Internal feedback type incremental hydraulic throttling digital valve

An incremental, water-hydraulic technology, applied in the field of hydraulic valves, can solve the problems of demanding medium cleanliness, high manufacturing and maintenance costs, corrosion and leakage, etc., to improve frequency response and closed-loop control accuracy, and strong anti-pollution performance. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

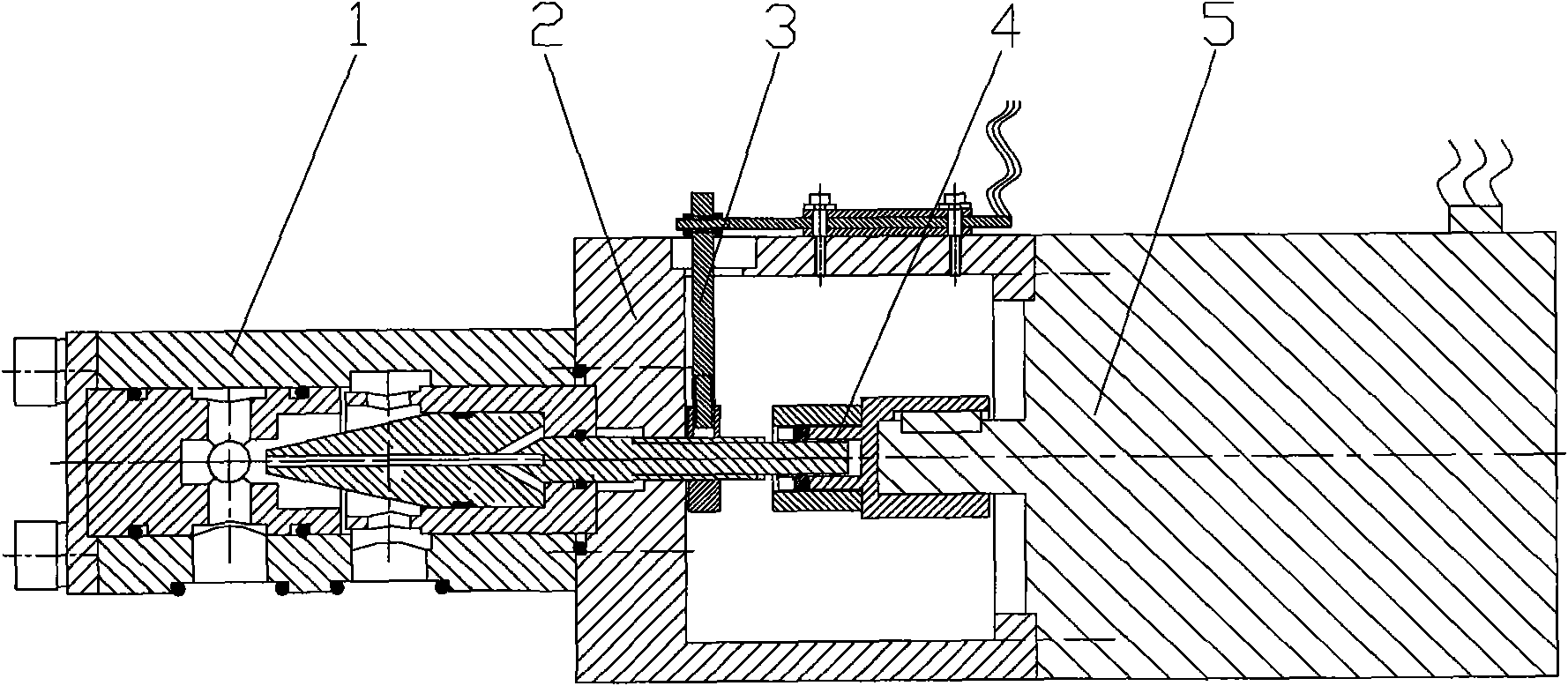

[0026] Such as figure 1 As shown, an internal feedback type incremental water hydraulic throttling digital valve includes a hydraulic valve 1, a fixed frame 2, a displacement sensing mechanism 3, a mechanical transmission mechanism 4 and a stepping motor 5, and the hydraulic valve 1, The displacement sensing mechanism 3 and the stepping motor 5 are installed on the fixed frame 2;

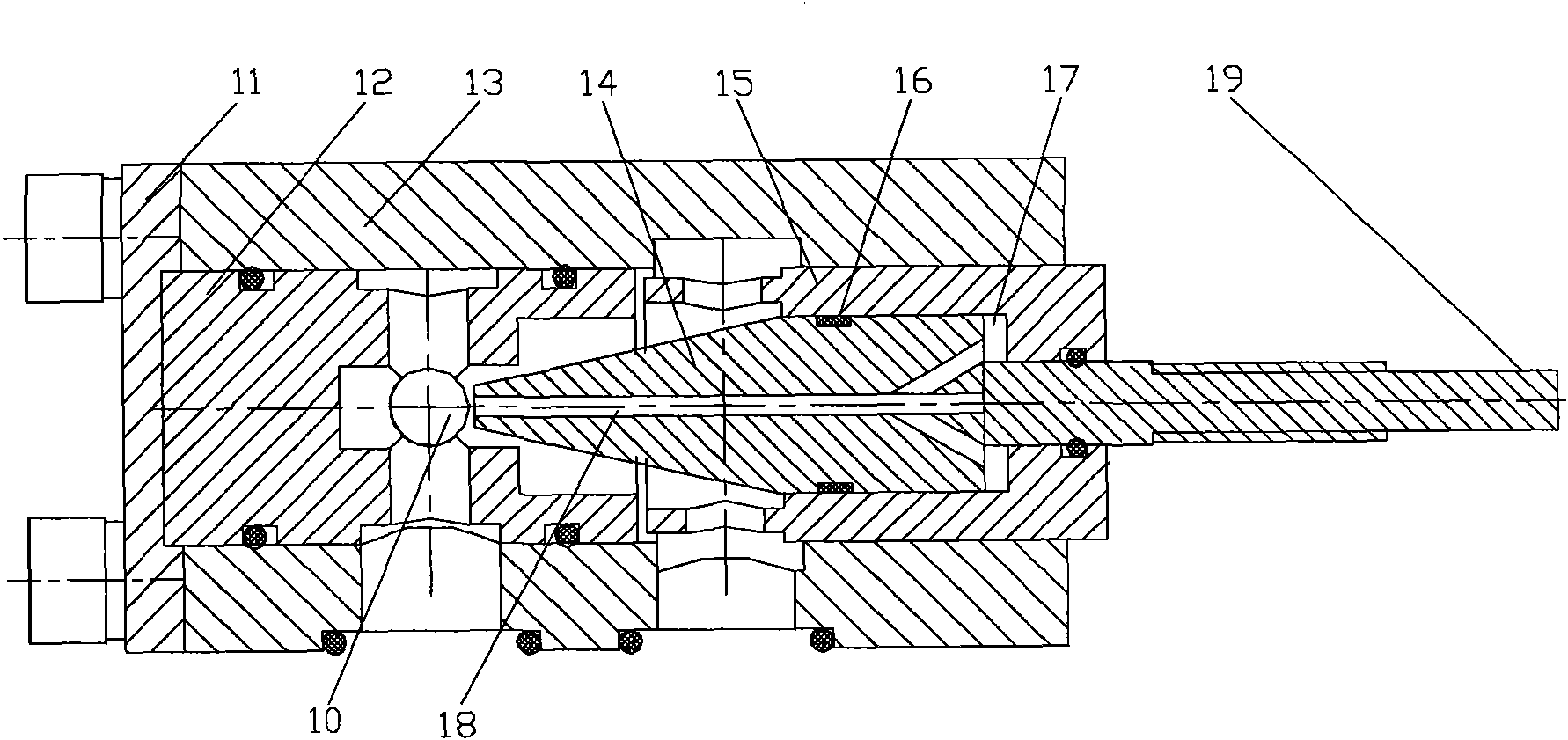

[0027] Such as figure 2 As shown, the hydraulic valve 1 includes a hydraulic valve end cover 11, a valve seat 12, a valve body 13, a valve core 14 and a valve sleeve 15, and a wear ring 16 is installed between the valve core 14 and the valve sleeve 15. The spool 14 is threadedly connected to the fixed frame 2, the sealing surface of the front end is a conical surface, the spool 14 moves axially to open / close the valve, and the rear end of the spool 14 is an adjusting rod 19, in order to meet the hydraulic pressure of the water medium. The valve core 14 and valve body 13 are made of stainless stee...

Embodiment 2

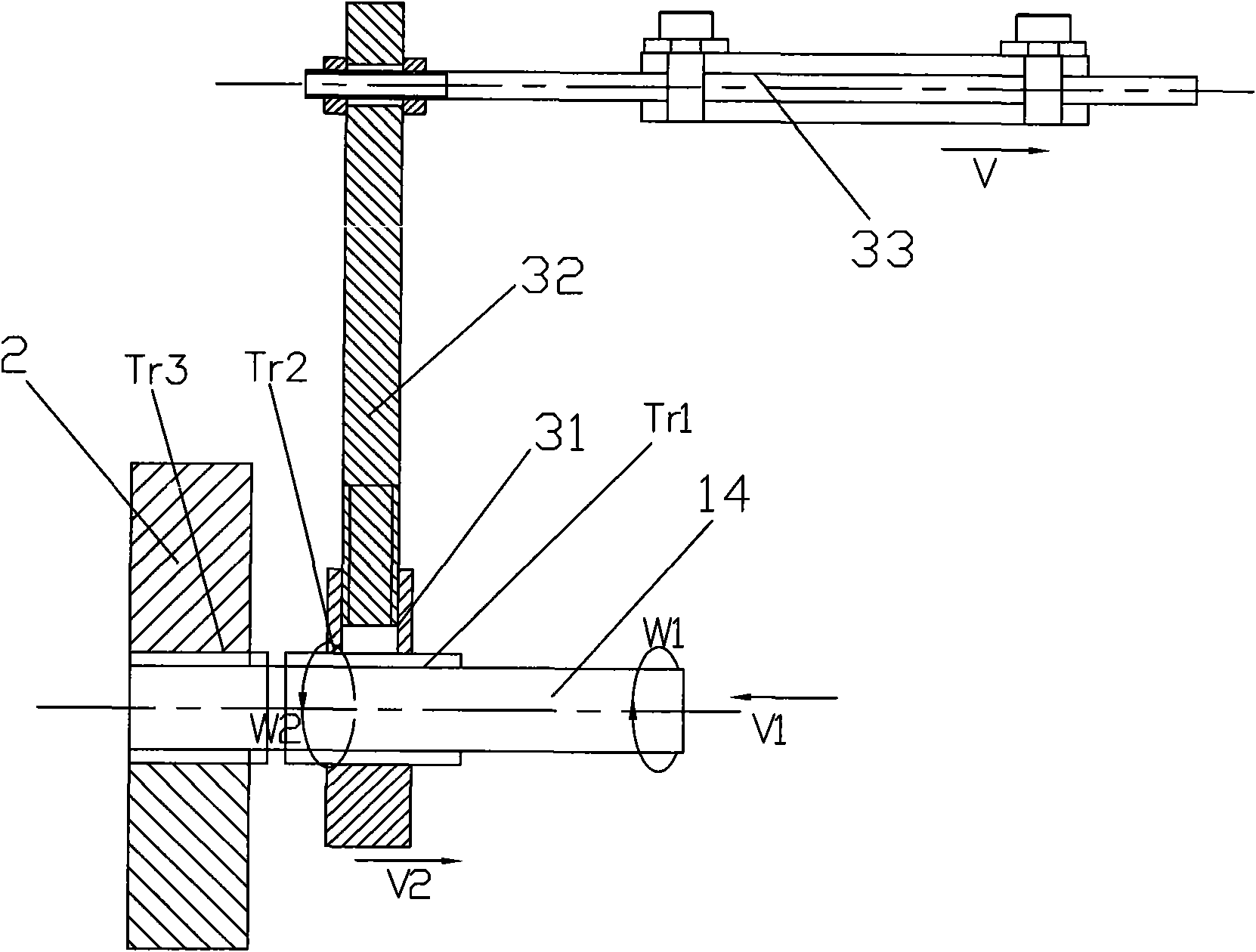

[0032] Such as Figure 4 As shown, an internal feedback type incremental water hydraulic throttling digital valve, the difference between embodiment 2 and embodiment 1 is that the connecting device 31 is a bushing with an annular groove, and the bushing is fixed On the spool 14, one end of the sensor bracket 32 is embedded in the annular groove, and the rotation of the annular groove drives the sensor bracket 32 to move axially; the inner hole of the coupling 42 and the end of the adjusting rod 19 are matched positive six Side shape, cylindrical ball 43 replaces with spherical ball. When the spool 14 rotates and moves axially, because the sleeve is fixed on the spool 14, the sleeve moves axially with the spool 14, and the sensor bracket 32 can rotate in the annular groove of the sleeve to offset the shaft Due to the rotation of the sleeve, the sensor bracket 32 only moves axially, thereby realizing the detection of the displacement of the spool 14 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com