Tubular micro-filtration membrane production equipment

A technology of tubular microfiltration membranes and production equipment, which is applied in membrane technology, semipermeable membrane separation, chemical instruments and methods, etc. It can solve problems such as direct waste water passing, membrane wear, perforation, peeling, and affecting the quality of produced water. Stable performance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

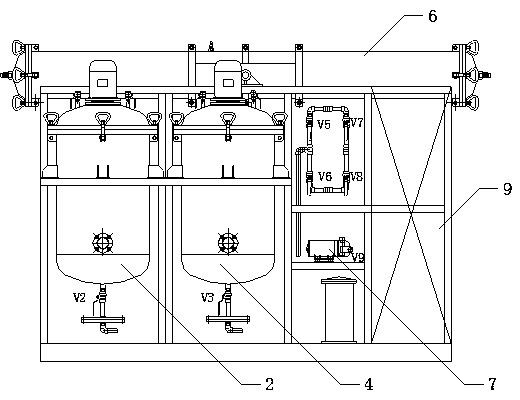

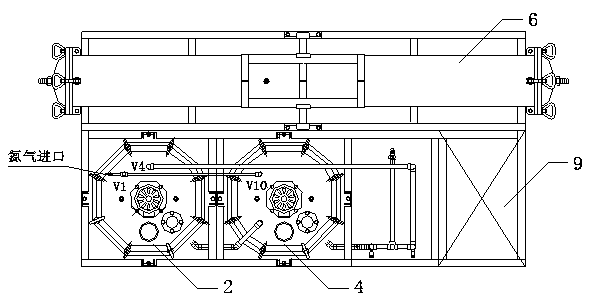

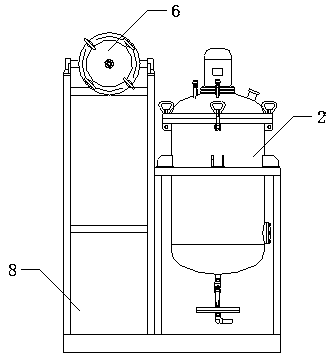

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0018] refer to Figure 1 to Figure 4 As shown, the present invention discloses a tubular microfiltration membrane production equipment, comprising a frame 8 and an instrument control cabinet 9 installed on the frame 8, an ingredient storage tank 2 and a film storage tank 4 connected to the ingredient storage tank 2, A pre-filter 3 is connected between the ingredient storage tank 2 and the film storage tank 4, and a second valve V2 is connected between the ingredient storage tank 2 and the pre-filter 3, and the first valve V1 and the ingredient storage tank 2 are also connected. The connected nitrogen cylinder 1, nitrogen cylinder 1 is connected to the film storage tank 4 through the tenth valve V10 at the same time, a sintering tube device 6 is arranged behind the film storage tank 4, and a post filter is connected between the film storage tank 4 and the sin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com