Membrane servo valve driven by piezoelectric ceramics

A piezoelectric ceramic drive and piezoelectric ceramic technology, which is applied in the field of servo valves to achieve the effects of reducing pressure difference, low manufacturing cost and improving control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

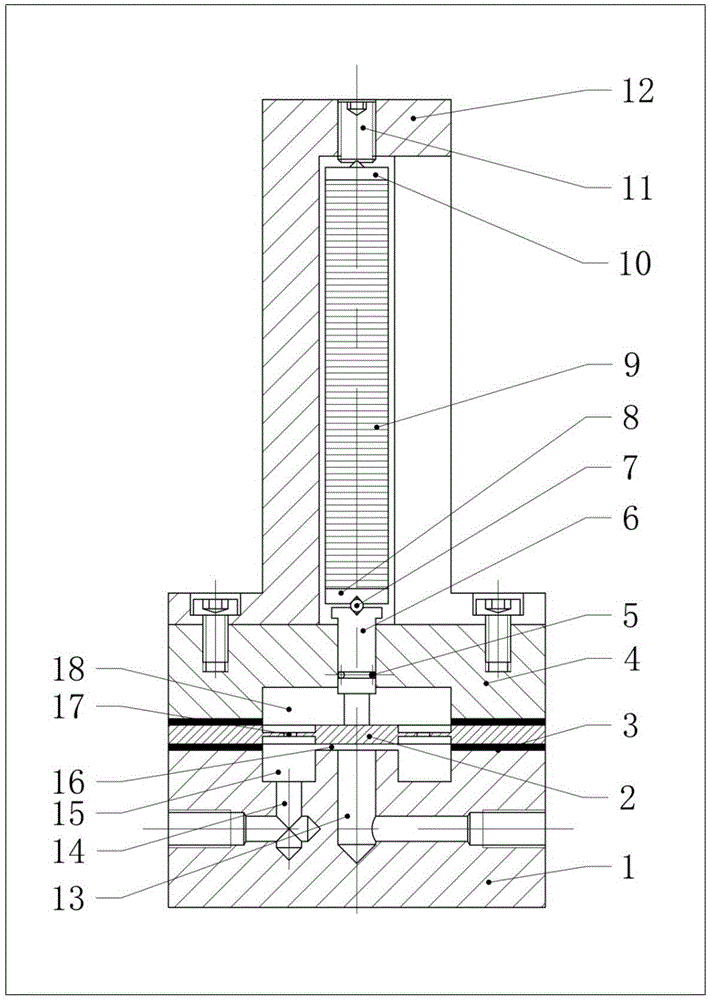

[0034] A piezoceramic driven thin-film servo valve, such as figure 1 As shown, it includes a housing composed of a lower valve body 1, an upper valve body 4 and a piezoelectric ceramic base 12. The central hole 13 of the lower valve body 1 is the hydraulic oil inlet, and the annular throttling oil of the lower valve body 1 Chamber 15 is connected to hydraulic oil outlet 14 . There is a circular pressure balance oil chamber 18 inside the upper valve body 4 . Between the upper valve body 4 and the lower valve body 1 is an elastic metal film 2 and adjusting gaskets 3 on both sides. The film 2 is designed as an island-shaped flexible hinge structure with a thick middle throttling part and a thin elastically deformed annular area around it. Four communication holes 17 connecting the throttling oil chamber 15 and the pressure balance oil chamber 18 are evenly distributed in the flexible hinge area. The central island of the membrane 2 and the annular boss at the center of the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com