Working roll bending device of plate band rolling mill

A technology of work roll bending and work roll, which is applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., which can solve the problem of increased oil supply time of the hydraulic system, reduced service life, and unfavorable normal use of stand rolls and other problems, to achieve the effect of reducing compensation amount and compensation time, reducing maintenance frequency and time, and reducing oil supply working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

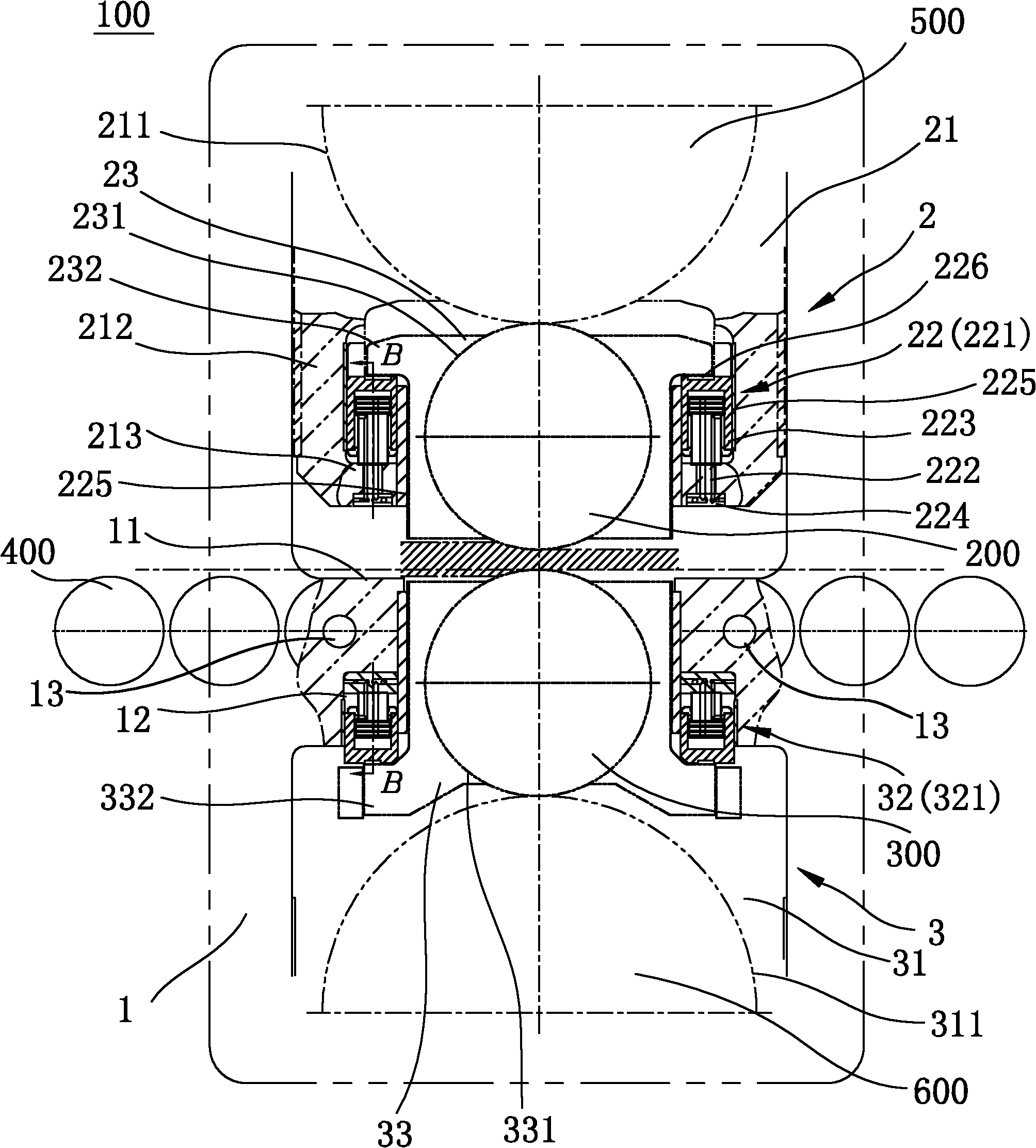

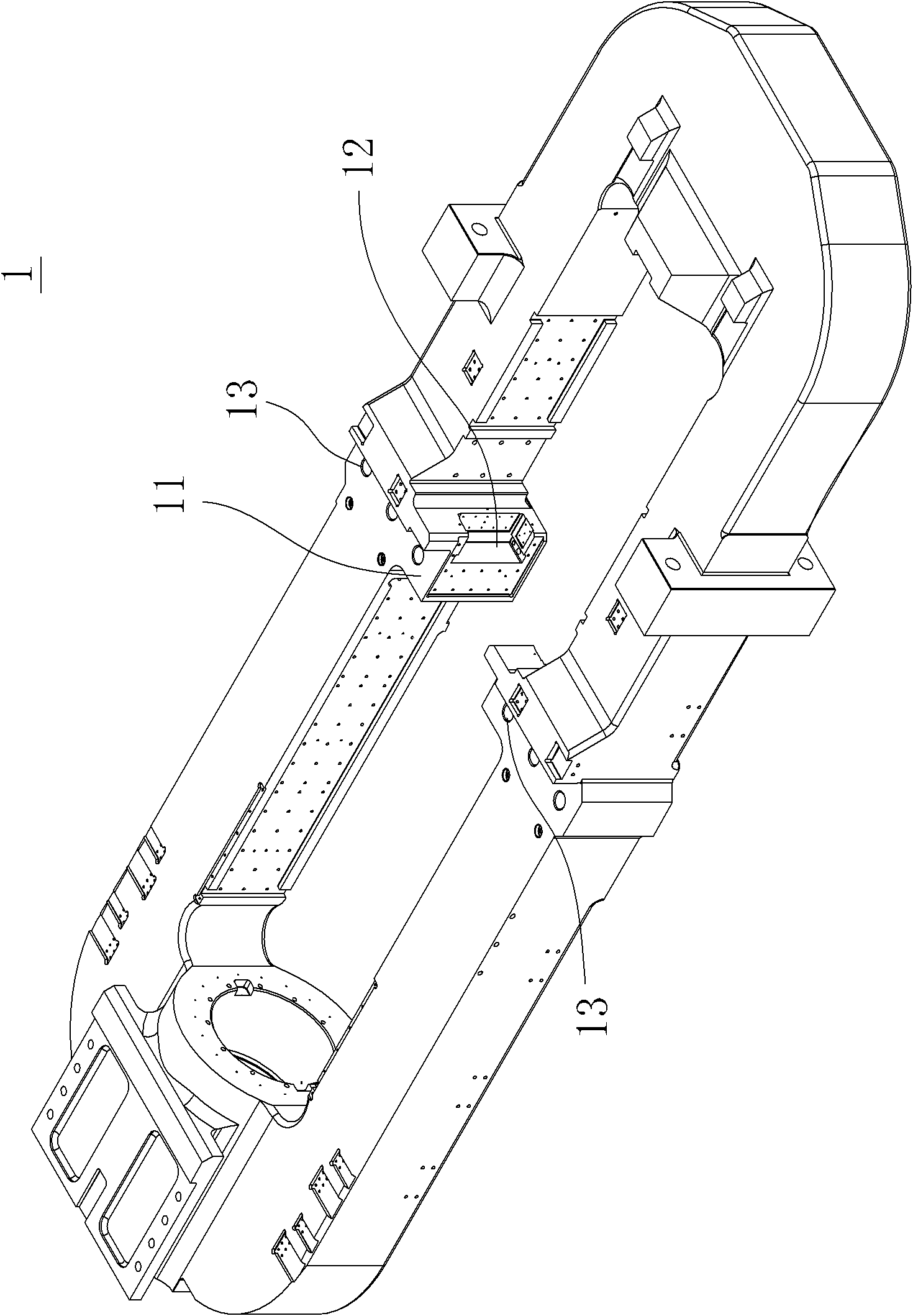

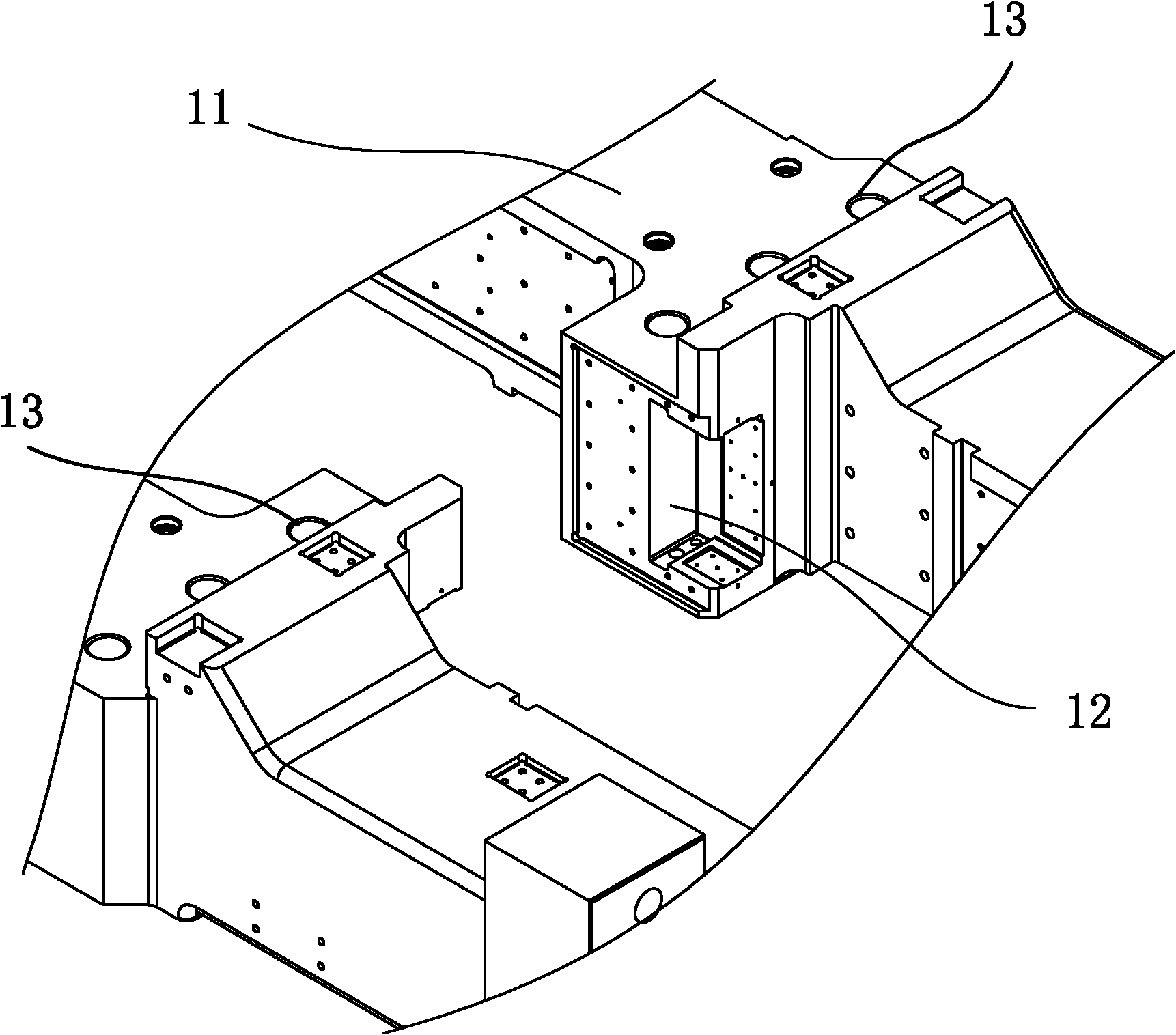

[0067] Please refer to figure 1 and figure 2 ,in figure 1 It is a schematic diagram of the overall structure of the work roll bending device of the strip mill of the present invention, figure 2 It is a schematic diagram of the archway of the work roll bending device of the strip mill of the present invention. As shown in the figure, the roll bending device 100 of the present invention is arranged at both ends of the upper work roll 200 and the lower work roll 300, that is to say, on the upper work roll 200 and the two ends of the lower work roll 300 are respectively equipped with the roll bending device 100 of the present invention, so as to realize the support, balance and roll bending control of the work roll device during ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com