Washing machine with flocculation and filtration module and control method

A technology for flocculation filtration and washing machine, which is applied in the field of washing machines, can solve the problems of inability to recycle laundry water, cannot use it, and high usage costs, and achieves the effects of simple structure, reduced energy consumption and production cost, and reduced pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

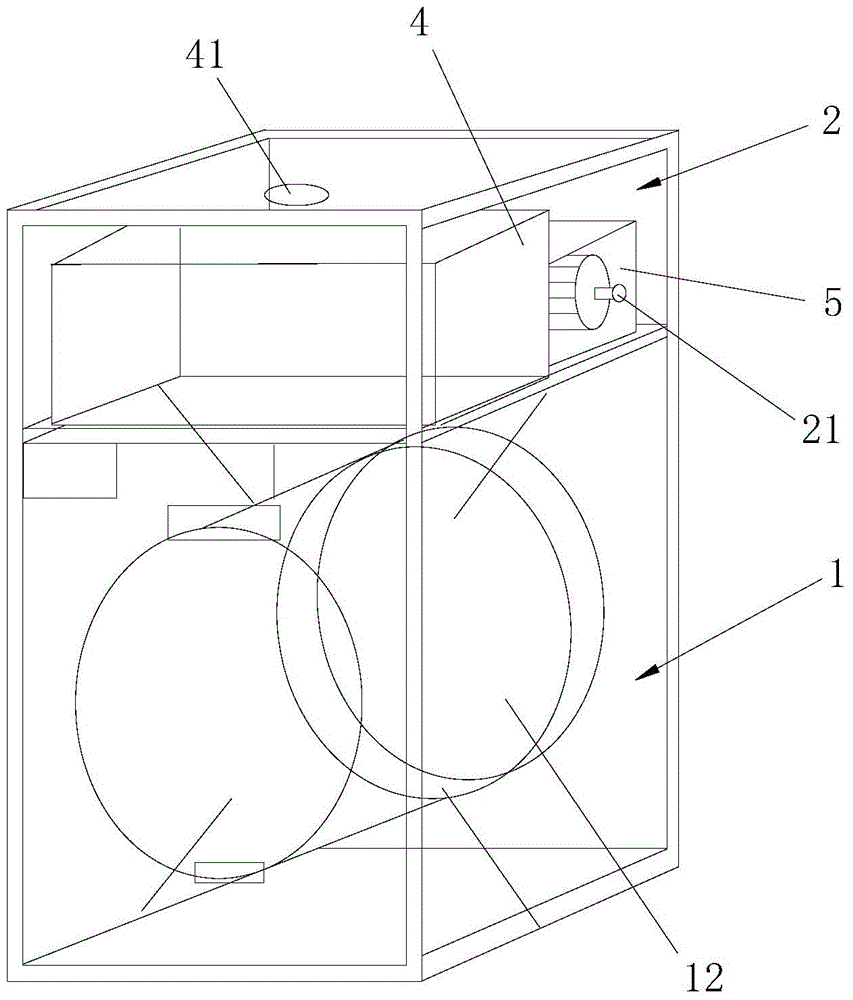

Embodiment 1

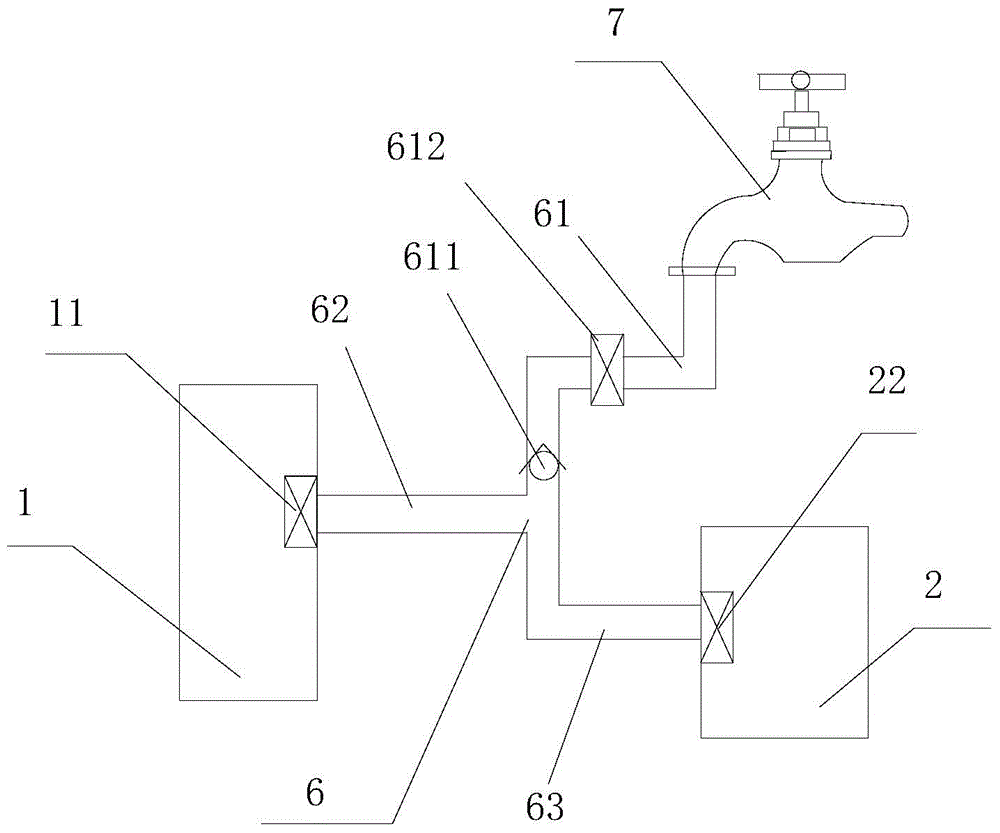

[0042] Such as figure 2 As shown, the three-way pipeline 6 described in this embodiment includes a first sub-pipeline 61, a second sub-pipeline 62 and a third sub-pipeline 63, the first sub-pipeline 61 is provided with a one-way valve 611, It communicates with the external water inlet faucet 7, the second sub-pipe 62 communicates with the water inlet valve 11 of the washing machine body, the third sub-pipe 63 communicates with the treated water outlet 21 of the flocculation filtration module 2, the first sub-pipe 61 and the second sub-pipe The channels 62 are connected to form an external clean water inlet channel, and the second sub-pipeline 62 and the third sub-pipeline 63 are connected to form a water inlet channel for circulating treatment.

[0043] Further, the first sub-pipeline 61 is provided with an external water inlet control valve 612, and the external water inlet control valve 612 is arranged between the one-way valve 611 and the external water inlet faucet 7, and...

Embodiment 2

[0045]This embodiment is an improvement on the basis of Embodiment 1. The flocculation filtration module 2 has a cleaning function. In the three-way pipeline 6, the first sub-pipeline 61 and the third sub-pipeline 63 communicate to form a flocculation filtration Module cleaning waterway; when the rinsing is completed, the water inlet valve 11 of the washing machine body can be closed, and the external water inlet control valve 612 can be opened, and the water inlet is from the first sub-pipeline 61, the third sub-pipeline 63, and the treated water outlet 21 to the flocculation filtration module 2 for cleaning.

Embodiment 3

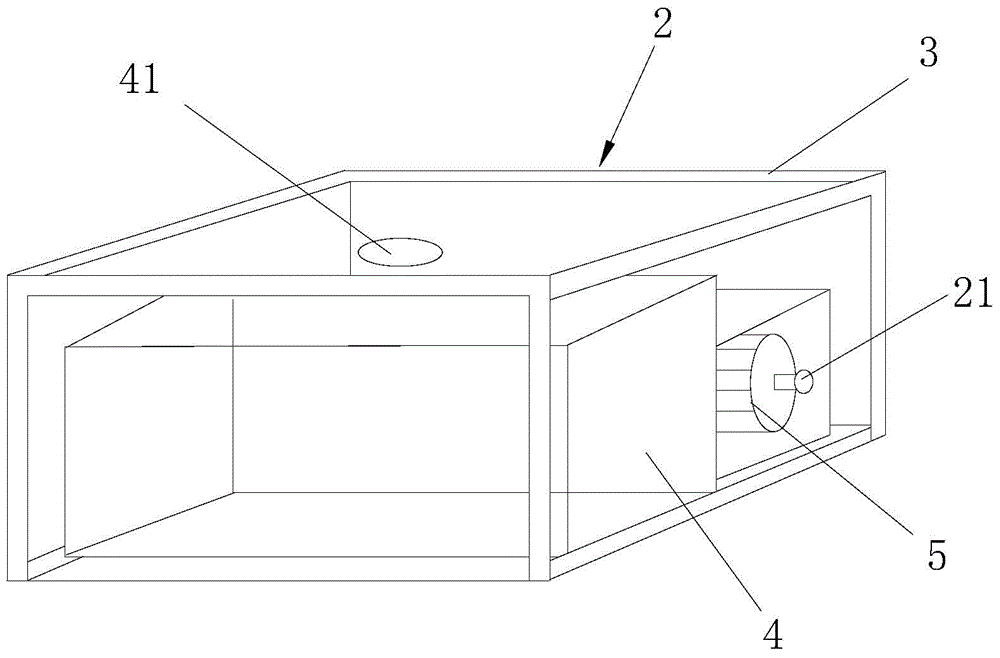

[0047] Such as Figure 4 and Figure 5 As shown, the filter unit 5 of the present invention includes a filter container 51 and a filter barrel 52 located inside the filter container 51. The filter container 51 is provided with a filter water inlet 511, and the filter water inlet 511 communicates with the flocculation unit 4. The filter barrel 52 A filter screen (not shown in the figure) is provided on the surface, and one end of the filter barrel 52 is sealed, and the other end communicates with the treated water outlet 21 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com