Transparent electrode grid-control transverse PIN blue and purple photo-detector and method for manufacturing same

A transparent electrode and detector technology, applied in the field of blue-violet light detection, can solve the problems of low quantum efficiency of photodetectors, difficulty in absorbing long-wavelength light, and limitation of response speed, etc., and achieve high quantum efficiency, fast frequency response, and increased output The effect of capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

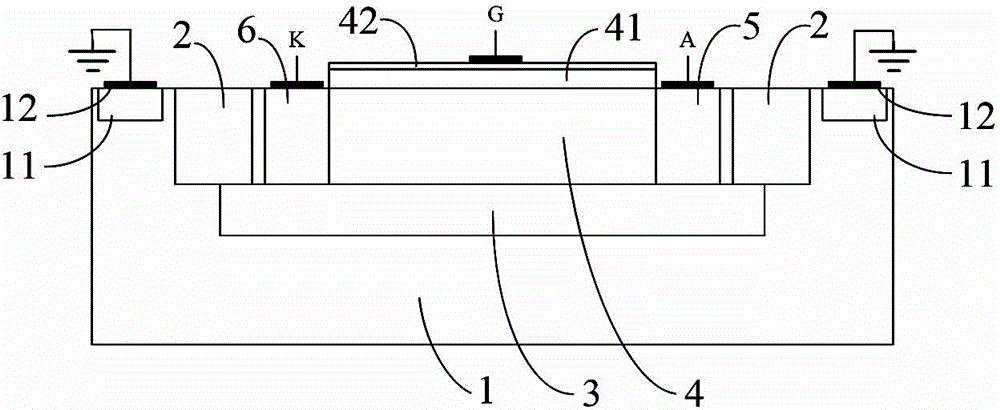

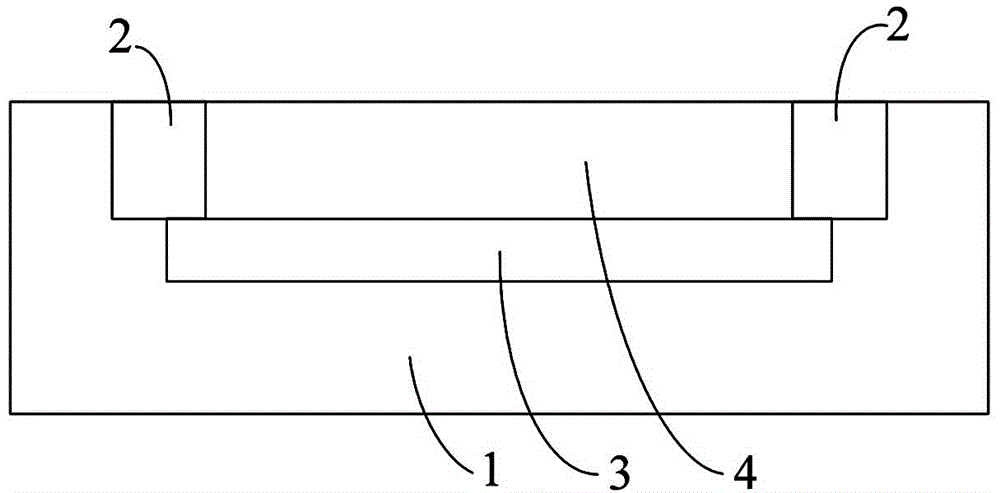

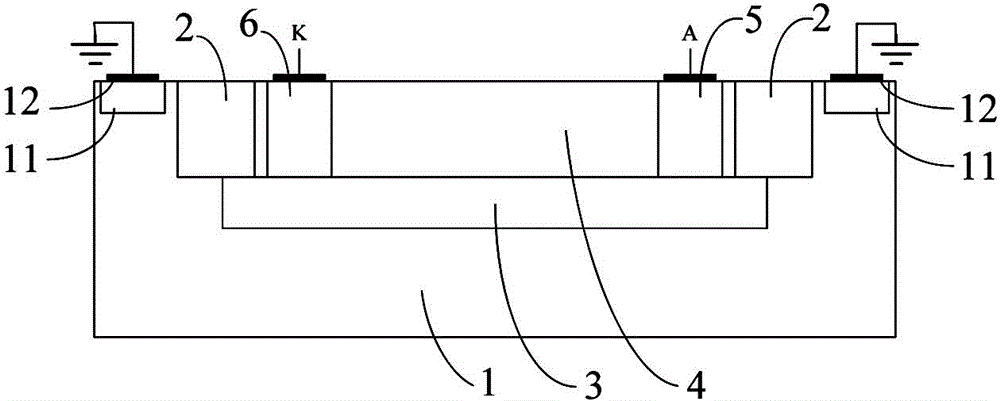

[0030] like figure 1 As shown, the transparent electrode gate-controlled lateral PIN blue-violet light detector of this embodiment includes a P-type substrate 1, and the P-type substrate 1 is provided with an N well 2 and a deep N well 3 formed by ion implantation doping. The bottom of the well 2 is in contact with the deep N well 3 and is isolated on the upper part of the P-type substrate 1 to form an anti-P well 4. The two sides of the anti-P well 4 are provided with N wells arranged in a lateral gap by means of diffusion doping. + Zone 5 and P + District 6 (N + Zone 5 and P + The lateral spacing of region 6 is determined by the required light-receiving area), and the anti-P well 4 is located in N + Zone 5 and P + The surface of the area between the regions 6 is covered with a gate oxide layer 41, the surface of the gate oxide layer 41 is covered with a transparent conductive film 42, and the transparent conductive film 42 is provided with gate electrodes G, N + Zone 5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com