Method for treating reverse osmosis concentrated water and circulating wastewater by whole membrane method

A technology of reverse osmosis concentrated water and circulating sewage, which is applied in the fields of filtration treatment, water/sewage treatment, chemical instruments and methods, etc. It can solve the problems of reducing the hardness of wastewater and reducing the salt content of wastewater, so as to reduce the amount of residual wastewater, The effect of saving electricity costs and increasing the concentration factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

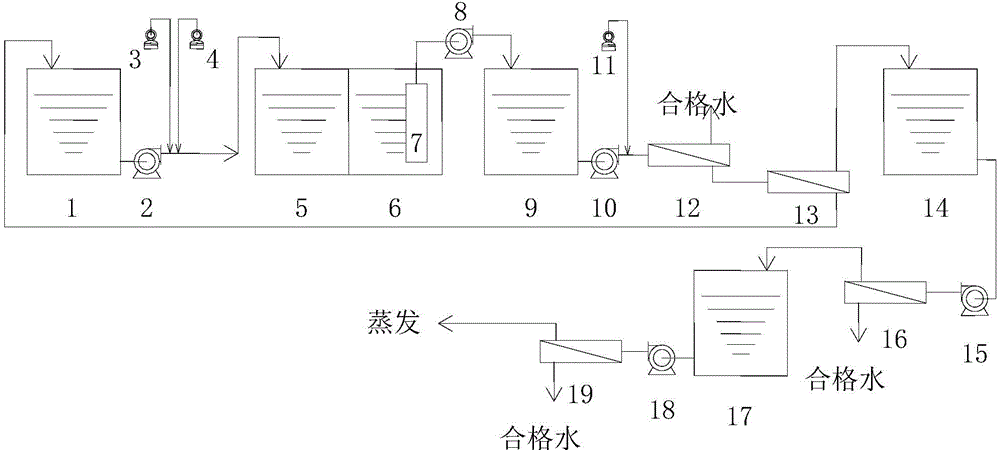

[0025] Such as figure 1 As shown, firstly, the waste water with a salt content of 5000ppm flows into the regulating tank 1, and is transported by the raw water pump 2, and sodium hydroxide and sodium carbonate are added by the first alkali-adding pump 3 and the second alkali-adding pump 4, and after reaching the reaction tank 5 Stir and react for 30 minutes to form calcium carbonate and magnesium hydroxide crystals. The mixed solution flows to the membrane tank 6 equipped with a flat ceramic membrane and is filtered through a flat ceramic membrane device 7. The calcium carbonate and magnesium hydroxide crystals in the water are trapped in the membrane. After reaching a certain concentration, it is discharged into the sludge tank and used for plate and frame filter. The permeate filtered by the flat ceramic membrane device 7 is sucked by the suction pump 8 and sent to the water production tank 9, pressurized by the first-stage booster pump 10, added acid by the acid pump 11 to ...

Embodiment 2

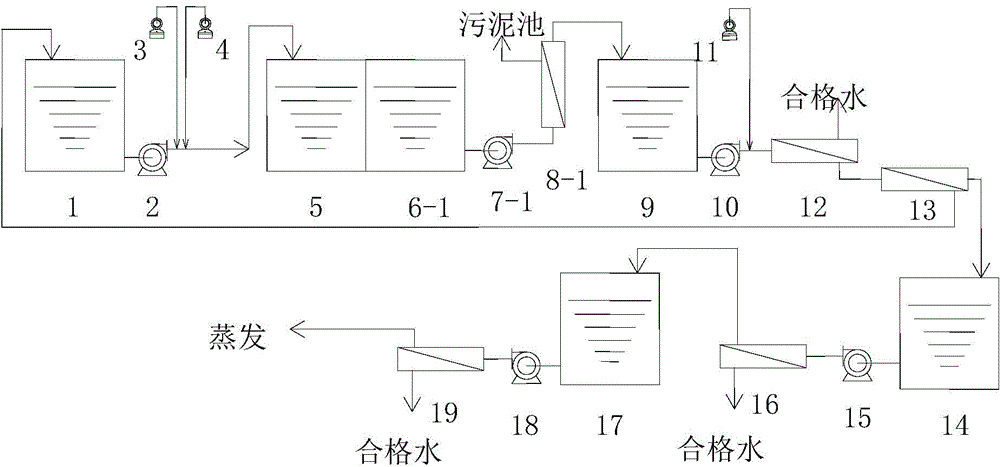

[0027] Such as figure 2 As shown, firstly, the waste water with a salt content of 5000ppm flows into the regulating tank 1, and is transported by the raw water pump 2, and sodium hydroxide and sodium carbonate are added by the first alkali-adding pump 3 and the second alkali-adding pump 4, and after reaching the reaction tank 5 Stir and react for 30 minutes to form calcium carbonate and magnesium hydroxide crystals. The mixed solution flows to the temporary storage pool 6-1 by itself, and is pressurized by the first booster pump 7-1 to enter the tubular ceramic membrane device 8-1 for filtration. Calcium carbonate and magnesium hydroxide crystals are intercepted by ceramic membranes, and the concentrated solution is discharged into the sludge tank for plate and frame pressure filtration. The permeate filtered by the tubular ceramic membrane device 8-1 flows into the water production tank 9, is pressurized by the first-stage booster pump 10, and is added with acid by the acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com