Electromagnetic drive adhesive dispensing valve comprising flexible amplification arm

A technology of flexible amplifying arm and driving point, which is applied to devices and coatings that apply liquid to the surface, can solve the problems of difficult to achieve high-viscosity glue injection, large injection needles, complicated manufacturing process, etc. The viscosity of the glue liquid is large, which is conducive to heat dissipation and good heat dissipation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

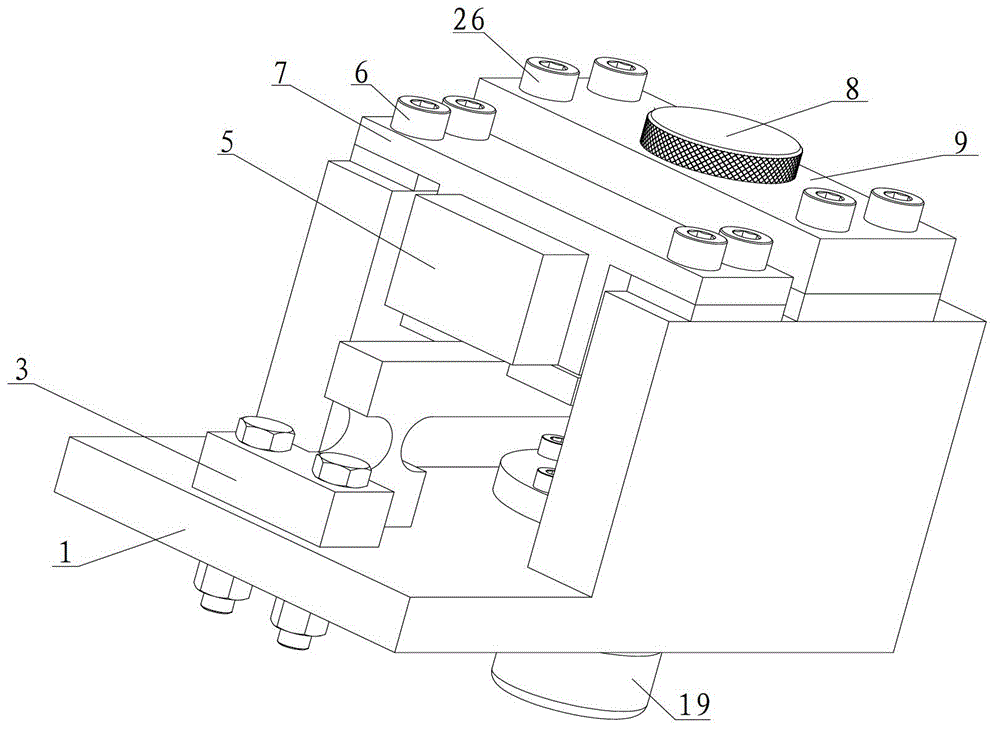

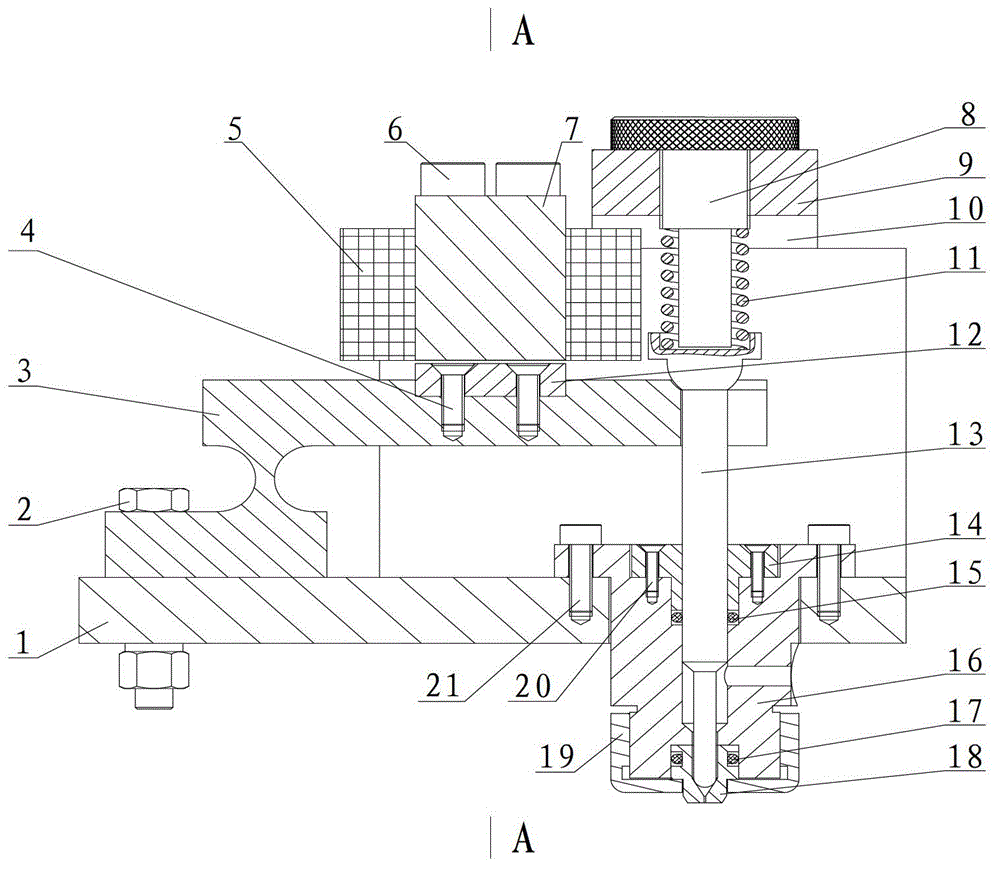

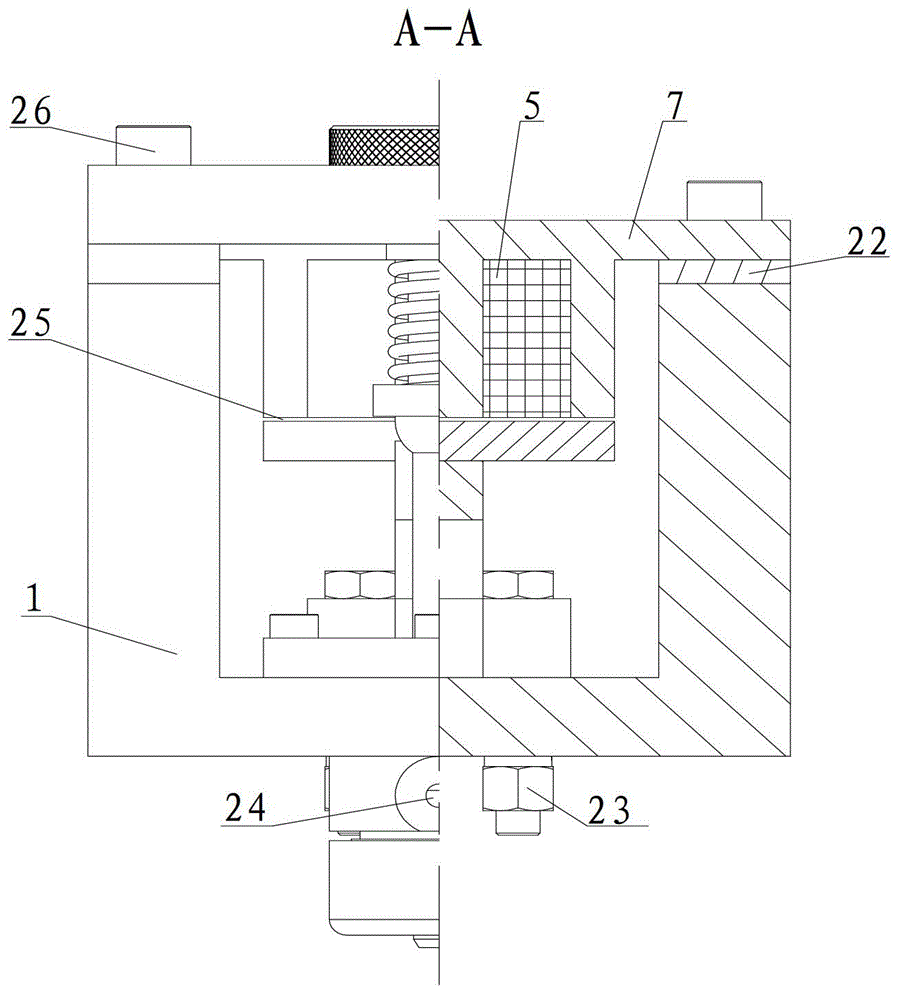

[0024] see figure 1 , figure 2 and image 3 , the bracket 1 is connected with other parts as the support of several other parts; the electromagnet is composed of an E-type electromagnet core 7 and an electromagnetic coil 5, and the electromagnet core 7 and the air gap adjusting gasket 22 are fixed on the bracket by the first screw 6 1, the length of the air gap 25 between the electromagnet core 7 and the armature 12 can be adjusted by changing the thickness of the air gap adjusting gasket 22, and finally adjust the stroke of the injection needle 13; Two screws 4 are rigidly connected; one end of the flexible amplifying arm 3 is fixed on one end of the bracket 1 by a bolt 2 and a nut 23, and the other end of the flexible amplifying arm 3 is connected with the injection needle 13 in transmission, and the connecting part is a smooth spherical surface; the supporting horizontal plate 9 and The gasket 10 is fixed on the bracket 1 by the third screw 26, and a compression spring 1...

Embodiment 2

[0031] refer to Figure 4 and Figure 5, the bracket 1 is connected with other parts as the support of several other parts; the electromagnet is composed of an E-type electromagnet core 7 and an electromagnetic coil 5, and the electromagnet core 7 and the air gap adjusting gasket 22 are fixed on the bracket by the first screw 6 1, the length of the air gap 25 between the electromagnet core 7 and the armature 12 can be adjusted by changing the thickness of the air gap adjusting gasket 22, and finally adjust the stroke of the injection needle 13; Two screws 4 are rigidly connected; one end of the flexible amplifying arm 3 is fixed on one end of the bracket 1 by a bolt 2 and a nut 23, and the other end of the flexible amplifying arm 3 is connected with the injection needle 13 in transmission, and the connecting part is a smooth spherical surface; the supporting horizontal plate 9 and The spacer 10 is fixed on the support 1 by the third screw 26, the adjusting screw 8 is threaded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com