects of rapid and sufficient mixing, complete drainage without residue, and no influence on washing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

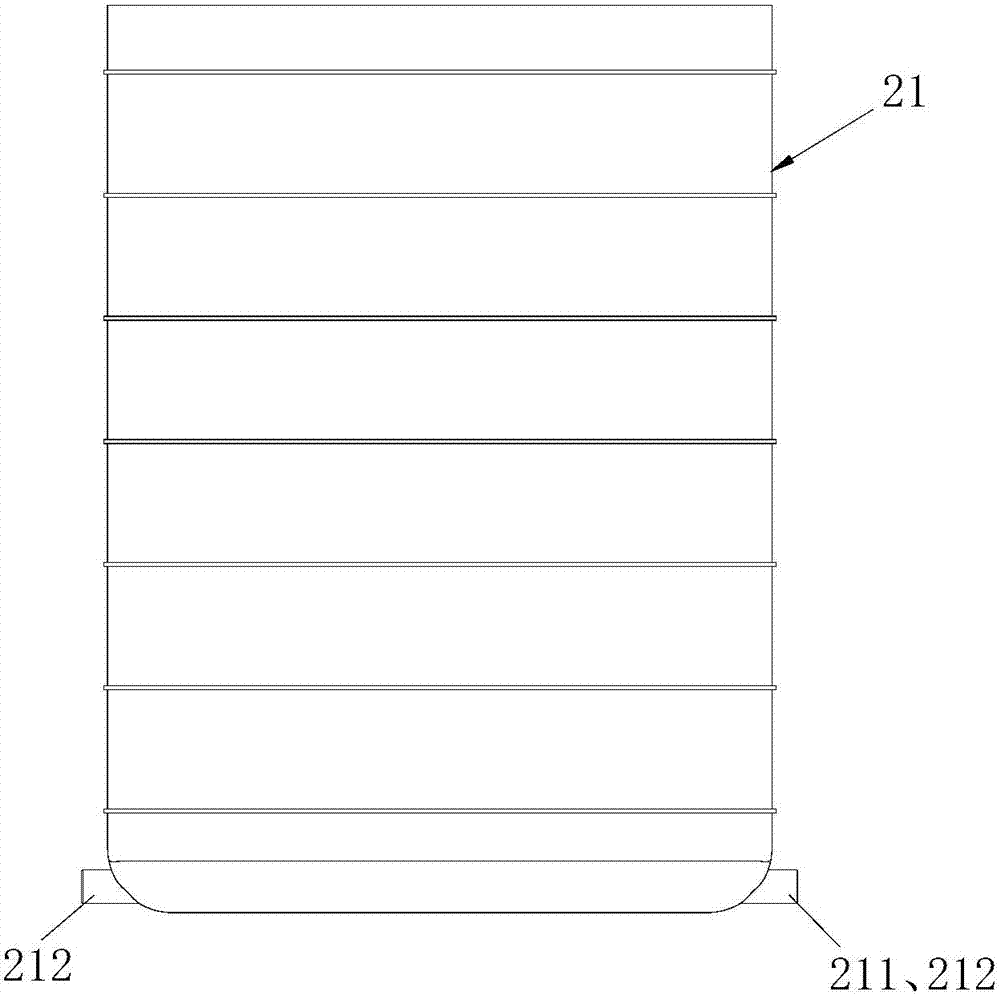

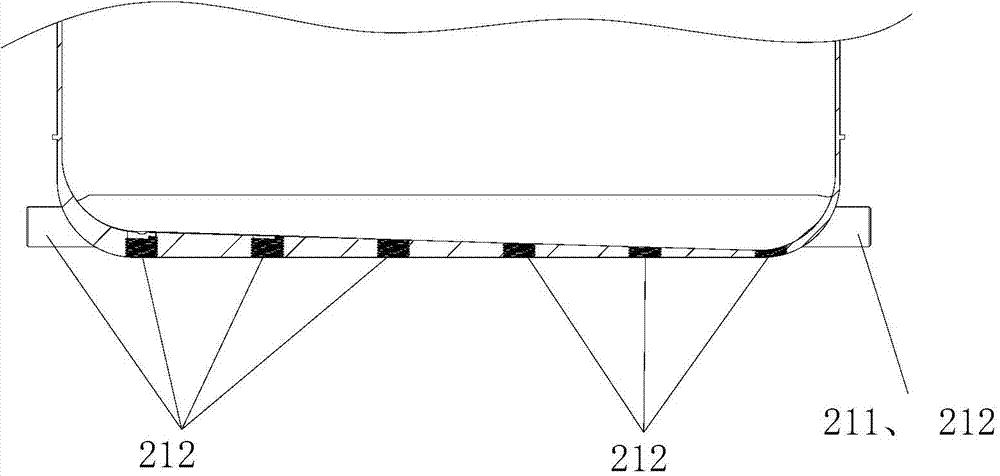

[0050] Such as Figure 2 to Figure 4 As shown, the flocculation container 21 is a rectangular box, the bottom of which is an inclined plane and is provided with 6 flocculation unit air inlets 212 (refer to image 3 ). The left and right sides of the box are narrow sides, and the inner surface of the bottom of the box is lowered from one narrow side to the other narrow side. There are two flocculation unit air inlets 212 respectively on the left and right sides, which are located on the lower side of the inclined surface. A flocculation unit air inlet 212 can also be used as the flocculation drain 211 of drainage after the flocculation reaction finishes (referring to Figure 4 ). Due to the inclined surface at the bottom of the box, the flocculation outlet 211 is located at the lowest point of the bottom of the box, ensuring complete drainage without residue. The arc transition between the bottom of the box and the surrounding sides can ensure that the air bubbles evenly blo...

Embodiment 2

[0052] Such as Figure 5 and Figure 6 As shown, the filter module 32 in the filter container 31 includes a filter element 321 and a filter screen (not shown in the figure) arranged on the outer surface of the filter element. The filter unit air inlet 314, water inlet 311 and sewage outlet 313 are all connected to the chamber 33 outside the filter module inside the filter container. The water inlet 311 in this embodiment is the filter unit air inlet 314.

[0053] The water after the flocculation treatment in the flocculation container 21 of the present invention directly enters the chamber 33 outside the filter module inside the filter container 31 through the water inlet 311, and the filter screen on the surface of the filter element 321 will trap tiny flocs outside the filter element, and the pure The water flows into the filter element inside, and is discharged to the outer tub 1 through the clear water outlet 312 to continue to use.

Embodiment 3

[0055] Such as Figure 7 and Figure 8 As shown, this embodiment is further improved on the basis of Embodiment 2. The filter element 321 is an ellipse, and the two ends of the major axis are respectively rotatably connected with the filter container 31, and one end is a swivel joint 3211, which is connected to the clear water drainage Port 312 is connected. The other end can use but is not limited to a waterproof bearing 3212, which ensures sealing and reduces the coefficient of friction to ensure that the filter element 321 rotates without resistance. The ellipsoidal structure of the filter element 321 ensures that there is no dead corner and no dirt residue on the surface of the filter element, which is more conducive to the self-cleaning of the filter screen. And in the process of rotating the filter screen, it is ensured that the force is even, which is more conducive to the rotation of the filter element.

[0056] In this embodiment, the surface of the filter element ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com