Low-pressure-drop spiral coil type membrane element

A low pressure drop and membrane element technology, applied in the field of filters in water purification devices, can solve the problems of increased operating energy consumption and ignoring operating costs, and achieve the effects of high water flow rate, reduced resistance, and reduced system energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

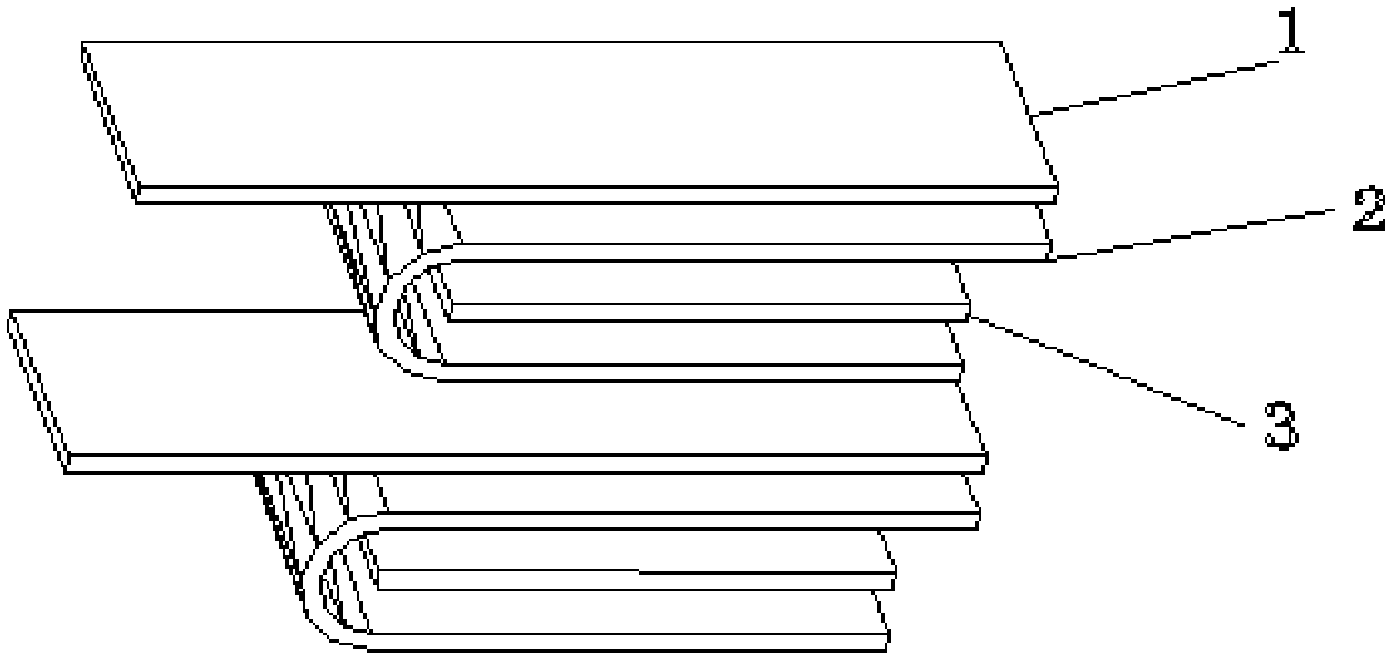

[0019] When designing membrane elements with the same diameter and the same membrane area, ensure that other raw materials and design parameters are consistent, and only increase the number of sheets of rolled diaphragms to reduce the pressure drop of the designed membrane element system by 10%-15%.

[0020] Taking the 8-inch membrane element as an example, the membrane area is 400ft 2 , under the condition that the performance of the diaphragm remains the same, two kinds of membrane elements are designed, and the number of diaphragm sheets is 20 and 30 respectively. The initial performance test of the two membrane elements and the comparison of the average system pressure drop for 5 months of long-term operation on the two systems (a single system is 4 membrane elements connected in series). Table 1 shows the test results of the two systems. The inlet water pressure of the membrane element system is 225psi, and the inlet water salt concentration is 2000ppm.

[0021] Table 1...

Embodiment 2

[0024] When designing membrane elements with the same diameter and the same membrane area, ensure that other raw materials and design parameters are consistent, and only increase the width of the water inlet flow channel (that is, increase the thickness of the water inlet flow channel cloth), so that the flow resistance of the water inlet inside the membrane element is reduced, so that After calculation, the pressure drop of the membrane element system is reduced by 20%-25%.

[0025] Taking the 8-inch membrane element as an example, the membrane area is 400ft 2 , under the condition that the performance of the diaphragm remains the same, two kinds of membrane elements are designed, and the widths of the water inlet channels are 28mil and 34mil respectively. The initial performance test of the two membrane elements and the comparison of the average system pressure drop for 5 months of long-term operation on the two systems (a single system is 4 membrane elements connected in se...

Embodiment 3

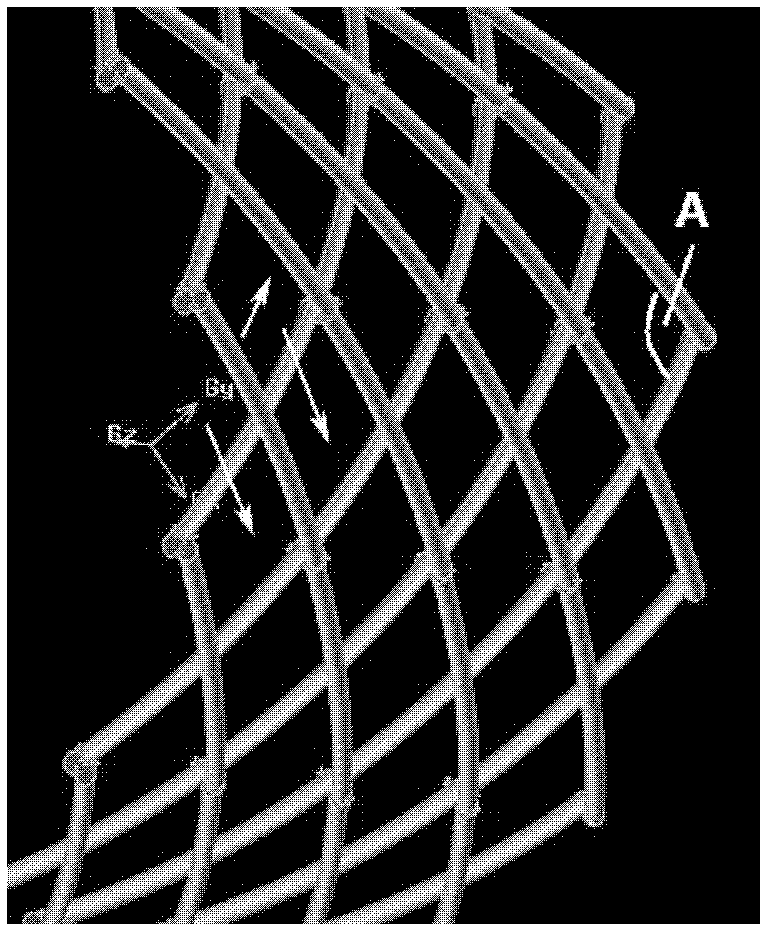

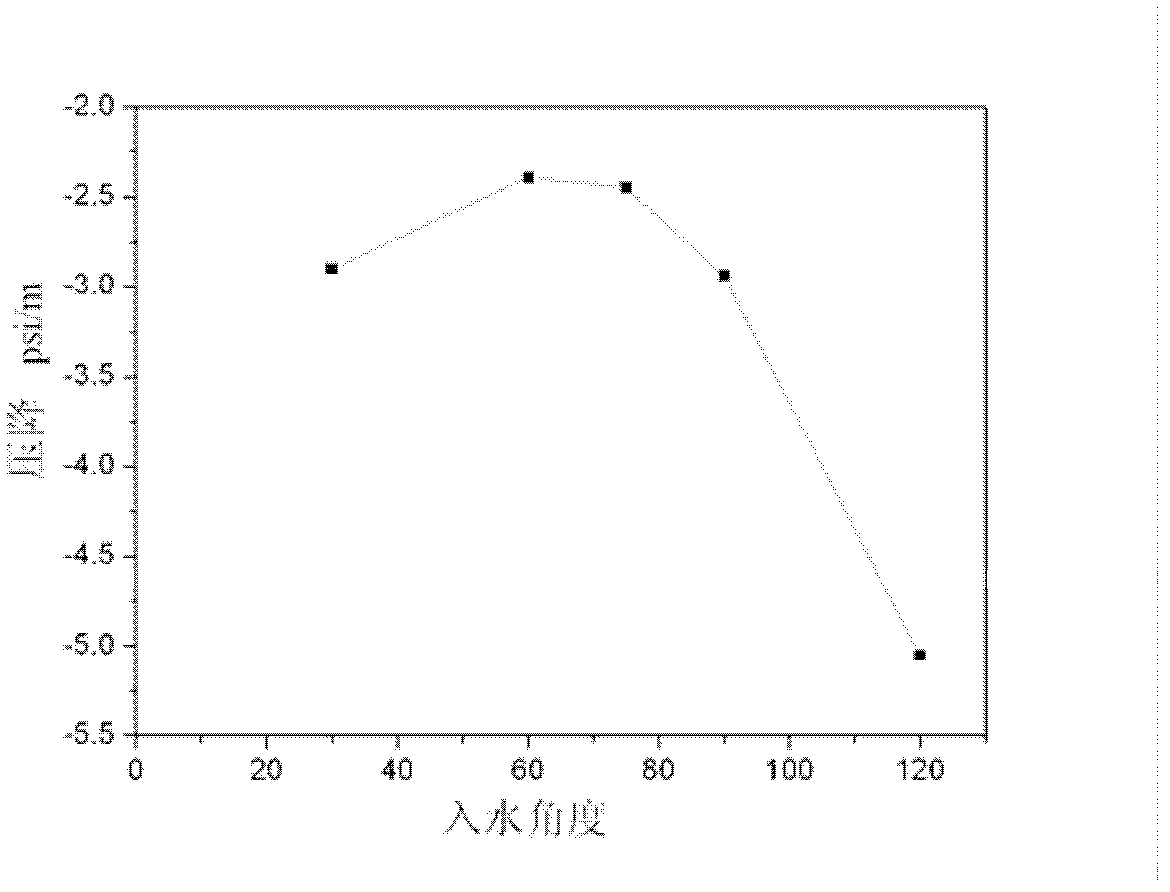

[0029] When designing membrane elements with the same diameter and the same membrane area, ensure that other raw materials and design parameters are consistent, and correspond to the actual operation of membrane elements through computer theoretical simulation. The water flow rate can reduce the resistance of the water running inside the membrane element, so that the calculated pressure drop of the membrane element system can be reduced by 25%-30%.

[0030] Theoretical basis: Carry out specific assumptions based on the structure of the 8-inch membrane element, and perform simulation calculations. In this simulation calculation, the channel width is selected as 28mil, the water inlet angle is simulated from 30 degrees to 120 degrees, and the diagonal length of the inlet channel grid is From 1.553mm-5.196mm (different diagonal lengths and longitude and latitude distances are different). After theoretical simulation, the relationship between water entry angle and pressure drop is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com