Technological process for producing red pigment by integrated membrane system

A technology of monascus red pigment and process method, which is applied in the field of producing monascus red pigment by the whole film method, can solve the problems of low color price, high cost, and high energy consumption of monascus red pigment, and achieve high quality, low cost, The effect of low production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

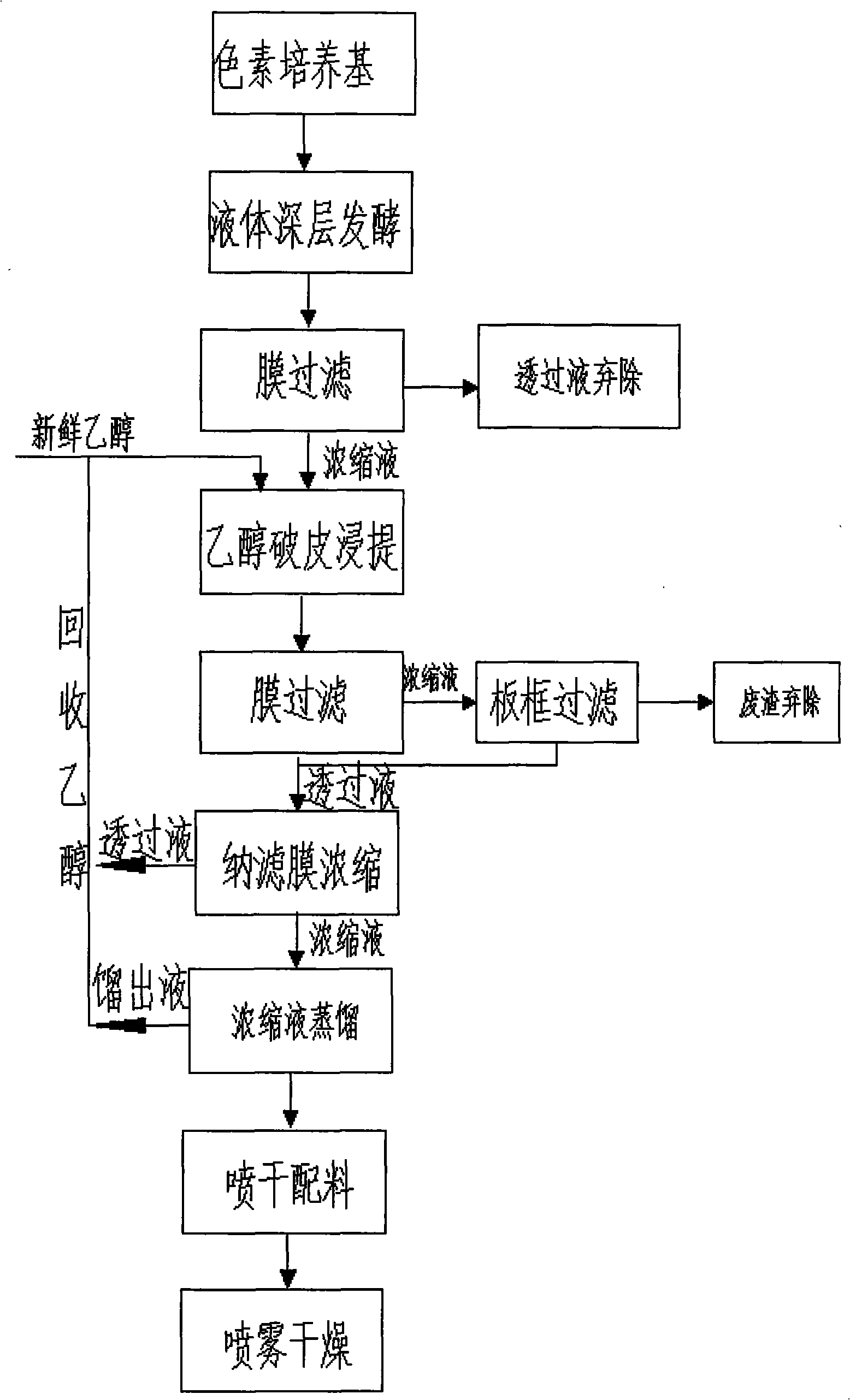

Embodiment 1

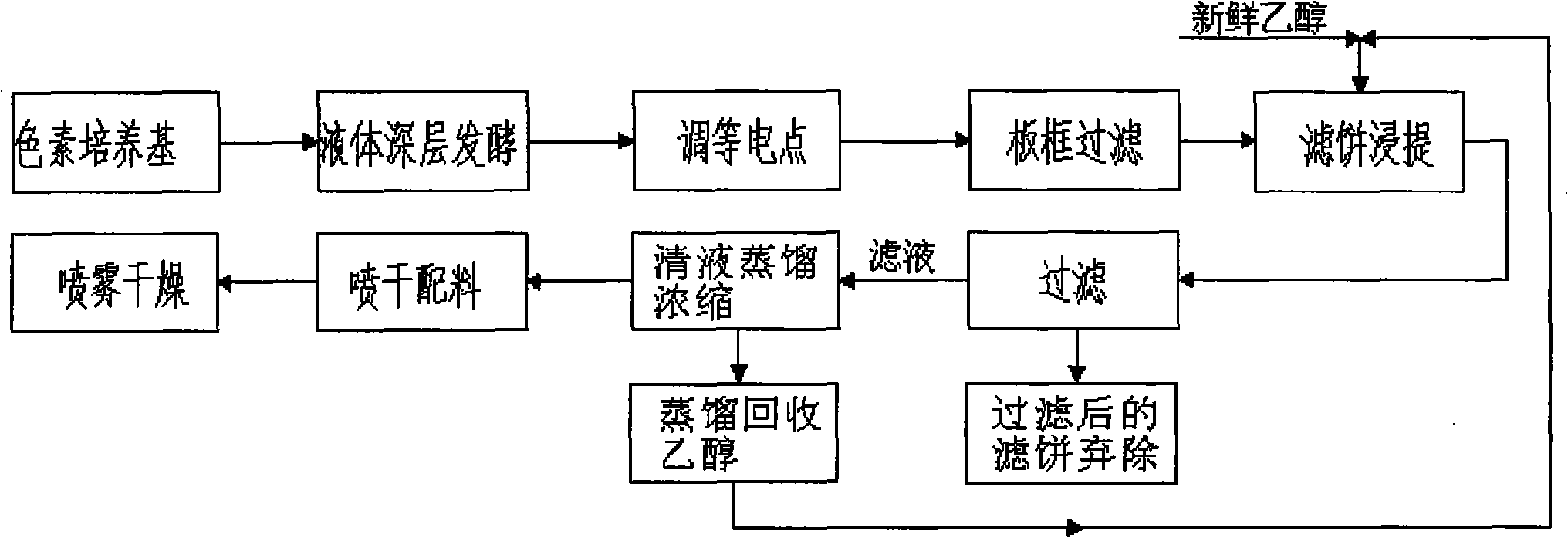

[0031] image 3 Shown is the embodiment of the present invention—a production process flow diagram of alcohol-extracted monascus red pigment. Such as image 3 As shown, the traditional fermentation medium was used to inoculate Monascus strains for liquid submerged fermentation; the fermentation liquid was filtered with an inorganic ceramic microfiltration membrane with a filtration accuracy of 0.2 microns; after most of the fermented mother liquid was removed, a certain amount of 70% to 80% concentration of ethanol to break the skin for a period of time; then filter through an inorganic ceramic ultrafiltration membrane with a filtration accuracy of 0.05 microns to obtain the permeated clear liquid, and a small amount of concentrated liquid, and then use conventional filtration to recover the filtrate , the filter residue is discarded, the clear liquid of membrane filtration and the clear liquid of conventional filtration are merged as product clear liquid; the filtrate is con...

Embodiment 2

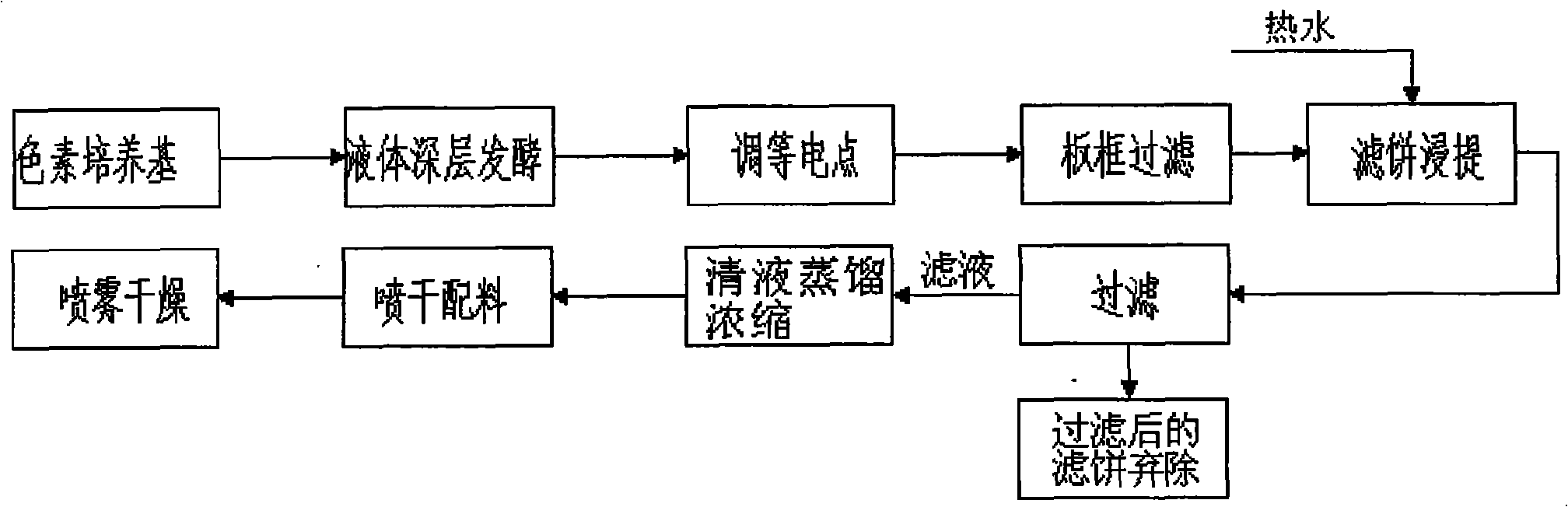

[0033] Figure 4 Shown is the production process flow chart of dihydric extraction of monascus red pigment according to the embodiment of the present invention. Such as Figure 4 As shown, the traditional fermentation medium was used to inoculate Monascus strains for liquid submerged fermentation; the fermentation liquid was filtered with an inorganic ceramic microfiltration membrane with a filtration accuracy of 0.2 microns; after most of the fermented mother liquid was removed, a certain amount of A large amount of hot water at 80-100°C was extracted for a period of time; then filtered with an inorganic ceramic ultrafiltration membrane with a filtration accuracy of 0.05 microns to obtain the clear liquid, and a small amount of concentrated liquid was recovered by conventional filtration, and the filter residue was discarded. In addition, the clear liquid of membrane filtration and the clear liquid of conventional filtration are combined as the product clear liquid; the filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com